JP2018186071A - 金属/カーボンナノチューブ複合材料ワイヤ - Google Patents

金属/カーボンナノチューブ複合材料ワイヤ Download PDFInfo

- Publication number

- JP2018186071A JP2018186071A JP2018016221A JP2018016221A JP2018186071A JP 2018186071 A JP2018186071 A JP 2018186071A JP 2018016221 A JP2018016221 A JP 2018016221A JP 2018016221 A JP2018016221 A JP 2018016221A JP 2018186071 A JP2018186071 A JP 2018186071A

- Authority

- JP

- Japan

- Prior art keywords

- strand

- conductor assembly

- composite conductor

- metal

- strands

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000002131 composite material Substances 0.000 title claims abstract description 60

- 239000002041 carbon nanotube Substances 0.000 title claims abstract description 49

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 title claims abstract description 48

- 229910021393 carbon nanotube Inorganic materials 0.000 title claims abstract description 48

- 229910052751 metal Inorganic materials 0.000 title claims abstract description 36

- 239000002184 metal Substances 0.000 title claims abstract description 36

- 239000004020 conductor Substances 0.000 claims abstract description 46

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims abstract description 26

- 229910052802 copper Inorganic materials 0.000 claims abstract description 24

- 239000010949 copper Substances 0.000 claims abstract description 24

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims abstract description 14

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims abstract description 11

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 claims abstract description 11

- 229910052737 gold Inorganic materials 0.000 claims abstract description 11

- 239000010931 gold Substances 0.000 claims abstract description 11

- 229910052709 silver Inorganic materials 0.000 claims abstract description 11

- 239000004332 silver Substances 0.000 claims abstract description 11

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims abstract description 10

- 229910052782 aluminium Inorganic materials 0.000 claims abstract description 10

- 239000000463 material Substances 0.000 claims abstract description 8

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims abstract description 7

- 229910052759 nickel Inorganic materials 0.000 claims abstract description 7

- 229910052718 tin Inorganic materials 0.000 claims abstract description 7

- 239000011135 tin Substances 0.000 claims abstract description 6

- 239000002861 polymer material Substances 0.000 claims description 2

- -1 polyethylene Polymers 0.000 description 6

- 238000000034 method Methods 0.000 description 5

- 239000010935 stainless steel Substances 0.000 description 5

- 229910001220 stainless steel Inorganic materials 0.000 description 5

- 238000002788 crimping Methods 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 3

- 239000004743 Polypropylene Substances 0.000 description 3

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 229920006231 aramid fiber Polymers 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 229920001155 polypropylene Polymers 0.000 description 3

- 239000004810 polytetrafluoroethylene Substances 0.000 description 3

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 3

- 239000004952 Polyamide Substances 0.000 description 2

- 239000004760 aramid Substances 0.000 description 2

- 229920003235 aromatic polyamide Polymers 0.000 description 2

- 239000003989 dielectric material Substances 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 230000008054 signal transmission Effects 0.000 description 2

- 239000004677 Nylon Substances 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000000578 dry spinning Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 229910000679 solder Inorganic materials 0.000 description 1

- 238000009987 spinning Methods 0.000 description 1

- 238000002166 wet spinning Methods 0.000 description 1

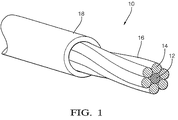

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B5/00—Non-insulated conductors or conductive bodies characterised by their form

- H01B5/08—Several wires or the like stranded in the form of a rope

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/02—Disposition of insulation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/02—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors mainly consisting of metals or alloys

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/02—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors mainly consisting of metals or alloys

- H01B1/023—Alloys based on aluminium

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/02—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors mainly consisting of metals or alloys

- H01B1/026—Alloys based on copper

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B1/00—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors

- H01B1/04—Conductors or conductive bodies characterised by the conductive materials; Selection of materials as conductors mainly consisting of carbon-silicon compounds, carbon or silicon

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B5/00—Non-insulated conductors or conductive bodies characterised by their form

- H01B5/02—Single bars, rods, wires, or strips

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/17—Protection against damage caused by external factors, e.g. sheaths or armouring

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/10—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation

- H01R4/18—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation by crimping

- H01R4/183—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation effected solely by twisting, wrapping, bending, crimping, or other permanent deformation by crimping for cylindrical elongated bodies, e.g. cables having circular cross-section

Landscapes

- Non-Insulated Conductors (AREA)

- Insulated Conductors (AREA)

- Connections Effected By Soldering, Adhesion, Or Permanent Deformation (AREA)

- Conductive Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/436,898 | 2017-02-20 | ||

| US15/436,898 US10109391B2 (en) | 2017-02-20 | 2017-02-20 | Metallic/carbon nanotube composite wire |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018186071A true JP2018186071A (ja) | 2018-11-22 |

| JP2018186071A5 JP2018186071A5 (enExample) | 2020-02-06 |

Family

ID=61386676

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018016221A Pending JP2018186071A (ja) | 2017-02-20 | 2018-02-01 | 金属/カーボンナノチューブ複合材料ワイヤ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10109391B2 (enExample) |

| EP (1) | EP3364422B1 (enExample) |

| JP (1) | JP2018186071A (enExample) |

| KR (1) | KR102005669B1 (enExample) |

| CN (1) | CN108461171B (enExample) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2020203725A1 (enExample) * | 2019-03-29 | 2020-10-08 | ||

| JP2020167101A (ja) * | 2019-03-29 | 2020-10-08 | 古河電気工業株式会社 | カーボンナノチューブ線材 |

| JPWO2021201096A1 (enExample) * | 2020-03-31 | 2021-10-07 | ||

| JP2022138319A (ja) * | 2021-03-10 | 2022-09-26 | 古河電気工業株式会社 | 端子付き電線の製造方法、端子付き電線、ワイヤハーネス |

| JP2023091827A (ja) * | 2021-12-21 | 2023-07-03 | 古河電気工業株式会社 | 積層電線およびその製造方法 |

| JP2023136313A (ja) * | 2022-03-16 | 2023-09-29 | 古河電気工業株式会社 | カーボンナノチューブ被覆線材 |

| JP2023136312A (ja) * | 2022-03-16 | 2023-09-29 | 古河電気工業株式会社 | カーボンナノチューブ被覆線材 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD852456S1 (en) * | 2016-12-19 | 2019-07-02 | Mars, Incorporated | Food product |

| US10128022B1 (en) * | 2017-10-24 | 2018-11-13 | Northrop Grumman Systems Corporation | Lightweight carbon nanotube cable comprising a pair of plated twisted wires |

| FR3086791A1 (fr) * | 2018-09-27 | 2020-04-03 | Nexans | Ame conductrice multibrin carbonee-metallique pour cable electrique |

| WO2020074992A1 (en) * | 2018-10-08 | 2020-04-16 | 3M Innovative Properties Company | Coil construction for automotive wireless charging |

| JP2021034296A (ja) | 2019-08-28 | 2021-03-01 | 株式会社デンソー | 導線およびコイル部材 |

| EP4044199A4 (en) * | 2019-12-31 | 2023-01-11 | Radiant Opto-electronics (Suzhou) Co., Ltd | SUSPENSION CABLE STRUCTURE AND LIGHTING DEVICE |

| WO2021241670A1 (ja) | 2020-05-27 | 2021-12-02 | 古河電気工業株式会社 | 端子付き電線、ワイヤハーネス、端子、端子圧着刃型、端子付き電線の製造方法 |

| US20230335307A1 (en) * | 2020-09-14 | 2023-10-19 | Nexans | Process for manufacturing a carbon-metal composite material and use thereof for manufacturing an electric cable |

| CN115440415B (zh) * | 2022-10-12 | 2025-04-04 | 湖南康达科新材料有限公司 | 一种结合强度高的镍包铜复合带材及其制备方法 |

| KR20240057150A (ko) * | 2022-10-24 | 2024-05-02 | 주식회사 엘지에너지솔루션 | 내화케이블 및 이를 구비한 배터리 팩 |

| CN116079699A (zh) * | 2023-02-15 | 2023-05-09 | 哈尔滨工业大学 | 一种基于超螺旋纤维结构的人工肌肉及其电驱动方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070284987A1 (en) * | 2006-06-09 | 2007-12-13 | Tsinghua University | Field emission element and manufacturing method thereof |

| US20140224524A1 (en) * | 2013-02-11 | 2014-08-14 | Tyco Electronics Corporation | Composite cable |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE0001123L (sv) * | 2000-03-30 | 2001-10-01 | Abb Ab | Kraftkabel |

| KR200291382Y1 (ko) * | 2002-07-20 | 2002-10-09 | 문인환 | 소켓과 세미리지드케이블을 납땜하는 장치 |

| CN105696139B (zh) * | 2004-11-09 | 2019-04-16 | 得克萨斯大学体系董事会 | 纳米纤维纱线、带和板的制造和应用 |

| WO2006116059A2 (en) * | 2005-04-22 | 2006-11-02 | The Regents Of The University Of California | Nanotubes as microwave frequency interconnects |

| TWI298520B (en) | 2005-09-12 | 2008-07-01 | Ind Tech Res Inst | Method of making an electroplated interconnection wire of a composite of metal and carbon nanotubes |

| US8013247B2 (en) * | 2006-04-25 | 2011-09-06 | The Mitre Corporation | Carbon nanotube-based electronic devices |

| US7408116B2 (en) * | 2006-06-23 | 2008-08-05 | Delphi Technologies, Inc. | Insulated non-halogenated heavy metal free vehicular cable |

| CN101286385B (zh) * | 2007-04-11 | 2010-05-26 | 清华大学 | 电磁屏蔽线缆 |

| JP2008277195A (ja) | 2007-05-02 | 2008-11-13 | Kurabe Ind Co Ltd | 電線導体及び絶縁電線 |

| KR101276898B1 (ko) * | 2008-02-01 | 2013-06-19 | 혼하이 프리시젼 인더스트리 컴퍼니 리미티드 | 탄소 나노튜브 복합재료 및 그 제조방법 |

| CN105244071B (zh) * | 2008-02-01 | 2018-11-30 | 北京富纳特创新科技有限公司 | 线缆 |

| WO2009137722A1 (en) * | 2008-05-07 | 2009-11-12 | Nanocomp Technologies, Inc. | Carbon nanotube-based coaxial electrical cables and wiring harness |

| MX2008013821A (es) * | 2008-10-28 | 2010-04-28 | Magnekon S A De C V | Alambre magneto con revestimiento adicionado con nanoestructuras tipo fulereno. |

| US8445788B1 (en) * | 2009-01-05 | 2013-05-21 | The Boeing Company | Carbon nanotube-enhanced, metallic wire |

| US9111658B2 (en) * | 2009-04-24 | 2015-08-18 | Applied Nanostructured Solutions, Llc | CNS-shielded wires |

| JP2012531016A (ja) * | 2009-06-19 | 2012-12-06 | スリーエム イノベイティブ プロパティズ カンパニー | 遮蔽された電気ケーブル |

| US8354593B2 (en) * | 2009-07-10 | 2013-01-15 | Nanocomp Technologies, Inc. | Hybrid conductors and method of making same |

| CN101998200A (zh) * | 2009-08-25 | 2011-03-30 | 鸿富锦精密工业(深圳)有限公司 | 一种耳机线及具有该耳机线的耳机 |

| WO2011148977A1 (ja) | 2010-05-25 | 2011-12-01 | 矢崎総業株式会社 | 導電材及びその製造方法 |

| CN102372253B (zh) | 2010-08-23 | 2014-01-15 | 清华大学 | 碳纳米管复合线状结构及其制备方法 |

| CN102063959B (zh) * | 2010-11-18 | 2013-02-13 | 清华大学 | 线缆 |

| US8853540B2 (en) * | 2011-04-19 | 2014-10-07 | Commscope, Inc. Of North Carolina | Carbon nanotube enhanced conductors for communications cables and related communications cables and methods |

| US20130048337A1 (en) * | 2011-08-24 | 2013-02-28 | Tyco Electronics Corporation | Carbon-based substrates with organometallic fillers |

| CN202205480U (zh) | 2011-09-13 | 2012-04-25 | 常熟泓淋电线电缆有限公司 | 圆铜线绞线 |

| US8808792B2 (en) * | 2012-01-17 | 2014-08-19 | Northrop Grumman Systems Corporation | Carbon nanotube conductor with enhanced electrical conductivity |

| KR20140137369A (ko) * | 2012-02-22 | 2014-12-02 | 셀던 테크놀로지, 인코포레이티드. | 전극들 및 응용들 |

| US9685258B2 (en) * | 2012-11-09 | 2017-06-20 | Northrop Grumman Systems Corporation | Hybrid carbon nanotube shielding for lightweight electrical cables |

-

2017

- 2017-02-20 US US15/436,898 patent/US10109391B2/en active Active

-

2018

- 2018-02-01 JP JP2018016221A patent/JP2018186071A/ja active Pending

- 2018-02-08 EP EP18155873.5A patent/EP3364422B1/en active Active

- 2018-02-13 CN CN201810150452.6A patent/CN108461171B/zh active Active

- 2018-02-20 KR KR1020180019634A patent/KR102005669B1/ko active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070284987A1 (en) * | 2006-06-09 | 2007-12-13 | Tsinghua University | Field emission element and manufacturing method thereof |

| US20140224524A1 (en) * | 2013-02-11 | 2014-08-14 | Tyco Electronics Corporation | Composite cable |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7269070B2 (ja) | 2019-03-29 | 2023-05-08 | 古河電気工業株式会社 | カーボンナノチューブ線材 |

| JP2020167101A (ja) * | 2019-03-29 | 2020-10-08 | 古河電気工業株式会社 | カーボンナノチューブ線材 |

| JP7479354B2 (ja) | 2019-03-29 | 2024-05-08 | 古河電気工業株式会社 | 基板とカーボンナノチューブ線材の接続構造体 |

| JPWO2020203725A1 (enExample) * | 2019-03-29 | 2020-10-08 | ||

| WO2021201096A1 (ja) * | 2020-03-31 | 2021-10-07 | 古河電気工業株式会社 | カーボンナノチューブ線材の接続構造体 |

| JPWO2021201096A1 (enExample) * | 2020-03-31 | 2021-10-07 | ||

| JP7598926B2 (ja) | 2020-03-31 | 2024-12-12 | 古河電気工業株式会社 | カーボンナノチューブ線材の接続構造体 |

| US12362077B2 (en) | 2020-03-31 | 2025-07-15 | Furukawa Electric Co., Ltd. | Connection structure of carbon nanotube wire |

| JP2022138319A (ja) * | 2021-03-10 | 2022-09-26 | 古河電気工業株式会社 | 端子付き電線の製造方法、端子付き電線、ワイヤハーネス |

| JP7645662B2 (ja) | 2021-03-10 | 2025-03-14 | 古河電気工業株式会社 | 端子付き電線の製造方法、ワイヤハーネスの製造方法 |

| JP2023091827A (ja) * | 2021-12-21 | 2023-07-03 | 古河電気工業株式会社 | 積層電線およびその製造方法 |

| JP2023136313A (ja) * | 2022-03-16 | 2023-09-29 | 古河電気工業株式会社 | カーボンナノチューブ被覆線材 |

| JP2023136312A (ja) * | 2022-03-16 | 2023-09-29 | 古河電気工業株式会社 | カーボンナノチューブ被覆線材 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108461171A (zh) | 2018-08-28 |

| KR20180096525A (ko) | 2018-08-29 |

| US10109391B2 (en) | 2018-10-23 |

| CN108461171B (zh) | 2022-02-11 |

| KR102005669B1 (ko) | 2019-07-30 |

| EP3364422A1 (en) | 2018-08-22 |

| US20180240569A1 (en) | 2018-08-23 |

| EP3364422B1 (en) | 2020-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108461171B (zh) | 金属/碳纳米管复合电线 | |

| US10115492B2 (en) | Electrically conductive carbon nanotube wire having a metallic coating and methods of forming same | |

| JP2018186071A5 (enExample) | ||

| JP3719163B2 (ja) | 可動部配線材用撚線導体及びそれを用いたケーブル | |

| JP4044805B2 (ja) | フラットシールドケーブル | |

| US9293233B2 (en) | Composite cable | |

| CN1311477C (zh) | 电缆 | |

| JP2000228116A (ja) | ハーネス用電線導体 | |

| JP2012003853A (ja) | 被覆電線および被覆電線と端子の組立体 | |

| JP2004087436A (ja) | 自動車用アルミケーブル | |

| CN1906708A (zh) | 同轴电缆 | |

| JP2014150022A (ja) | 絶縁電線 | |

| JP2012022989A (ja) | 電線導体及びその製造方法 | |

| JPS6129133Y2 (enExample) | ||

| JP2021163652A (ja) | 電線導体、電線、通信用電線、シールド電線、端子付き電線及び自動車用ワイヤーハーネス | |

| CN217933200U (zh) | 一种适用于超声波焊接新能源汽车用高压电缆 | |

| CN106575535A (zh) | 用于航空应用的电导体 | |

| CN212541927U (zh) | 一种高强度导线 | |

| JP2020191248A (ja) | 端子付き電線、導電性素線、電線、端子付き通信ケーブル及びワイヤハーネス | |

| JP7295817B2 (ja) | ワイヤーハーネス用導体撚線 | |

| CN220709988U (zh) | 一种强扭力线缆 | |

| CN209947451U (zh) | 一种绞线及绞线电缆 | |

| RU205212U1 (ru) | Бортовой авиационный электрический провод | |

| CN217086172U (zh) | 柔软耐压接型扁电缆 | |

| RU204344U1 (ru) | Бортовой авиационный электрический провод |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20180618 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20190206 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20190207 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20190208 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190516 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20190619 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20190918 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20191219 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20200106 |