JP2018176582A - 可塑化装置の材料供給方法および可塑化装置の材料供給装置 - Google Patents

可塑化装置の材料供給方法および可塑化装置の材料供給装置 Download PDFInfo

- Publication number

- JP2018176582A JP2018176582A JP2017080952A JP2017080952A JP2018176582A JP 2018176582 A JP2018176582 A JP 2018176582A JP 2017080952 A JP2017080952 A JP 2017080952A JP 2017080952 A JP2017080952 A JP 2017080952A JP 2018176582 A JP2018176582 A JP 2018176582A

- Authority

- JP

- Japan

- Prior art keywords

- supplied

- supply

- weight

- storage device

- materials

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000463 material Substances 0.000 title claims abstract description 257

- 238000000034 method Methods 0.000 title claims abstract description 23

- 238000003860 storage Methods 0.000 claims abstract description 62

- 238000005259 measurement Methods 0.000 claims description 15

- 238000005303 weighing Methods 0.000 claims description 9

- 239000002657 fibrous material Substances 0.000 description 40

- 239000011347 resin Substances 0.000 description 35

- 229920005989 resin Polymers 0.000 description 35

- 238000010438 heat treatment Methods 0.000 description 13

- 238000002347 injection Methods 0.000 description 11

- 239000007924 injection Substances 0.000 description 11

- 238000009792 diffusion process Methods 0.000 description 10

- 239000000835 fiber Substances 0.000 description 7

- 238000000465 moulding Methods 0.000 description 6

- 229920000049 Carbon (fiber) Polymers 0.000 description 5

- 239000004917 carbon fiber Substances 0.000 description 5

- 238000001746 injection moulding Methods 0.000 description 4

- 238000003756 stirring Methods 0.000 description 4

- 239000008188 pellet Substances 0.000 description 3

- 238000013459 approach Methods 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 230000005484 gravity Effects 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- 230000000704 physical effect Effects 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 238000004260 weight control Methods 0.000 description 2

- 239000004594 Masterbatch (MB) Substances 0.000 description 1

- 230000001154 acute effect Effects 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 238000004040 coloring Methods 0.000 description 1

- 239000000805 composite resin Substances 0.000 description 1

- 238000000748 compression moulding Methods 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 235000003642 hunger Nutrition 0.000 description 1

- 238000004898 kneading Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000012778 molding material Substances 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000002250 progressing effect Effects 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 230000037351 starvation Effects 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

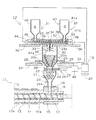

Images

Landscapes

- Injection Moulding Of Plastics Or The Like (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017080952A JP2018176582A (ja) | 2017-04-14 | 2017-04-14 | 可塑化装置の材料供給方法および可塑化装置の材料供給装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017080952A JP2018176582A (ja) | 2017-04-14 | 2017-04-14 | 可塑化装置の材料供給方法および可塑化装置の材料供給装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018176582A true JP2018176582A (ja) | 2018-11-15 |

| JP2018176582A5 JP2018176582A5 (OSRAM) | 2018-12-27 |

Family

ID=64280721

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017080952A Pending JP2018176582A (ja) | 2017-04-14 | 2017-04-14 | 可塑化装置の材料供給方法および可塑化装置の材料供給装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2018176582A (OSRAM) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102168551B1 (ko) * | 2020-07-22 | 2020-10-21 | 주식회사 피티케이 | 연구용 다중단위 펠릿 시스템 |

| JPWO2022234658A1 (OSRAM) * | 2021-05-07 | 2022-11-10 |

-

2017

- 2017-04-14 JP JP2017080952A patent/JP2018176582A/ja active Pending

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102168551B1 (ko) * | 2020-07-22 | 2020-10-21 | 주식회사 피티케이 | 연구용 다중단위 펠릿 시스템 |

| JPWO2022234658A1 (OSRAM) * | 2021-05-07 | 2022-11-10 | ||

| JP7612008B2 (ja) | 2021-05-07 | 2025-01-10 | 三菱電機株式会社 | 数値制御装置および数値制御方法 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9821498B2 (en) | Injection molding method and injection molding device | |

| JP5913062B2 (ja) | 射出成形機、射出成形システム、および原料計量装置 | |

| CN111263690B (zh) | 用于制造塑料成型件的方法 | |

| JP6661223B2 (ja) | 可塑化装置の材料供給装置および可塑化装置の材料供給方法 | |

| JP2018176582A (ja) | 可塑化装置の材料供給方法および可塑化装置の材料供給装置 | |

| JP6983967B2 (ja) | 計量供給システム | |

| EP2442960B1 (en) | In an injection unit having a filter, a method of controlling melt pressure in accordance with a target pressure range | |

| KR20190104117A (ko) | 사출성형기 | |

| JP6677957B2 (ja) | 射出成形機の可塑化装置 | |

| JP5913251B2 (ja) | 繊維強化樹脂の射出成形装置および射出成形方法 | |

| CN111873301A (zh) | 注塑成型设备及注塑成型的方法、机器可读存储介质 | |

| JP6472143B2 (ja) | 可塑化装置の材料供給方法および可塑化装置 | |

| JP2020168802A (ja) | 可塑化装置の材料供給方法および可塑化装置の材料供給装置 | |

| TW202335823A (zh) | 給料器以及射出成形機 | |

| JPH0477224A (ja) | 射出成形方法 | |

| JP7158526B1 (ja) | 可塑化装置の材料供給装置および可塑化装置の材料供給方法 | |

| JP2019048435A (ja) | 複合材料の可塑化装置および複合材料の可塑化方法 | |

| JP2018183938A (ja) | 可塑化装置 | |

| SE462379B (sv) | Foerfarande foer styrning av vissa parametrar vid framstaellning av plastvaror | |

| JP7698263B2 (ja) | 成形装置 | |

| CN208497590U (zh) | 一种注塑机注射装置 | |

| JP6591891B2 (ja) | 射出成形品の製造方法 | |

| CN203945633U (zh) | 塑料挤出机称重加料装置 | |

| CN104924551B (zh) | 塑胶射出机的射出机构 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20181116 |