JP2017500263A - ガラス形成装置およびガラスリボンの形成方法 - Google Patents

ガラス形成装置およびガラスリボンの形成方法 Download PDFInfo

- Publication number

- JP2017500263A JP2017500263A JP2016533118A JP2016533118A JP2017500263A JP 2017500263 A JP2017500263 A JP 2017500263A JP 2016533118 A JP2016533118 A JP 2016533118A JP 2016533118 A JP2016533118 A JP 2016533118A JP 2017500263 A JP2017500263 A JP 2017500263A

- Authority

- JP

- Japan

- Prior art keywords

- glass

- monazite

- refractory material

- forming apparatus

- glass forming

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

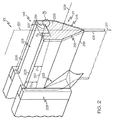

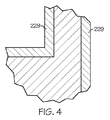

- C03B17/00—Forming molten glass by flowing-out, pushing-out, extruding or drawing downwardly or laterally from forming slits or by overflowing over lips

- C03B17/06—Forming glass sheets

- C03B17/064—Forming glass sheets by the overflow downdraw fusion process; Isopipes therefor

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B5/00—Melting in furnaces; Furnaces so far as specially adapted for glass manufacture

- C03B5/16—Special features of the melting process; Auxiliary means specially adapted for glass-melting furnaces

- C03B5/42—Details of construction of furnace walls, e.g. to prevent corrosion; Use of materials for furnace walls

- C03B5/43—Use of materials for furnace walls, e.g. fire-bricks

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/447—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on phosphates, e.g. hydroxyapatite

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/50—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on rare-earth compounds

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3224—Rare earth oxide or oxide forming salts thereof, e.g. scandium oxide

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3224—Rare earth oxide or oxide forming salts thereof, e.g. scandium oxide

- C04B2235/3225—Yttrium oxide or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3224—Rare earth oxide or oxide forming salts thereof, e.g. scandium oxide

- C04B2235/3227—Lanthanum oxide or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3224—Rare earth oxide or oxide forming salts thereof, e.g. scandium oxide

- C04B2235/3229—Cerium oxides or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3231—Refractory metal oxides, their mixed metal oxides, or oxide-forming salts thereof

- C04B2235/3244—Zirconium oxides, zirconates, hafnium oxides, hafnates, or oxide-forming salts thereof

- C04B2235/3248—Zirconates or hafnates, e.g. zircon

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/34—Non-metal oxides, non-metal mixed oxides, or salts thereof that form the non-metal oxides upon heating, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3418—Silicon oxide, silicic acids or oxide forming salts thereof, e.g. silica sol, fused silica, silica fume, cristobalite, quartz or flint

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/44—Metal salt constituents or additives chosen for the nature of the anions, e.g. hydrides or acetylacetonate

- C04B2235/447—Phosphates or phosphites, e.g. orthophosphate or hypophosphite

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/65—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes

- C04B2235/656—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes characterised by specific heating conditions during heat treatment

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/65—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes

- C04B2235/656—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes characterised by specific heating conditions during heat treatment

- C04B2235/6567—Treatment time

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

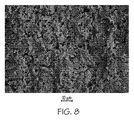

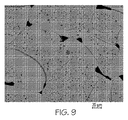

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/74—Physical characteristics

- C04B2235/78—Grain sizes and shapes, product microstructures, e.g. acicular grains, equiaxed grains, platelet-structures

- C04B2235/786—Micrometer sized grains, i.e. from 1 to 100 micron

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/80—Phases present in the sintered or melt-cast ceramic products other than the main phase

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/80—Phases present in the sintered or melt-cast ceramic products other than the main phase

- C04B2235/81—Materials characterised by the absence of phases other than the main phase, i.e. single phase materials

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/96—Properties of ceramic products, e.g. mechanical properties such as strength, toughness, wear resistance

- C04B2235/9669—Resistance against chemicals, e.g. against molten glass or molten salts

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Structural Engineering (AREA)

- Compositions Of Oxide Ceramics (AREA)

- Glass Compositions (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201361909064P | 2013-11-26 | 2013-11-26 | |

| US61/909,064 | 2013-11-26 | ||

| PCT/US2014/067037 WO2015080995A1 (en) | 2013-11-26 | 2014-11-24 | Glass forming apparatus and methods of forming a glass ribbon |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2017500263A true JP2017500263A (ja) | 2017-01-05 |

| JP2017500263A5 JP2017500263A5 (enExample) | 2018-02-01 |

Family

ID=52011340

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016533118A Abandoned JP2017500263A (ja) | 2013-11-26 | 2014-11-24 | ガラス形成装置およびガラスリボンの形成方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20170044041A1 (enExample) |

| EP (1) | EP3074352A1 (enExample) |

| JP (1) | JP2017500263A (enExample) |

| KR (1) | KR20160090334A (enExample) |

| CN (1) | CN105873867A (enExample) |

| TW (1) | TW201527231A (enExample) |

| WO (1) | WO2015080995A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019124079A1 (ja) * | 2017-12-21 | 2019-06-27 | 三井金属鉱業株式会社 | 粒子混合体、それを用いた光散乱性向上方法、並びにそれを含む光散乱部材及び光学デバイス |

| JP2023003617A (ja) * | 2021-06-24 | 2023-01-17 | Agc株式会社 | 成形装置 |

| US11702355B2 (en) | 2017-11-22 | 2023-07-18 | Corning Incorporated | Apparatuses including edge directors for forming glass ribbons |

| US11970395B2 (en) | 2017-12-21 | 2024-04-30 | Mitsui Mining & Smelting Co., Ltd. | Rare earth phosphate particles, method for improving light scattering using same, and light scattering member and optical device including same |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106255670B (zh) * | 2014-04-25 | 2019-04-09 | 康宁股份有限公司 | 复合玻璃制品的制造设备和方法 |

| CN108290764B (zh) * | 2015-11-20 | 2021-11-26 | 康宁股份有限公司 | 层压玻璃带及用于形成层压玻璃带的设备 |

| TWI766041B (zh) | 2017-06-14 | 2022-06-01 | 美商康寧公司 | 控制壓實的方法 |

| CN110436957B (zh) * | 2019-08-13 | 2021-08-03 | 武汉科技大学 | 一种MgO-CePO4材料及其制备方法 |

| US12434991B2 (en) * | 2019-12-19 | 2025-10-07 | Nippon Electric Glass Co., Ltd. | Method for producing glass article and glass article |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3451798A (en) | 1966-04-04 | 1969-06-24 | Corning Glass Works | Sheet glass edge control device |

| US3519448A (en) * | 1968-01-26 | 1970-07-07 | Corhart Refractories Co | Zirconia-alumina fused refractory materials and structures |

| US3537834A (en) | 1968-08-07 | 1970-11-03 | Corning Glass Works | Maintaining sheet glass width |

| US6863999B1 (en) * | 2002-01-23 | 2005-03-08 | Innovative Technology Licensing, Llc | Monazite-based thermal barrier coatings |

| WO2006073841A1 (en) * | 2004-12-30 | 2006-07-13 | Corning Incorporated | Refractory materials |

| US7409839B2 (en) | 2005-04-29 | 2008-08-12 | Corning Incorporated | Method and apparatus for making a glass sheet |

| WO2009070230A1 (en) * | 2007-11-29 | 2009-06-04 | Corning Incorporated | Creep resistant multiple layer refractory used in a glass manufacturing system |

| US8796168B2 (en) * | 2008-02-27 | 2014-08-05 | Corning Incorporated | Modified synthetic xenotime material, article comprising same and method for making the articles |

-

2014

- 2014-11-24 WO PCT/US2014/067037 patent/WO2015080995A1/en not_active Ceased

- 2014-11-24 US US15/039,252 patent/US20170044041A1/en not_active Abandoned

- 2014-11-24 CN CN201480071859.XA patent/CN105873867A/zh active Pending

- 2014-11-24 KR KR1020167016623A patent/KR20160090334A/ko not_active Ceased

- 2014-11-24 JP JP2016533118A patent/JP2017500263A/ja not_active Abandoned

- 2014-11-24 EP EP14808800.8A patent/EP3074352A1/en not_active Withdrawn

- 2014-11-26 TW TW103141036A patent/TW201527231A/zh unknown

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11702355B2 (en) | 2017-11-22 | 2023-07-18 | Corning Incorporated | Apparatuses including edge directors for forming glass ribbons |

| WO2019124079A1 (ja) * | 2017-12-21 | 2019-06-27 | 三井金属鉱業株式会社 | 粒子混合体、それを用いた光散乱性向上方法、並びにそれを含む光散乱部材及び光学デバイス |

| CN111433639A (zh) * | 2017-12-21 | 2020-07-17 | 三井金属矿业株式会社 | 粒子混合体、使用了其的光散射性提高方法、以及包含其的光散射构件及光学设备 |

| JPWO2019124079A1 (ja) * | 2017-12-21 | 2020-12-24 | 三井金属鉱業株式会社 | 粒子混合体、それを用いた光散乱性向上方法、並びにそれを含む光散乱部材及び光学デバイス |

| JP7046980B2 (ja) | 2017-12-21 | 2022-04-04 | 三井金属鉱業株式会社 | 粒子混合体、それを用いた光散乱性向上方法、並びにそれを含む光散乱部材及び光学デバイス |

| CN111433639B (zh) * | 2017-12-21 | 2022-06-21 | 三井金属矿业株式会社 | 粒子混合体、使用了其的光散射性提高方法、以及包含其的光散射构件及光学设备 |

| US11970395B2 (en) | 2017-12-21 | 2024-04-30 | Mitsui Mining & Smelting Co., Ltd. | Rare earth phosphate particles, method for improving light scattering using same, and light scattering member and optical device including same |

| JP2023003617A (ja) * | 2021-06-24 | 2023-01-17 | Agc株式会社 | 成形装置 |

| JP7673520B2 (ja) | 2021-06-24 | 2025-05-09 | Agc株式会社 | 成形装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20160090334A (ko) | 2016-07-29 |

| US20170044041A1 (en) | 2017-02-16 |

| CN105873867A (zh) | 2016-08-17 |

| WO2015080995A1 (en) | 2015-06-04 |

| EP3074352A1 (en) | 2016-10-05 |

| TW201527231A (zh) | 2015-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2017500263A (ja) | ガラス形成装置およびガラスリボンの形成方法 | |

| CN102584259B (zh) | 耐火材料 | |

| Lofgren et al. | An experimental study of trace-element partitioning between Ti-Al-clinopyroxene and melt: Equilibrium and kinetic effects including sector zoning | |

| TWI491570B (zh) | 與含錫玻璃一併使用的氧化鋁等靜壓管 | |

| CN110054486A (zh) | 耐火物体和使用所述耐火物体形成玻璃片的方法 | |

| TW201223914A (en) | High zirconia refractory product | |

| JP4720777B2 (ja) | ガラス製造装置および製造方法 | |

| EP2539300B1 (en) | Making xenotime ceramics by reactive ceramming | |

| Wang et al. | Regulation of phase evolution of CaAl12O19 on properties of in-situ formed MgAl2O4–CaAl12O19 composites | |

| KR101292854B1 (ko) | 유리 제조 장치 및 제조 방법 | |

| JP5347424B2 (ja) | ガラス製造装置および製造方法 | |

| CN102515476B (zh) | 用于生产含锡玻璃的氧化铝等压管 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20171122 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20171122 |

|

| A762 | Written abandonment of application |

Free format text: JAPANESE INTERMEDIATE CODE: A762 Effective date: 20180226 |