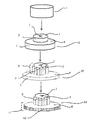

JP2015136736A - 鍛造と2段冷間押出しプロセスによる2段歯ギヤの製造方法 - Google Patents

鍛造と2段冷間押出しプロセスによる2段歯ギヤの製造方法 Download PDFInfo

- Publication number

- JP2015136736A JP2015136736A JP2014040916A JP2014040916A JP2015136736A JP 2015136736 A JP2015136736 A JP 2015136736A JP 2014040916 A JP2014040916 A JP 2014040916A JP 2014040916 A JP2014040916 A JP 2014040916A JP 2015136736 A JP2015136736 A JP 2015136736A

- Authority

- JP

- Japan

- Prior art keywords

- gear

- stage

- teeth

- cold extrusion

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000641 cold extrusion Methods 0.000 title claims abstract description 47

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 45

- 238000005242 forging Methods 0.000 title claims abstract description 27

- 238000012545 processing Methods 0.000 title claims description 4

- 238000000034 method Methods 0.000 claims abstract description 16

- 239000002994 raw material Substances 0.000 claims abstract description 7

- 230000002093 peripheral effect Effects 0.000 claims description 31

- 239000000463 material Substances 0.000 claims description 16

- 238000003754 machining Methods 0.000 claims description 15

- 238000005422 blasting Methods 0.000 claims description 9

- 229910019142 PO4 Inorganic materials 0.000 claims description 7

- 239000011248 coating agent Substances 0.000 claims description 7

- 238000000576 coating method Methods 0.000 claims description 7

- 239000012467 final product Substances 0.000 claims description 7

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 claims description 7

- 239000010452 phosphate Substances 0.000 claims description 7

- 238000010791 quenching Methods 0.000 claims description 4

- 230000000171 quenching effect Effects 0.000 claims description 4

- 239000002184 metal Substances 0.000 claims 3

- 239000000047 product Substances 0.000 abstract description 4

- 238000000137 annealing Methods 0.000 abstract description 3

- 239000007795 chemical reaction product Substances 0.000 abstract 1

- 238000005520 cutting process Methods 0.000 description 10

- 238000010273 cold forging Methods 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 3

- 238000005255 carburizing Methods 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 229910000640 Fe alloy Inorganic materials 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21K—MAKING FORGED OR PRESSED METAL PRODUCTS, e.g. HORSE-SHOES, RIVETS, BOLTS OR WHEELS

- B21K1/00—Making machine elements

- B21K1/28—Making machine elements wheels; discs

- B21K1/30—Making machine elements wheels; discs with gear-teeth

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23F—MAKING GEARS OR TOOTHED RACKS

- B23F15/00—Methods or machines for making gear wheels of special kinds not covered by groups B23F7/00 - B23F13/00

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49462—Gear making

- Y10T29/49467—Gear shaping

- Y10T29/49474—Die-press shaping

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Forging (AREA)

- Gears, Cams (AREA)

- Gear Processing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN219DE2014 IN2014DE00219A (enExample) | 2014-01-24 | 2014-01-24 | |

| IN219/DEL/2014 | 2014-01-24 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2015136736A true JP2015136736A (ja) | 2015-07-30 |

Family

ID=51176049

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014040916A Pending JP2015136736A (ja) | 2014-01-24 | 2014-03-03 | 鍛造と2段冷間押出しプロセスによる2段歯ギヤの製造方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20150209881A1 (enExample) |

| EP (1) | EP2898965A1 (enExample) |

| JP (1) | JP2015136736A (enExample) |

| KR (1) | KR20150088688A (enExample) |

| CN (1) | CN104801651A (enExample) |

| IN (1) | IN2014DE00219A (enExample) |

| TW (1) | TW201529272A (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023510493A (ja) * | 2020-01-22 | 2023-03-14 | ライシャウァー アーゲー | 2つの歯部を有するワークを加工する方法、ワークの基準回転角度位置を求める位置決め装置、及びそのような位置決め装置を備える動力工具 |

| WO2024247442A1 (ja) * | 2023-05-29 | 2024-12-05 | 株式会社ジェイテクト | 歯車研削加工方法 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109483187A (zh) * | 2019-01-03 | 2019-03-19 | 盐城金刚星精密锻造有限公司 | 一种大规格弧齿锥齿轮近净成型工艺 |

| CN109967687B (zh) * | 2019-03-28 | 2022-12-06 | 常州市爱伦机械有限公司 | 一种齿轮锻造废料回收再加工装置 |

| NL2023814B1 (en) * | 2019-09-11 | 2021-05-17 | Vcst Ind Products Bvba | Method for manufacturing a stepped gear made from one workpiece |

| CN114042851B (zh) * | 2021-11-10 | 2023-11-14 | 宁波固强机械有限公司 | 一种用于制造螺杆头的模具套件及螺杆头的制造方法 |

| CN116571819B (zh) * | 2023-07-12 | 2023-12-08 | 陕西法士特齿轮有限责任公司 | 一种提高齿轮疲劳强度和胶合承载能力的加工方法 |

| CN116922009A (zh) * | 2023-07-27 | 2023-10-24 | 江苏太平洋精锻科技股份有限公司 | 一种耳形锁板零件的制造方法 |

| CN117483634B (zh) * | 2023-12-29 | 2024-03-01 | 常州日恒通用航空有限公司 | 一种齿轮制造用挤压成型设备 |

| CN119281998B (zh) * | 2024-11-12 | 2025-10-31 | 中国机械总院集团郑州机械研究所有限公司 | 一种全齿高超大模数直齿轮锻件及其成形装置 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61296926A (ja) * | 1985-06-25 | 1986-12-27 | Tsubakimoto Chain Co | 板金製2段歯付プ−リの製造方法 |

| JPS6228040A (ja) * | 1985-07-31 | 1987-02-06 | Nissan Motor Co Ltd | 歯車の押出成形方法 |

| JPH09112659A (ja) * | 1995-10-19 | 1997-05-02 | Aichi Mach Ind Co Ltd | ギヤの製造方法 |

| JPH11193861A (ja) * | 1997-12-26 | 1999-07-21 | Metalart Corp | 変速用歯車並びにその製造方法及び装置 |

| JP2004261895A (ja) * | 2003-02-28 | 2004-09-24 | Ooka Giken Kk | 鍛造成形品および鍛造成形品の製造方法ならびに装置 |

| JP2009285688A (ja) * | 2008-05-29 | 2009-12-10 | Kondoo Seikoo Kk | 中空歯形部品の製造方法 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0729171B2 (ja) * | 1987-02-05 | 1995-04-05 | 株式会社横山製作所 | ボス付歯形製品の製造方法 |

| JP2632620B2 (ja) * | 1992-01-14 | 1997-07-23 | 大岡技研株式会社 | 歯車製品 |

| JP3919682B2 (ja) * | 2003-03-04 | 2007-05-30 | 株式会社日立製作所 | 車両の摩擦攪拌接合方法、その装置及び摩擦攪拌接合用構造部材 |

| JPWO2007026756A1 (ja) * | 2005-08-31 | 2009-03-12 | アイシン・エィ・ダブリュ株式会社 | 環状部材の製造方法および脚付き環状部材 |

| US7718116B2 (en) * | 2006-03-24 | 2010-05-18 | Gkn Sinter Metals, Inc. | Forged carburized powder metal part and method |

| WO2011161742A1 (ja) * | 2010-06-21 | 2011-12-29 | 大岡技研株式会社 | 自由曲面歯車 |

| DE102011110169B4 (de) * | 2011-08-13 | 2022-10-13 | Volkswagen Aktiengesellschaft | Verfahren zur Herstellung eines Schaltrads für ein Schaltgetriebe |

-

2014

- 2014-01-24 IN IN219DE2014 patent/IN2014DE00219A/en unknown

- 2014-02-13 US US14/179,904 patent/US20150209881A1/en not_active Abandoned

- 2014-02-27 TW TW103106720A patent/TW201529272A/zh unknown

- 2014-03-03 JP JP2014040916A patent/JP2015136736A/ja active Pending

- 2014-03-11 KR KR1020140028043A patent/KR20150088688A/ko not_active Ceased

- 2014-06-06 EP EP14171486.5A patent/EP2898965A1/en not_active Withdrawn

- 2014-09-03 CN CN201410445947.3A patent/CN104801651A/zh active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61296926A (ja) * | 1985-06-25 | 1986-12-27 | Tsubakimoto Chain Co | 板金製2段歯付プ−リの製造方法 |

| JPS6228040A (ja) * | 1985-07-31 | 1987-02-06 | Nissan Motor Co Ltd | 歯車の押出成形方法 |

| JPH09112659A (ja) * | 1995-10-19 | 1997-05-02 | Aichi Mach Ind Co Ltd | ギヤの製造方法 |

| JPH11193861A (ja) * | 1997-12-26 | 1999-07-21 | Metalart Corp | 変速用歯車並びにその製造方法及び装置 |

| JP2004261895A (ja) * | 2003-02-28 | 2004-09-24 | Ooka Giken Kk | 鍛造成形品および鍛造成形品の製造方法ならびに装置 |

| JP2009285688A (ja) * | 2008-05-29 | 2009-12-10 | Kondoo Seikoo Kk | 中空歯形部品の製造方法 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023510493A (ja) * | 2020-01-22 | 2023-03-14 | ライシャウァー アーゲー | 2つの歯部を有するワークを加工する方法、ワークの基準回転角度位置を求める位置決め装置、及びそのような位置決め装置を備える動力工具 |

| JP7561849B2 (ja) | 2020-01-22 | 2024-10-04 | ライシャウァー アーゲー | 2つの歯部を有するワークを加工する方法、ワークの基準回転角度位置を求める位置決め装置、及びそのような位置決め装置を備える動力工具 |

| WO2024247442A1 (ja) * | 2023-05-29 | 2024-12-05 | 株式会社ジェイテクト | 歯車研削加工方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20150088688A (ko) | 2015-08-03 |

| EP2898965A1 (en) | 2015-07-29 |

| US20150209881A1 (en) | 2015-07-30 |

| IN2014DE00219A (enExample) | 2015-07-31 |

| TW201529272A (zh) | 2015-08-01 |

| CN104801651A (zh) | 2015-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2015136736A (ja) | 鍛造と2段冷間押出しプロセスによる2段歯ギヤの製造方法 | |

| CN101422861B (zh) | 一种异形深孔类零件的精密成形方法 | |

| CN108290256B (zh) | 液力端及制造其的方法 | |

| Dean | The net-shape forming of gears | |

| US9446445B2 (en) | Method for manufacturing hollow shafts | |

| JP4798674B1 (ja) | ラックバー及びその製造方法 | |

| CN110091138A (zh) | 一种新型空心轴制造方法 | |

| CN103567338B (zh) | 金属件制造方法 | |

| US20150196980A1 (en) | Method of manufacturing gear with teeth involving forging | |

| US11052451B2 (en) | Gear manufacturing method and gear manufactured thereby | |

| TW201041673A (en) | Gear forming method | |

| CN103624506B (zh) | 绞盘内齿环精锻塑性成型工艺 | |

| EP2763804A1 (en) | A process for making forged and machined components | |

| JP5062760B2 (ja) | ボルトの製造方法、ボルト製造装置およびボルト製造用金型 | |

| CN105179450A (zh) | 轿车变速器输入轴毂的生产方法 | |

| JP5443358B2 (ja) | 可変ケース深さの粉末金属歯車及びその製造方法 | |

| JP5969273B2 (ja) | 焼結歯車の製造方法 | |

| EP2896471A1 (en) | Method of manufacturing gear with teeth involving forging | |

| CN101827675B (zh) | 用于获得锻造渗碳粉末金属部件的方法 | |

| WO2017163189A1 (en) | A method of manufacturing a crown wheel, and a crown wheel | |

| JP5081177B2 (ja) | 押出用ダイスの製造方法 | |

| JP4946166B2 (ja) | 歯形付き成形品の製造方法 | |

| JP2005103601A5 (enExample) | ||

| CN113649519A (zh) | 一种法兰锻件轴向辗压成形方法 | |

| CN106391983B (zh) | 一种精准快速实现齿成型的加工方法及模具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170228 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180125 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180130 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20180904 |