JP2014528362A - 小型化されたインサート - Google Patents

小型化されたインサート Download PDFInfo

- Publication number

- JP2014528362A JP2014528362A JP2014533914A JP2014533914A JP2014528362A JP 2014528362 A JP2014528362 A JP 2014528362A JP 2014533914 A JP2014533914 A JP 2014533914A JP 2014533914 A JP2014533914 A JP 2014533914A JP 2014528362 A JP2014528362 A JP 2014528362A

- Authority

- JP

- Japan

- Prior art keywords

- insert

- tightening

- recess

- convex portion

- tip

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B27/00—Tools for turning or boring machines; Tools of a similar kind in general; Accessories therefor

- B23B27/14—Cutting tools of which the bits or tips or cutting inserts are of special material

- B23B27/16—Cutting tools of which the bits or tips or cutting inserts are of special material with exchangeable cutting bits or cutting inserts, e.g. able to be clamped

- B23B27/1625—Cutting tools of which the bits or tips or cutting inserts are of special material with exchangeable cutting bits or cutting inserts, e.g. able to be clamped with plate-like cutting inserts of special shape clamped by a clamping member acting almost perpendicularly on the chip-forming plane

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B27/00—Tools for turning or boring machines; Tools of a similar kind in general; Accessories therefor

- B23B27/14—Cutting tools of which the bits or tips or cutting inserts are of special material

- B23B27/16—Cutting tools of which the bits or tips or cutting inserts are of special material with exchangeable cutting bits or cutting inserts, e.g. able to be clamped

- B23B27/1644—Cutting tools of which the bits or tips or cutting inserts are of special material with exchangeable cutting bits or cutting inserts, e.g. able to be clamped with plate-like cutting inserts of special shape clamped by a clamping member acting almost perpendicularly on the chip-forming plane and at the same time upon the wall of a hole in the cutting insert

- B23B27/1651—Cutting tools of which the bits or tips or cutting inserts are of special material with exchangeable cutting bits or cutting inserts, e.g. able to be clamped with plate-like cutting inserts of special shape clamped by a clamping member acting almost perpendicularly on the chip-forming plane and at the same time upon the wall of a hole in the cutting insert characterised by having a special shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2200/00—Details of cutting inserts

- B23B2200/08—Rake or top surfaces

- B23B2200/086—Rake or top surfaces with one or more grooves

- B23B2200/088—Rake or top surfaces with one or more grooves for clamping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2226/00—Materials of tools or workpieces not comprising a metal

- B23B2226/12—Boron nitride

- B23B2226/125—Boron nitride cubic [CBN]

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B27/00—Tools for turning or boring machines; Tools of a similar kind in general; Accessories therefor

- B23B27/14—Cutting tools of which the bits or tips or cutting inserts are of special material

- B23B27/16—Cutting tools of which the bits or tips or cutting inserts are of special material with exchangeable cutting bits or cutting inserts, e.g. able to be clamped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B27/00—Tools for turning or boring machines; Tools of a similar kind in general; Accessories therefor

- B23B27/22—Cutting tools with chip-breaking equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B29/00—Holders for non-rotary cutting tools; Boring bars or boring heads; Accessories for tool holders

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T407/00—Cutters, for shaping

- Y10T407/22—Cutters, for shaping including holder having seat for inserted tool

- Y10T407/2272—Cutters, for shaping including holder having seat for inserted tool with separate means to fasten tool to holder

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T407/00—Cutters, for shaping

- Y10T407/22—Cutters, for shaping including holder having seat for inserted tool

- Y10T407/2272—Cutters, for shaping including holder having seat for inserted tool with separate means to fasten tool to holder

- Y10T407/2282—Cutters, for shaping including holder having seat for inserted tool with separate means to fasten tool to holder including tool holding clamp and clamp actuator

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cutting Tools, Boring Holders, And Turrets (AREA)

- Clamps And Clips (AREA)

Abstract

Description

Claims (12)

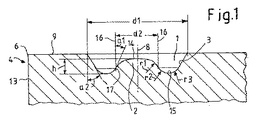

- 切削工具に用いられるインサート(4)であって、インサート上面(9)およびインサート下面(10)と、1つ以上の側面(13)と、該側面(13)へのインサート上面(9)の移行部に設けられたカッティングエッジ(6)と、インサート上面(9)に設けられた、外径d1を有する円形の緊締窪み(1)とを備えた、切削工具に用いられるインサートにおいて、緊締窪み(1)の外径d1が、2mm<d1≦6mm、好適には2mm<d1<5mmに設定されていることを特徴とする、切削工具に用いられるインサート。

- 緊締窪み(1)が、内部に位置する円形の凸部(2)を有しており、該凸部(2)の先端部(14)が、緊締窪み(1)の底部(15)よりは上側でインサート上面(9)よりは下側に位置しており、凸部(2)が、外径d2と、緊締窪み(1)の底部(15)から凸部(2)の先端部(14)までの高さhとを有しており、凸部(2)の外径d2が、凸部(2)の半分の高さhにおいて測定されており、凸部(2)の外径d2が、0.8mm<d2<3.5mmに設定されている、請求項1記載のインサート。

- インサート(4)が、そのインサート下面(10)にインサート上面(9)と同じ緊締窪み(1)を有していて、ひいては、スローアウェイチップとして形成されている、請求項1または2記載のインサート。

- インサート(4)が、PcBN(多結晶立方晶窒化ホウ素)から成っている、請求項1から3までのいずれか1項記載のインサート。

- 緊締窪み(1)が、V<8mm3、好適にはV<6mm3の容積を有している、請求項1から4までのいずれか1項記載のインサート。

- 凸部(2)の先端部(14)が、インサート上面(9)の垂線(16)に対して凸部角α1を成して傾けられた側面(17)を介して、緊締窪み(1)の底部(15)に移行しており、凸部角α1が、7°<α1<55°、好適には7°<α1<35°に設定されている、請求項2から5までのいずれか1項記載のインサート。

- 凸部角α1が、27°<α1<28°に設定されている、請求項6記載のインサート。

- 凸部(2)の高さh、すなわち、底部(15)から凸部(2)の先端部(14)までの間隔が、2×d2≧h≧0.4×d2に設定されている、請求項2から7までのいずれか1項記載のインサート。

- 凸部(2)の先端部(14)が、曲率半径r1を有する移行部を介して、側面(17)に移行しており、該側面(17)が、曲率半径r2を有する移行部を介して、緊締窪み(1)の底部(15)に移行しており、該緊締窪み(1)の底部(15)が、曲率半径r3を有する移行部を介して、緊締窪み(1)の底部(15)をインサート上面(9)/インサート下面(10)に接続する側面(3)に移行しており、曲率半径r1、r2,r3が、0.05mm〜0.6mm、好適には0.2mm〜0.3mmに設定されている、請求項2から8までのいずれか1項記載のインサート。

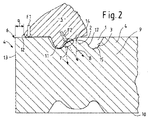

- 緊締窪み(1)内に係合する突起(11)が配置された緊締駒(5)と、該緊締駒(5)に設けられた、インサート(4)のカッティングエッジ(6)から見て緊締窪み(1)の手前でインサート上面(9)/インサート下面(10)に載置されるノーズ(12)とによってクランプする、請求項1から9までのいずれか1項記載のインサート(4)の使用。

- カッティングエッジ(6)から緊締駒(5)のノーズ(12)までの間隔aが、12.7mmの内接円を有するインサート(4)では少なくとも2.2mmに設定されていて、12.7mmよりも小さな内接円を有するインサート(4)では少なくとも1.3mmに設定されている、請求項10記載の使用。

- 焼入れ鋼を切削加工するための請求項1から9までのいずれか1項記載のインサート(4)の使用。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102011084091.5 | 2011-10-06 | ||

| DE102011084091 | 2011-10-06 | ||

| PCT/EP2012/069705 WO2013050520A1 (de) | 2011-10-06 | 2012-10-05 | Miniaturisierte schneidplatte |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2014528362A true JP2014528362A (ja) | 2014-10-27 |

| JP6138139B2 JP6138139B2 (ja) | 2017-05-31 |

Family

ID=47018993

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014533914A Active JP6138139B2 (ja) | 2011-10-06 | 2012-10-05 | 小型化されたインサート |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US9770762B2 (ja) |

| EP (1) | EP2763809B1 (ja) |

| JP (1) | JP6138139B2 (ja) |

| KR (1) | KR101990608B1 (ja) |

| CN (1) | CN103987480B (ja) |

| DE (1) | DE102012218193A1 (ja) |

| DK (1) | DK2763809T3 (ja) |

| ES (1) | ES2817782T3 (ja) |

| HU (1) | HUE051769T2 (ja) |

| PL (1) | PL2763809T3 (ja) |

| PT (1) | PT2763809T (ja) |

| SI (1) | SI2763809T1 (ja) |

| WO (1) | WO2013050520A1 (ja) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014104886A1 (de) | 2014-04-07 | 2015-10-08 | Mas Gmbh | Schneidplatte, Zerspanungswerkzeug und Verfahren zur Herstellung einer Schneidplatte |

| PL3242764T3 (pl) * | 2015-01-09 | 2022-03-28 | Ceramtec Gmbh | Narzędzie nośne |

| US11241747B2 (en) * | 2017-10-16 | 2022-02-08 | Iscar, Ltd. | Cutting tool and undersized bore-less indexable insert therefor |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1602817A1 (de) * | 1967-09-20 | 1970-05-06 | Hans Heinlein | Wendeplattenanordnung |

| JPH1177408A (ja) * | 1997-09-09 | 1999-03-23 | Sumitomo Electric Ind Ltd | セラミックチップクランプ型切削工具 |

| JP2002508260A (ja) * | 1997-12-03 | 2002-03-19 | サンドビック アクティエボラーグ | セラミック製切断用インサート |

| US20030086766A1 (en) * | 2001-11-08 | 2003-05-08 | Andras Linn R | Dimpled insert with retaining clamp |

| US20030219319A1 (en) * | 2002-03-21 | 2003-11-27 | Sandvik Aktiebolag | Tool for chip removing machining and rotatable cutting insert for such tools |

| JPWO2003015968A1 (ja) * | 2001-08-10 | 2004-12-02 | 住友電気工業株式会社 | くぼみ又は溝を有する超高圧焼結体切削工具とその保持機構及びその製造方法 |

| JP2009101513A (ja) * | 2001-07-26 | 2009-05-14 | Ceramtec Ag Innov Ceramic Eng | 切削板 |

| WO2010069541A1 (de) * | 2008-12-19 | 2010-06-24 | MAPAL Fabrik für Präzisionswerkzeuge Dr. Kress KG | Reibahle, messerplatten dafür und verfahren zum einstellen des bearbeitungsdurchmessers einer solchen reibahle |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4240295A1 (en) * | 1991-12-03 | 1993-06-09 | Ursula 7310 Plochingen De Groeschel | Clamp for securing throw-away tooltips in turning tool holder - has pulling ball clamp between depression in top face of tooltip and opposing thrust plate to seat tooltip in recess |

| DE4430171C2 (de) * | 1994-08-25 | 1996-08-14 | Walter Ag | Formschlüssig gesicherte Schneidplatte |

| DE19524945A1 (de) * | 1995-07-08 | 1997-01-09 | Cerasiv Gmbh | Spanabhebendes Schneidwerkzeug |

| DE19854873A1 (de) * | 1998-11-27 | 2000-05-31 | Widia Gmbh | Schneideinsatz und Schneidwerkzeug |

| KR100676954B1 (ko) * | 1999-04-26 | 2007-01-31 | 산드빅 인터렉츄얼 프로퍼티 에이비 | 커팅 인써트를 잡아주는 공구 홀더 및 클램프 판 |

| US6379087B1 (en) * | 2000-02-07 | 2002-04-30 | Kennametal Inc. | Cutting insert with split face clamping surfaces and toolholder therefor |

| DE10208266A1 (de) | 2001-07-26 | 2003-02-13 | Ceram Tec Ag Innovative Cerami | Spanabhebendes Schneidwerkzeug und Schneidplatte in Donut-Form |

| DE10239451A1 (de) * | 2002-08-28 | 2004-03-11 | Ceramtec Ag Innovative Ceramic Engineering | Schneidplatte mit Doppelmulde |

| US7429152B2 (en) * | 2003-06-17 | 2008-09-30 | Kennametal Inc. | Uncoated cutting tool using brazed-in superhard blank |

| SE0602512L (sv) * | 2006-10-13 | 2008-04-22 | Seco Tools Ab | Negativt svarvskär med en fas mellan skäregg och släppningssida |

| DE102008001857A1 (de) * | 2007-05-22 | 2008-11-27 | Ceramtec Ag | Plattensitz mit Einlegestücken |

| US7547163B2 (en) * | 2007-07-16 | 2009-06-16 | Kennametal Inc. | Clamping tool holder |

| JP4987081B2 (ja) * | 2008-03-26 | 2012-07-25 | 京セラ株式会社 | 切削工具 |

| CN201432116Y (zh) * | 2009-06-29 | 2010-03-31 | 株洲钻石切削刀具股份有限公司 | 用于可转位刀片的固定刀夹 |

-

2012

- 2012-10-05 US US14/348,632 patent/US9770762B2/en not_active Expired - Fee Related

- 2012-10-05 HU HUE12772755A patent/HUE051769T2/hu unknown

- 2012-10-05 DK DK12772755.0T patent/DK2763809T3/da active

- 2012-10-05 SI SI201231832T patent/SI2763809T1/sl unknown

- 2012-10-05 WO PCT/EP2012/069705 patent/WO2013050520A1/de not_active Ceased

- 2012-10-05 KR KR1020147012267A patent/KR101990608B1/ko active Active

- 2012-10-05 ES ES12772755T patent/ES2817782T3/es active Active

- 2012-10-05 EP EP12772755.0A patent/EP2763809B1/de active Active

- 2012-10-05 JP JP2014533914A patent/JP6138139B2/ja active Active

- 2012-10-05 PT PT127727550T patent/PT2763809T/pt unknown

- 2012-10-05 DE DE102012218193A patent/DE102012218193A1/de not_active Withdrawn

- 2012-10-05 PL PL12772755T patent/PL2763809T3/pl unknown

- 2012-10-05 CN CN201280060005.2A patent/CN103987480B/zh active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1602817A1 (de) * | 1967-09-20 | 1970-05-06 | Hans Heinlein | Wendeplattenanordnung |

| JPH1177408A (ja) * | 1997-09-09 | 1999-03-23 | Sumitomo Electric Ind Ltd | セラミックチップクランプ型切削工具 |

| JP2002508260A (ja) * | 1997-12-03 | 2002-03-19 | サンドビック アクティエボラーグ | セラミック製切断用インサート |

| JP2009101513A (ja) * | 2001-07-26 | 2009-05-14 | Ceramtec Ag Innov Ceramic Eng | 切削板 |

| JPWO2003015968A1 (ja) * | 2001-08-10 | 2004-12-02 | 住友電気工業株式会社 | くぼみ又は溝を有する超高圧焼結体切削工具とその保持機構及びその製造方法 |

| US20030086766A1 (en) * | 2001-11-08 | 2003-05-08 | Andras Linn R | Dimpled insert with retaining clamp |

| US20030219319A1 (en) * | 2002-03-21 | 2003-11-27 | Sandvik Aktiebolag | Tool for chip removing machining and rotatable cutting insert for such tools |

| WO2010069541A1 (de) * | 2008-12-19 | 2010-06-24 | MAPAL Fabrik für Präzisionswerkzeuge Dr. Kress KG | Reibahle, messerplatten dafür und verfahren zum einstellen des bearbeitungsdurchmessers einer solchen reibahle |

Also Published As

| Publication number | Publication date |

|---|---|

| HUE051769T2 (hu) | 2021-03-29 |

| SI2763809T1 (sl) | 2020-10-30 |

| KR20140078727A (ko) | 2014-06-25 |

| US9770762B2 (en) | 2017-09-26 |

| CN103987480A (zh) | 2014-08-13 |

| EP2763809A1 (de) | 2014-08-13 |

| US20140234041A1 (en) | 2014-08-21 |

| DK2763809T3 (da) | 2020-09-07 |

| EP2763809B1 (de) | 2020-06-24 |

| ES2817782T3 (es) | 2021-04-08 |

| CN103987480B (zh) | 2017-09-12 |

| PT2763809T (pt) | 2020-09-04 |

| JP6138139B2 (ja) | 2017-05-31 |

| DE102012218193A1 (de) | 2013-04-11 |

| WO2013050520A1 (de) | 2013-04-11 |

| PL2763809T3 (pl) | 2020-10-19 |

| KR101990608B1 (ko) | 2019-06-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5115148B2 (ja) | インサート着脱式切削工具のヘッド部材およびインサート着脱式切削工具 | |

| CN108602130B (zh) | 用于金属切削的面切槽刀具主体 | |

| JP5396539B2 (ja) | 両面インデックサブル切削インサート及び補強材の組立体 | |

| JP2010522087A (ja) | 合わせ面を有する工具インサート | |

| CN212793066U (zh) | 用于切削加工的工具 | |

| CN103998166B (zh) | 刀具系统 | |

| CN105142833A (zh) | 铣刀 | |

| JP5040591B2 (ja) | インサート着脱式切削工具のヘッド部材およびインサート着脱式切削工具 | |

| JP5488374B2 (ja) | ヘッド交換式切削工具 | |

| CN103384578A (zh) | 用于硬切削加工的铣刀 | |

| JP6138139B2 (ja) | 小型化されたインサート | |

| US9782841B2 (en) | Cutting tool | |

| US10286459B2 (en) | Machining tool | |

| CN107206505A (zh) | 切削刀具 | |

| WO2013057776A1 (ja) | ヘッド交換式切削工具 | |

| JP6496744B2 (ja) | ワークピースを機械加工するためのツール | |

| US10415385B2 (en) | Pick, in particular a round-shank pick | |

| US20190001419A1 (en) | Carrier tool, cutting insert, and clamping element | |

| JP2003145320A (ja) | スローアウェイチップおよびそのクランプ機構 | |

| CN104741472A (zh) | 热压成型工艺中板料的全方位定位结构及定位方法 | |

| JP4203212B2 (ja) | スローアウェイ式ボールエンドミル | |

| JP5071048B2 (ja) | インサート着脱式切削工具のヘッド部材およびインサート着脱式切削工具 | |

| JP2007290057A (ja) | 超高圧焼結体切削工具 | |

| JP2008290214A (ja) | 中ぐり加工用チップおよびこれを用いた中ぐり工具 | |

| JP2008006538A (ja) | スローアウェイ式切削工具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150925 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160818 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160829 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161115 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170403 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170425 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6138139 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |