JP2013544959A - 部品を加工する方法およびその方法によって得られた複合稠密部品 - Google Patents

部品を加工する方法およびその方法によって得られた複合稠密部品 Download PDFInfo

- Publication number

- JP2013544959A JP2013544959A JP2013530783A JP2013530783A JP2013544959A JP 2013544959 A JP2013544959 A JP 2013544959A JP 2013530783 A JP2013530783 A JP 2013530783A JP 2013530783 A JP2013530783 A JP 2013530783A JP 2013544959 A JP2013544959 A JP 2013544959A

- Authority

- JP

- Japan

- Prior art keywords

- metal

- fiber

- yarns

- weaving

- reinforcing edge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000002131 composite material Substances 0.000 title claims abstract description 28

- 238000000034 method Methods 0.000 title claims abstract description 21

- 239000000835 fiber Substances 0.000 claims abstract description 63

- 230000003014 reinforcing effect Effects 0.000 claims abstract description 60

- 238000009941 weaving Methods 0.000 claims abstract description 51

- 229910052751 metal Inorganic materials 0.000 claims abstract description 38

- 239000002184 metal Substances 0.000 claims abstract description 38

- 239000000919 ceramic Substances 0.000 claims abstract description 20

- 238000001513 hot isostatic pressing Methods 0.000 claims abstract description 15

- 229910045601 alloy Inorganic materials 0.000 claims abstract description 12

- 239000000956 alloy Substances 0.000 claims abstract description 12

- 239000011159 matrix material Substances 0.000 claims abstract description 7

- 230000002787 reinforcement Effects 0.000 claims description 12

- 229910001069 Ti alloy Inorganic materials 0.000 claims description 10

- 239000010936 titanium Substances 0.000 claims description 10

- 238000000576 coating method Methods 0.000 claims description 9

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 7

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical group [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 claims description 7

- 229910052719 titanium Inorganic materials 0.000 claims description 7

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 5

- 229910052796 boron Inorganic materials 0.000 claims description 5

- 229910001092 metal group alloy Inorganic materials 0.000 claims description 3

- 150000002739 metals Chemical class 0.000 claims description 3

- 238000003754 machining Methods 0.000 abstract description 5

- 239000011248 coating agent Substances 0.000 description 7

- 238000003466 welding Methods 0.000 description 6

- 238000011144 upstream manufacturing Methods 0.000 description 4

- 239000000853 adhesive Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- 229910010271 silicon carbide Inorganic materials 0.000 description 3

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000003672 processing method Methods 0.000 description 2

- 229910000521 B alloy Inorganic materials 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000000295 complement effect Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 238000009432 framing Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 238000009958 sewing Methods 0.000 description 1

- 238000003856 thermoforming Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

- F01D5/282—Selecting composite materials, e.g. blades with reinforcing filaments

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/26—Rotors specially for elastic fluids

- F04D29/32—Rotors specially for elastic fluids for axial flow pumps

- F04D29/321—Rotors specially for elastic fluids for axial flow pumps for axial flow compressors

- F04D29/324—Blades

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/12—Both compacting and sintering

- B22F3/14—Both compacting and sintering simultaneously

- B22F3/15—Hot isostatic pressing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F5/04—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product of turbine blades

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C47/00—Making alloys containing metallic or non-metallic fibres or filaments

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C47/00—Making alloys containing metallic or non-metallic fibres or filaments

- C22C47/02—Pretreatment of the fibres or filaments

- C22C47/06—Pretreatment of the fibres or filaments by forming the fibres or filaments into a preformed structure, e.g. using a temporary binder to form a mat-like element

- C22C47/062—Pretreatment of the fibres or filaments by forming the fibres or filaments into a preformed structure, e.g. using a temporary binder to form a mat-like element from wires or filaments only

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D25/00—Woven fabrics not otherwise provided for

- D03D25/005—Three-dimensional woven fabrics

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/14—Form or construction

- F01D5/147—Construction, i.e. structural features, e.g. of weight-saving hollow blades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B11/00—Making preforms

- B29B11/14—Making preforms characterised by structure or composition

- B29B11/16—Making preforms characterised by structure or composition comprising fillers or reinforcement

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/28—Selecting particular materials; Particular measures relating thereto; Measures against erosion or corrosion

- F01D5/288—Protective coatings for blades

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/36—Application in turbines specially adapted for the fan of turbofan engines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2240/00—Components

- F05D2240/20—Rotors

- F05D2240/30—Characteristics of rotor blades, i.e. of any element transforming dynamic fluid energy to or from rotational energy and being attached to a rotor

- F05D2240/303—Characteristics of rotor blades, i.e. of any element transforming dynamic fluid energy to or from rotational energy and being attached to a rotor related to the leading edge of a rotor blade

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2300/00—Materials; Properties thereof

- F05D2300/10—Metals, alloys or intermetallic compounds

- F05D2300/13—Refractory metals, i.e. Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W

- F05D2300/133—Titanium

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T50/00—Aeronautics or air transport

- Y02T50/60—Efficient propulsion technologies, e.g. for aircraft

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Composite Materials (AREA)

- Crystallography & Structural Chemistry (AREA)

- Textile Engineering (AREA)

- Architecture (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Woven Fabrics (AREA)

- Manufacture Of Alloys Or Alloy Compounds (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Powder Metallurgy (AREA)

Abstract

金属糸を三次元的に織ることによって少なくとも1つの繊維構造を作製するステップと、

金属糸を稠密部品を得るような方法で塊状化するようにして繊維構造に熱間等静圧圧縮成形を受けさせるステップとを有する。

複合稠密部品、特にターボ機械ブレード用補強縁(20)は、三次元的に織られたセラミック繊維(32、39)の補強構造(40)、および金属または合金マトリックス(41)を有する。

Description

金属糸を三次元的に織ることによって少なくとも1つの繊維構造を作製するステップと、

金属糸を稠密部品を得るような方法で塊状化するようにして繊維構造に熱間等静圧圧縮成形を受けさせるステップとを有する方法を提供する。

金属または合金、特にチタン(Ti)またはチタン合金からなる糸、および/または

特に炭化ケイ素(SiC)からなる中心セラミック繊維、および特にチタン、チタン合金、またはホウ素からなる金属または合金コーティングを有する複合糸。

チタン(またはホウ素)合金のコーティング34によって被覆された炭化ケイ素(SiC)からなる中心セラミック繊維32を有する大きな直径(例えば0.5mm)の複合糸30であり、このタイプの糸は、当業者によって、「SiC/Ti糸」または「SiC−Ti糸」(ホウ素合金のコーティング用または「SiC/B糸」または「SiC−B糸」と称する);

チタン合金(例えば、TA6V、Ti6242などのタイプの合金)のより小さな直径(例えば0.1mm)糸36;および

チタン(またはホウ素)合金のコーティング37によって被覆された炭化ケイ素(SiC)の中心セラミック繊維39を有する小さな直径(例えば0.25mm)の複合糸38。

サブ構造が異なる方向性を有することが可能である;

サブ構造間の形状および厚みの大きな変化があることが可能であり、このようにして、最終構造において、いかなる他の方法で得ることが困難な形状および厚みの大きな変化を有することを可能にする;

織られたサブ構造の1つに特に平らな形状を達成することが可能である。

Claims (12)

- 部品を加工する方法であって、

金属糸を三次元的に織ることによって少なくとも1つの繊維構造(25)を作製するステップと、

金属糸を稠密部品を得るような方法で塊状化するようにして繊維構造(25)に熱間等静圧圧縮成形を受けさせるステップとを有する、方法。 - 前記部品が、第1の方向に延在し、第1の方向に直角な平面において変化する厚みを示し、

三次元製織のために使用される縦糸は、第1の方向に沿って延在し、

部品の厚みの変化は、異なる直径の縦糸を使用することによって、および任意に織り方を変えることによって得られる、請求項1に記載の方法。 - 金属糸が、

金属または金属合金、特にチタンまたはチタン合金からなる糸(36)、および/または

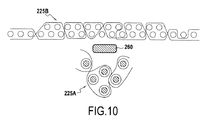

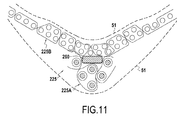

セラミック繊維芯(32、39)、特に炭化ケイ素芯、および特にチタン、またはチタン合金、またはホウ素からなる金属または合金コーティング(34,37)を有する複合糸(30、38)である、請求項1または2に記載の方法。 - 少なくとも2つの繊維構造(125A、125B;225A、225B)が三次元製織によって作製され、これらの繊維構造はまとめられ、これらのまとめられた繊維構造によって形成された集合体(125、225)は、前記熱間等静圧圧縮成形を受ける、請求項1から3のいずれか1項に記載の方法。

- 金属インサート(260)が、2つの繊維構造(225A、225B)がまとめられる前に、2つの繊維構造(225A、225B)間に設置される、請求項4に記載の方法。

- 前記部品が、ターボ機械ファンブレード用補強縁(20)である、請求項1から5のいずれか1項に記載の方法。

- 三次元的に織られたセラミック繊維(32、39)の補強構造(40)および金属または合金マトリックス(41)を有する複合稠密部品。

- ターボ機械ファンブレード用補強縁(20)を構成する、請求項7に記載の複合稠密部品。

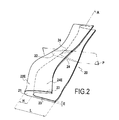

- 補強縁(20)が、第1の方向(A)の長手方向に延在し、第1の方向(A)に直角な平面の断面において、より大きな厚みの中央部分(22)および先細状の枝(24)を備えた略C形状の輪郭を示し、三次元的に織られたセラミック繊維の補強構造(40)は、少なくとも中央部分(22)の外側領域に位置する、請求項8に記載の複合稠密部品。

- 補強構造(40)のより大きな直径の縦糸が、少なくとも中央部分(22)の外側領域に位置する、請求項9に記載の複合稠密部品。

- 請求項8から10のいずれか1項に記載の補強縁(20)を有するターボ機械ファンブレード。

- 請求項11に記載のファンブレードを有するターボ機械。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1057799A FR2965202B1 (fr) | 2010-09-28 | 2010-09-28 | Procede de fabrication d'une piece et piece massive composite obtenue par ce procede |

| FR1057799 | 2010-09-28 | ||

| PCT/FR2011/052239 WO2012042160A1 (fr) | 2010-09-28 | 2011-09-26 | Procede de fabrication d'une piece et piece massive composite obtenue par ce procede |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016092600A Division JP6130553B2 (ja) | 2010-09-28 | 2016-05-02 | 部品を加工する方法およびその方法によって得られた複合稠密部品 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2013544959A true JP2013544959A (ja) | 2013-12-19 |

| JP2013544959A5 JP2013544959A5 (ja) | 2016-01-07 |

Family

ID=43500255

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013530783A Pending JP2013544959A (ja) | 2010-09-28 | 2011-09-26 | 部品を加工する方法およびその方法によって得られた複合稠密部品 |

| JP2016092600A Active JP6130553B2 (ja) | 2010-09-28 | 2016-05-02 | 部品を加工する方法およびその方法によって得られた複合稠密部品 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2016092600A Active JP6130553B2 (ja) | 2010-09-28 | 2016-05-02 | 部品を加工する方法およびその方法によって得られた複合稠密部品 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US9476309B2 (ja) |

| EP (1) | EP2621651B1 (ja) |

| JP (2) | JP2013544959A (ja) |

| CN (1) | CN103124606B (ja) |

| BR (1) | BR112013006453B1 (ja) |

| CA (1) | CA2811477C (ja) |

| FR (1) | FR2965202B1 (ja) |

| RU (2) | RU2708286C2 (ja) |

| WO (1) | WO2012042160A1 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015520033A (ja) * | 2012-04-19 | 2015-07-16 | スネクマ | 複合物でできた前縁を保護するためのインサートを備えた金属補強材を形成するための方法 |

| US10934851B2 (en) | 2015-12-21 | 2021-03-02 | Safran Aircraft Engines | Leading edge shield |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7655581B2 (en) * | 2005-11-17 | 2010-02-02 | Albany Engineered Composites, Inc. | Hybrid three-dimensional woven/laminated struts for composite structural applications |

| FR2957545B1 (fr) * | 2010-03-19 | 2012-07-27 | Snecma | Procede de realisation d'un insert metallique pour la protection d'un bord d'attaque en materiau composite |

| FR2970715B1 (fr) * | 2011-01-21 | 2014-10-17 | Snecma | Structure fibreuse tissee multicouches ayant une partie tubulaire creuse, procede de fabrication et piece composite la comportant |

| JP6174839B2 (ja) * | 2011-10-14 | 2017-08-02 | 株式会社Ihi | セラミックス基複合部材およびその製造方法 |

| FR2989991B1 (fr) | 2012-04-30 | 2016-01-08 | Snecma | Renfort structurel metallique d'aube de turbomachine |

| FR3025248B1 (fr) * | 2014-08-27 | 2019-08-23 | Safran | Aube de redresseur en materiau composite pour moteur a turbine a gaz et son procede de fabrication |

| CN104743099B (zh) * | 2015-03-26 | 2017-09-12 | 北京勤达远致新材料科技股份有限公司 | 一种飞机用三维编织复合材料螺旋桨叶片及其制备方法 |

| CN106523430B (zh) * | 2015-09-11 | 2019-07-09 | 中国航发商用航空发动机有限责任公司 | 风扇叶片及其制备方法 |

| CN105436505B (zh) * | 2015-11-14 | 2017-10-13 | 华中科技大学 | 一种用于提高零件表面质量的热等静压成形方法 |

| EP3495612B1 (en) * | 2017-12-06 | 2021-05-12 | Ansaldo Energia IP UK Limited | Method for manufacturing composite component |

| CN109605777B (zh) * | 2018-12-03 | 2021-01-26 | 江西洪都航空工业集团有限责任公司 | 一种实芯复合材料边缘条预制体制造方法 |

| FR3100270B1 (fr) | 2019-08-28 | 2021-07-30 | Safran Aircraft Engines | Hybridation des fibres du renfort fibreux d’une aube de soufflante |

| FR3109184B1 (fr) * | 2020-04-14 | 2022-04-01 | Safran | Aube en matériau composite comportant des renforts métalliques, et procédé de fabrication d’une telle aube |

| US11421538B2 (en) * | 2020-05-12 | 2022-08-23 | Rolls-Royce Corporation | Composite aerofoils |

| US11506083B2 (en) | 2020-06-03 | 2022-11-22 | Rolls-Royce Corporalion | Composite liners for turbofan engines |

| FR3112142B1 (fr) * | 2020-07-03 | 2022-09-09 | Safran Ceram | Procédé de fabrication d’une aube de distributeur en matériau composite à matrice céramique |

| FR3116311B1 (fr) * | 2020-11-17 | 2023-05-19 | Safran Aircraft Engines | Aube de soufflante comprenant un bouclier à densité variable |

| CN112453834A (zh) * | 2020-11-19 | 2021-03-09 | 中国航空制造技术研究院 | 复杂型面钛合金零件结构的制备方法 |

| CN114211204B (zh) * | 2021-12-21 | 2023-02-03 | 北京星航机电装备有限公司 | 一种γ形半截面端环及其超塑成形方法 |

| US20240280027A1 (en) * | 2023-02-21 | 2024-08-22 | General Electric Company | Turbine engine airfoil with a woven core and woven layer |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62120445A (ja) * | 1985-11-20 | 1987-06-01 | Nippon Carbon Co Ltd | 繊維強化金属複合材料成形品の製造法 |

| JPH0193104A (ja) * | 1987-10-05 | 1989-04-12 | Kobe Steel Ltd | 磁気異方体の製造方法 |

| JP2005113908A (ja) * | 2003-09-05 | 2005-04-28 | General Electric Co <Ge> | 補強ファンブレード及び製造方法 |

| JP2005133717A (ja) * | 2003-10-20 | 2005-05-26 | Snecma Moteurs | ターボ機関ブレード、特にファンブレード及びその製造方法 |

| WO2009034264A2 (fr) * | 2007-07-26 | 2009-03-19 | Snecma | Piece mecanique comportant un insert en materiau composite |

| WO2010061140A1 (fr) * | 2008-11-28 | 2010-06-03 | Snecma Propulsion Solide | Aube de turbomachine en materiau composite et procede pour sa fabrication |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US826063A (en) | 1905-03-07 | 1906-07-17 | Joseph Reid | Well-drilling cable. |

| FR858098A (fr) * | 1938-08-02 | 1940-11-16 | Tube de pitot chauffé électriquement | |

| US4762268A (en) * | 1986-05-02 | 1988-08-09 | Airfoil Textron Inc. | Fabrication method for long-length or large-sized dense filamentary monotapes |

| SU1454872A1 (ru) * | 1987-05-25 | 1989-01-30 | Институт проблем сверхпластичности металлов АН СССР | Способ получени полуфабрикатов дл композиционных материалов |

| US5277973A (en) * | 1988-08-12 | 1994-01-11 | Ube Industries, Ltd. | Carbon fibers having high strength and high modulus of elasticity and polymer composition for their production |

| US5115962A (en) | 1988-12-20 | 1992-05-26 | United Technologies Corporation | Method of attaching ceramic fiber arrays to metallic substrates |

| US5104726A (en) * | 1989-12-29 | 1992-04-14 | Woven Electronics Corporation | Woven fabric and process for reinforced structural composites |

| FR2759096B1 (fr) * | 1997-02-04 | 1999-02-26 | Snecma | Texture multicouche liee pour materiaux composites structuraux |

| JP2004084524A (ja) * | 2002-08-26 | 2004-03-18 | Mitsubishi Heavy Ind Ltd | ファンのブレード、ファン及びファンのブレードの補強方法 |

| FR2884550B1 (fr) * | 2005-04-15 | 2010-09-17 | Snecma Moteurs | Piece pour proteger le bord d'attaque d'une pale |

| FR2886290B1 (fr) | 2005-05-27 | 2007-07-13 | Snecma Moteurs Sa | Procede de fabrication d'une piece avec un insert en materiau composite a matrice metallique et fibres ceramiques |

| FR2887601B1 (fr) * | 2005-06-24 | 2007-10-05 | Snecma Moteurs Sa | Piece mecanique et procede de fabrication d'une telle piece |

| US7413999B2 (en) * | 2005-11-03 | 2008-08-19 | Albany Engineered Composites, Inc. | Corner fitting using fiber transfer |

| FR2913053B1 (fr) * | 2007-02-23 | 2009-05-22 | Snecma Sa | Procede de fabrication d'un carter de turbine a gaz en materiau composite et carter ainsi obtenu |

| US7964520B2 (en) * | 2007-12-21 | 2011-06-21 | Albany Engineered Composites, Inc. | Method for weaving substrates with integral sidewalls |

| US8715439B2 (en) | 2008-03-07 | 2014-05-06 | The Boeing Company | Method for making hybrid metal-ceramic matrix composite structures and structures made thereby |

| FR2939130B1 (fr) * | 2008-11-28 | 2011-09-16 | Snecma Propulsion Solide | Procede de fabrication de piece de forme de forme complexe en materiau composite. |

| US8499450B2 (en) * | 2010-01-26 | 2013-08-06 | United Technologies Corporation | Three-dimensionally woven composite blade with spanwise weft yarns |

| CA2804957C (fr) | 2010-07-12 | 2018-04-10 | Snecma | Procede de realisation d'une piece massive |

-

2010

- 2010-09-28 FR FR1057799A patent/FR2965202B1/fr not_active Expired - Fee Related

-

2011

- 2011-09-26 EP EP11773781.7A patent/EP2621651B1/fr active Active

- 2011-09-26 RU RU2015153536A patent/RU2708286C2/ru active

- 2011-09-26 BR BR112013006453A patent/BR112013006453B1/pt active IP Right Grant

- 2011-09-26 CA CA2811477A patent/CA2811477C/fr active Active

- 2011-09-26 RU RU2013119666/02A patent/RU2578886C2/ru active

- 2011-09-26 WO PCT/FR2011/052239 patent/WO2012042160A1/fr active Application Filing

- 2011-09-26 JP JP2013530783A patent/JP2013544959A/ja active Pending

- 2011-09-26 US US13/824,728 patent/US9476309B2/en active Active

- 2011-09-26 CN CN201180046446.2A patent/CN103124606B/zh active Active

-

2016

- 2016-05-02 JP JP2016092600A patent/JP6130553B2/ja active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62120445A (ja) * | 1985-11-20 | 1987-06-01 | Nippon Carbon Co Ltd | 繊維強化金属複合材料成形品の製造法 |

| JPH0193104A (ja) * | 1987-10-05 | 1989-04-12 | Kobe Steel Ltd | 磁気異方体の製造方法 |

| JP2005113908A (ja) * | 2003-09-05 | 2005-04-28 | General Electric Co <Ge> | 補強ファンブレード及び製造方法 |

| JP2005133717A (ja) * | 2003-10-20 | 2005-05-26 | Snecma Moteurs | ターボ機関ブレード、特にファンブレード及びその製造方法 |

| WO2009034264A2 (fr) * | 2007-07-26 | 2009-03-19 | Snecma | Piece mecanique comportant un insert en materiau composite |

| JP2010534764A (ja) * | 2007-07-26 | 2010-11-11 | スネクマ | 複合材料で製作された挿入物を含む機械部品 |

| WO2010061140A1 (fr) * | 2008-11-28 | 2010-06-03 | Snecma Propulsion Solide | Aube de turbomachine en materiau composite et procede pour sa fabrication |

| JP2012510586A (ja) * | 2008-11-28 | 2012-05-10 | スネクマ・プロピュルシオン・ソリド | 複合材料ターボ機械機関羽根及びそれを製造する為の方法 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015520033A (ja) * | 2012-04-19 | 2015-07-16 | スネクマ | 複合物でできた前縁を保護するためのインサートを備えた金属補強材を形成するための方法 |

| US10934851B2 (en) | 2015-12-21 | 2021-03-02 | Safran Aircraft Engines | Leading edge shield |

Also Published As

| Publication number | Publication date |

|---|---|

| CA2811477C (fr) | 2018-11-20 |

| BR112013006453A8 (pt) | 2018-03-13 |

| US9476309B2 (en) | 2016-10-25 |

| RU2708286C2 (ru) | 2019-12-05 |

| CN103124606B (zh) | 2016-02-10 |

| CA2811477A1 (fr) | 2012-04-05 |

| CN103124606A (zh) | 2013-05-29 |

| RU2013119666A (ru) | 2014-11-10 |

| RU2578886C2 (ru) | 2016-03-27 |

| BR112013006453A2 (pt) | 2016-07-26 |

| FR2965202A1 (fr) | 2012-03-30 |

| EP2621651B1 (fr) | 2015-01-14 |

| US20130259701A1 (en) | 2013-10-03 |

| EP2621651A1 (fr) | 2013-08-07 |

| RU2015153536A3 (ja) | 2019-07-17 |

| WO2012042160A1 (fr) | 2012-04-05 |

| JP2016180406A (ja) | 2016-10-13 |

| BR112013006453B1 (pt) | 2018-10-16 |

| JP6130553B2 (ja) | 2017-05-17 |

| FR2965202B1 (fr) | 2012-10-12 |

| RU2015153536A (ru) | 2019-01-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6130553B2 (ja) | 部品を加工する方法およびその方法によって得られた複合稠密部品 | |

| EP2295723B1 (en) | A composite airfoil made of a three dimensional woven core and a composite skin and method of manufacturing this airfoil | |

| EP3292991B1 (en) | Fiber composite material for a fan blade | |

| US9605364B2 (en) | Method for producing a fibrous metal structure by means of weaving | |

| US20160348518A1 (en) | Fiber preform for a hollow turbine engine vane | |

| RU2566696C2 (ru) | Способ изготовления массивной детали | |

| JP6818692B2 (ja) | インサートを含むプラットフォームを備えるブレード | |

| US20110176927A1 (en) | Composite fan blade | |

| JP6732743B2 (ja) | 補強材を有するプラットフォームを含む複合翼 | |

| GB2507146A (en) | Composite turbine engine blade, eg fan blade, with a structural reinforcement on its leading edge | |

| GB2503386A (en) | System for changing the pitch of the contra-rotating propellers of a turboshaft engine | |

| US20180274374A1 (en) | Blade comprising a leading edge shield and method for producing the blade | |

| GB2582398A (en) | Fibrous texture for producing a fan blade made of composite material | |

| US20200108569A1 (en) | Method for manufacturing a composite material part comprising a body extended by a reinforced attachment end | |

| CN110344887B (zh) | 混合材料风扇叶片及其制备方法 | |

| US8808847B2 (en) | Layered composite component | |

| US20130319067A1 (en) | Method for manufacturing a metal part | |

| CN115244272B (zh) | 复合材料涡轮发动机叶片的纤维织构 | |

| US11808171B2 (en) | Hybridization of the fibers of the fibrous reinforcement of a fan blade |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140903 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150811 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151111 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20151111 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20160105 |