JP2010533756A - 無鉛焼結潤滑材料及びその製造のための焼結粉末 - Google Patents

無鉛焼結潤滑材料及びその製造のための焼結粉末 Download PDFInfo

- Publication number

- JP2010533756A JP2010533756A JP2010516489A JP2010516489A JP2010533756A JP 2010533756 A JP2010533756 A JP 2010533756A JP 2010516489 A JP2010516489 A JP 2010516489A JP 2010516489 A JP2010516489 A JP 2010516489A JP 2010533756 A JP2010533756 A JP 2010533756A

- Authority

- JP

- Japan

- Prior art keywords

- lubricating material

- sintered

- boron nitride

- material according

- hexagonal boron

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M103/00—Lubricating compositions characterised by the base-material being an inorganic material

- C10M103/04—Metals; Alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C1/00—Making non-ferrous alloys

- C22C1/04—Making non-ferrous alloys by powder metallurgy

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C32/00—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ

- C22C32/0047—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with carbides, nitrides, borides or silicides as the main non-metallic constituents

- C22C32/0068—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with carbides, nitrides, borides or silicides as the main non-metallic constituents only nitrides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

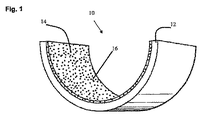

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/02—Parts of sliding-contact bearings

- F16C33/04—Brasses; Bushes; Linings

- F16C33/06—Sliding surface mainly made of metal

- F16C33/12—Structural composition; Use of special materials or surface treatments, e.g. for rust-proofing

- F16C33/121—Use of special materials

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M7/00—Solid or semi-solid compositions essentially based on lubricating components other than mineral lubricating oils or fatty oils and their use as lubricants; Use as lubricants of single solid or semi-solid substances

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2204/00—Metallic materials; Alloys

- F16C2204/10—Alloys based on copper

- F16C2204/12—Alloys based on copper with tin as the next major constituent

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Organic Chemistry (AREA)

- Metallurgy (AREA)

- General Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Sliding-Contact Bearings (AREA)

- Powder Metallurgy (AREA)

- Lubricants (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007033902A DE102007033902B3 (de) | 2007-07-20 | 2007-07-20 | Bleifreier gesinterter Gleitlagerwerkstoff und Sinterpulver zur Herstellung desselben |

| PCT/EP2008/059233 WO2009013178A2 (de) | 2007-07-20 | 2008-07-15 | Bleifreier gesinterter gleitlagerwerkstoff und sinterpulver zur herstellung desselben |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010533756A true JP2010533756A (ja) | 2010-10-28 |

| JP2010533756A5 JP2010533756A5 (enExample) | 2013-09-05 |

Family

ID=39967413

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010516489A Pending JP2010533756A (ja) | 2007-07-20 | 2008-07-15 | 無鉛焼結潤滑材料及びその製造のための焼結粉末 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8703660B2 (enExample) |

| EP (1) | EP2171109B1 (enExample) |

| JP (1) | JP2010533756A (enExample) |

| KR (1) | KR20100049605A (enExample) |

| BR (1) | BRPI0814442A2 (enExample) |

| DE (1) | DE102007033902B3 (enExample) |

| WO (1) | WO2009013178A2 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009002442B4 (de) * | 2009-04-16 | 2013-04-18 | Federal-Mogul Wiesbaden Gmbh | Gesinterter Gleitlagerwerkstoff und Gleitlagerelement |

| DE102009002894A1 (de) | 2009-05-07 | 2010-11-18 | Federal-Mogul Wiesbaden Gmbh | Gleitlagermaterial |

| DE102009052302A1 (de) * | 2009-11-09 | 2011-05-12 | Dow Corning Gmbh | Lagerelement mit festschmierstoffhaltiger Imprägnierung |

| US9187682B2 (en) | 2011-06-24 | 2015-11-17 | Emerson Climate Technologies, Inc. | Refrigeration compressor lubricant |

| JP5971995B2 (ja) * | 2012-03-19 | 2016-08-17 | 大同メタル工業株式会社 | 半割軸受及びすべり軸受 |

| US20150147012A1 (en) * | 2013-11-27 | 2015-05-28 | Emerson Climate Technologies, Inc. | Bearing performance for compressors using high energy refrigerants with sulfur-based oil additives |

| GB2538283B (en) | 2015-05-14 | 2021-06-23 | Mahle Int Gmbh | Plain bearing and method |

| DE102015223643B4 (de) * | 2015-11-30 | 2018-02-22 | Robert Bosch Gmbh | Verfahren zur Herstellung einer Pendelanordnung einer Pendellaservorrichtung sowie Pendellaservorrichtung |

| DE102017105602B3 (de) * | 2017-03-16 | 2018-05-17 | Ks Gleitlager Gmbh | Gleitlagerverbundwerkstoff mit einer metallischen Stützschicht und einer metallischen Lagermetallschicht |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62255591A (ja) * | 1986-04-30 | 1987-11-07 | Riken Corp | 摺動部材の組合せ |

| JPH0499834A (ja) * | 1990-08-14 | 1992-03-31 | Taiho Kogyo Co Ltd | 摺動材料 |

| JPH04320495A (ja) * | 1991-04-18 | 1992-11-11 | Nippon Steel Corp | 自己潤滑性複合材料及びその製造方法 |

| JPH11246884A (ja) * | 1998-02-27 | 1999-09-14 | Shin Etsu Chem Co Ltd | 熱伝導性シリコーン組成物 |

| JP2002285262A (ja) * | 2001-03-23 | 2002-10-03 | Daido Metal Co Ltd | 銅系複層摺動材料 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1035216A (en) * | 1962-03-28 | 1966-07-06 | Gert Deventer | Method of and apparatus for fabricating self-lubricating articles or components, and articles or components made by the method |

| DE3576833D1 (de) * | 1985-11-04 | 1990-05-03 | Jpi Transport Prod | Werkstoffe fuer lager. |

| JP2601333B2 (ja) * | 1988-10-05 | 1997-04-16 | 三井金属鉱業株式会社 | 複合砥石およびその製造方法 |

| JP3340908B2 (ja) * | 1996-02-29 | 2002-11-05 | 大同メタル工業株式会社 | 焼結摺動部材及びその製造方法 |

| JP2002295473A (ja) * | 2001-03-28 | 2002-10-09 | Senju Metal Ind Co Ltd | 鉛フリージャーナル軸受 |

| JP3839740B2 (ja) * | 2002-03-18 | 2006-11-01 | 大同メタル工業株式会社 | 摺動材料 |

| US6837915B2 (en) * | 2002-09-20 | 2005-01-04 | Scm Metal Products, Inc. | High density, metal-based materials having low coefficients of friction and wear rates |

| DE102004011831B3 (de) * | 2004-03-11 | 2005-03-31 | Federal-Mogul Deva Gmbh | Gesinterter Gleitlagerwerkstoff, Gleitlagerverbundwerkstoff sowie dessen Verwendungen |

-

2007

- 2007-07-20 DE DE102007033902A patent/DE102007033902B3/de not_active Expired - Fee Related

-

2008

- 2008-07-15 BR BRPI0814442-7A2A patent/BRPI0814442A2/pt not_active IP Right Cessation

- 2008-07-15 WO PCT/EP2008/059233 patent/WO2009013178A2/de not_active Ceased

- 2008-07-15 JP JP2010516489A patent/JP2010533756A/ja active Pending

- 2008-07-15 KR KR1020107003725A patent/KR20100049605A/ko not_active Ceased

- 2008-07-15 EP EP08775092.3A patent/EP2171109B1/de not_active Not-in-force

- 2008-07-15 US US12/669,363 patent/US8703660B2/en not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62255591A (ja) * | 1986-04-30 | 1987-11-07 | Riken Corp | 摺動部材の組合せ |

| JPH0499834A (ja) * | 1990-08-14 | 1992-03-31 | Taiho Kogyo Co Ltd | 摺動材料 |

| JPH04320495A (ja) * | 1991-04-18 | 1992-11-11 | Nippon Steel Corp | 自己潤滑性複合材料及びその製造方法 |

| JPH11246884A (ja) * | 1998-02-27 | 1999-09-14 | Shin Etsu Chem Co Ltd | 熱伝導性シリコーン組成物 |

| JP2002285262A (ja) * | 2001-03-23 | 2002-10-03 | Daido Metal Co Ltd | 銅系複層摺動材料 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2171109B1 (de) | 2018-10-03 |

| BRPI0814442A2 (pt) | 2015-01-06 |

| US20100190667A1 (en) | 2010-07-29 |

| KR20100049605A (ko) | 2010-05-12 |

| WO2009013178A2 (de) | 2009-01-29 |

| WO2009013178A3 (de) | 2009-03-19 |

| DE102007033902B3 (de) | 2008-12-18 |

| US8703660B2 (en) | 2014-04-22 |

| EP2171109A2 (de) | 2010-04-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2010533756A (ja) | 無鉛焼結潤滑材料及びその製造のための焼結粉末 | |

| CN101684536B (zh) | 铁系烧结轴承及其制造方法 | |

| JP4675563B2 (ja) | 軸受およびその製造方法 | |

| EP2087250B1 (en) | Bearing having improved consume resistivity and manufacturing method thereof | |

| US6305847B1 (en) | Sliding bearing | |

| CN101760662B (zh) | 无铅铜合金滑动材料 | |

| JP3839740B2 (ja) | 摺動材料 | |

| JPWO2008140100A1 (ja) | Pbフリー銅合金摺動材料、及びすべり軸受 | |

| JPH03247732A (ja) | 摺動材料 | |

| CN102439183A (zh) | 无铅铜系烧结滑动材料及滑动部件 | |

| JP2019173060A (ja) | 摺動部材 | |

| CN116710219A (zh) | 滑动构件、轴承、滑动构件的制造方法、轴承的制造方法 | |

| JP2008007796A (ja) | 耐摩擦摩耗性に優れたCu−Ni−Sn系銅基焼結合金およびその合金からなる軸受材 | |

| CN101970701A (zh) | 烧结铜合金滑动材料的制造方法以及烧结铜合金滑动材料 | |

| JP3484444B2 (ja) | 摺動部材 | |

| JP2013144849A (ja) | 耐摩擦摩耗性に優れたCu−Ni−Sn系銅基焼結合金とその製造方法およびその合金からなる軸受材 | |

| CN102227569B (zh) | 轴承材料 | |

| JP3042539B2 (ja) | 摺動材料 | |

| JP2006037180A (ja) | 耐焼付性に優れたPbフリー銅合金複合摺動材 | |

| JP2001107106A (ja) | 銅系焼結摺動材料 | |

| JP4427410B2 (ja) | 耐焼付性に優れたPbフリー銅合金摺動材 | |

| JP3370785B2 (ja) | 銅系焼結摺動材料 | |

| JP2006037179A (ja) | 耐焼付性に優れたPbフリー銅合金系複合摺動材 | |

| JP2745699B2 (ja) | 高温で耐摩耗性にすぐれた銅基焼結合金 | |

| JP7488527B2 (ja) | 摺動部品およびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110328 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20130327 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130417 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130716 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20130716 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140326 |