JP2007524003A - 回転炉または反射炉でのアルミニウムの処理方法 - Google Patents

回転炉または反射炉でのアルミニウムの処理方法 Download PDFInfo

- Publication number

- JP2007524003A JP2007524003A JP2007500266A JP2007500266A JP2007524003A JP 2007524003 A JP2007524003 A JP 2007524003A JP 2007500266 A JP2007500266 A JP 2007500266A JP 2007500266 A JP2007500266 A JP 2007500266A JP 2007524003 A JP2007524003 A JP 2007524003A

- Authority

- JP

- Japan

- Prior art keywords

- aluminum

- furnace

- volume

- stage

- fuel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 title claims abstract description 45

- 229910052782 aluminium Inorganic materials 0.000 title claims abstract description 45

- 238000000034 method Methods 0.000 title claims abstract description 36

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 claims abstract description 25

- 239000000446 fuel Substances 0.000 claims abstract description 22

- 239000000463 material Substances 0.000 claims abstract description 19

- 230000003647 oxidation Effects 0.000 claims abstract description 16

- 238000007254 oxidation reaction Methods 0.000 claims abstract description 16

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 14

- 239000001301 oxygen Substances 0.000 claims abstract description 14

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 14

- 229910002091 carbon monoxide Inorganic materials 0.000 claims abstract description 12

- 229910052739 hydrogen Inorganic materials 0.000 claims abstract description 11

- 239000001257 hydrogen Substances 0.000 claims abstract description 10

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 claims abstract description 9

- 150000003839 salts Chemical class 0.000 claims abstract description 8

- 239000010802 sludge Substances 0.000 claims abstract description 7

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims abstract description 3

- 238000010438 heat treatment Methods 0.000 claims abstract description 3

- 239000007800 oxidant agent Substances 0.000 claims description 20

- 230000001590 oxidative effect Effects 0.000 claims description 17

- 239000003546 flue gas Substances 0.000 claims description 15

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 claims description 14

- 238000002485 combustion reaction Methods 0.000 claims description 12

- 150000002894 organic compounds Chemical class 0.000 claims description 8

- 229930195733 hydrocarbon Natural products 0.000 claims description 7

- 150000002430 hydrocarbons Chemical class 0.000 claims description 7

- 239000003345 natural gas Substances 0.000 claims description 6

- 230000008569 process Effects 0.000 claims description 6

- 239000004215 Carbon black (E152) Substances 0.000 claims description 5

- 238000005259 measurement Methods 0.000 claims description 4

- 230000006641 stabilisation Effects 0.000 claims description 3

- 238000011105 stabilization Methods 0.000 claims description 3

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 claims description 2

- 239000010771 distillate fuel oil Substances 0.000 claims description 2

- 239000010763 heavy fuel oil Substances 0.000 claims description 2

- 238000000197 pyrolysis Methods 0.000 claims description 2

- 230000006378 damage Effects 0.000 claims 1

- 150000002431 hydrogen Chemical class 0.000 claims 1

- 230000001105 regulatory effect Effects 0.000 claims 1

- 238000002844 melting Methods 0.000 abstract description 17

- 230000008018 melting Effects 0.000 abstract description 17

- 239000000779 smoke Substances 0.000 abstract 2

- 229910052751 metal Inorganic materials 0.000 description 9

- 239000002184 metal Substances 0.000 description 9

- 230000008859 change Effects 0.000 description 7

- 239000012855 volatile organic compound Substances 0.000 description 7

- 238000001514 detection method Methods 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 239000007789 gas Substances 0.000 description 3

- 238000002347 injection Methods 0.000 description 3

- 239000007924 injection Substances 0.000 description 3

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 3

- 235000014214 soft drink Nutrition 0.000 description 3

- 239000002699 waste material Substances 0.000 description 3

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 2

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical class [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 2

- 230000004888 barrier function Effects 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000010309 melting process Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 230000004580 weight loss Effects 0.000 description 2

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

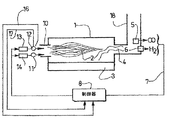

- 238000010586 diagram Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000000295 fuel oil Substances 0.000 description 1

- 238000004868 gas analysis Methods 0.000 description 1

- 229910001338 liquidmetal Inorganic materials 0.000 description 1

- 239000000155 melt Substances 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000005416 organic matter Substances 0.000 description 1

- 125000005575 polycyclic aromatic hydrocarbon group Chemical group 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- 230000003134 recirculating effect Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 235000021058 soft food Nutrition 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B3/00—Hearth-type furnaces, e.g. of reverberatory type; Electric arc furnaces ; Tank furnaces

- F27B3/10—Details, accessories or equipment, e.g. dust-collectors, specially adapted for hearth-type furnaces

- F27B3/28—Arrangement of controlling, monitoring, alarm or the like devices

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B21/00—Obtaining aluminium

- C22B21/0084—Obtaining aluminium melting and handling molten aluminium

- C22B21/0092—Remelting scrap, skimmings or any secondary source aluminium

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B21/00—Obtaining aluminium

- C22B21/06—Obtaining aluminium refining

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22B—PRODUCTION AND REFINING OF METALS; PRETREATMENT OF RAW MATERIALS

- C22B9/00—General processes of refining or remelting of metals; Apparatus for electroslag or arc remelting of metals

- C22B9/006—General processes of refining or remelting of metals; Apparatus for electroslag or arc remelting of metals with use of an inert protective material including the use of an inert gas

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D19/00—Arrangements of controlling devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D19/00—Arrangements of controlling devices

- F27D2019/0006—Monitoring the characteristics (composition, quantities, temperature, pressure) of at least one of the gases of the kiln atmosphere and using it as a controlling value

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D19/00—Arrangements of controlling devices

- F27D2019/0028—Regulation

- F27D2019/0034—Regulation through control of a heating quantity such as fuel, oxidant or intensity of current

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/20—Recycling

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

- Muffle Furnaces And Rotary Kilns (AREA)

- Tunnel Furnaces (AREA)

- Control Of Heat Treatment Processes (AREA)

- Air Bags (AREA)

- Vertical, Hearth, Or Arc Furnaces (AREA)

- Crucibles And Fluidized-Bed Furnaces (AREA)

- Furnace Details (AREA)

- Processing Of Solid Wastes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0450351A FR2866656B1 (fr) | 2004-02-25 | 2004-02-25 | Procede de traitement d'aluminium dans un four rotatif ou reverbere |

| PCT/FR2005/050074 WO2005085732A1 (fr) | 2004-02-25 | 2005-02-07 | Procede de traitement d'aluminium dans un four rotatif ou reverbere |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007524003A true JP2007524003A (ja) | 2007-08-23 |

| JP2007524003A5 JP2007524003A5 (enExample) | 2010-08-26 |

Family

ID=34834242

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007500266A Pending JP2007524003A (ja) | 2004-02-25 | 2005-02-07 | 回転炉または反射炉でのアルミニウムの処理方法 |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US7655067B2 (enExample) |

| EP (1) | EP1721111B1 (enExample) |

| JP (1) | JP2007524003A (enExample) |

| AT (1) | ATE399296T1 (enExample) |

| CA (1) | CA2557288A1 (enExample) |

| DE (1) | DE602005007710D1 (enExample) |

| ES (1) | ES2308464T3 (enExample) |

| FR (1) | FR2866656B1 (enExample) |

| PL (1) | PL1721111T3 (enExample) |

| WO (1) | WO2005085732A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009002639A (ja) * | 2007-05-02 | 2009-01-08 | Air Products & Chemicals Inc | 溶融炉への熱供給方法 |

| CN102085689A (zh) * | 2010-11-26 | 2011-06-08 | 卢文成 | 无机发泡板的生产方法 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2832732B1 (fr) * | 2001-11-29 | 2004-02-13 | Air Liquide | Utilisation de l'analyse des fumees dans les fours d'aluminium |

| FR2854408B1 (fr) * | 2003-04-30 | 2006-05-26 | Air Liquide | Procede de traitement d'aluminium dans un four |

| ATE404703T1 (de) * | 2005-11-29 | 2008-08-15 | Linde Ag | Kontrolle eines schmelzprozesses |

| US8071062B2 (en) * | 2009-03-06 | 2011-12-06 | Siemens Energy, Inc. | High temperature catalytic process to reduce emissions of carbon monoxide |

| GB2477753B (en) * | 2010-02-11 | 2012-04-18 | Rifat Al Chalabi | Metal recovery process |

| FR2959298B1 (fr) * | 2010-04-23 | 2012-09-21 | Air Liquide | Four a flamme et procede de regulation de la combustion dans un four a flamme |

| EP2664884B1 (en) | 2012-05-18 | 2019-08-07 | Air Products and Chemicals, Inc. | Method and apparatus for heating metals |

| CN105890347B (zh) * | 2016-04-29 | 2018-04-10 | 青岛智邦炉窑设计研究有限公司 | 一种回转窑式还原焙烧装置及工艺 |

| US10991087B2 (en) | 2017-01-16 | 2021-04-27 | Praxair Technology, Inc. | Flame image analysis for furnace combustion control |

| RU2751829C1 (ru) * | 2018-03-02 | 2021-07-19 | Праксайр Текнолоджи, Инк. | Анализ изображений пламени для управления процессом горения в печи |

| JP2021025882A (ja) * | 2019-08-06 | 2021-02-22 | 日本エア・リキード合同会社 | 炉を制御するための方法、およびこの方法を行うための分析装置 |

| EP3974754A1 (en) * | 2020-09-23 | 2022-03-30 | Nippon Gases Euro-Holding, S.L.U. | System for measuring temperature in a furnace and method for controlling combustion inside the same |

| FR3143391A1 (fr) | 2022-12-16 | 2024-06-21 | Constellium Neuf-Brisach | Système de fusion, et procédé de fusion de déchets d’aluminium |

| CN117249672B (zh) * | 2023-10-11 | 2025-12-19 | 江西金德铅业股份有限公司 | 一种可控制下料的反射炉单独放铅装置 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60121235A (ja) * | 1983-12-01 | 1985-06-28 | Furukawa Electric Co Ltd:The | ガス焚反射炉の非鉄金属溶解法 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3759702A (en) | 1971-04-07 | 1973-09-18 | Chemetron Corp | Method of melting aluminum |

| US5616167A (en) * | 1993-07-13 | 1997-04-01 | Eckert; C. Edward | Method for fluxing molten metal |

| US5563903A (en) * | 1995-06-13 | 1996-10-08 | Praxair Technology, Inc. | Aluminum melting with reduced dross formation |

| FR2777075B1 (fr) * | 1998-04-02 | 2000-05-19 | Air Liquide | Procede de conduite d'un four et dispositif pour la mise en oeuvre du procede |

| DE19824573A1 (de) * | 1998-06-02 | 1999-12-09 | Linde Ag | Verfahren zum Schmelzen von Metallen |

| US6245122B1 (en) * | 2000-01-20 | 2001-06-12 | J. W. Aluminum Company | Apparatus and method for reclaiming scrap metal |

| AT409269B (de) | 2000-09-08 | 2002-07-25 | Heribert Dipl Ing Dr Summer | Verfahren zum salzlosen und oxidationsfreien umschmelzen von aluminium |

| DE10114179A1 (de) * | 2001-03-23 | 2002-09-26 | Linde Ag | Vorrichtung zum Einschmelzen von Aluminiumschrott |

| FR2832732B1 (fr) * | 2001-11-29 | 2004-02-13 | Air Liquide | Utilisation de l'analyse des fumees dans les fours d'aluminium |

| FR2854408B1 (fr) * | 2003-04-30 | 2006-05-26 | Air Liquide | Procede de traitement d'aluminium dans un four |

-

2004

- 2004-02-25 FR FR0450351A patent/FR2866656B1/fr not_active Expired - Fee Related

-

2005

- 2005-02-07 AT AT05717705T patent/ATE399296T1/de not_active IP Right Cessation

- 2005-02-07 PL PL05717705T patent/PL1721111T3/pl unknown

- 2005-02-07 US US10/589,935 patent/US7655067B2/en not_active Expired - Lifetime

- 2005-02-07 JP JP2007500266A patent/JP2007524003A/ja active Pending

- 2005-02-07 CA CA 2557288 patent/CA2557288A1/fr not_active Abandoned

- 2005-02-07 ES ES05717705T patent/ES2308464T3/es not_active Expired - Lifetime

- 2005-02-07 EP EP05717705A patent/EP1721111B1/fr not_active Expired - Lifetime

- 2005-02-07 DE DE200560007710 patent/DE602005007710D1/de not_active Expired - Lifetime

- 2005-02-07 WO PCT/FR2005/050074 patent/WO2005085732A1/fr not_active Ceased

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60121235A (ja) * | 1983-12-01 | 1985-06-28 | Furukawa Electric Co Ltd:The | ガス焚反射炉の非鉄金属溶解法 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009002639A (ja) * | 2007-05-02 | 2009-01-08 | Air Products & Chemicals Inc | 溶融炉への熱供給方法 |

| CN102085689A (zh) * | 2010-11-26 | 2011-06-08 | 卢文成 | 无机发泡板的生产方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2866656B1 (fr) | 2006-05-26 |

| EP1721111A1 (fr) | 2006-11-15 |

| PL1721111T3 (pl) | 2008-11-28 |

| US7655067B2 (en) | 2010-02-02 |

| EP1721111B1 (fr) | 2008-06-25 |

| US20070171954A1 (en) | 2007-07-26 |

| FR2866656A1 (fr) | 2005-08-26 |

| ATE399296T1 (de) | 2008-07-15 |

| WO2005085732A1 (fr) | 2005-09-15 |

| DE602005007710D1 (de) | 2008-08-07 |

| ES2308464T3 (es) | 2008-12-01 |

| CA2557288A1 (fr) | 2005-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2007524003A (ja) | 回転炉または反射炉でのアルミニウムの処理方法 | |

| JP4571407B2 (ja) | アルミニウム酸化物の形成を検出する装置及びアルミニウム溶融炉 | |

| RU2507461C2 (ru) | Способ эксплуатации печи, а также устройство для осуществления этого способа | |

| US20230142380A1 (en) | Foundry coke products and associated processing methods via cupolas | |

| JP2007524003A5 (enExample) | ||

| BR112012027190B1 (pt) | Forno alimentado a combustível e método para controlar a combustão em um forno alimentado a combustível | |

| WO2009087142A1 (en) | Combined burner and lance apparatus for electric arc furnaces | |

| CA2806432C (en) | Process for melting scrap metal | |

| CA3072967A1 (en) | Furnace system and method for operating a furnace | |

| CA2198682A1 (en) | Furnace waste gas combustion control | |

| JP4554596B2 (ja) | 炉内アルミニウム処理方法 | |

| SK283426B6 (sk) | Spôsob riadeného spaľovania | |

| ES2207389B1 (es) | Mejoras en el objeto de la patente principal n.200102624, por "procedimiento para la fusion de una carga de aluminio". | |

| JP2005213591A (ja) | 高炉への固体燃料吹き込み方法及び吹き込みランス | |

| JP5406482B2 (ja) | 流動層式焼却装置の運転制御方法及び流動層式焼却装置 | |

| US20200284513A1 (en) | Method for controlling a combustion and furnace | |

| US20230194082A1 (en) | Combustion process | |

| SU1364639A1 (ru) | Способ отоплени мартеновской печи | |

| JP2011196554A (ja) | 溶融炉における排ガス脱硝方法および溶融炉における排ガス脱硝装置 | |

| WO2004083469A1 (en) | Process for melting an aluminum charge containing organic material | |

| US6245124B1 (en) | Vertical shaft furnaces | |

| JP2005249222A (ja) | 灰分溶融炉における湯口の温度制御方法 | |

| JPH10330816A (ja) | 鋳鉄の製造方法 | |

| JPH0470364B2 (enExample) | ||

| FR2585725A1 (fr) | Procede d'elaboration d'acier dans un convertisseur a lance a oxygene et acier obtenu par ledit procede |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071214 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20100707 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101026 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110120 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20110726 |