JP2006525128A - 鋳物を修理するための方法 - Google Patents

鋳物を修理するための方法 Download PDFInfo

- Publication number

- JP2006525128A JP2006525128A JP2006507243A JP2006507243A JP2006525128A JP 2006525128 A JP2006525128 A JP 2006525128A JP 2006507243 A JP2006507243 A JP 2006507243A JP 2006507243 A JP2006507243 A JP 2006507243A JP 2006525128 A JP2006525128 A JP 2006525128A

- Authority

- JP

- Japan

- Prior art keywords

- cast part

- repairing

- casting

- cast

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 28

- 238000005266 casting Methods 0.000 title claims abstract description 21

- 239000000463 material Substances 0.000 claims abstract description 49

- 229910052751 metal Inorganic materials 0.000 claims abstract description 4

- 239000002184 metal Substances 0.000 claims abstract description 4

- 239000000945 filler Substances 0.000 claims description 23

- 238000001816 cooling Methods 0.000 claims description 6

- 229910001018 Cast iron Inorganic materials 0.000 claims description 5

- 230000004907 flux Effects 0.000 claims description 4

- 238000010438 heat treatment Methods 0.000 claims description 3

- 229910052782 aluminium Inorganic materials 0.000 claims description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical group [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims 1

- 238000002485 combustion reaction Methods 0.000 abstract description 5

- 239000012768 molten material Substances 0.000 abstract description 2

- 230000008439 repair process Effects 0.000 description 10

- 239000011159 matrix material Substances 0.000 description 8

- 239000000446 fuel Substances 0.000 description 7

- 238000003466 welding Methods 0.000 description 6

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 5

- 229910002804 graphite Inorganic materials 0.000 description 5

- 239000010439 graphite Substances 0.000 description 5

- 238000003754 machining Methods 0.000 description 5

- 238000005336 cracking Methods 0.000 description 3

- 239000000356 contaminant Substances 0.000 description 2

- 239000002826 coolant Substances 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 238000000227 grinding Methods 0.000 description 2

- 238000005461 lubrication Methods 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 239000002893 slag Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 241000220317 Rosa Species 0.000 description 1

- 229910021538 borax Inorganic materials 0.000 description 1

- 238000005094 computer simulation Methods 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 239000003779 heat-resistant material Substances 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000005058 metal casting Methods 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 239000004328 sodium tetraborate Substances 0.000 description 1

- 235000010339 sodium tetraborate Nutrition 0.000 description 1

- 230000009466 transformation Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

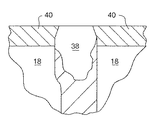

- B23P6/00—Restoring or reconditioning objects

- B23P6/02—Pistons or cylinders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K5/00—Gas flame welding

- B23K5/18—Gas flame welding for purposes other than joining parts, e.g. built-up welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/04—Welding for other purposes than joining, e.g. built-up welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P6/00—Restoring or reconditioning objects

- B23P6/04—Repairing fractures or cracked metal parts or products, e.g. castings

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49721—Repairing with disassembling

- Y10T29/49723—Repairing with disassembling including reconditioning of part

- Y10T29/49725—Repairing with disassembling including reconditioning of part by shaping

- Y10T29/49726—Removing material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49721—Repairing with disassembling

- Y10T29/49723—Repairing with disassembling including reconditioning of part

- Y10T29/49725—Repairing with disassembling including reconditioning of part by shaping

- Y10T29/49726—Removing material

- Y10T29/49728—Removing material and by a metallurgical operation, e.g., welding, diffusion bonding, casting

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49732—Repairing by attaching repair preform, e.g., remaking, restoring, or patching

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49732—Repairing by attaching repair preform, e.g., remaking, restoring, or patching

- Y10T29/49734—Repairing by attaching repair preform, e.g., remaking, restoring, or patching and removing damaged material

- Y10T29/49737—Metallurgically attaching preform

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49732—Repairing by attaching repair preform, e.g., remaking, restoring, or patching

- Y10T29/49742—Metallurgically attaching preform

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49718—Repairing

- Y10T29/49746—Repairing by applying fluent material, e.g., coating, casting

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Cylinder Crankcases Of Internal Combustion Engines (AREA)

- Heat Treatment Of Articles (AREA)

- Molds, Cores, And Manufacturing Methods Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/428,871 US7047612B2 (en) | 2003-05-02 | 2003-05-02 | Method for repairing a casting |

| PCT/US2004/008040 WO2004098827A1 (en) | 2003-05-02 | 2004-03-16 | Method for repairing a casting |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006525128A true JP2006525128A (ja) | 2006-11-09 |

| JP2006525128A5 JP2006525128A5 (enExample) | 2007-04-19 |

Family

ID=33310499

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006507243A Pending JP2006525128A (ja) | 2003-05-02 | 2004-03-16 | 鋳物を修理するための方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7047612B2 (enExample) |

| JP (1) | JP2006525128A (enExample) |

| CN (1) | CN100509263C (enExample) |

| GB (1) | GB2414695B (enExample) |

| WO (1) | WO2004098827A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015533948A (ja) * | 2012-09-28 | 2015-11-26 | ゼネラル・エレクトリック・カンパニイ | 材料を結合するための方法およびシステム |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6944925B2 (en) * | 2001-06-13 | 2005-09-20 | Ttx Company | Articulated connector reconditioning process and apparatuses |

| US7676897B2 (en) * | 2005-03-17 | 2010-03-16 | Keate Robert A | Process of refurbishing brake components |

| JP4834402B2 (ja) * | 2005-12-28 | 2011-12-14 | 株式会社東芝 | 回転電機ロータのき裂補修方法、回転電機ロータのき裂進展防止方法、回転電機ロータおよび回転電機 |

| US8011097B2 (en) * | 2006-12-04 | 2011-09-06 | General Electric Company | Method, system, and computer software code for repairing a transition section of an engine |

| US8485243B2 (en) | 2007-03-30 | 2013-07-16 | Caterpillar Inc. | Method for casting a component |

| US20080241579A1 (en) * | 2007-03-30 | 2008-10-02 | Caterpillar Inc. | Method for casting a component |

| CN100443232C (zh) * | 2007-09-26 | 2008-12-17 | 李小鸽 | 一种江海挖泥船用泥浆泵壳的修复方法 |

| FI123783B (fi) * | 2008-06-12 | 2013-10-31 | Waertsilae Finland Oy | Menetelmä polttomoottorin sylinterikannen kunnostamiseksi |

| US8191529B2 (en) * | 2008-07-03 | 2012-06-05 | Caterpillar Inc. | Method of manufacturing an engine block |

| DE102008050388B3 (de) * | 2008-10-02 | 2009-10-22 | Märkisches Werk GmbH | Verfahren zur Reparatur von Schäden eines wassergekühlten Zylinderkopfes bei 4-Takt-Verbrennungsmotoren, sowie Zylinderkopf |

| AT506468B1 (de) * | 2009-03-24 | 2010-12-15 | Avl List Gmbh | Zylinderkopf einer brennkraftmaschine |

| WO2013086721A1 (en) | 2011-12-15 | 2013-06-20 | Vestas Wind Systems A/S | A method of repairing defects in cast iron workpieces, and a method of connecting cast iron workpieces |

| CN102527999A (zh) * | 2011-12-16 | 2012-07-04 | 保定天威集团有限公司 | 灰铸铁件边缘焊接铸造修补工艺 |

| US20130277416A1 (en) * | 2012-04-23 | 2013-10-24 | Arthur Lindemanis | Remote melt joining methods and remote melt joining systems |

| US20130277348A1 (en) * | 2012-04-23 | 2013-10-24 | General Electric Company | Methods and apparatuses for preheated interval welding |

| CN103084563B (zh) * | 2013-02-27 | 2016-01-20 | 南京信息工程大学 | 一种修补普通碳钢机械零件表面损伤的方法 |

| US20140312096A1 (en) | 2013-04-18 | 2014-10-23 | Caterpillar Inc. | Oxy-fuel weld repair of metallic components |

| US9370845B2 (en) | 2013-07-19 | 2016-06-21 | Cummins Inc. | Method of repairing a cracked head using an injector bore insert |

| CN103386582A (zh) * | 2013-07-31 | 2013-11-13 | 海门市柯成汽车零部件制造有限公司 | 一种金属铸件缺陷修补的工艺 |

| US20150159585A1 (en) | 2013-12-06 | 2015-06-11 | Caterpillar Inc. | System and method for repair of cast component |

| CN103934624B (zh) * | 2014-04-29 | 2017-02-01 | 南通迪施有限公司 | 钻孔冷却式缸盖割盆翻新工艺 |

| CN104907552A (zh) * | 2015-06-02 | 2015-09-16 | 遵义金业机械铸造有限公司 | 一种铸件缝隙修补设备 |

| CN106239031A (zh) * | 2016-08-29 | 2016-12-21 | 中航动力股份有限公司 | 一种预防气膜冷却孔焊接堵塞的方法 |

| US20240279815A1 (en) * | 2023-02-20 | 2024-08-22 | Spirit Aerosystems, Inc. | Method to produce void-free ferrous & non-ferrous aerospace structural castings |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58151987A (ja) * | 1982-03-02 | 1983-09-09 | Toshiba Corp | アルテンサイト系ステンレス鋳鋼で構成された部材の鋳造欠陥部の補修方法 |

| JPS5942177A (ja) * | 1982-09-03 | 1984-03-08 | Kubota Ltd | 球状黒鉛鋼ロ−ルの補修方法 |

| US4918805A (en) * | 1988-12-22 | 1990-04-24 | General Motors Corporation | Welding method for cylinder head repair |

| US6109505A (en) * | 1998-06-23 | 2000-08-29 | Snecma Services | Method of diffusion brazing superalloy parts |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1777531A (en) | 1927-08-26 | 1930-10-07 | Peterson Roy | Welding process |

| US1777532A (en) * | 1927-11-14 | 1930-10-07 | Signode Steel Strapping Co | Tag fastener |

| US2120525A (en) | 1937-06-01 | 1938-06-14 | Thomas J Mckerihan | Method of building up pitted holes in a metal sheet |

| US2632944A (en) | 1950-09-18 | 1953-03-31 | Engineering Dev Corp | Process for controlling warpage in iron castings during welding |

| US2751671A (en) | 1952-09-15 | 1956-06-26 | Novi Equipment Co | Method of repairing cracked castings |

| US3192618A (en) | 1964-02-18 | 1965-07-06 | George A Altgelt | Method of repairing aircraft cylinder heads |

| US3392435A (en) | 1965-04-14 | 1968-07-16 | Dwain K. Swick | Process for welding cast iron structures |

| US3246392A (en) * | 1965-07-01 | 1966-04-19 | George A Altgelt | Method of repairing aircraft cylinder heads |

| US3445914A (en) | 1966-04-18 | 1969-05-27 | Chrome Plate Inc | Method of repairing aircraft cylinder heads |

| US3449816A (en) | 1967-04-24 | 1969-06-17 | Dwain K Swick | Method of repairing screw-in precombustion chamber type openings in cylinder heads |

| US4068111A (en) | 1975-08-20 | 1978-01-10 | De Rotterdamsche Droogdok Maatschappij B.V. | Process of working imperfections or defects on generally thickwalled metal worked-pieces |

| US4919805A (en) * | 1986-11-26 | 1990-04-24 | Johnson Willard L | Vertical leaf filter flush |

| US4967458A (en) * | 1987-12-31 | 1990-11-06 | Automotive Aftermarket Development Corporation | Process for renewing cylinder heads |

| US4878953A (en) | 1988-01-13 | 1989-11-07 | Metallurgical Industries, Inc. | Method of refurbishing cast gas turbine engine components and refurbished component |

| DE4039807C1 (enExample) * | 1990-12-13 | 1991-10-02 | Mtu Muenchen Gmbh | |

| US5284442A (en) * | 1992-05-20 | 1994-02-08 | Peterson Ken N | Tooth caps and artificial teeth and the method of forming same |

| JP3330987B2 (ja) | 1992-11-10 | 2002-10-07 | 誠 西村 | 金属のろう付け方法およびその装置 |

| US5802716A (en) | 1994-09-30 | 1998-09-08 | Toyota Jidosha Kabushiki Kaisha | Method for bonding a valve seat with a cylinder head |

| FR2727889A1 (fr) * | 1994-12-09 | 1996-06-14 | Ferry Capitain Sarl | Procede de soudage par fusion de pieces de fonte a graphite spheroidal |

| US5897801A (en) | 1997-01-22 | 1999-04-27 | General Electric Company | Welding of nickel-base superalloys having a nil-ductility range |

| CN1060707C (zh) | 1997-06-27 | 2001-01-17 | 重庆大学 | 铸铁件表面缺陷的修补工艺 |

| SE513287C2 (sv) | 1998-11-06 | 2000-08-21 | Volvo Lastvagnar Ab | Metod och anordning för kokillgjutning |

| US6491207B1 (en) * | 1999-12-10 | 2002-12-10 | General Electric Company | Weld repair of directionally solidified articles |

-

2003

- 2003-05-02 US US10/428,871 patent/US7047612B2/en not_active Expired - Fee Related

-

2004

- 2004-03-16 GB GB0519689A patent/GB2414695B/en not_active Expired - Fee Related

- 2004-03-16 CN CN200480011744.8A patent/CN100509263C/zh not_active Expired - Lifetime

- 2004-03-16 WO PCT/US2004/008040 patent/WO2004098827A1/en not_active Ceased

- 2004-03-16 JP JP2006507243A patent/JP2006525128A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58151987A (ja) * | 1982-03-02 | 1983-09-09 | Toshiba Corp | アルテンサイト系ステンレス鋳鋼で構成された部材の鋳造欠陥部の補修方法 |

| JPS5942177A (ja) * | 1982-09-03 | 1984-03-08 | Kubota Ltd | 球状黒鉛鋼ロ−ルの補修方法 |

| US4918805A (en) * | 1988-12-22 | 1990-04-24 | General Motors Corporation | Welding method for cylinder head repair |

| US6109505A (en) * | 1998-06-23 | 2000-08-29 | Snecma Services | Method of diffusion brazing superalloy parts |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015533948A (ja) * | 2012-09-28 | 2015-11-26 | ゼネラル・エレクトリック・カンパニイ | 材料を結合するための方法およびシステム |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2004098827A1 (en) | 2004-11-18 |

| GB2414695B (en) | 2006-10-18 |

| GB0519689D0 (en) | 2005-11-02 |

| CN100509263C (zh) | 2009-07-08 |

| US7047612B2 (en) | 2006-05-23 |

| GB2414695A (en) | 2005-12-07 |

| US20040216295A1 (en) | 2004-11-04 |

| CN1819892A (zh) | 2006-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006525128A (ja) | 鋳物を修理するための方法 | |

| EP2300196B1 (en) | Method of reconditioning a cast iron cylinder head of an internal combustion engine | |

| US6199746B1 (en) | Method for preparing superalloy castings using a metallurgically bonded tapered plug | |

| KR100818862B1 (ko) | 용접 수리 방법 | |

| JP3752830B2 (ja) | 接合金属部材及び該部材の接合方法 | |

| CA2843194C (en) | Resistance weld repairing of casing flange holes | |

| US20150159585A1 (en) | System and method for repair of cast component | |

| JP2006525128A5 (enExample) | ||

| US8485243B2 (en) | Method for casting a component | |

| US6991150B2 (en) | Method of build up welding to thin-walled portion | |

| US6311652B2 (en) | Method of repairing a cylinder head having cooling water passages | |

| US20140312096A1 (en) | Oxy-fuel weld repair of metallic components | |

| US20080241579A1 (en) | Method for casting a component | |

| JP3752834B2 (ja) | 金属部材の接合方法 | |

| JP3824336B2 (ja) | 射出成形用ノズルの製造方法 | |

| JP2004034133A (ja) | 金型の製造方法 | |

| JP3752833B2 (ja) | 金属部材の接合方法 | |

| JP4292100B2 (ja) | バルブシート付シリンダヘッドの製造方法 | |

| JP3752831B2 (ja) | 金属部材の接合方法 | |

| JP2010007480A (ja) | シリンダヘッド鋳造粗材とシリンダヘッドの製造方法と金型 | |

| JPS62107049A (ja) | エンジンのシリンダヘツドの熱処理方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070227 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070227 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091113 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100406 |