JP2005514229A - テクスチャーを有するポリマーフィルムに間接的に印刷するための連続法 - Google Patents

テクスチャーを有するポリマーフィルムに間接的に印刷するための連続法 Download PDFInfo

- Publication number

- JP2005514229A JP2005514229A JP2003557786A JP2003557786A JP2005514229A JP 2005514229 A JP2005514229 A JP 2005514229A JP 2003557786 A JP2003557786 A JP 2003557786A JP 2003557786 A JP2003557786 A JP 2003557786A JP 2005514229 A JP2005514229 A JP 2005514229A

- Authority

- JP

- Japan

- Prior art keywords

- ink

- texture

- thermoplastic

- protrusions

- molded part

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000007639 printing Methods 0.000 title claims abstract description 12

- 238000010924 continuous production Methods 0.000 title description 4

- 229920006254 polymer film Polymers 0.000 title description 2

- 229920001169 thermoplastic Polymers 0.000 claims abstract description 79

- 239000004416 thermosoftening plastic Substances 0.000 claims abstract description 78

- 238000000465 moulding Methods 0.000 claims abstract description 57

- 238000000034 method Methods 0.000 claims abstract description 42

- 239000000463 material Substances 0.000 claims abstract description 13

- 238000001035 drying Methods 0.000 claims abstract description 6

- 238000010791 quenching Methods 0.000 claims abstract description 4

- 230000000171 quenching effect Effects 0.000 claims abstract description 4

- 238000001125 extrusion Methods 0.000 claims description 6

- 229920005989 resin Polymers 0.000 claims description 5

- 239000011347 resin Substances 0.000 claims description 5

- 239000012778 molding material Substances 0.000 claims 1

- 229920005992 thermoplastic resin Polymers 0.000 abstract description 2

- 238000002844 melting Methods 0.000 abstract 1

- 230000008018 melting Effects 0.000 abstract 1

- 239000000976 ink Substances 0.000 description 100

- 230000000052 comparative effect Effects 0.000 description 23

- 238000012360 testing method Methods 0.000 description 21

- 229920000642 polymer Polymers 0.000 description 20

- 239000000155 melt Substances 0.000 description 6

- 238000001723 curing Methods 0.000 description 5

- -1 Polypropylene Polymers 0.000 description 4

- 238000005299 abrasion Methods 0.000 description 4

- 229920001577 copolymer Polymers 0.000 description 4

- 239000004743 Polypropylene Substances 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 229920001155 polypropylene Polymers 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- VTYYLEPIZMXCLO-UHFFFAOYSA-L Calcium carbonate Chemical compound [Ca+2].[O-]C([O-])=O VTYYLEPIZMXCLO-UHFFFAOYSA-L 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 239000002861 polymer material Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000010998 test method Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 2

- 230000004580 weight loss Effects 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- IMROMDMJAWUWLK-UHFFFAOYSA-N Ethenol Chemical compound OC=C IMROMDMJAWUWLK-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- 229920002633 Kraton (polymer) Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 1

- 239000004809 Teflon Substances 0.000 description 1

- 229920006362 Teflon® Polymers 0.000 description 1

- 238000003848 UV Light-Curing Methods 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- 239000006096 absorbing agent Substances 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 150000004645 aluminates Chemical class 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 229910000019 calcium carbonate Inorganic materials 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 238000011161 development Methods 0.000 description 1

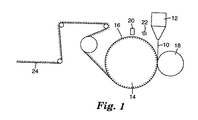

- 238000010586 diagram Methods 0.000 description 1

- 229920006242 ethylene acrylic acid copolymer Polymers 0.000 description 1

- 239000010433 feldspar Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- HCDGVLDPFQMKDK-UHFFFAOYSA-N hexafluoropropylene Chemical group FC(F)=C(F)C(F)(F)F HCDGVLDPFQMKDK-UHFFFAOYSA-N 0.000 description 1

- 238000007641 inkjet printing Methods 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000000178 monomer Substances 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- HLWRUJAIJJEZDL-UHFFFAOYSA-M sodium;2-[2-[bis(carboxymethyl)amino]ethyl-(carboxymethyl)amino]acetate Chemical group [Na+].OC(=O)CN(CC(O)=O)CCN(CC(O)=O)CC([O-])=O HLWRUJAIJJEZDL-UHFFFAOYSA-M 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000000454 talc Substances 0.000 description 1

- 229910052623 talc Inorganic materials 0.000 description 1

- 229920001897 terpolymer Polymers 0.000 description 1

- BFKJFAAPBSQJPD-UHFFFAOYSA-N tetrafluoroethene Chemical compound FC(F)=C(F)F BFKJFAAPBSQJPD-UHFFFAOYSA-N 0.000 description 1

- 239000012815 thermoplastic material Substances 0.000 description 1

- 239000004408 titanium dioxide Substances 0.000 description 1

- 150000003673 urethanes Chemical class 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/0041—Digital printing on surfaces other than ordinary paper

- B41M5/0064—Digital printing on surfaces other than ordinary paper on plastics, horn, rubber, or other organic polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/22—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/22—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length

- B29C43/222—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of indefinite length characterised by the shape of the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/07—Flat, e.g. panels

- B29C48/08—Flat, e.g. panels flexible, e.g. films

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C59/00—Surface shaping of articles, e.g. embossing; Apparatus therefor

- B29C59/02—Surface shaping of articles, e.g. embossing; Apparatus therefor by mechanical means, e.g. pressing

- B29C59/022—Surface shaping of articles, e.g. embossing; Apparatus therefor by mechanical means, e.g. pressing characterised by the disposition or the configuration, e.g. dimensions, of the embossments or the shaping tools therefor

- B29C59/025—Fibrous surfaces with piles or similar fibres substantially perpendicular to the surface

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C59/00—Surface shaping of articles, e.g. embossing; Apparatus therefor

- B29C59/02—Surface shaping of articles, e.g. embossing; Apparatus therefor by mechanical means, e.g. pressing

- B29C59/04—Surface shaping of articles, e.g. embossing; Apparatus therefor by mechanical means, e.g. pressing using rollers or endless belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2795/00—Printing on articles made from plastics or substances in a plastic state

- B29C2795/005—Printing on articles made from plastics or substances in a plastic state during shaping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C37/0025—Applying surface layers, e.g. coatings, decorative layers, printed layers, to articles during shaping, e.g. in-mould printing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M7/00—After-treatment of prints, e.g. heating, irradiating, setting of the ink, protection of the printed stock

- B41M7/0081—After-treatment of prints, e.g. heating, irradiating, setting of the ink, protection of the printed stock using electromagnetic radiation or waves, e.g. ultraviolet radiation, electron beams

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

- Y10T428/24612—Composite web or sheet

- Y10T428/2462—Composite web or sheet with partial filling of valleys on outer surface

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Ink Jet Recording Methods And Recording Media Thereof (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

- Printing Methods (AREA)

- Treatments Of Macromolecular Shaped Articles (AREA)

- Ink Jet (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/028,617 US6676869B2 (en) | 2001-12-21 | 2001-12-21 | Continuous process for indirect printing of polymeric films having texture |

| PCT/US2002/035345 WO2003057445A1 (en) | 2001-12-21 | 2002-11-04 | Continuous process for indirect printing of polymeric films having texture |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005514229A true JP2005514229A (ja) | 2005-05-19 |

| JP2005514229A5 JP2005514229A5 (enExample) | 2006-01-05 |

Family

ID=21844448

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003557786A Pending JP2005514229A (ja) | 2001-12-21 | 2002-11-04 | テクスチャーを有するポリマーフィルムに間接的に印刷するための連続法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US6676869B2 (enExample) |

| EP (1) | EP1455996B1 (enExample) |

| JP (1) | JP2005514229A (enExample) |

| KR (1) | KR100903232B1 (enExample) |

| AT (1) | ATE370827T1 (enExample) |

| AU (1) | AU2002350122A1 (enExample) |

| DE (1) | DE60222018T2 (enExample) |

| WO (1) | WO2003057445A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB0417634D0 (en) * | 2004-08-09 | 2004-09-08 | Structural Polymer Systems Ltd | Mould |

| FR2879948B1 (fr) | 2004-12-23 | 2007-03-23 | Inst Francais Du Petrole | Dispositif et procede de realisation de surfaces structurees dans des conduites en vue de reduire la trainee aerodynamique |

| US20090035507A1 (en) * | 2007-08-01 | 2009-02-05 | Velcro Industries B.V. | Touch Fasteners With Images |

| DE102009003683B4 (de) * | 2009-03-26 | 2011-03-24 | Hydro Aluminium Deutschland Gmbh | Verfahren zur Herstellung eines beschichteten Aluminiumbandes, Aluminiumband und dessen Verwendung |

| FR2950561B1 (fr) * | 2009-09-30 | 2011-10-28 | Ds Smith Kaysersberg | Plaque en materiau thermoplastique avec proprietes optiques ameliorees procede de fabrication d'une telle plaque et son utilisation |

| ITBO20110484A1 (it) * | 2011-08-03 | 2013-02-04 | Magis S P A | Materiale multistrato e procedimento per la realizzazione di un materiale multistrato |

| EP4119529B1 (en) * | 2012-08-20 | 2025-06-11 | CoteX Technologies Inc. | Manufacturing polymer coated controlled release fertilizers |

| EP2724864B1 (de) * | 2012-10-24 | 2018-12-26 | Heidelberger Druckmaschinen AG | Verfahren und Vorrichtung zur Erzeugung und Übertragung diffraktiver Mikrostrukturen auf einen Bedruckstoff |

| ES2551661B1 (es) * | 2014-05-20 | 2016-09-14 | Bsh Electrodomésticos España, S.A. | Método para producir un componente de aparato doméstico con un recubrimiento de color de tinta, y componente de aparato doméstico |

| US11591276B2 (en) | 2018-09-09 | 2023-02-28 | Cotex Technologies Inc. | System and method for manufacturing polymer coated controlled release fertilizers |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3236712A (en) * | 1962-03-28 | 1966-02-22 | American Biltrite Rubber Co | Process of producing molded and printed surface pattern in plastic stock |

| US4775310A (en) | 1984-04-16 | 1988-10-04 | Velcro Industries B.V. | Apparatus for making a separable fastener |

| US4959265A (en) | 1989-04-17 | 1990-09-25 | Minnesota Mining And Manufacturing Company | Pressure-sensitive adhesive tape fastener for releasably attaching an object to a fabric |

| US5845375A (en) | 1990-09-21 | 1998-12-08 | Minnesota Mining And Manufacturing Company | Mushroom-type hook strip for a mechanical fastener |

| US5077870A (en) | 1990-09-21 | 1992-01-07 | Minnesota Mining And Manufacturing Company | Mushroom-type hook strip for a mechanical fastener |

| JP2778331B2 (ja) * | 1992-01-29 | 1998-07-23 | 富士ゼロックス株式会社 | インクジェット記録装置 |

| US5271765A (en) | 1992-02-03 | 1993-12-21 | E. I. Du Pont De Nemours And Company | Aqueous cationic dye-based ink jet inks |

| US5707472A (en) * | 1992-10-06 | 1998-01-13 | Decora Incorporated | Composite for in-mold transfer printing and process for in-mold printing of molded plastic or rubber articles therewith |

| WO1994029070A1 (en) | 1993-06-11 | 1994-12-22 | Minnesota Mining And Manufacturing Company | Laser machined replication tooling |

| JPH08216250A (ja) | 1995-02-16 | 1996-08-27 | Kasamatsu Kako Kenkyusho:Kk | 玉虫色のプラスチックシートを製造する方法および装置 |

| US5558740A (en) * | 1995-05-19 | 1996-09-24 | Reflexite Corporation | Method and apparatus for producing seamless retroreflective sheeting |

| US6130777A (en) * | 1996-05-16 | 2000-10-10 | Dai Nippon Printing Co., Ltd. | Lenticular lens sheet with both a base sheet having lenticular elements and a surface diffusing part having elements of elementary shape smaller than lenticular elements |

| JP3312850B2 (ja) * | 1996-08-19 | 2002-08-12 | 有限会社トーワ | 合成樹脂多色着色レース模様地の製造方法 |

| ATE215439T1 (de) * | 1996-10-14 | 2002-04-15 | Idemitsu Petrochemical Co | Verfahren zur herstellung einer dekorfolie und vorrichtung zu seiner herstellung |

| DE19646318A1 (de) | 1996-11-09 | 1998-05-14 | Binder Gottlieb Gmbh & Co | Rationelles Verfahren zur Herstellung eines Haftverschlußteils aus thermoplatischem Kunststoff |

| JPH10146940A (ja) | 1996-11-15 | 1998-06-02 | Aica Kogyo Co Ltd | 化粧シートの製造方法 |

| US6120636A (en) * | 1998-01-26 | 2000-09-19 | Reflexite Corporation | Apparatus and method for producing retroreflective material having printed patterns thereon |

| US6372323B1 (en) | 1998-10-05 | 2002-04-16 | 3M Innovative Properties Company | Slip control article for wet and dry applications |

| US6190594B1 (en) | 1999-03-01 | 2001-02-20 | 3M Innovative Properties Company | Tooling for articles with structured surfaces |

| WO2000073082A1 (en) | 1999-06-01 | 2000-12-07 | 3M Innovative Properties Company | Random microembossed receptor media |

| DE60004228T2 (de) | 1999-06-01 | 2004-04-22 | 3M Innovative Properties Co., St. Paul | Optisch transparente mikrogeprägte empfangsmedien |

| US6472028B1 (en) * | 1999-08-12 | 2002-10-29 | Joseph Frazzitta | Method of producing a high gloss coating on a printed surface |

| ATE304453T1 (de) | 2000-02-08 | 2005-09-15 | 3M Innovative Properties Co | Verbesserte verfahren für kalten bildtransfer |

-

2001

- 2001-12-21 US US10/028,617 patent/US6676869B2/en not_active Expired - Fee Related

-

2002

- 2002-11-04 KR KR1020047009602A patent/KR100903232B1/ko not_active Expired - Fee Related

- 2002-11-04 DE DE60222018T patent/DE60222018T2/de not_active Expired - Lifetime

- 2002-11-04 AU AU2002350122A patent/AU2002350122A1/en not_active Abandoned

- 2002-11-04 JP JP2003557786A patent/JP2005514229A/ja active Pending

- 2002-11-04 WO PCT/US2002/035345 patent/WO2003057445A1/en not_active Ceased

- 2002-11-04 EP EP02786650A patent/EP1455996B1/en not_active Expired - Lifetime

- 2002-11-04 AT AT02786650T patent/ATE370827T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| US20030118783A1 (en) | 2003-06-26 |

| DE60222018D1 (de) | 2007-10-04 |

| US6676869B2 (en) | 2004-01-13 |

| KR20040068288A (ko) | 2004-07-30 |

| KR100903232B1 (ko) | 2009-06-17 |

| EP1455996B1 (en) | 2007-08-22 |

| WO2003057445A1 (en) | 2003-07-17 |

| AU2002350122A1 (en) | 2003-07-24 |

| DE60222018T2 (de) | 2008-05-15 |

| EP1455996A1 (en) | 2004-09-15 |

| ATE370827T1 (de) | 2007-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1173835C (zh) | 具有压纹表面的喷墨打印接受片 | |

| CN100341714C (zh) | 墨水受体介质 | |

| US6649249B1 (en) | Random microembossed receptor media | |

| CN1170693C (zh) | 喷墨接受介质及其制法、成象喷墨接受介质、图象的制法 | |

| JP2005514229A (ja) | テクスチャーを有するポリマーフィルムに間接的に印刷するための連続法 | |

| JPH02502175A (ja) | 高温溶解インクの噴射印字におけるインク滴の拡散の制御 | |

| JP6151702B2 (ja) | 印刷可能なフィルム | |

| WO1997020697A1 (en) | Ink jet printable microporous film | |

| EP2496650B1 (en) | Inkjet recording material | |

| CN108463351B (zh) | 转印图像 | |

| EP3154791B1 (en) | Printable recording media | |

| JP3900558B2 (ja) | 感熱転写記録用受像シート | |

| JP4133189B2 (ja) | 保護層転写媒体 | |

| JP3925979B2 (ja) | ホットメルト型インクジェット記録用紙 | |

| JPS62261480A (ja) | 感熱転写媒体 | |

| JPH08142499A (ja) | インクジェット記録用白色ポリエステルフィルム及びインクジェット記録白色ポリエステルフィルム | |

| JPS61143175A (ja) | 被記録材 | |

| KR20050016610A (ko) | 이축-배향된 잉크 수용 매체 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051102 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20051102 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080715 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20081216 |