JP2004183194A - Carbon fiber bundle, acrylonitrile-based precursor fiber to the carbon fiber and method for producing the same - Google Patents

Carbon fiber bundle, acrylonitrile-based precursor fiber to the carbon fiber and method for producing the same Download PDFInfo

- Publication number

- JP2004183194A JP2004183194A JP2003315501A JP2003315501A JP2004183194A JP 2004183194 A JP2004183194 A JP 2004183194A JP 2003315501 A JP2003315501 A JP 2003315501A JP 2003315501 A JP2003315501 A JP 2003315501A JP 2004183194 A JP2004183194 A JP 2004183194A

- Authority

- JP

- Japan

- Prior art keywords

- fiber

- carbon fiber

- acrylonitrile

- yarn

- wet heat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Artificial Filaments (AREA)

- Inorganic Fibers (AREA)

Abstract

Description

本発明は、各種の複合材料において補強繊維材料として利用される炭素繊維束、特に強度発現性に優れる炭素繊維束、その炭素繊維用アクリロニトリル系前駆体繊維及びその製造方法に関する。 The present invention relates to a carbon fiber bundle used as a reinforcing fiber material in various composite materials, particularly a carbon fiber bundle excellent in strength development, an acrylonitrile precursor fiber for the carbon fiber, and a method for producing the same.

従来、アクリル系繊維を前駆体とする炭素繊維はその優れた力学的性質により、航空宇宙用途を始め、スポーツ、レジャー用途の高性能複合材の補強繊維素材として広い範囲で利用されている。さらに、産業用途への広がりが進む中で、炭素繊維のさらなる高性能化が求められている。 BACKGROUND ART Conventionally, carbon fibers using acrylic fibers as precursors have been widely used as reinforcing fiber materials for high-performance composite materials for aerospace applications, sports and leisure applications due to their excellent mechanical properties. Further, as the use of carbon fiber has spread to industrial applications, further improvement in the performance of carbon fiber is required.

こうした要求に対し、特許文献1、特許文献2、特許文献3では炭素繊維の表面平滑性を制御することで炭素繊維複合材の性能を向上させる方法が提案されている。

In response to such demands,

しかし、炭素繊維は直径十数μm以下と非常に細いので、繊維表面の曲率が非常に大きい割に表面の凹凸は非常に微細であること、繊維断面が円形でない場合は繊維表面の曲率が複数あること、そして、微細な区間で測られた平滑性は必ずしも繊維全体で一様でないことから、測定値の平均値で表される表面平滑性に十分な信頼性がない場合があり、そのため、測定された表面平滑性と炭素繊維及び複合材料の性能との関係が必ずしも一致しない場合があった。 However, since carbon fibers are very thin with a diameter of less than 10 μm, the surface irregularities are very fine in spite of the extremely large curvature of the fiber surface.If the fiber cross section is not circular, the fiber surface has multiple curvatures. There is, and because the smoothness measured in the fine section is not necessarily uniform throughout the fiber, the surface smoothness represented by the average of the measured values may not be sufficiently reliable, In some cases, the relationship between the measured surface smoothness and the performance of the carbon fiber and the composite material did not always match.

さらに、特許文献3では、高強度炭素繊維を得る方法として、湿式紡糸法により得られる前駆体繊維の湿熱延伸倍率を最も好ましい範囲として2倍以下にする技術が提案されている。

Further,

しかし、ポリマー組成、紡糸原液溶媒、紡浴条件等の条件が異なった場合、適応できないことがあり、生産されている種々の品種に応用できないこともあった。また、この方法では乾燥緻密化前の延伸倍率が低いために、生産性を変更しないとした場合、乾燥緻密化後の延伸倍率を通常に比べ非常に大きくする必要がある。こうした場合、糸条全体の切断、あるいは全切断までは行かないものの部分的な糸の切断が発生し、毛羽が発生し品位の低下、紡糸及び焼成工程での工程通過性の低下を招くことがあり、実生産のためには優れた方法とはいえない。 However, when the conditions such as the polymer composition, the spinning solution solvent, and the spin bath conditions are different, it may not be possible to adapt to the various varieties being produced. Further, in this method, since the draw ratio before dry densification is low, if the productivity is not changed, the draw ratio after dry densification needs to be much larger than usual. In such a case, cutting of the entire yarn or cutting of the whole yarn may not be performed, but partial cutting of the yarn may occur, resulting in fluff and deterioration of quality, and deterioration in processability in the spinning and firing processes. Yes, it is not an excellent method for actual production.

特許文献4では、ねじり弾性率を向上させる方法として、単繊維表層部に異種元素を含有させ、単繊維中心部よりも結晶性の低い領域を作り出す技術が提案されている。

しかし、ねじり強度の向上については言及されておらず、異種元素を混入させることで、逆にねじり強度の低下をもたらす可能性があった。

本発明の課題は、用途に応じた種々の複合材において優れた特性を実現し得る炭素繊維束、その前駆体繊維、及びその製造方法を提供することである。 It is an object of the present invention to provide a carbon fiber bundle, a precursor fiber thereof, and a method for producing the same, which can realize excellent characteristics in various composite materials according to applications.

本発明者らは、上記課題を解決するため鋭意研究の結果、本発明に至った。 Means for Solving the Problems The present inventors have conducted intensive studies to solve the above-mentioned problems, and as a result, have reached the present invention.

本発明により、単繊維ねじり弾性率(GPa)に対する単繊維ねじり強度(GPa)の比が0.1以上である炭素繊維の単繊維を70質量%以上含むことを特徴とする炭素繊維束が提供される。 According to the present invention, there is provided a carbon fiber bundle comprising at least 70% by mass of a single fiber of a carbon fiber having a ratio of a single fiber torsional strength (GPa) to a single fiber torsional elasticity (GPa) of 0.1 or more. Is done.

この炭素繊維束が、単繊維ねじり弾性率(GPa)に対する単繊維ねじり強度(GPa)の比が0.09以上である炭素繊維の単繊維を90質量%以上含むことが好ましい。 The carbon fiber bundle preferably contains 90% by mass or more of carbon fiber single fibers having a ratio of single fiber torsional strength (GPa) to single fiber torsional elasticity (GPa) of 0.09 or more.

本発明により、トータル延伸倍率とポリアクリロニトリルの(100)反射から得られる結晶領域サイズが次式を満たすことを特徴とする炭素繊維用アクリロニトリル系前駆体繊維が提供される。 According to the present invention, there is provided an acrylonitrile-based precursor fiber for carbon fiber, wherein the total draw ratio and the crystal domain size obtained from the (100) reflection of polyacrylonitrile satisfy the following formula.

本発明により溶剤と該溶剤に溶解したアクリロニトリル系重合体とを含む紡糸原液を紡糸して凝固糸を得る紡糸工程、該凝固糸を湿熱延伸する湿熱延伸工程、該延伸した糸を油剤処理する油剤処理工程、該油剤処理した糸を乾燥緻密化する乾燥緻密化工程を有する炭素繊維用アクリロニトリル系前駆体繊維の製造方法において、

湿熱延伸倍率の値を、湿熱延伸糸膨潤度が最大値あるいは飽和に達する延伸倍率以下にすることを特徴とする炭素繊維用アクリロニトリル系前駆体繊維の製造方法が提供される。

A spinning step of spinning an undiluted spinning solution containing a solvent and an acrylonitrile-based polymer dissolved in the solvent according to the present invention to obtain a coagulated yarn, a wet heat drawing step of wet-heat drawing the coagulated yarn, and an oil agent for treating the drawn yarn with an oil solution In the method for producing an acrylonitrile-based precursor fiber for carbon fiber, comprising a treatment step, a dry-densification step of drying and densifying the oil-treated yarn,

A method for producing an acrylonitrile-based precursor fiber for carbon fiber, characterized in that the value of the wet heat draw ratio is not more than the draw ratio at which the swelling degree of the wet heat drawn yarn reaches the maximum value or reaches saturation.

本発明により、溶剤と該溶剤に溶解したアクリロニトリル系重合体とを含む紡糸原液を紡糸して凝固糸を得る紡糸工程、該凝固糸を湿熱延伸する湿熱延伸工程、該延伸した糸を油剤処理する油剤処理工程、該油剤処理した糸を乾燥緻密化する乾燥緻密化工程を有する炭素繊維用アクリロニトリル系前駆体繊維の製造方法において、

湿熱延伸倍率の値を、湿熱延伸糸の平均細孔半径が最大値あるいは飽和に達する延伸倍率以下にすることを特徴とする炭素繊維用アクリロニトリル系前駆体繊維の製造方法が提供される。

According to the present invention, a spinning step of spinning an undiluted spinning solution containing a solvent and an acrylonitrile-based polymer dissolved in the solvent to obtain a coagulated yarn, a wet heat drawing step of wet-heat drawing the coagulated yarn, and treating the drawn yarn with an oil agent An oil agent treatment step, a method for producing an acrylonitrile-based precursor fiber for carbon fiber having a dry densification step of drying and densifying the oil-treated yarn,

A method for producing an acrylonitrile-based precursor fiber for carbon fiber, characterized in that the value of the wet heat drawing ratio is equal to or less than the drawing ratio at which the average pore radius of the wet heat drawn yarn reaches the maximum value or saturation.

本発明により、溶剤と該溶剤に溶解したアクリロニトリル系重合体とを含む紡糸原液を紡糸して凝固糸を得る紡糸工程、該凝固糸を湿熱延伸する湿熱延伸工程、該延伸した糸を油剤処理する油剤処理工程、該油剤処理した糸を乾燥緻密化する乾燥緻密化工程を有する炭素繊維用アクリロニトリル系前駆体繊維の製造方法において、

湿熱延伸倍率の値を、乾燥緻密化直後の繊維配向度が最大値あるいは飽和に達する延伸倍率以下にすることを特徴とする炭素繊維用アクリロニトリル系前駆体繊維の製造方法が提供される。

According to the present invention, a spinning step of spinning an undiluted spinning solution containing a solvent and an acrylonitrile-based polymer dissolved in the solvent to obtain a coagulated yarn, a wet heat drawing step of wet-heat drawing the coagulated yarn, and treating the drawn yarn with an oil agent An oil agent treatment step, a method for producing an acrylonitrile-based precursor fiber for carbon fiber having a dry densification step of drying and densifying the oil-treated yarn,

A method for producing an acrylonitrile-based precursor fiber for carbon fiber, characterized in that the value of the wet heat draw ratio is not more than the draw ratio at which the degree of fiber orientation immediately after dry densification reaches the maximum value or reaches saturation.

上記炭素繊維用アクリロニトリル系前駆体繊維の製造方法において、前記溶剤がジメチルアセトアミドあるいはジメチルホルムアミドであり、前記湿熱延伸を行う際の湿熱延伸糸膨潤度が120%以下であることが好ましい。 In the method for producing an acrylonitrile-based precursor fiber for carbon fiber, it is preferable that the solvent is dimethylacetamide or dimethylformamide, and that the wet heat drawn yarn swelling degree when performing the wet heat drawing is 120% or less.

本発明によれば、用途に応じた種々の複合材において優れた特性を実現し得る炭素繊維束とその製造に好適な前駆体繊維が提供され、さらにこの前駆体繊維を好適に製造することのできる製造方法が提供される。 According to the present invention, a carbon fiber bundle capable of realizing excellent properties in various composite materials according to the application and a precursor fiber suitable for the production thereof are provided, and furthermore, the precursor fiber is suitably produced. A possible manufacturing method is provided.

本発明の炭素繊維束は、単繊維ねじり弾性率に対する単繊維ねじり強度の比(単繊維ねじり強度(GPa)/単繊維ねじり弾性率(GPa))が0.1以上である炭素繊維の単繊維を70質量%以上含む炭素繊維束である。 The carbon fiber bundle of the present invention is a carbon fiber single fiber having a ratio of single fiber torsional strength to single fiber torsional elasticity (single fiber torsional strength (GPa) / single fiber torsional elastic modulus (GPa)) of 0.1 or more. Is 70 mass% or more.

上記比が0.1以上となる単繊維が70%未満の場合、ねじり弾性率に対するねじり強度が低い炭素繊維単繊維の割合が多くなり、複合材料とした場合に、複雑な応力に対しての強度が著しく低下する。同様の観点から、上記比が0.09以上である炭素繊維の短繊維を90質量%以上含むことが好ましい。単繊維ねじり強度(GPa)/単繊維ねじり弾性率(GPa)の値が0.1以上を示す炭素繊維単繊維の割合は、大きければ大きいほど好ましい。 When the ratio of the single fibers having the ratio of 0.1 or more is less than 70%, the ratio of the carbon fiber single fibers having a low torsional strength to the torsional elasticity increases, and in the case of a composite material, the ratio of the single fibers to the complex stress increases. The strength is significantly reduced. From the same viewpoint, it is preferable that the short fiber of the carbon fiber having the above ratio of 0.09 or more contains 90% by mass or more. The larger the ratio of single fiber torsion strength (GPa) / single fiber torsional modulus (GPa) is 0.1 or more, the more preferable.

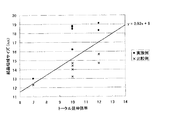

また本発明は、トータル延伸倍率とポリアクリロニトリルの(100)反射から得られる結晶領域サイズが次式を満たすことを特徴とする炭素繊維用アクリロニトリル系前駆体繊維である。尚、ここで言うトータル延伸倍率とは、乾燥緻密化前に凝固糸を延伸する延伸倍率と乾燥緻密化後の延伸倍率を掛け合わせた値であり、紡糸の最終ロール速度を凝固糸の引き取り速度で割った値でも同じである。 Further, the present invention is an acrylonitrile-based precursor fiber for carbon fiber, wherein the total draw ratio and the crystal region size obtained from the (100) reflection of polyacrylonitrile satisfy the following expression. The total draw ratio referred to herein is a value obtained by multiplying a draw ratio for drawing a coagulated yarn before dry densification and a draw ratio after dry densification. The same applies to the value divided by.

かかる炭素繊維用アクリロニトリル系前駆体繊維は、後述する本発明の製造方法により好適に得ることができ、かかる本発明の炭素繊維用アクリロニトリル系前駆体繊維を焼成することによって上述した本発明の炭素繊維束を好適に得ることができる。上記式が満たされると、本発明の炭素繊維束を好適に得ることができ、延伸により繊維内の結晶領域、もしくは結晶領域と非晶領域の界面が破壊されることを防止し、焼成時にグラファイト結晶網面内およびその付近に欠陥が生じて炭素繊維性能が著しく低下することを防止することができる。 The acrylonitrile-based precursor fiber for carbon fiber can be suitably obtained by the production method of the present invention described below, and the carbon fiber of the present invention described above by firing the acrylonitrile-based precursor fiber for carbon fiber of the present invention. A bundle can be suitably obtained. When the above formula is satisfied, the carbon fiber bundle of the present invention can be suitably obtained, and the crystal region in the fiber, or the interface between the crystal region and the amorphous region is prevented from being broken by drawing, and graphite is fired during firing. It is possible to prevent the occurrence of defects in the crystal network plane and the vicinity thereof to significantly lower the carbon fiber performance.

以下に本発明の炭素繊維束及び炭素繊維用アクリロニトリル系前駆体繊維の製造方法について詳しく説明する。 Hereinafter, the method for producing the carbon fiber bundle and the acrylonitrile-based precursor fiber for carbon fiber of the present invention will be described in detail.

本発明の炭素繊維用アクリロニトリル系前駆体繊維に用いるアクリロニトリル系重合体としてはアクリロニトリルのホモポリマー及び/又は他のモノマーとの共重合体を用いることができる。この場合、炭素化を良好に行う目的で共重合体中のアクリロニトリル組成は90質量%以上であることが好ましく、炭素繊維にした時の共重合成分に起因する欠陥点を少なくし、炭素繊維の品位並びに性能を向上させる目的からアクリロニトリルが95質量%以上であることがより好ましい。 As the acrylonitrile-based polymer used for the acrylonitrile-based precursor fiber for carbon fiber of the present invention, a homopolymer of acrylonitrile and / or a copolymer with another monomer can be used. In this case, the acrylonitrile composition in the copolymer is preferably 90% by mass or more for the purpose of satisfactorily carbonizing the carbon fiber. Acrylonitrile is more preferably 95% by mass or more for the purpose of improving quality and performance.

アクリロニトリル系重合体の共重合成分モノマーとしては、特に制限は無いが、例えばアクリル酸メチル、アクリル酸エチル、アクリル酸イソプロピル、アクリル酸n−ブチル、アクリル酸2−エチルヘキシル、アクリル酸2−ヒドロキシエチル、アクリル酸ヒドロキシプロピルなどに代表されるアクリル酸エステル類;メタクリル酸メチル、メタクリル酸エチル、メタクリル酸イソプロピル、メタクリル酸n−ブチル、メタクリル酸n−ヘキシル、メタクリル酸シクロヘキシル、メタクリル酸ラウリル、メタクリル酸2−ヒドロキシエチル、メタクリル酸ヒドロキシプロピル、メタクリル酸ジエチルアミノエチルなどに代表されるメタクリル酸エステル類;アクリル酸、メタクリル酸、マレイン酸、イタコン酸、アクリルアミド、N−メチロールアクリルアミド、ジアセトンアクリルアミド、スチレン、ビニルトルエン、酢酸ビニル、塩化ビニル、塩化ビニリデン、臭化ビニル、臭化ビニリデン、フッ化ビニル、フッ化ビニリデンなどの不飽和モノマー類;p−スルホフェニルメタリルエーテル、メタリルスルホン酸、アリルスルホン酸、スチレンスルホン酸、2−アクリルアミド−2−メチルプロパンスルホン酸及びこれらのアルカリ金属塩などが挙げられる。 The copolymerization component monomer of the acrylonitrile-based polymer is not particularly limited. For example, methyl acrylate, ethyl acrylate, isopropyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate, 2-hydroxyethyl acrylate, Acrylic esters such as hydroxypropyl acrylate; methyl methacrylate, ethyl methacrylate, isopropyl methacrylate, n-butyl methacrylate, n-hexyl methacrylate, cyclohexyl methacrylate, lauryl methacrylate, 2-methacrylic acid 2- Methacrylic esters represented by hydroxyethyl, hydroxypropyl methacrylate, diethylaminoethyl methacrylate, etc .; acrylic acid, methacrylic acid, maleic acid, itaconic acid, acrylamide, N-methyl Unsaturated monomers such as acrylacrylamide, diacetone acrylamide, styrene, vinyltoluene, vinyl acetate, vinyl chloride, vinylidene chloride, vinyl bromide, vinylidene bromide, vinyl fluoride and vinylidene fluoride; p-sulfophenyl methallyl ether , Methallylsulfonic acid, allylsulfonic acid, styrenesulfonic acid, 2-acrylamido-2-methylpropanesulfonic acid, and alkali metal salts thereof.

アクリロニトリル系重合体の共重合成分モノマーとして、炭素化工程における環化反応を促進する目的でカルボン酸基を有するモノマーやアクリルアミド系モノマーを用いることが好ましい。このようなカルボン酸基を有するモノマーとしては、メタクリル酸やイタコン酸が好ましい。又、アクリルアミド系モノマーとしてはアクリルアミドが好ましい。そして、溶剤に対する溶解性の向上、凝固糸の緻密性の向上の観点から、アクリルアミドは共重合体に1質量%以上含まれることが好ましい。従って、この場合必然的にアクリロニトリルは99質量%以下が好ましい範囲となる。凝固糸の緻密性については、特に、湿式紡糸であるか乾湿式紡糸であるかに関わらず、取り得る可能なほとんどの凝固浴条件で凝固糸にボイドの発生がないために、品種に応じた任意の凝固浴条件で優れた炭素繊維を実現することが可能である。アクリルアミドの含有量の上限は特に限定はされないが、好ましくは4質量%未満である。 As the copolymer component monomer of the acrylonitrile-based polymer, it is preferable to use a monomer having a carboxylic acid group or an acrylamide-based monomer for the purpose of promoting the cyclization reaction in the carbonization step. As such a monomer having a carboxylic acid group, methacrylic acid and itaconic acid are preferred. Acrylamide is preferably used as the acrylamide monomer. From the viewpoint of improving the solubility in a solvent and improving the denseness of the coagulated yarn, it is preferable that acrylamide is contained in the copolymer in an amount of 1% by mass or more. Therefore, in this case, the preferred range of acrylonitrile is necessarily 99% by mass or less. Regarding the denseness of the coagulated yarn, in particular, irrespective of wet spinning or dry-wet spinning, the coagulated yarn did not generate voids under almost all possible coagulation bath conditions, so it was determined according to the variety. It is possible to realize excellent carbon fibers under any coagulation bath conditions. The upper limit of the acrylamide content is not particularly limited, but is preferably less than 4% by mass.

原料に用いるアクリロニトリル系重合体の重合方法には、溶液重合、懸濁重合など、公知の重合方法の何れをも採用することができる。重合された共重合体から、未反応モノマーや重合触媒残渣、その他の不純物類を極力除く処理を施すことが好ましい。また、前駆体繊維紡糸での延伸性や炭素繊維の性能発現性等の点から、共重合体の重合度は、極限粘度〔η〕が1.0以上が好ましく、特に1.4以上の範囲が好ましい。重合度が高いと溶媒への溶解や製糸が困難となる傾向があるので、極限粘度〔η〕は、4.0を超えない範囲のものが好ましく利用される。 As a polymerization method of the acrylonitrile polymer used as a raw material, any of known polymerization methods such as solution polymerization and suspension polymerization can be employed. It is preferable to remove the unreacted monomer, polymerization catalyst residue, and other impurities from the polymerized copolymer as much as possible. Further, from the viewpoints of elongation in precursor fiber spinning and performance development of carbon fiber, the degree of polymerization of the copolymer is preferably such that the intrinsic viscosity [η] is 1.0 or more, particularly 1.4 or more. Is preferred. If the degree of polymerization is high, dissolution in a solvent or spinning tends to be difficult, so that the intrinsic viscosity [η] in a range not exceeding 4.0 is preferably used.

次に、アクリロニトリル系共重合体、好ましくは不純物の除去処理を施した前記共重合体を溶剤に溶解し、紡糸原液とする。溶剤としては、ジメチルアセトアミド、ジメチルスルホキシド、ジメチルホルムアミドなどの有機溶剤や、塩化亜鉛、チオシアン酸ナトリウムなどの無機化合物の水溶液が使用できる。作製される繊維中に金属を含有せず、また、工程が簡略化される点で有機溶剤が好ましい。その中でも凝固糸及び湿熱延伸糸の緻密性が高いという点で、ジメチルアセトアミドあるいはジメチルホルムアミドを溶剤に用いることがより好ましい。 Next, the acrylonitrile-based copolymer, preferably the above-mentioned copolymer that has been subjected to the impurity removal treatment, is dissolved in a solvent to obtain a spinning solution. As the solvent, an organic solvent such as dimethylacetamide, dimethylsulfoxide and dimethylformamide, and an aqueous solution of an inorganic compound such as zinc chloride and sodium thiocyanate can be used. Organic solvents are preferred because they do not contain metal in the fiber to be produced and the process is simplified. Among them, dimethylacetamide or dimethylformamide is more preferably used as the solvent, since the coagulated yarn and the wet heat drawn yarn have high densities.

紡糸した際、緻密な凝固糸を得るためには、紡糸原液として、ある程度以上のポリマー濃度を有する重合体溶液を使用することが好ましい。具体的には、紡糸原液中の重合体濃度は、好ましくは17質量%以上、より好ましくは19質量%以上の範囲とする。用いる重合体の重合度にもよるが、適正な粘度・流動性を有するものとするため、重合体濃度は、25質量%を超えない範囲が好ましい。 In order to obtain a dense coagulated yarn at the time of spinning, it is preferable to use a polymer solution having a polymer concentration of a certain level or more as a spinning solution. Specifically, the polymer concentration in the spinning dope is preferably in the range of 17% by mass or more, more preferably 19% by mass or more. Although it depends on the degree of polymerization of the polymer used, the polymer concentration is preferably in the range not exceeding 25% by mass in order to have appropriate viscosity and fluidity.

炭素繊維用アクリロニトリル系前駆体繊維の紡糸法は、湿式紡糸法か乾湿式紡糸法が好ましいが乾式紡糸法でも良い。湿式紡糸法、乾湿式紡糸法は用途に応じ使い分けられる。 The spinning method of the acrylonitrile-based precursor fiber for carbon fiber is preferably a wet spinning method or a dry-wet spinning method, but may be a dry spinning method. The wet spinning method and the dry-wet spinning method can be used depending on the application.

紡糸工程は、先ず、前記の紡糸原液をノズル孔より凝固浴中に吐出し凝固糸とする。ノズル孔の形状に制限はないが、円形が一般的に使用される。凝固浴は、まず作製される凝固糸引き取りに十分な余裕がある条件に設定する。そして、凝固糸の断面形状が、円形、空豆形、楕円形など炭素繊維の用途に応じた形状になるように、凝固浴に含まれる溶剤濃度、温度を設定する。 In the spinning step, first, the spinning solution is discharged from a nozzle hole into a coagulation bath to form a coagulated yarn. Although the shape of the nozzle hole is not limited, a circular shape is generally used. The coagulation bath is first set to a condition having a sufficient margin for taking out the coagulated yarn to be produced. Then, the concentration and the temperature of the solvent contained in the coagulation bath are set so that the cross-sectional shape of the coagulated yarn becomes a shape corresponding to the use of the carbon fiber, such as a circle, a bean shape, and an oval shape.

凝固浴には、紡糸原液に用いられる溶剤を含む水溶液が好適に使用される。ノズル孔より吐出される紡糸原液が所望の繊維径の凝固糸となるように、含まれる溶剤の濃度を調節する。使用する溶剤の種類にも依存するが、例えば、ジメチルアセトアミドあるいはジメチルホルムアミドを使用する場合、その濃度は50〜80質量%に選択することが好ましい。 For the coagulation bath, an aqueous solution containing the solvent used for the spinning solution is preferably used. The concentration of the contained solvent is adjusted so that the spinning dope discharged from the nozzle hole becomes a coagulated yarn having a desired fiber diameter. Although it depends on the type of solvent used, for example, when dimethylacetamide or dimethylformamide is used, the concentration is preferably selected from 50 to 80% by mass.

また、凝固浴の温度は、凝固糸の緻密性の観点からは温度が低い方が好ましい。しかしながら、湿式紡糸の場合、凝固浴の温度を下げると凝固糸の引き取り速度が低下し、全体的な生産性が低下する点を考慮し、通常、好ましくは50℃以下、より好ましくは20℃以上40℃以下の範囲に選択する。 The temperature of the coagulation bath is preferably lower from the viewpoint of the denseness of the coagulated yarn. However, in the case of wet spinning, taking into account that when the temperature of the coagulation bath is lowered, the take-up speed of the coagulated yarn is reduced, and overall productivity is reduced, it is usually preferably 50 ° C. or lower, more preferably 20 ° C. or higher. Select in the range below 40 ° C.

上記凝固糸は続いて湿熱延伸を施される。本発明で言う湿熱延伸とは該凝固糸が乾燥緻密化までになされる延伸のことを指す。従って、湿熱延伸倍率とは乾燥緻密化を行うロール速度と凝固糸を引き取るロール速度との比で定義され、湿熱延伸糸とは乾燥緻密化直前の糸を言う。湿熱延伸方法としては、空中での延伸、水、溶媒/水混合液、グリセリンなどの液体媒体中での延伸及び加圧あるいは常圧の水蒸気中での延伸などの方法を任意の順番で組み合わせてよい。途中に緩和工程を含んでも良い。但し、乾燥緻密化までに含まれている溶剤の洗浄を完了する観点から、温水中での延伸倍率が半分以上占めるのが好ましい。例えば、湿熱延伸倍率が3倍の場合は温水中の延伸は1.7(=√3)倍以上が好ましい。さらに、温水温度は単糸同士が融着しない範囲で、できるだけ高温にすることが効果的である。この観点から、延伸浴の温度は70℃以上の高温とすることが好ましい。また、温水の多段延伸の場合は、その最終浴を90℃以上の高温にすることが好ましい。また、この湿熱延伸に先立って、温水中で溶剤の洗浄を行っても良い。本発明者らは、湿熱延伸倍率が高くなるにつれ湿熱延伸糸の膨潤度が高くなり、ある延伸倍率で膨潤度が最大あるいは飽和になることを見出した。そして、湿熱延伸糸の平均細孔半径や乾燥緻密化直後の糸の繊維配向度も同様の関係であることを見出した。これらは、湿熱延伸倍率がある値以上になると湿熱延伸糸の膨潤度や平均細孔半径はほとんど変化しないか小さくなり緻密性が向上したように見えるが、実際は配向の向上しない延伸が行われており、繊維内部構造の破壊が起こったことを示している。この破壊が炭素繊維の欠陥の元となり性能の低下を招くのである。特に、ねじり物性ではこれが顕著に現れ、ねじり弾性率に対するねじり強度を大きく低下させる。尚、乾燥緻密化直後の糸とは、湿熱延伸糸を後述する油剤付与及びそれに続く乾燥緻密化処理を行い、その後の延伸を行わない段階の糸のことである。 The coagulated yarn is subsequently subjected to wet heat drawing. The term “wet heat drawing” as used in the present invention refers to drawing in which the coagulated yarn is dried and densified. Accordingly, the wet heat draw ratio is defined by the ratio of the roll speed for performing dry densification to the roll speed for drawing the coagulated yarn, and the wet heat drawn yarn refers to the yarn immediately before dry densification. As the wet heat stretching method, stretching in the air, stretching in a liquid medium such as water, a solvent / water mixture, or glycerin and stretching in pressurized or normal pressure steam are combined in any order. Good. A relaxation step may be included on the way. However, it is preferable that the stretching ratio in warm water accounts for half or more from the viewpoint of completing the washing of the solvent contained before the drying and densification. For example, when the wet heat stretching ratio is 3 times, stretching in warm water is preferably 1.7 (= √3) times or more. Further, it is effective to make the hot water temperature as high as possible within a range in which the single yarns do not fuse together. From this viewpoint, the temperature of the stretching bath is preferably set to a high temperature of 70 ° C. or higher. In the case of multi-stage stretching of warm water, the final bath is preferably heated to a high temperature of 90 ° C. or higher. Prior to the wet heat stretching, the solvent may be washed in warm water. The present inventors have found that the swelling degree of the wet heat drawn yarn increases as the wet heat drawing ratio increases, and that the swelling degree becomes maximum or saturated at a certain drawing ratio. The inventors have also found that the average pore radius of the wet-heat drawn yarn and the fiber orientation degree of the yarn immediately after dry densification have the same relationship. These are such that when the wet heat draw ratio becomes a certain value or more, the degree of swelling and the average pore radius of the wet heat drawn yarn hardly change or become small, and it seems that the denseness is improved, but in reality, the drawing in which the orientation is not improved is performed. Indicating that the internal structure of the fiber had been destroyed. This destruction causes a defect of the carbon fiber and causes a decrease in performance. In particular, this remarkably appears in torsional physical properties, and greatly reduces torsional strength with respect to torsional elasticity. In addition, the yarn immediately after dry densification is a yarn at a stage where the wet heat drawn yarn is subjected to an oil agent application described later and a subsequent dry densification treatment, and thereafter is not drawn.

このような現象を防止するためには、湿熱延伸糸膨潤度、平均細孔半径、乾燥緻密化直後の配向度の内の少なくとも1つについて、その値が最大値あるいは飽和に達する延伸倍率以下になる湿熱延伸倍率を選ぶことが有効である。 In order to prevent such a phenomenon, at least one of the degree of wet-heat drawn yarn swelling, the average pore radius, and the degree of orientation immediately after dry densification is not more than the draw ratio at which the value reaches the maximum value or saturation. It is effective to select a suitable wet heat stretching ratio.

湿熱延伸糸膨潤度、平均細孔半径及び乾燥緻密化直後の糸の繊維配向度が最大値あるいは飽和に達する湿熱延伸倍率は、当然、重合体組成、紡糸原液溶媒、紡浴条件等の条件に依り異なってくるので、条件ごとに上記各値の最大値あるいは飽和に達する湿熱延伸倍率を求めた後に、湿熱延伸倍率を設定することで本発明は達成される。上記各値の最大値あるいは飽和に達する湿熱延伸倍率は、湿熱延伸倍率0.2倍以上0.8倍以下ごとに各値を測定するのが好ましい。0.8倍より大きい場合は、正確に最大値あるいは飽和に達する湿熱延伸倍率を求めることができないことがある。0.2倍より小さい場合は、測定点が増え測定が煩雑になるだけである。尚、飽和点とは、横軸に湿熱延伸倍率、縦軸に測定値をとったとき測定点を結ぶ線分の傾きの絶対値が最大の傾きの10分の1以下になった点とする。 The wet heat draw ratio at which the wet heat drawn yarn swelling degree, the average pore radius, and the fiber orientation degree of the yarn immediately after dry densification reach the maximum value or saturation, naturally depends on the conditions such as the polymer composition, spinning solution solvent, and spin bath conditions. Therefore, the present invention can be achieved by setting the wet heat stretching ratio after obtaining the maximum value of the above values or the wet heat stretching ratio reaching the saturation for each condition. It is preferable to measure each value of the wet heat stretch ratio at which the maximum value of each of the above values or the saturation is reached is 0.2 to 0.8 times. If the ratio is larger than 0.8, it may not be possible to accurately determine the maximum heat draw ratio or the wet heat draw ratio that reaches saturation. When it is smaller than 0.2 times, the number of measurement points increases and the measurement becomes complicated. The saturation point is defined as a point at which the absolute value of the gradient of the line connecting the measurement points when the horizontal axis represents the wet heat draw ratio and the vertical axis represents the measured value is 1/10 or less of the maximum gradient. .

湿熱延伸倍率をより低い値に設定すると、乾燥緻密化後の延伸倍率をより大きくする必要があり紡糸工程通過性が相対的に悪くなる傾向がある。そのため、安定に生産するには、紡糸速度を遅くするなど生産性を落とす必要が生じる場合がある。かかる観点から、湿熱延伸倍率は1.5倍以上が好ましい。 If the wet heat draw ratio is set to a lower value, the draw ratio after drying and densification needs to be increased, and the spinning process passability tends to be relatively poor. Therefore, for stable production, it may be necessary to lower the productivity such as reducing the spinning speed. From such a viewpoint, the wet heat stretching ratio is preferably 1.5 times or more.

このように乾燥緻密化前の延伸倍率を設定することで、本発明の炭素繊維及び炭素繊維用アクリロニトリル系前駆体繊維を得ることができ、重合体組成、紡糸原液溶媒、湿式あるいは乾湿式等の紡糸方式、紡浴条件、繊維断面形状、単糸繊度及び総繊度等の各条件に依らず、優れた複合材特性を実現し得る炭素繊維を得ることが可能となる。 By setting the draw ratio before drying and densification in this way, the acrylonitrile-based precursor fiber for carbon fiber and carbon fiber of the present invention can be obtained, and the polymer composition, spinning solution solvent, wet or dry-wet, etc. It is possible to obtain carbon fibers capable of realizing excellent composite material characteristics irrespective of conditions such as spinning method, spinning bath conditions, fiber cross-sectional shape, single yarn fineness and total fineness.

湿熱延伸、洗浄後、繊維表面には、公知の方法によって油剤処理を施す。油剤の種類は特に限定されないが、アミノシリコン系界面活性剤が好適に使用される。この油剤処理後、乾燥緻密化が行われる。この乾燥緻密化の温度は、繊維のガラス転移温度を超える温度に選択する。ガラス転移温度は、繊維自体の状態が、実質的には含水状態から乾燥状態へと変化することによって異なることもあり、温度が100〜200℃程度の加熱ローラーを用いる方法が好ましい。 After wet heat drawing and washing, the fiber surface is subjected to an oil treatment by a known method. The type of the oil agent is not particularly limited, but an aminosilicone-based surfactant is preferably used. After this oil agent treatment, dry densification is performed. The temperature of this dry densification is chosen to be above the glass transition temperature of the fiber. The glass transition temperature may vary depending on the fact that the state of the fiber itself changes substantially from a water-containing state to a dry state, and a method using a heating roller having a temperature of about 100 to 200 ° C is preferable.

乾燥緻密化後、再度延伸を行うことで、前駆体繊維を所望の繊維径とする後延伸工程を設けることが好ましい。この後延伸は、高温の加熱ローラー、熱盤などを利用する乾熱延伸、あるいは加圧スチームによるスチーム延伸など、繊維自体の状態を大きく変えない限り、種々の方式を用いることができる。また、多段で行うことも可能である。後延伸工程自体の延伸倍率は、乾燥緻密化の前に実施される延伸と前記乾燥緻密化の後に実施される後延伸工程と、これら全体として、所定の延伸倍率を達成するように、後延伸工程における延伸倍率は選択される。 After the drying and densification, it is preferable to provide a post-stretching step in which the precursor fiber has a desired fiber diameter by drawing again. After this, various methods can be used as long as the state of the fiber itself is not significantly changed, such as dry heat drawing using a high-temperature heating roller or a hot plate, or steam drawing by pressurized steam. It is also possible to carry out in multiple stages. The stretching ratio of the post-stretching step itself is the stretching performed before the dry densification and the post-stretching step performed after the dry densification, and as a whole, the post-stretching is performed so as to achieve a predetermined stretching ratio. The stretching ratio in the process is selected.

また、乾燥緻密化前の延伸倍率と後延伸倍率を合わせた合計延伸倍率は、繊維の配向性に優れ、優れた性能の炭素繊維を得る観点から好ましくは6倍以上、より好ましくは8倍以上とし、糸切れを良好に防止して優れた生産性を実現する観点から好ましくは20倍以下、より好ましくは15倍以下とする。 The total draw ratio of the draw ratio before and after the dry densification is preferably 6 times or more, more preferably 8 times or more, from the viewpoint of obtaining carbon fibers having excellent fiber orientation and excellent performance. It is preferably 20 times or less, more preferably 15 times or less, from the viewpoint of favorably preventing yarn breakage and achieving excellent productivity.

以上説明したように、溶剤とこの溶剤に溶解したアクリロニトリル系共重合体を含む紡糸原液を紡糸して凝固糸を得る紡糸工程、この凝固糸を湿熱延伸する湿熱延伸工程、延伸した糸を油剤処理する油剤処理工程、油剤処理した糸を乾燥緻密化する乾燥緻密化工程を有する炭素繊維用アクリロニトリル系前駆体繊維の製造方法において、湿熱延伸倍率を前述の範囲にすることにより、優れた炭素繊維用アクリロニトリル系前駆体繊維を得ることができる。 As described above, a spinning step of spinning a spinning stock solution containing a solvent and an acrylonitrile-based copolymer dissolved in the solvent to obtain a coagulated yarn, a wet-heat drawing step of wet-heat-drawing the coagulated yarn, and treating the drawn yarn with an oil agent In the method for producing an acrylonitrile-based precursor fiber for carbon fiber, which has a dry densification step of drying and densifying the oil-treated yarn, the wet heat drawing ratio is in the above-mentioned range, whereby an excellent carbon fiber An acrylonitrile-based precursor fiber can be obtained.

この前駆体繊維を、耐炎化工程、炭素化工程など公知の技術により焼成し、アクリロニトリル系炭素繊維を得ることができる。 This precursor fiber is fired by a known technique such as a flame-proofing step and a carbonization step, so that an acrylonitrile-based carbon fiber can be obtained.

以下に、実施例により本発明をより具体的に説明する。なお、以下に述べる実施例は、本発明における最良の実施形態の一例であるものの、本発明は、これら実施例により限定されるものではない。 Hereinafter, the present invention will be described more specifically with reference to examples. The following embodiments are examples of the best embodiment of the present invention, but the present invention is not limited to these embodiments.

本発明を記載する際に利用される、炭素繊維用アクリロニトリル系前駆体繊維及び炭素繊維の各種物性、具体的には、「膨潤度」、「平均細孔半径」、「配向度」、「結晶領域サイズ」、「ストランド強度、弾性率」ならびに「ねじり強度、弾性率」に関して、その評価方法を予め説明する。実施例中、特記がなされていない場合、記載する各種物性値、指標は、ここに記載する方法により測定、評価された値を表す。通常、複数の試料に対して、評価し、その平均値を採用している。また、含有率、濃度、配合量の表記に用いる「%」、「部」はそれぞれ質量%、質量部を表すこととする。 Various physical properties of acrylonitrile-based precursor fiber and carbon fiber for carbon fiber used in describing the present invention, specifically, “swelling degree”, “average pore radius”, “degree of orientation”, “crystal” With respect to the “region size”, “strand strength, elastic modulus” and “torsion strength, elastic modulus”, evaluation methods thereof will be described in advance. In the examples, unless otherwise specified, the various physical property values and indices described are values measured and evaluated by the methods described herein. Normally, a plurality of samples are evaluated and the average value is adopted. Further, “%” and “parts” used in the description of the content rate, the concentration, and the blending amount represent mass% and mass parts, respectively.

(イ)「膨潤度」

膨潤糸を遠心脱水機を用いて付着水を除去した(毎分1800回転を10分間)後の質量(W)と、これを沸水洗浄してから熱風乾燥機で80℃で16時間乾燥した後の質量(Wo)から以下の式で求めた値である。

(B) "Swelling degree"

The mass (W) of the swollen yarn after removing adhering water using a centrifugal dehydrator (at 1800 revolutions per minute for 10 minutes), washing it with boiling water and drying it at 80 ° C. for 16 hours with a hot air drier Is the value obtained by the following equation from the mass (Wo).

(ロ)「平均細孔半径」

延伸浴から出た糸条を採取し、t−ブタノールと脱イオン水の混合液でt−ブタノールの濃度を7段階に渡り濃くした溶液に順次浸漬し、繊維構造の変化がないように糸条内の液を全てt−ブタノールに置換する。これを−20℃以下に冷却しながら24時間真空下(3Pa以下)で乾燥する。この乾燥試料を約0.2g精秤し、ディラトメーターに入れる。次に水銀注入装置を用いて容器内を真空(7Pa以下)にし、その後水銀を充填する。そして、ポロシメーターを用いて測定を行う。圧力は最大400MPaまでかける。そして、細孔半径rは下式により算出される。平均細孔半径は、圧入された全水銀量の半分が圧入された時点の圧力から求められる細孔半径とした。

(B) “Average pore radius”

The yarn coming out of the stretching bath is collected and immersed sequentially in a solution in which the concentration of t-butanol is increased in seven stages with a mixed solution of t-butanol and deionized water, so that the fiber structure is not changed. Replace all the liquid inside with t-butanol. This is dried under vacuum (3 Pa or less) for 24 hours while cooling it to -20 ° C or less. About 0.2 g of the dried sample is precisely weighed and placed in a dilatometer. Next, the inside of the container is evacuated (7 Pa or less) using a mercury injection device, and then filled with mercury. Then, the measurement is performed using a porosimeter. The pressure is applied up to 400 MPa. Then, the pore radius r is calculated by the following equation. The average pore radius was a pore radius obtained from the pressure at the time when half of the total amount of mercury injected was injected.

(ハ)「配向度」

数百本の炭素繊維を酢酸ビニル/メタノール溶液で固め、幅0.5mmほどのサンプルを作製し、サンプルをX線に対して垂直な面上で360°回転させ、(002)反射における最高強度を含む子午線方向のプロファイルの半価幅から下記の式を用いて配向度を算出した。X線源として、リガク社製のCuKα線(Niフィルター使用)X線発生装置を用い、出力は40kV−100mAであった。

(C) "Degree of orientation"

Hundreds of carbon fibers are hardened with a vinyl acetate / methanol solution to prepare a sample having a width of about 0.5 mm, and the sample is rotated by 360 ° on a plane perpendicular to X-rays to obtain the highest intensity in (002) reflection. Was calculated from the half width of the profile in the meridian direction including the following formula using the following formula. As the X-ray source, a CuKα ray (using a Ni filter) X-ray generator manufactured by Rigaku Corporation was used, and the output was 40 kV-100 mA.

(ニ)「結晶領域サイズ」

前駆体繊維を50mm長に切断し、これを30mg精秤採取し、試料繊維軸が正確に平行になるようにして引き揃えた後、試料調整用治具を用いて巾1mmの厚さが均一な繊維試料束に整えた。この繊維試料束に酢酸ビニル/メタノール溶液を含浸させて形態が崩れないように固定した後、これを広角X線回折試料台に固定した。X線源として、リガク社製のCuKα線(Niフィルター使用)X線発生装置を用い、同じくリガク社製のゴニオメーターにより、透過法によってグラファイトの面指数(100)に相当する2θ=17°近傍の回折ピークをシンチレーションカウンターにより検出した。出力は40kV−100mAにて測定した。回折ピークにおける半値巾から下記の式(2)を用いて、結晶領域サイズLaを求めた。

(D) “Crystal region size”

The precursor fiber was cut into a length of 50 mm, 30 mg was precisely weighed and collected so that the sample fiber axes were exactly parallel to each other. Then, the thickness of 1 mm width was uniform using a jig for sample adjustment. The fiber bundle was prepared. The fiber sample bundle was impregnated with a vinyl acetate / methanol solution so as to be fixed so as not to lose its shape, and then fixed to a wide-angle X-ray diffraction sample table. As the X-ray source, a CuKα ray (using a Ni filter) X-ray generator manufactured by Rigaku Corporation is used, and a goniometer also manufactured by Rigaku Corporation is used. Was detected by a scintillation counter. The output was measured at 40 kV-100 mA. The crystal region size La was determined from the half width at the diffraction peak using the following equation (2).

(式中、Kはシェラー定数0.9、λは用いたX線の波長(ここではCuKα線を用いているので、1.5418Å)、θはBraggの回折角、β0は真の半値巾、β0=βE−β1(βEは見かけの半値巾、β1は装置定数であり、ここでは1.05×10-2rad)である。)

(ホ)「ストランド強度、弾性率」

JIS R−7601記載の方法で測定した。ストランドの作成は、油化シェル社製「エピコート828(商品名)」(100部)、無水メチルナジック酸(90部)、ジベンジルメチルアミン(2部)、アセトン(50部)を混合した組成の樹脂を炭素繊維に含浸後、50℃で1時間保持し、50℃から130℃に1時間かけて昇温後、130℃で2時間保持し硬化した。

(Where K is the Scherrer constant of 0.9, λ is the wavelength of the X-ray used (1.5418 ° because CuKα rays are used here), θ is the Bragg diffraction angle, and β 0 is the true half-value width. , Β 0 = β E −β 1 (β E is an apparent half width, β 1 is a device constant, and is 1.05 × 10 −2 rad here.)

(E) "Strand strength and elastic modulus"

It was measured by the method described in JIS R-7601. The strand was prepared by mixing “Epicoat 828 (trade name)” (manufactured by Yuka Shell Co., Ltd.) (100 parts), methylnadic anhydride (90 parts), dibenzylmethylamine (2 parts), and acetone (50 parts). After the resin was impregnated with the carbon fiber, it was kept at 50 ° C. for 1 hour, heated from 50 ° C. to 130 ° C. for 1 hour, and kept at 130 ° C. for 2 hours to cure.

(ヘ)「単繊維ねじり強度、弾性率」

長さ約2mmの単繊維試料の両端を台紙に固定し、この台紙の一端を、単繊維ねじり試験装置の金属フックに取り付けると共に、前記台紙のもう一方の端に金属フックを吊り下げ、溝のついた回転筒にセットし、回転筒を8mg/1回転にて、一定速度で回転させ、単繊維が破断したときのひずみと応力を検出することによって、単繊維ねじり強度(GPa)とねじり弾性率(GPa)を求めた。

(F) "Torsion strength and elastic modulus of single fiber"

Both ends of a single fiber sample having a length of about 2 mm were fixed to a mount, and one end of the mount was attached to a metal hook of a single fiber torsion test device, and a metal hook was suspended from the other end of the mount, and a groove was formed. The rotating cylinder is set at 8 mg / rotation at a constant speed, and the strain and the stress when the single fiber breaks are detected to determine the torsional strength (GPa) and torsional elasticity of the single fiber. The rate (GPa) was determined.

単繊維の試料数は25〜30とし、それぞれの試料について単繊維ねじり弾性率に対する単繊維ねじり強度の比を算出し、この比が0.1以上である単繊維の割合を算出した。 The number of single fiber samples was 25 to 30, and the ratio of the single fiber torsional strength to the single fiber torsional modulus was calculated for each sample, and the ratio of single fibers having this ratio of 0.1 or more was calculated.

実施例1、2、比較例1、2

アクリロニトリル96%、メタクリル酸1%、アクリルアミド3%で共重合したアクリル系共重合体を、ジメチルアセトアミドに溶解して紡糸原液(重合体濃度21%、原液温度60℃)を調整した。この紡糸原液を、直径0.075mm、孔数6000の口金を用いて、温度40℃、濃度65%のジメチルアセトアミド水溶液に吐出し凝固糸とした。

Examples 1 and 2, Comparative Examples 1 and 2

An acrylic copolymer copolymerized with 96% acrylonitrile, 1% methacrylic acid, and 3% acrylamide was dissolved in dimethylacetamide to prepare a spinning stock solution (polymer concentration 21%,

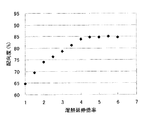

この凝固糸を、1.0倍、1.5倍、2.0倍というように0.5倍ごとに延伸倍率を高くしていき6.0倍までの全12条件で70℃、90℃、95℃の3段の温水中湿熱延伸を施した。6.5倍以上では繊維の破断が起こり安定に延伸できなかった。この湿熱延伸糸の膨潤度と平均細孔半径は表1にまとめ、それぞれグラフ化したものを図1、2に示す。結果、湿熱延伸倍率4.0倍で膨潤度は最大となり、延伸倍率4.5倍で平均細孔半径が最大になった。続いて、各条件の湿熱延伸糸をアミノシリコン系油剤1%水溶液中に浸漬し、180℃の加熱ローラーにて乾燥緻密化した。この乾燥緻密化後糸の配向度を測定した所、表1、図3のようになり延伸倍率4.5倍で乾燥緻密化後糸配向度が飽和に達することがわかった。 This coagulated yarn is stretched at a draw ratio of 0.5, such as 1.0 times, 1.5 times, and 2.0 times, at 70 ° C, 90 ° C under all 12 conditions up to 6.0 times. , 95 ° C. in three stages of hot water. At 6.5 times or more, the fiber was broken and could not be drawn stably. The swelling degree and the average pore radius of the wet heat drawn yarn are summarized in Table 1, and graphs are shown in FIGS. As a result, the swelling degree was maximum at a wet heat stretching ratio of 4.0, and the average pore radius was maximum at a stretching ratio of 4.5. Subsequently, the wet-heat drawn yarn under each condition was immersed in a 1% aqueous solution of an aminosilicone oil agent, and dried and densified with a heating roller at 180 ° C. When the degree of orientation of the dried and densified yarn was measured, the results were as shown in Table 1 and FIG. 3, and it was found that the degree of orientation of the dried and densified yarn reached saturation at a draw ratio of 4.5.

以上の結果から、湿熱延伸倍率を2倍、3倍、5倍、6倍に設定したものをそれぞれ実施例1、2、比較例1、2とした。それぞれ上記の乾燥緻密化後、0.25MPaの加圧水蒸気中で延伸倍率が合計12倍になるように延伸を施して、単糸繊度が1.2dtex、トータル繊度が7200dtex、断面形状がほぼ円形のアクリロニトリル系前駆体繊維を得た。実施例1では、実用上全く問題にならない程度であるが、この加圧水蒸気中の延伸前の糸条が幅広になり、糸条端部の耳折れや延伸機とのこすれがあってときどき毛羽が見られた。実施例1、2、比較例1、2のアクリロニトリル系前駆体繊維の結晶領域サイズは表2のようになった。結晶領域サイズとトータル延伸倍率の関係を図4に示す。 From the above results, those in which the wet heat stretching ratio was set to 2, 3, 5, and 6 times were designated as Examples 1 and 2 and Comparative Examples 1 and 2, respectively. After each of the above-mentioned dry densifications, it is stretched in a pressurized steam of 0.25 MPa so that the stretching ratio becomes 12 times in total, and the single yarn fineness is 1.2 dtex, the total fineness is 7200 dtex, and the cross-sectional shape is substantially circular. An acrylonitrile-based precursor fiber was obtained. In Example 1, although there is no practical problem at all, the yarn before drawing in the pressurized steam becomes wide, and the ends of the yarn are broken and the yarn is sometimes rubbed due to rubbing with the drawing machine. Was done. The crystal region sizes of the acrylonitrile-based precursor fibers of Examples 1 and 2 and Comparative Examples 1 and 2 are as shown in Table 2. FIG. 4 shows the relationship between the crystal region size and the total stretching ratio.

得られた前駆体繊維を密度1.35g/cm2となるように空気中230〜260℃で加熱処理し耐炎化繊維とした。引き続き該繊維を窒素雰囲気中最終的に最高温度1300℃で処理した後、硝酸中で電解処理を施し、炭素繊維を得た。ストランド強度、弾性率、ねじり強度、弾性率の結果は表3にまとめた。 The obtained precursor fiber was subjected to heat treatment at 230 to 260 ° C. in air so as to have a density of 1.35 g / cm 2 to obtain a flame-resistant fiber. Subsequently, the fibers were finally treated at a maximum temperature of 1300 ° C. in a nitrogen atmosphere, and then subjected to electrolytic treatment in nitric acid to obtain carbon fibers. Table 3 summarizes the results of the strand strength, elastic modulus, torsional strength, and elastic modulus.

実施例では引っ張り強度及びねじり物性の優れた炭素繊維が得られた。また、実施例1と実施例2の比較では、実施例1の方がやや強度が高くなったが、先述のように前駆体繊維の紡糸安定性が実施例2よりやや劣った。 In the examples, carbon fibers excellent in tensile strength and torsion properties were obtained. In addition, in comparison between Example 1 and Example 2, although the strength of Example 1 was slightly higher, the spinning stability of the precursor fiber was slightly inferior to Example 2 as described above.

実施例3、比較例3

実施例1と同じ紡糸原液を、直径0.075mm、孔数3000の口金を用いて、温度35℃、濃度60%のジメチルアセトアミド水溶液に吐出し凝固糸とした。

Example 3, Comparative Example 3

The same spinning dope as in Example 1 was discharged into a dimethylacetamide aqueous solution having a temperature of 35 ° C. and a concentration of 60% using a die having a diameter of 0.075 mm and a number of holes of 3,000 to obtain a coagulated yarn.

この凝固糸を、先の例と同様に0.5倍ごとに延伸倍率を高くしていき6.0倍までの全12条件で70℃、90℃、95℃の3段の温水中湿熱延伸を施し、続いて各条件の湿熱延伸糸をアミノシリコン系油剤1%水溶液中に浸漬し、180℃の加熱ローラーにて乾燥緻密化した。各データを採った所、膨潤度の最大点、平均細孔半径の最大点及び乾燥緻密化後糸の配向度の飽和点はそれぞれ湿熱延伸倍率5.0倍、5.5倍及び5.5倍であった。これらの結果から、湿熱延伸倍率を3.0倍、6.0倍に設定したものをそれぞれ実施例3、比較例3とした。続いて0.25MPaの加圧水蒸気中で延伸倍率が合計10倍になるように延伸を施して、単糸繊度が1.2dtex、トータル繊度が3600dtex、断面形状が空豆形のアクリロニトリル系前駆体繊維を得た。得られたアクリロニトリル系前駆体繊維の結晶領域サイズは表2のようになった。結晶領域サイズとトータル延伸倍率の関係を図4に示す。 This coagulated yarn is stretched by 0.5 times in the same manner as in the previous example, and stretched in hot water in three stages of 70 ° C., 90 ° C., and 95 ° C. under all 12 conditions up to 6.0 times. Then, the wet heat drawn yarn under each condition was immersed in a 1% aqueous solution of an aminosilicone-based oil agent, and dried and densified with a heating roller at 180 ° C. When each data was taken, the maximum point of the degree of swelling, the maximum point of the average pore radius, and the saturation point of the degree of orientation of the dried and densified yarn were 5.0 times, 5.5 times and 5.5 times the wet heat draw ratio, respectively. It was twice. From these results, those with the wet heat stretching ratio set to 3.0 times and 6.0 times were designated as Example 3 and Comparative Example 3, respectively. Subsequently, the acrylonitrile-based precursor fiber having a single-fiber fineness of 1.2 dtex, a total fineness of 3600 dtex and a cross-sectional shape of empty bean is drawn by applying a draw ratio of 10 times in a pressurized steam of 0.25 MPa. Obtained. Table 2 shows the crystal region size of the obtained acrylonitrile-based precursor fiber. FIG. 4 shows the relationship between the crystal region size and the total stretching ratio.

実施例1と同じ条件で焼成、電解処理を行い、炭素繊維を得た。ストランド強度、弾性率、ねじり強度、弾性率の結果は表3のようになった。実施例では引っ張り強度及びねじり物性の優れた炭素繊維が得られた。 Firing and electrolytic treatment were performed under the same conditions as in Example 1 to obtain carbon fibers. Table 3 shows the results of the strand strength, elastic modulus, torsional strength, and elastic modulus. In the examples, carbon fibers excellent in tensile strength and torsion properties were obtained.

実施例4、比較例4

実施例1と同じ紡糸原液を、直径0.075mm、孔数6000の口金を用いて、温度35℃、濃度65%のジメチルアセトアミド水溶液に吐出し凝固糸とした。

Example 4, Comparative Example 4

The same spinning dope as in Example 1 was discharged into a dimethylacetamide aqueous solution having a temperature of 35 ° C. and a concentration of 65% using a ferrule having a diameter of 0.075 mm and a number of holes of 6000 to obtain a coagulated yarn.

この凝固糸を、先の例と同様に0.5倍ごとに延伸倍率を高くしていき6.0倍までの全12条件で70℃、90℃、95℃の3段の温水中湿熱延伸を施し、続いて各条件の湿熱延伸糸をアミノシリコン系油剤1%水溶液中に浸漬し、180℃の加熱ローラーにて乾燥緻密化した。各データを採った所、膨潤度の最大点、平均細孔半径の最大点及び乾燥緻密化後糸の配向度の飽和点はそれぞれ湿熱延伸倍率4.0倍、4.5倍及び4.5倍であった。これらの結果から、湿熱延伸倍率を3.0倍、5.0倍に設定したものをそれぞれ実施例4、比較例4とした。続いて0.25MPaの加圧水蒸気中で延伸倍率が合計10倍になるように延伸を施して、単糸繊度が0.8dtex、トータル繊度が4800dtex、断面形状がほぼ円形のアクリロニトリル系前駆体繊維を得た。得られたアクリロニトリル系前駆体繊維の結晶領域サイズは表2のようになった。結晶領域サイズとトータル延伸倍率の関係を図4に示す。 This coagulated yarn is stretched by 0.5 times in the same manner as in the previous example, and stretched in hot water in three stages of 70 ° C., 90 ° C., and 95 ° C. under all 12 conditions up to 6.0 times. Then, the wet heat drawn yarn under each condition was immersed in a 1% aqueous solution of an aminosilicone-based oil agent, and dried and densified with a heating roller at 180 ° C. When each data was taken, the maximum point of the degree of swelling, the maximum point of the average pore radius, and the saturation point of the degree of orientation of the dried and densified yarn were 4.0 times, 4.5 times and 4.5 times the wet heat draw ratio, respectively. It was twice. From these results, those in which the wet heat stretching ratio was set to 3.0 times and 5.0 times were designated as Example 4 and Comparative Example 4, respectively. Subsequently, it is stretched in a pressurized steam of 0.25 MPa so that the stretching ratio becomes a total of 10 times, and an acrylonitrile-based precursor fiber having a single-fiber fineness of 0.8 dtex, a total fineness of 4800 dtex, and a substantially circular cross section is obtained. Obtained. Table 2 shows the crystal region size of the obtained acrylonitrile-based precursor fiber. FIG. 4 shows the relationship between the crystal region size and the total stretching ratio.

得られた前駆体繊維を密度1.35g/cm2となるように空気中230〜260℃で加熱処理し耐炎化繊維とした。引き続き該繊維を窒素雰囲気中最終的に最高温度1400℃で処理した後、硝酸中で電解処理を施し、炭素繊維を得た。ストランド強度、弾性率、ねじり強度、弾性率の結果は表3にまとめた。実施例では引っ張り強度及びねじり物性の優れた炭素繊維が得られた。 The obtained precursor fiber was subjected to heat treatment at 230 to 260 ° C. in air so as to have a density of 1.35 g / cm 2 to obtain a flame-resistant fiber. Subsequently, the fibers were finally treated at a maximum temperature of 1400 ° C. in a nitrogen atmosphere, and then subjected to electrolytic treatment in nitric acid to obtain carbon fibers. Table 3 summarizes the results of the strand strength, elastic modulus, torsional strength, and elastic modulus. In the examples, carbon fibers excellent in tensile strength and torsion properties were obtained.

実施例5、比較例5

実施例1と同じ紡糸原液を、直径0.15mm、孔数1500の口金を用いて、一旦空気中に吐出し約5mmの空気中を通過させた後、温度20℃、濃度80%のジメチルアセトアミド水溶液に導き凝固糸を得た。

Example 5, Comparative Example 5

The same spinning dope as in Example 1 was discharged into the air once using a die having a diameter of 0.15 mm and a number of holes of 1500, and allowed to pass through the air having a diameter of about 5 mm. It was led to an aqueous solution to obtain a coagulated yarn.

この凝固糸を、先の例と同様に0.5倍ごとに延伸倍率を高くしていき6.0倍までの全12条件で70℃、90℃、95℃の3段の温水中湿熱延伸を施し、続いて各条件の湿熱延伸糸をアミノシリコン系油剤1%水溶液中に浸漬し、180℃の加熱ローラーにて乾燥緻密化した。各データを採った所、膨潤度の最大点、平均細孔半径の最大点及び乾燥緻密化後糸の配向度の飽和点はいずれも湿熱延伸倍率4.0倍であった。これらの結果から、湿熱延伸倍率を3.0倍、5.0倍に設定したものをそれぞれ実施例5、比較例5とした。4本合糸後、0.25MPaの加圧水蒸気中で延伸倍率が合計10倍になるように延伸を施して、単糸繊度が1.2dtex、トータル繊度が7200dtex、断面形状がほぼ円形のアクリロニトリル系前駆体繊維を得た。得られたアクリロニトリル系前駆体繊維の結晶領域サイズは表2のようになった。結晶領域サイズとトータル延伸倍率の関係を図4に示す。 This coagulated yarn is stretched by 0.5 times in the same manner as in the previous example, and stretched in hot water in three stages of 70 ° C., 90 ° C., and 95 ° C. under all 12 conditions up to 6.0 times. Then, the wet heat drawn yarn under each condition was immersed in a 1% aqueous solution of an aminosilicone-based oil agent, and dried and densified with a heating roller at 180 ° C. When each data was taken, the maximum point of the degree of swelling, the maximum point of the average pore radius, and the saturation point of the orientation degree of the dried and densified yarn were all 4.0 times the wet heat draw ratio. From these results, those in which the wet heat stretching ratio was set to 3.0 times and 5.0 times were designated as Example 5 and Comparative Example 5, respectively. After the four yarns are joined, they are stretched in a pressurized steam of 0.25 MPa so that the draw ratio becomes 10 times in total, and an acrylonitrile-based fiber having a single-fiber fineness of 1.2 dtex, a total fineness of 7200 dtex, and a substantially circular cross section is used. A precursor fiber was obtained. Table 2 shows the crystal region size of the obtained acrylonitrile-based precursor fiber. FIG. 4 shows the relationship between the crystal region size and the total stretching ratio.

得られた前駆体繊維を実施例1と同じ条件で焼成、電解処理を行い、炭素繊維を得た。ストランド強度、弾性率、ねじり強度、弾性率の結果は表3にまとめた。実施例では引っ張り強度及びねじり物性の優れた炭素繊維が得られた。 The obtained precursor fiber was fired and electrolyzed under the same conditions as in Example 1 to obtain a carbon fiber. Table 3 summarizes the results of the strand strength, elastic modulus, torsional strength, and elastic modulus. In the examples, carbon fibers excellent in tensile strength and torsion properties were obtained.

実施例6、比較例6

アクリロニトリル98%、メタクリル酸2%で共重合したアクリル系共重合体を、ジメチルホルムアミドに溶解して紡糸原液(重合体濃度23%、原液温度60℃)を調整した。この紡糸原液を、直径0.075mm、孔数6000の口金を用いて、温度30℃、濃度50%のジメチルホルムアミド水溶液に吐出し凝固糸とした。

Example 6, Comparative Example 6

An acrylic copolymer copolymerized with 98% acrylonitrile and 2% methacrylic acid was dissolved in dimethylformamide to prepare a spinning stock solution (polymer concentration 23%,

この凝固糸を、先の例と同様に0.5倍ごとに延伸倍率を高くしていき6.0倍までの全12条件で70℃、90℃、95℃の3段の温水中湿熱延伸を施し、続いて各条件の湿熱延伸糸をアミノシリコン系油剤1%水溶液中に浸漬し、180℃の加熱ローラーにて乾燥緻密化した。各データを採った所、膨潤度の最大点、平均細孔半径の最大点及び乾燥緻密化後糸の配向度の飽和点はいずれも湿熱延伸倍率3.5倍であった。これらの結果から、湿熱延伸倍率を2.0倍、5.0倍に設定したものをそれぞれ実施例6、比較例6とした。続いて0.25MPaの加圧水蒸気中で延伸倍率が合計10倍になるように延伸を施して、単糸繊度が0.8dtex、トータル繊度が4800dtex、断面形状がほぼ円形のアクリロニトリル系前駆体繊維を得た。得られたアクリロニトリル系前駆体繊維の結晶領域サイズは表2のようになった。結晶領域サイズとトータル延伸倍率の関係を図4に示す。 This coagulated yarn is stretched by 0.5 times in the same manner as in the previous example, and stretched in hot water in three stages of 70 ° C., 90 ° C., and 95 ° C. under all 12 conditions up to 6.0 times. Then, the wet heat drawn yarn under each condition was immersed in a 1% aqueous solution of an aminosilicone-based oil agent, and dried and densified with a heating roller at 180 ° C. When each data was taken, the maximum point of the degree of swelling, the maximum point of the average pore radius, and the saturation point of the degree of orientation of the dried and densified yarn were all 3.5 times the wet heat draw ratio. From these results, those in which the wet heat stretching ratio was set to 2.0 times and 5.0 times were designated as Example 6 and Comparative Example 6, respectively. Subsequently, it is stretched in a pressurized steam of 0.25 MPa so that the stretching ratio becomes a total of 10 times, and an acrylonitrile-based precursor fiber having a single-fiber fineness of 0.8 dtex, a total fineness of 4800 dtex, and a substantially circular cross section is obtained. Obtained. Table 2 shows the crystal region size of the obtained acrylonitrile-based precursor fiber. FIG. 4 shows the relationship between the crystal region size and the total stretching ratio.

得られた前駆体繊維を実施例1と同じ条件で焼成、電解処理を行い、炭素繊維を得た。ストランド強度、弾性率、ねじり強度、弾性率の結果は表3にまとめた。実施例では引っ張り強度及びねじり物性の優れた炭素繊維が得られた。 The obtained precursor fiber was fired and electrolyzed under the same conditions as in Example 1 to obtain a carbon fiber. Table 3 summarizes the results of the strand strength, elastic modulus, torsional strength, and elastic modulus. In the examples, carbon fibers excellent in tensile strength and torsion properties were obtained.

実施例7、比較例7

実施例1と同じ紡糸原液を、直径0.045mm、孔数6000の口金を用いて、温度35℃、濃度65%のジメチルアセトアミド水溶液に吐出し凝固糸とした。

Example 7, Comparative Example 7

The same spinning dope as in Example 1 was discharged into a dimethylacetamide aqueous solution having a temperature of 35 ° C. and a concentration of 65% using a die having a diameter of 0.045 mm and a number of holes of 6000, to obtain a coagulated yarn.

この凝固糸を、同様に0.5倍ごとに延伸倍率を高くしていき6.0倍までの全12条件で70℃、90℃、95℃の3段の温水中湿熱延伸を施し、続いて各条件の湿熱延伸糸をアミノシリコン系油剤1.5%水溶液中に浸漬し、180℃の加熱ローラーにて乾燥緻密化した。各データを採った所、膨潤度の最大点、平均細孔半径の最大点及び乾燥緻密化後糸の配向度の飽和点はそれぞれ湿熱延伸倍率3.5倍、3.5倍及び4.0倍であった。これらの結果から、湿熱延伸倍率を2.5倍、5.0倍に設定したものをそれぞれ実施例7、比較例7とした。続いて180℃に加熱した熱ロール間で延伸倍率が合計7倍になるように延伸を施して、単糸繊度が1.2dtex、トータル繊度が7200dtex、断面形状が空豆形のアクリロニトリル系前駆体繊維を得た。得られたアクリロニトリル系前駆体繊維の結晶領域サイズは表2のようになった。結晶領域サイズとトータル延伸倍率の関係を図4に示す。 This coagulated yarn is similarly stretched by a factor of 0.5, and subjected to wet heat stretching in three stages of 70 ° C., 90 ° C. and 95 ° C. in all 12 conditions up to 6.0 times, followed by The wet-heat drawn yarn under each condition was immersed in a 1.5% aqueous solution of an aminosilicone oil agent, and dried and densified with a heating roller at 180 ° C. When each data was taken, the maximum point of the degree of swelling, the maximum point of the average pore radius, and the saturation point of the degree of orientation of the dried and densified yarn were 3.5 times, 3.5 times and 4.0 times the wet heat draw ratio, respectively. It was twice. From these results, those in which the wet heat stretching ratio was set to 2.5 times and 5.0 times were designated as Example 7 and Comparative Example 7, respectively. Subsequently, the acrylonitrile-based precursor fiber having a single fiber fineness of 1.2 dtex, a total fineness of 7200 dtex, and a cross-sectional shape of bean-bean-shaped is drawn by applying a drawing ratio of 7 times between hot rolls heated to 180 ° C. Got. Table 2 shows the crystal region size of the obtained acrylonitrile-based precursor fiber. FIG. 4 shows the relationship between the crystal region size and the total stretching ratio.

得られた前駆体繊維を実施例4と同じ条件で焼成、電解処理を行い、炭素繊維を得た。ストランド強度、弾性率、ねじり強度、弾性率の結果は表3にまとめた。実施例では引っ張り強度及びねじり物性の優れた炭素繊維が得られた。 The obtained precursor fiber was fired and electrolyzed under the same conditions as in Example 4 to obtain a carbon fiber. Table 3 summarizes the results of the strand strength, elastic modulus, torsional strength, and elastic modulus. In the examples, carbon fibers excellent in tensile strength and torsion properties were obtained.

Claims (7)

湿熱延伸倍率の値を、湿熱延伸糸膨潤度が最大値あるいは飽和に達する延伸倍率以下にすることを特徴とする炭素繊維用アクリロニトリル系前駆体繊維の製造方法。 A spinning step of spinning a stock spinning solution containing a solvent and an acrylonitrile-based polymer dissolved in the solvent to obtain a coagulated yarn, a wet heat drawing step of wet and heat drawing the coagulated yarn, an oil treatment step of oil treating the drawn yarn, A method for producing an acrylonitrile-based precursor fiber for carbon fiber, comprising a dry densification step of drying and densifying the oil-treated yarn,

A method for producing an acrylonitrile-based precursor fiber for carbon fiber, wherein the value of the wet heat draw ratio is not more than the draw ratio at which the wet heat drawn yarn swelling reaches the maximum value or saturation.

湿熱延伸倍率の値を、湿熱延伸糸の平均細孔半径が最大値あるいは飽和に達する延伸倍率以下にすることを特徴とする炭素繊維用アクリロニトリル系前駆体繊維の製造方法。 A spinning step of spinning a stock spinning solution containing a solvent and an acrylonitrile-based polymer dissolved in the solvent to obtain a coagulated yarn, a wet heat drawing step of wet and heat drawing the coagulated yarn, an oil treatment step of oil treating the drawn yarn, A method for producing an acrylonitrile-based precursor fiber for carbon fiber, comprising a dry densification step of drying and densifying the oil-treated yarn,

A method for producing an acrylonitrile-based precursor fiber for carbon fiber, wherein the value of the wet heat draw ratio is not more than the draw ratio at which the average pore radius of the wet heat drawn yarn reaches the maximum value or saturation.

湿熱延伸倍率の値を、乾燥緻密化直後の繊維配向度が最大値あるいは飽和に達する延伸倍率以下にすることを特徴とする炭素繊維用アクリロニトリル系前駆体繊維の製造方法。 A spinning step of spinning a stock spinning solution containing a solvent and an acrylonitrile-based polymer dissolved in the solvent to obtain a coagulated yarn, a wet heat drawing step of wet and heat drawing the coagulated yarn, an oil treatment step of oil treating the drawn yarn, A method for producing an acrylonitrile-based precursor fiber for carbon fiber, comprising a dry densification step of drying and densifying the oil-treated yarn,

A method for producing an acrylonitrile precursor fiber for carbon fiber, wherein the value of the wet heat draw ratio is not more than the draw ratio at which the fiber orientation degree immediately after dry densification reaches the maximum value or reaches saturation.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003315501A JP2004183194A (en) | 2002-11-22 | 2003-09-08 | Carbon fiber bundle, acrylonitrile-based precursor fiber to the carbon fiber and method for producing the same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002339420 | 2002-11-22 | ||

| JP2003315501A JP2004183194A (en) | 2002-11-22 | 2003-09-08 | Carbon fiber bundle, acrylonitrile-based precursor fiber to the carbon fiber and method for producing the same |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006258806A Division JP4446991B2 (en) | 2002-11-22 | 2006-09-25 | Method for producing acrylonitrile-based precursor fiber for carbon fiber |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2004183194A true JP2004183194A (en) | 2004-07-02 |

| JP2004183194A5 JP2004183194A5 (en) | 2006-10-26 |

Family

ID=32774699

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003315501A Pending JP2004183194A (en) | 2002-11-22 | 2003-09-08 | Carbon fiber bundle, acrylonitrile-based precursor fiber to the carbon fiber and method for producing the same |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2004183194A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007018136A1 (en) * | 2005-08-09 | 2007-02-15 | Toray Industries, Inc. | Flame-resistant fiber, carbon fiber, and processes for the production of both |

| JP2011038202A (en) * | 2009-08-10 | 2011-02-24 | Mitsubishi Rayon Co Ltd | Carbon fiber precursor fiber bundle, method for producing the same, and carbon fiber bundle |

| WO2013015210A1 (en) * | 2011-07-22 | 2013-01-31 | 三菱レイヨン株式会社 | Polyacrylonitrile-based copolymer, polyacrylonitrile-based precursor fiber for carbon fiber, carbon fiber bundles, process for producing flameproofed fiber bundles, and process for producing carbon fiber bundles |

| TWI408267B (en) * | 2010-03-19 | 2013-09-11 | ||

| CN114262496A (en) * | 2022-01-14 | 2022-04-01 | 福建优安纳伞业科技有限公司 | Preparation method of carbon fiber resin matrix composite material for umbrella ribs |

| CN114481349A (en) * | 2020-10-26 | 2022-05-13 | 中国石油化工股份有限公司 | Preparation method of high-strength alkali-resistant polyacrylonitrile fiber and polyacrylonitrile fiber |

-

2003

- 2003-09-08 JP JP2003315501A patent/JP2004183194A/en active Pending

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI406983B (en) * | 2005-08-09 | 2013-09-01 | Toray Industries | Flame resistance, carbon fiber and method for producing the same |

| JPWO2007018136A1 (en) * | 2005-08-09 | 2009-02-19 | 東レ株式会社 | Flame resistant fiber, carbon fiber and method for producing them |

| US7976945B2 (en) | 2005-08-09 | 2011-07-12 | Toray Industires, Inc. | Flame resistant fiber, carbon fiber and production method thereof |

| WO2007018136A1 (en) * | 2005-08-09 | 2007-02-15 | Toray Industries, Inc. | Flame-resistant fiber, carbon fiber, and processes for the production of both |

| JP2011038202A (en) * | 2009-08-10 | 2011-02-24 | Mitsubishi Rayon Co Ltd | Carbon fiber precursor fiber bundle, method for producing the same, and carbon fiber bundle |

| TWI408267B (en) * | 2010-03-19 | 2013-09-11 | ||

| WO2013015210A1 (en) * | 2011-07-22 | 2013-01-31 | 三菱レイヨン株式会社 | Polyacrylonitrile-based copolymer, polyacrylonitrile-based precursor fiber for carbon fiber, carbon fiber bundles, process for producing flameproofed fiber bundles, and process for producing carbon fiber bundles |

| JP5565467B2 (en) * | 2011-07-22 | 2014-08-06 | 三菱レイヨン株式会社 | Polyacrylonitrile-based copolymer, polyacrylonitrile-based precursor fiber for carbon fiber, carbon fiber bundle, method for producing flame-resistant fiber bundle, and method for producing carbon fiber bundle |

| JPWO2013015210A1 (en) * | 2011-07-22 | 2015-02-23 | 三菱レイヨン株式会社 | Polyacrylonitrile-based copolymer, polyacrylonitrile-based precursor fiber for carbon fiber, carbon fiber bundle, method for producing flame-resistant fiber bundle, and method for producing carbon fiber bundle |

| US10017881B2 (en) | 2011-07-22 | 2018-07-10 | Mitsubishi Chemical Corporation | Polyacrylonitrile-based copolymer, polyacrylonitrile-based precursor fiber for carbon fiber, carbon fiber bundles, process for producing stabilized fiber bundles, and process for producing carbon fiber bundles |

| CN114481349A (en) * | 2020-10-26 | 2022-05-13 | 中国石油化工股份有限公司 | Preparation method of high-strength alkali-resistant polyacrylonitrile fiber and polyacrylonitrile fiber |

| CN114481349B (en) * | 2020-10-26 | 2024-01-30 | 中国石油化工股份有限公司 | Preparation method of high-strength alkali-resistant polyacrylonitrile fiber and polyacrylonitrile fiber |

| CN114262496A (en) * | 2022-01-14 | 2022-04-01 | 福建优安纳伞业科技有限公司 | Preparation method of carbon fiber resin matrix composite material for umbrella ribs |

| CN114262496B (en) * | 2022-01-14 | 2023-11-28 | 福建优安纳伞业科技有限公司 | Preparation method of carbon fiber resin matrix composite material for umbrella ribs |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5765420B2 (en) | Carbon fiber bundle and method for producing carbon fiber | |

| JP7225173B2 (en) | Manufacture of intermediate modulus carbon fiber | |

| WO2013157613A1 (en) | Carbon fiber bundle and method of producing carbon fiber bundle | |

| JP4446991B2 (en) | Method for producing acrylonitrile-based precursor fiber for carbon fiber | |

| JP2004183194A (en) | Carbon fiber bundle, acrylonitrile-based precursor fiber to the carbon fiber and method for producing the same | |

| JPH086210B2 (en) | High-strength and high-modulus carbon fiber and method for producing the same | |

| JP2011017100A (en) | Method for producing carbon fiber | |

| JPH04257313A (en) | Production of precursor fiber for carbon fiber | |

| JP2004232155A (en) | Light-weight polyacrylonitrile-based carbon fiber and method for producing the same | |

| JP2004156161A (en) | Polyacrylonitrile-derived carbon fiber and method for producing the same | |

| JPH0615722B2 (en) | Method for producing acrylic fiber for producing carbon fiber | |

| JP2021139062A (en) | Production method of carbon fiber bundle | |

| JP2007321267A (en) | Method for producing polyacrylonitrile-based fiber and carbon fiber | |

| JP2004060126A (en) | Carbon fiber and method for producing the same | |

| JP3964011B2 (en) | Acrylonitrile-based precursor fiber for carbon fiber and method for producing the same | |

| JP5842343B2 (en) | Method for producing carbon fiber precursor acrylic fiber bundle | |

| JPS6317929B2 (en) | ||

| KR870000534B1 (en) | Carbon fiber and it's making method | |

| JP2011213774A (en) | Polyacrylonitrile for producing carbon fiber, polyacrylonitrile-based precursor fiber, and method for producing carbon fiber | |

| JP6881090B2 (en) | Carbon fiber bundle | |

| JP2005248358A (en) | Precursor fiber for carbon fiber | |

| JP2006233360A (en) | Carbon fiber and method for producing the carbon fiber | |

| JP5892455B2 (en) | Acrylonitrile precursor fiber for carbon fiber and method for producing the same | |

| JPH01321913A (en) | Acrylic precursor fiber for carbon fiber | |

| JPS6156328B2 (en) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060905 |

|

| A621 | Written request for application examination |

Effective date: 20060905 Free format text: JAPANESE INTERMEDIATE CODE: A621 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20081104 |

|

| A131 | Notification of reasons for refusal |

Effective date: 20081203 Free format text: JAPANESE INTERMEDIATE CODE: A131 |

|

| A521 | Written amendment |

Effective date: 20090123 Free format text: JAPANESE INTERMEDIATE CODE: A523 |

|

| A02 | Decision of refusal |

Effective date: 20091007 Free format text: JAPANESE INTERMEDIATE CODE: A02 |