EP4240905B1 - Segment für rauchartikel mit kalandrierter faserbahn - Google Patents

Segment für rauchartikel mit kalandrierter faserbahn Download PDFInfo

- Publication number

- EP4240905B1 EP4240905B1 EP23701682.9A EP23701682A EP4240905B1 EP 4240905 B1 EP4240905 B1 EP 4240905B1 EP 23701682 A EP23701682 A EP 23701682A EP 4240905 B1 EP4240905 B1 EP 4240905B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- segment

- calendered

- fibrous web

- filter

- fibers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/52—Incorporating filters or mouthpieces into a cigarette rod or a tobacco rod

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/04—Tobacco smoke filters characterised by their shape or structure

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/062—Use of materials for tobacco smoke filters characterised by structural features

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/062—Use of materials for tobacco smoke filters characterised by structural features

- A24D3/063—Use of materials for tobacco smoke filters characterised by structural features of the fibers

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/08—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent

- A24D3/10—Use of materials for tobacco smoke filters of organic materials as carrier or major constituent of cellulose or cellulose derivatives

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24D—CIGARS; CIGARETTES; TOBACCO SMOKE FILTERS; MOUTHPIECES FOR CIGARS OR CIGARETTES; MANUFACTURE OF TOBACCO SMOKE FILTERS OR MOUTHPIECES

- A24D3/00—Tobacco smoke filters, e.g. filter-tips, filtering inserts; Filters specially adapted for simulated smoking devices; Mouthpieces for cigars or cigarettes

- A24D3/06—Use of materials for tobacco smoke filters

- A24D3/14—Use of materials for tobacco smoke filters of organic materials as additive

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H13/00—Pulp or paper, comprising synthetic cellulose or non-cellulose fibres or web-forming material

- D21H13/02—Synthetic cellulose fibres

- D21H13/04—Cellulose ethers

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H13/00—Pulp or paper, comprising synthetic cellulose or non-cellulose fibres or web-forming material

- D21H13/02—Synthetic cellulose fibres

- D21H13/06—Cellulose esters

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H13/00—Pulp or paper, comprising synthetic cellulose or non-cellulose fibres or web-forming material

- D21H13/02—Synthetic cellulose fibres

- D21H13/08—Synthetic cellulose fibres from regenerated cellulose

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H25/00—After-treatment of paper not provided for in groups D21H17/00 - D21H23/00

- D21H25/08—Rearranging applied substances, e.g. metering, smoothing; Removing excess material

- D21H25/12—Rearranging applied substances, e.g. metering, smoothing; Removing excess material with an essentially cylindrical body, e.g. roll or rod

- D21H25/14—Rearranging applied substances, e.g. metering, smoothing; Removing excess material with an essentially cylindrical body, e.g. roll or rod the body being a casting drum, a heated roll or a calender

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H5/00—Special paper or cardboard not otherwise provided for

- D21H5/12—Special paper or cardboard not otherwise provided for characterised by the use of special fibrous materials

- D21H5/14—Special paper or cardboard not otherwise provided for characterised by the use of special fibrous materials of cellulose fibres only

- D21H5/16—Tobacco or cigarette paper

Definitions

- the invention relates to a segment of a smoking article, wherein the segment comprises a filter material that allows the properties of the segment, in particular draw resistance and filtration efficiency, to be easily and reliably adjusted over a wide range.

- the filter material of the segment comprises a calendered fiber web with special properties.

- Smoking articles are typically rod-shaped articles consisting of at least two consecutively arranged rod-shaped segments.

- One segment contains a material capable of forming an aerosol when heated, and at least one other segment contains a material designed to influence the properties of the aerosol.

- the smoking article may be a filter cigarette, in which a first segment contains the aerosol-forming material, in particular tobacco, and a further segment, designed as a filter, serves to filter the aerosol.

- the aerosol is generated by burning the aerosol-forming material, and the filter primarily serves to filter the aerosol and provide the filter cigarette with a defined draw resistance.

- the smoking article can also be a so-called tobacco heater, in which the aerosol-forming material is only heated but not burned. This reduces the number and quantity of harmful substances in the aerosol.

- a smoking article also consists of at least two, but more often of more, in particular four, segments.

- One segment contains the aerosol-forming material, which typically includes tobacco, reconstituted tobacco, tobacco prepared using other methods, or nicotine and glycerol or propylene glycol.

- Other, sometimes optional, segments in the tobacco heater serve to conduct the aerosol, cool the aerosol, or filter the aerosol.

- the segments are usually wrapped in a wrapping material. Paper is often used as the wrapping material.

- DE 197 53195 A1 discloses a filter for tobacco products, in particular cigarettes, which is made from a cellulose fleece produced by an air-laid process.

- DE 199 51062 A1 discloses a cigarette filter with mechanical disintegrability based on continuous cellulose ester fibers.

- the special feature of this cigarette filter is that the acetate weight/draw resistance ratio, based on the filament titer, exceeds a predetermined threshold.

- US$3,346,682 discloses methods for producing a material for filtering tobacco smoke, in which a crystalline synthetic polymer is spun through a nozzle to to form a strand, the strand is intercepted as it exits the die by an oscillating surface arranged at an angle to the direction of travel of the strand to spread the strand into a web and direct the web downwards to a moving collecting surface, collecting the web on the collecting surface in overlapping, multi-directionally intersecting layers to form a sheet, calendering the sheet, cutting the pressed sheet into ribbons, feeding a ribbon into a gas jet, injecting a gas stream onto the plane of the ribbon and at an angle of between about 10° and 45° thereto to increase the cross-sectional area of the ribbon by at least five times and reduce its density, and collecting the bulked ribbon.

- the invention is based on the object of providing a segment of a smoking article or for a smoking article whose draw resistance and filtration efficiency can be easily and reliably adjusted largely independently of each other and which is superior to conventional segments in this respect.

- a further object of the invention is to provide a readily biodegradable segment for smoking articles.

- a segment of a smoking article which comprises a wrapping material and a filter material, wherein the wrapping material wraps the filter material and the filter material is formed to at least 10% and at most 100% of its mass by a calendered fibrous web, and wherein at least 50% and at most 100% of the mass of the calendered fibrous web is formed by organic polymer fibers and wherein the calendered fibrous web has a compression factor of at least 0.45 and at most 0.85, wherein the compression factor is the ratio between the density of the calendered fibrous web and the volume-weighted density of the components of the calendered fibrous web.

- the skilled person would like the filter material in a segment of a smoking article to have a porous structure with a low density in order to provide the aerosol flowing through the segment with a sufficient surface area so that components of the aerosol can be efficiently filtered.

- the relationship between draw resistance and filtration efficiency is examined separately, and the type and mass of filter material in the segment are determined for the desired parameters.

- other aspects also play a role, in particular the hardness of the segment, which is determined primarily by the mass of the filter material and partly by the wrapping material.

- it has proven difficult to achieve low draw resistance and low filtration efficiency with sufficient hardness.

- a calendered fiber web as a component of the segment in a smoking article can solve this problem.

- a person skilled in the art would not consider a calendered fiber web for use as a filter material in a generic segment because they would assume that calendering would compact the fiber web, smooth and seal the surface, and thus create a non-porous structure that has very little filtration efficiency and makes such a fiber web unsuitable for segments in smoking articles.

- calendered fiber webs are suitable as a filter material for such segments if they are calendered such that their compression factor lies within the range according to the invention.

- the surprising effect is that the tensile strength of a segment made from it is comparatively low, but the filtration efficiency is nevertheless in the medium range.

- the filtration efficiency is virtually independent of the tensile strength and the mass of the calendered fiber web in the segment and constant.

- a calendered fiber web with the compression factor according to the invention therefore allows the tensile strength or hardness of the segment to be adjusted without changing the filtration efficiency. This is not possible to the same extent with the filter materials available in the prior art.

- the compression factor is the ratio of the density of the calendered fiber web to the volume-weighted density of the components of the calendered fiber web. This ratio essentially describes how strongly the fiber web is compressed.

- a compression factor of 1 represents maximum compression, meaning there is no pore volume in the calendered fiber web, while lower compression factors still retain pore volume in the calendered fiber web.

- the basis weight can be determined according to ISO 536:2019 and the thickness according to ISO 534:2011.

- the compression factor C must be at least 0.45 and at most 0.85. Calculating the compression factor C does not require the totality of all components. It is sufficient if the components used for the calculation together account for at least 90% of the mass of the calendered fiber web. Exemplary calculations of the compression factor are presented below.

- a calendered fiber web exhibits a filtration efficiency in the mid-range and why, in the compression factor range according to the invention, the tensile resistance is decoupled from the filtration efficiency.

- the compression factor of the calendered fiber web is the essential criterion for achieving the inventive effect. It can also be assumed that the porous structure and surface of the calendered fiber web created by calendering to the compression factor according to the invention are important.

- the segment according to the invention comprises a filter material, wherein at least 10% and at most 100% of the mass of the filter material is formed by a calendered fiber web.

- the calendered fiber web allows the tensile strength and filtration efficiency to be adjusted independently of one another. For example, the proportion of the calendered fiber web in the filter material can be increased to increase the tensile strength but leave the filtration efficiency unchanged. Therefore, at least 20% and at most 90% of the Mass of the filter material is formed by the calendered fiber web, and more preferably at least 25% and at most 75% of the mass of the filter material. In some embodiments, the proportion of the calendered fiber web in the filter material is rather high, amounting to at least 30% and at most 100% of the mass of the filter material.

- the compression factor of the calendered fiber web is essential for the segment according to the invention because, according to the inventors' findings, the tensile resistance and the filtration efficiency are decoupled only for a specific compression factor interval.

- the compression factor of the calendered fiber web is preferably at least 0.50 and at most 0.80, and particularly preferably at least 0.55 and at most 0.75.

- the inventors' investigations show that tensile resistance and filtration efficiency are decoupled from each other; however, the calendering process can be carried out particularly efficiently within the preferred compression factor intervals.

- the fiber web which forms at least part of the filter material, is calendered.

- This can mean that the fiber web has passed through at least one roll nip during its production, in which mechanical pressure is exerted on the fiber web, thereby compressing and smoothing it.

- the mechanical pressure and the number of roll nips can be selected such that the compression factor of the calendered fiber web lies within the range according to the invention.

- the rollers forming the roll nip can be heated and/or the moisture content of the fiber web can be adjusted before calendering.

- the moisture content of the fiber web is increased during calendering compared to the equilibrium state of a dry fiber web in order to achieve a compression factor according to the invention.

- the person skilled in the art is able to adjust further parameters of the calendering process based on the properties of the fiber web so that the desired compression factor is achieved.

- This calendering process must be distinguished from other processes, such as those in a size press or a coating unit, in which substances are applied to the surface of a fiber web.

- the fiber web may also pass through a roll nip, no significant pressure is exerted on the fiber web, so the fiber web is not compressed or is only slightly compressed, and the compression factor according to the invention is not achieved.

- the calendered fiber web comprises organic polymer fibers.

- Organic polymer fibers are fibers consisting of polymers whose main chain contains carbon atoms.

- Polymer fibers are, in principle, suitable for forming and calendering a fiber web, so that the invention can be realized with them.

- Inorganic fibers such as glass fibers, metal fibers or mineral fibers and fibers made of inorganic polymers such as polysiloxanes are not included in the invention.

- the biodegradability of the calendered fiber web can be improved or even enabled by the selection of organic polymer fibers. Since smoking articles are often disposed of in the environment after use, it is important that the segments that make up the smoking article are readily biodegradable.

- the organic polymer fibers are therefore preferably fibers made from biopolymers.

- Biopolymers are polymers that are synthesized by living organisms or are chemically identical to polymers synthesized by living organisms. Modified polymers synthesized or synthesizable by living organisms are also biopolymers within the meaning of this invention.

- Synthetic polymers such as polyethylene or polypropylene, for example, are not biopolymers and are therefore less preferred but are in accordance with the invention.

- at least 80% by weight, particularly preferably at least 90% by weight, and ideally all of the organic polymer fibers mentioned are fibers made from biopolymers.

- the organic polymer fibers are fibers made from cellulose-based biopolymers.

- fibers made from cellulose-based biopolymers are cellulose fibers, fibers made from regenerated cellulose, and fibers made from cellulose acetate.

- fibers made from polylactides which are a biopolymer but not a cellulose-based biopolymer and are less biodegradable than, for example, cellulose fibers.

- fibers made from cellulose acetate which are a cellulose-based biopolymer but are even less biodegradable than fibers made from polylactides.

- the said fibers made of biopolymers are pulp fibers, fibers made of regenerated cellulose or a mixture thereof.

- the said organic polymer fibers are cellulose fibers obtained from coniferous trees, deciduous trees, or other plants such as hemp, flax, jute, ramie, kenaf, kapok, coconut, abaca, sisal, bamboo, cotton, or esparto grass, or a mixture of cellulose fibers from two or more of these trees or plants.

- the cellulose fibers can be obtained from exactly one of the above-mentioned sources. It can be either a mixture of pulp fibers obtained from two or more of the above-mentioned sources. In addition to optimal biodegradability, the fibers are also available in consistent quality and large quantities.

- the proportion of organic polymer fibers in the calendered fiber web can vary. According to the invention, it is at least 50% and at most 100% of the mass of the calendered fiber web in order to impart strength to the fiber web favorable for further processing. However, the proportion of organic polymer fibers in the mass of the calendered fiber web is preferably higher, amounting to at least 60% and at most 100%, and particularly preferably at least 70% and at most 95%. A higher proportion of organic polymer fibers allows the fiber web to be calendered with less pressure in order to achieve the compression factor according to the invention.

- the calendered fibrous web contains less than 40%, more preferably less than 30%, and most preferably less than 20% cellulose acetate fibers, with the percentages referring to the mass of the calendered fibrous web.

- the calendered fibrous web is free of cellulose acetate fibers.

- the calendered fibrous web may contain filler.

- Filler creates a porous structure in the fibrous web and is generally not very compressible, so calendering the fibrous web requires higher pressure to achieve the desired compression factor.

- the filler content is therefore preferably at least 0% and at most 50% of the mass of the calendered fibrous web, more preferably at least 0% and at most 30%, and most preferably at least 0% and at most 5%, each based on the mass of the calendered fibrous web.

- the filler can be useful for increasing the whiteness of the fibrous web. This can be particularly important if the segment made from it is located at one end of the smoking article and its cross-sectional area is visible.

- the filler can also be used because it is cheaper than organic polymer fibers. For these reasons, a filler content of at least 5% and at most 35% based on the mass of the calendered fibrous web is also preferred.

- the filler is selected from the group consisting of calcium carbonate, magnesium carbonate, titanium dioxide, magnesium oxide, magnesium hydroxide, aluminum hydroxide, magnesium silicate, aluminum silicate, kaolin, talc, and bentonite, or formed by a mixture of two or more of these filler types.

- the calendered fibrous web may contain additives to impart special properties to the calendered fibrous web. These additives can, for example, influence the strength in the dry or wet state, water absorption, and filtration efficiency overall or for individual substances.

- the proportion of additives in the calendered fibrous web is preferably at least 0% and at most 10% of the mass of the calendered fibrous web, more preferably at least 1% and at most 9% of the mass of the calendered fibrous web.

- the basis weight of the calendered fiber web is preferably at least 15 g/m 2 and at most 44 g/m 2 , preferably at least 20 g/m 2 and at most 40 g/m 2 , and particularly preferably at least 23 g/m 2 and at most 38 g/m 2 , in particular at least 31 g/m 2 and at most 37 g/m 2 .

- This basis weight is advantageous for facilitating the calendering of the fiber web and the further processing of the calendered fiber web into the segment of a smoking article, and it can impart favorable strength to the calendered fiber web.

- the data refer to a basis weight measured according to ISO 536:2019.

- the thickness of the calendered fiber web is preferably at least 15 ⁇ m and at most 55 ⁇ m, more preferably at least 20 ⁇ m and at most 50 ⁇ m, and most preferably at least 30 ⁇ m and at most 37 ⁇ m.

- the thickness can be measured according to ISO 534:2011 and refers to the thickness of the fiber web after calendering.

- the mechanical properties of the calendered fiber web are important for processing into a segment for a smoking article.

- the width-related tensile strength of the calendered fiber web measured according to ISO 1924-2:2008, is preferably at least 6 N/15 mm and at most 70 N/15 mm, particularly preferably at least 8 N/15 mm and at most 60 N/15 mm.

- the elongation at break of the calendered fiber web is important because when the fiber web is processed into a segment of a smoking article, the fiber web is often crimped and A particularly high elongation at break is advantageous.

- the elongation at break of the calendered fiber web measured according to ISO 1924-2:2008, is therefore preferably at least 0.8% and at most 3.0%, and particularly preferably at least 1.0% and at most 2.5%.

- Tensile strength and elongation at break may depend on the direction in which the sample was taken from the filter material for measurement. However, due to calendering, this directional dependence is minimal. The aforementioned characteristics of the calendered fiber web are met if the tensile strength or elongation at break lie within the specified preferred or particularly preferred intervals in at least one direction.

- a coating can enhance the effectiveness of calendering and achieve an even better decoupling of tensile strength and filtration efficiency, especially when the basis weight of the calendered fiber web is low.

- a coating also allows the surface of the fiber web to be modified, for example, to achieve selective filtration of certain aerosol substances.

- the coating can be applied in the form of a composition comprising the coating material and a solvent, with the solvent being removed after application, for example, by drying. Only those components of the composition that remain on the calendered fiber web are considered to be the coating.

- the calendered fibrous web is coated on at least one side, wherein the coating on at least one side covers at least 20% and at most 100% of the area of this side of the calendered fibrous web, and wherein the coating comprises a material selected from the group consisting of sizing agents, alkyl ketene dimers (AKD), alkenyl succinic anhydrides (ASA), fatty acids, starch, starch derivatives, carboxymethylcellulose, alginates, chitosan, wet strength agents, citrates, trisodium citrate, tripotassium citrate, malates, tartrates, acetates, nitrates, succinates, fumarates, gluconates, glycolates, lactates, oxylates, salicylates, ⁇ -hydroxycaprylates, phosphates, polyphosphates, chlorides, hydrogen carbonates, triacetin, propylene glycol, ethylene glycol, sorbitol, Glycerol

- the coating comprises a material selected from the group consisting of starch, starch derivatives, cellulose derivatives and Mixtures thereof.

- the coating comprises a material selected from the group consisting of starch, starch derivatives, cellulose derivatives, and mixtures thereof (i.e., the material is a mixture of two or more of these substances), and the proportion of this material in the coating is at least 20% and at most 100%, preferably at least 50% and at most 100%, more preferably at least 70% and at most 98%, and most preferably at least 80% and at most 95%, in each case based on the mass of the coating applied to the calendered fibrous web.

- only one side of the calendered fiber web is coated, and the coating covers at least 50% and at most 100% of the surface area of the coated side of the calendered fiber web, and very particularly preferably at least 90% and at most 100% of the surface area of the coated side of the calendered fiber web, in particular, if, for example, one wishes to refrain from coating the entire surface of the fiber web for technical reasons, at least 80% and at most 95% of the surface area of the coated side of the calendered fiber web.

- Such technical reasons may be that part of the calendered fiber web should remain uncoated in order to be able to determine the properties of the fiber web without the coating on the finished fiber web.

- the calendered fiber web is coated on both sides and the coating covers at least 20% and at most 100% of the area of each of the two sides of the calendered fiber web and very particularly preferably at least 50% and at most 100% of the area of each of the two sides of the calendered fiber web, in particular at least 90% and at most 100% of the area of each of the two sides of the calendered fiber web, or, if, for example, for technical reasons, one wishes to refrain from coating the fiber web over the entire area, at least 80% and at most 95% of the area of each of the two sides of the calendered fiber web.

- the amount of coating material applied to one side or both sides of the calendered fiber web is particularly preferably at least 0.5 g/m 2 and at most 5.0 g/m 2 , most preferably at least 0.7 g/m 2 and at most 4.0 g/m 2 , wherein the amount in g/m 2 refers only to the area to which the coating material is actually applied.

- the calendered fibrous web is coated on at least one side, wherein the coating on at least one side covers at least 20% and at most 100% of the area of this side of the calendered fibrous web, and the basis weight of the calendered fibrous web including coating is at least 20 g/m 2 and at most 35 g/m 2 .

- the coating comprises a material selected from the group consisting of starch, starch derivatives, cellulose derivatives, and mixtures of two or more thereof.

- the calendered fibrous web is preferably a calendered paper or a calendered nonwoven. Such preferred calendered fibrous webs can be produced using methods known in the art.

- the segment according to the invention comprises a filter material, wherein at least 10% of the mass of the filter material is formed by the calendered fiber web.

- the filter material can be formed entirely by the calendered fiber web.

- the purpose of the calendered fiber web is primarily to decouple the segment's tensile resistance from the filtration efficiency.

- at least 10% of the mass of the filter material must be formed by the calendered fiber web.

- the filter material of the segment according to the invention comprises the calendered fiber web and a further filtration material, wherein the further filtration material is preferably selected from the group consisting of filter papers, nonwovens or tows and combinations thereof.

- the additional filtration material is selected from the group consisting of filter papers, cellulose-based nonwovens, wet-needled nonwovens, tows comprising cellulose acetate, tows comprising regenerated cellulose, and combinations of two or more thereof. These additional filtration materials allow for particularly effective influence on the filtration efficiency of the segment.

- the additional filtration material is a filter paper, a cellulose-based nonwoven, a wet-needled nonwoven, or a combination of two or more of these. These additional filtration materials exhibit good biodegradability and can therefore be particularly advantageously combined with the calendered fiber web.

- the additional filtration material is web-shaped and laminated to the calendered fiber web.

- At least 10% and at most 90% and particularly preferably at least 20% and at most 70% of the mass of the filter material is formed by the further filtration material.

- the segment of a smoking article comprises a wrapping material and a filter material, wherein the wrapping material wraps the filter material and at least 70% and at most 100% of the mass of the filter material is formed by a calendered fiber web, and wherein at least 50% and at most 100% of the mass of the calendered fiber web is formed by organic polymer fibers and wherein the calendered fiber web has a compression factor of at least 0.45 and at most 0.85 and at most 30% and in particular at most 20% of the mass of the filter material is formed by cellulose acetate.

- the segment according to the invention for a smoking article comprises the filter material and a wrapping material, wherein the wrapping material wraps the filter material and is preferably a paper or a film.

- the wrapping material must be strictly distinguished from the calendered fiber web, which is a component of the filter material.

- the wrapping material of a segment for a smoking article has completely different requirements, such as processability through bonding, air permeability, color, suitability for perforation, and, in some cases, printability. Filtration properties and the effect on draw resistance are irrelevant.

- the wrapping material of the segment according to the invention preferably has a basis weight of at least 20 g/m 2 and at most 150 g/m 2 , particularly preferably of at least 30 g/m 2 and at most 130 g/m 2 .

- a wrapping material with this preferred or particularly preferred basis weight imparts a particularly advantageous hardness to the wrapped segment according to the invention, in combination with the filter material. This prevents the smoker from accidentally compressing the segment contained in the smoking article.

- the segment is cylindrical with an approximately circular or oval outer boundary of the cross-sectional area with a nominal diameter of this boundary of at least 3 mm and at most 10 mm, particularly preferably of at least 4 mm and at most 9 mm and most preferably of at least 5 mm and at most 8 mm.

- These nominal Diameters are favorable for the use of the segments according to the invention in smoking articles.

- the nominal diameter can be determined according to ISO 2971:2013.

- the segment has a length of at least 4 mm and at most 40 mm, particularly preferably of at least 6 mm and at most 35 mm and most preferably of at least 10 mm and at most 28 mm.

- the draw resistance of the segment determines, among other things, the pressure difference the smoker must apply when consuming the smoking article to generate a certain volume flow through the smoking article, and therefore significantly influences the smoker's acceptance of the smoking article.

- the draw resistance of the segment can be measured according to ISO 6565:2015 and is expressed in mm water column (mmWG). To a very good approximation, the draw resistance of the segment is proportional to the length of the segment, so the draw resistance can also be measured on rods that differ from the segment only in length. From this, the draw resistance of the segment can be easily calculated.

- the tensile resistance of the segment per length of the segment is preferably at least 0.05 mmWG/mm and at most 12.0 mmWG/mm, more preferably at least 0.1 mmWG/mm and at most 10.0 mmWG/mm and most preferably at least 0.1 mmWG/mm and at most 4.0 mmWG/mm.

- the segment typically has a substantially cylindrical shape with an approximately circular or oval outer cross-sectional area and may have one or more cavities inside it, for example to accommodate activated carbon particles or breakable capsules containing flavorings.

- the cavities may also be formed as one or more elongated tubes that run at least approximately parallel to the longitudinal axis of the segment and are located entirely within the segment or terminate at one or both end surfaces of the segment. Such cavities can also influence filtration efficiency and draw resistance.

- the direction of the longitudinal axis corresponds to the flow direction of the aerosol in the smoking article when the smoker draws on the smoking article during use.

- the segment according to the invention may also contain an aerosol-forming material, in particular a tobacco material.

- the filter rod according to the invention is cylindrical with an approximately circular or oval outer boundary of the cross-sectional area, has a length of at least 40 mm and at most 200 mm and comprises at least one segment according to the invention.

- the filter rod preferably comprises at least one segment according to the invention and at least one further segment comprising a filter material, wherein the segments are arranged one after the other in the longitudinal direction of the filter rod.

- the filter material of the further segment comprises cellulose acetate.

- the filter rod preferably comprises a plurality of segments according to the invention and a plurality of further, mutually similar segments, wherein the number of segments according to the invention and the number of further, mutually similar segments in the filter rod are the same, and one segment according to the invention and one further segment are arranged alternately one after the other in the longitudinal direction of the filter rod.

- the number of segments according to the invention and the number of further, mutually similar segments is two, three, four, five, or six, respectively.

- Such a filter rod referred to as a “dual filter” allows the advantageous properties of the segment according to the invention to be combined with another segment which, in addition to its filtration properties, also ensures a good visual appearance of the mouth end of a smoking article made from the filter rod.

- the filter rod is cylindrical with an approximately circular or oval outer boundary of the cross-sectional area and a nominal diameter of at least 3 mm and at most 10 mm, more preferably at least 4 mm and at most 9 mm, and most preferably at least 5 mm and at most 8 mm.

- the nominal diameter can be determined according to ISO 2971:2013.

- the smoking article according to the invention comprises at least two segments, wherein one of the segments is a segment according to one of the embodiments described above and at least one of the segments contains an aerosol-forming material.

- the segments according to the invention can be used particularly advantageously in smoking articles which comprise at least three segments, wherein a first segment contains an aerosol-forming material, a second segment is a segment according to one of the embodiments described above and a third segment can serve for filtration, and wherein the second segment is arranged between the first and the third segment.

- a smoking article can be manufactured, for example, from the filter rod referred to above as a "dual filter.”

- the smoking article therefore comprises at least three segments, wherein a first segment contains an aerosol-forming material, a second segment is a segment according to one of the embodiments described above, and wherein the second segment is arranged between the first and the third segment.

- the draw resistance of the third segment is higher than that of the second segment.

- the ratio of the length of the second segment to the length of the third segment is at least 1:2 and at most 5:1, particularly preferably at least 1:1 and at most 3:1. The length of the segments influences the draw resistance, so that the draw resistance can be adjusted even better by choosing the length.

- the third segment comprises a filter paper, a cellulose-based nonwoven, a wet-needled nonwoven, a tow comprising cellulose acetate or a tow comprising regenerated cellulose.

- the smoking article is a filter cigarette and the aerosol-forming material comprises tobacco.

- the segment according to the invention is particularly well suited for smoking articles in which the aerosol-forming material is only heated but not burned during intended use.

- Such smoking articles often consist of several, typically two to four, segments, with one segment containing the aerosol-forming material and the other segments containing the These segments can be used for transferring, cooling, or filtering the aerosol.

- These segments require highly varying draw resistances and filtration efficiencies, so there is a particular need for such smoking articles to be able to easily and reliably adjust the draw resistance and filtration efficiency of a segment over a wide range.

- the smoking article is therefore a smoking article in which, during its intended use, the aerosol-forming material is only heated but not burned.

- the aerosol-forming material comprises a material selected from the group consisting of tobacco, reconstituted tobacco, nicotine, glycerol, propylene glycol, and flavorings, or a mixture of two or more of these materials. Particularly preferably, the aerosol-forming material is electrically heated.

- the aerosol-forming material can also be in gel or liquid form and can preferably be contained in a container in a segment of the smoking article.

- Both the segment according to the invention and a smoking article according to the invention can be produced by methods known from the prior art.

- the densities of the components of the calendered fiber web are generally known from the state of the art. Table 1 shows some typical values. Table 1 density g/ cm3 cellulose 1.5 Regenerated cellulose 1.5 Cellulose acetate 1.3 Polylactide 1.2 - 1.4 Polyethylene 0.9 - 1.0 Polypropylen 0.9 Calcium carbonate 2.7 Titanium dioxide 4.2 talc 2.6 - 2.8

- a pulp fiber mixture consisting of 80% spruce and pine pulp fibers and 20% birch pulp fibers was used to produce the calendered fiber web.

- the spruce and pine pulp fibers were refined to a freeness of 67 °SR, measured according to ISO 5267-1:1999.

- Starch was added to the fiber web so that it consisted of approximately 95% pulp fibers and 5% starch.

- the fiber web was produced on a conventional paper machine and calendered in a calender integrated into the paper machine at elevated moisture levels.

- the tensile strength and elongation at break of the calendered fiber web A were determined according to ISO 1924-2:2008, with a value of 51.6 N/15 mm for the tensile strength in the machine direction and 1.1% for the elongation at break in the machine direction.

- the fiber web was also calendered more and less intensively, resulting in different thicknesses and compression factors, as shown below in Table 3.

- Regenerated cellulose fibers were refined to a freeness of 73°SR, measured according to ISO 5267-1:1999.

- the fibers were formed into a fiber web on a paper machine using suitable processing aids, so that the fiber web consisted of approximately 99% of its mass from regenerated cellulose fibers.

- the fiber web was calendered in a calender integrated into the paper machine at elevated moisture levels.

- the tensile strength and elongation at break of the calendered fiber web B were determined according to ISO 1924-2:2008, with a value of 61.7 N/15 mm for the tensile strength in the machine direction and 1.0% for the elongation at break in the machine direction.

- Cylindrical filter rods with a length of 108 mm and a diameter of approximately 7.1 mm were manufactured from the calendered fiber webs A and B.

- the filter material of the filter rods was formed entirely by the calendered fiber web and wrapped in a suitable wrapping material with a basis weight of 78 g/ m2 .

- the width of the fiber web used to manufacture the filter rods varied between 60 mm and 242 mm, allowing different amounts of filter material to be present in the filter rod to vary the tensile strength.

- the length of the calendered fiber web used to manufacture the filter rods was approximately 108 mm.

- Filter cigarettes were made from the 108 mm long filter rods.

- the tobacco blend of the filter cigarettes was an American Blend , and the filter cigarettes differed, within the usual production tolerances, only in the filter segment.

- the filtration efficiency for nicotine was measured.

- the filter cigarettes were smoked according to the procedure specified in ISO 3308:2012 and both the mass of nicotine exiting the mouth end (m) and the mass of nicotine contained in the filter segment (m Filter ) were determined and divided by m Filter / m + m Filter

- the filtration efficiency for nicotine is calculated. It can be expressed as a percentage and describes the ratio of the amount of nicotine retained in the filter to the amount of nicotine flowing into the filter.

- Table 2 shows the used fiber web width (W), the draw resistance (PD), and the filtration efficiency (FE) for nicotine for an 18 mm long segment made from the calendered fiber webs A and B.

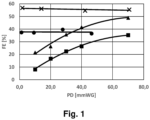

- Fig. 1 The diagram in Fig. 1 shows the draw resistance (PD) of an 18 mm long segment in mmWG on the horizontal axis and the filtration efficiency (FE) for nicotine in % on the vertical axis. Values are shown for segments made from calendered fiber web A (circles), calendered fiber web B (crosses), non-calendered filter paper (triangles), and cellulose acetate (square).

- PD draw resistance

- FE filtration efficiency

- a fiber web with the composition of fiber web A was tested at different settings of the calender, resulting in different thicknesses and densities of the calendered fiber web.

- 108 mm long filter rods were manufactured from a 40 mm and a 159 mm wide calendered fiber web and cut into 18 mm long segments.

- the draw resistance of the segments, ⁇ p 40 for the 40 mm wide fiber web and ⁇ p 159 for the 159 mm wide fiber web, and the filtration efficiency for nicotine of the segments, F 40 for the 40 mm wide fiber web and F 159 for the 159 mm wide fiber web, were determined as described above, and from this, an average rate of change in the filtration efficiency for nicotine was calculated based on the change in draw resistance by F 159 ⁇ F 40 / ⁇ p 159 ⁇ ⁇ p 40 certainly.

- Table 3 shows the thickness (D), compression factor (C), and mean rate of change of nicotine filtration efficiency ( ⁇ F/ ⁇ P).

- Table 3 shows that within a compression factor range of approximately 0.45 to approximately 0.85 for the calendered fiber web, the draw resistance and filtration efficiency for nicotine are largely decoupled. Although the average rate of change in filtration efficiency ( ⁇ F/ ⁇ P) is still low even at a compression factor above 0.85, the pressure required for calendering is already very high, so it is advantageous to select a compression factor no higher than 0.85.

- the data for the calendered fiber web B also shows that a decoupling of tensile resistance and filtration efficiency is largely occurs regardless of the composition of the calendered fiber web.

- the compression factor interval according to the invention therefore applies regardless of the composition of the fiber web.

- a fiber web with a basis weight of 23 g/ m2 was produced from a pulp fiber blend consisting of 45% spruce and pine pulp fibers and 55% eucalyptus pulp fibers.

- the spruce and pine pulp fibers were refined to a freeness of 94 °SR, measured according to ISO 5267-1:1999.

- the fiber web was produced on a conventional paper machine, then fully coated on both sides with starch in a separate coating device, and calendered in another device at elevated moisture content to obtain calendered fiber web C.

- the amount of starch applied to both sides together by the coating was approximately 1.5 g/m 2 , i.e. 6.12% of the mass of the calendered fiber web, resulting in a basis weight of 24.5 g/m 2 .

- the tensile strength and elongation at break of the calendered fiber web C were determined according to ISO 1924-2:2008, with a value of 29 N/15 mm for the tensile strength in the machine direction and 2.0% for the elongation at break in the machine direction.

- a calendered fiber web D was produced in the same way, but without coating.

- Filter rods with a length of 108 mm were produced from the calendered fiber webs, using calendered fiber web C in widths of 120 mm and 220 mm and calendered fiber web D in widths of 120 mm and 180 mm to produce four different segments.

- the length of the calendered fiber web was consistent in all In these cases, the filter rod length was approximately 108 mm.

- the filter rods were wrapped with a wrapping material with a basis weight of 78 g/ m2 .

- Table 4 shows the width (W) of the calendered fiber web, the draw resistance (PD) of an 18 mm long segment, and the filtration efficiency (FE) for nicotine.

- Table 4 Fibrous web W PD FE [mm] [mmWG] [%] C 120 5.9 29.3 C 220 22.5 30.8 D 120 2.9 35.9 D 180 6.7 37.4

- a filter cigarette F according to the invention with a length of 83 mm and a diameter of 7.8 mm was produced, consisting of three segments.

- the first segment contained an American Blend tobacco blend

- the second segment was a segment according to the invention made of the calendered fiber web C

- the third segment contained a filter paper.

- the second segment was arranged between the first and third segments, and the third segment formed the mouth end of the filter cigarette.

- the second segment was 18 mm long with a tensile strength of 22 mmWG, while the third segment was 9 mm long and had a tensile strength of 46 mmWG.

- the filter paper in the third segment was a paper consisting essentially of 100% cellulose fibers with a basis weight of 35 g/m 2 and a thickness of 88 ⁇ m.

- a filter cigarette X with a diameter of 83 mm, a diameter of 7.8 mm, an American Blend tobacco blend, and a 27 mm long filter segment made of cellulose acetate was produced.

- the filter cigarette F according to the invention and the filter cigarette X serving as a comparative example not according to the invention contained the same mass of tobacco and were ventilated by a perforation in the area of the filter, the degree of ventilation being adjusted so that both filter cigarettes had an open draw resistance of approximately 110 mmWG.

- Table 5 TPM nicotine CO PC cigarette mg/cig mg/cig mg/cig F 10.7 0.68 13.6 7.8 X 10.5 0.70 13.4 7.7

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Paper (AREA)

- Cigarettes, Filters, And Manufacturing Of Filters (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

- Nonwoven Fabrics (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102022102066.5A DE102022102066B4 (de) | 2022-01-28 | 2022-01-28 | Segment für rauchartikel mit kalandrierter faserbahn |

| PCT/EP2023/051409 WO2023144038A1 (de) | 2022-01-28 | 2023-01-20 | Segment für rauchartikel mit kalandrierter faserbahn |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4240905A1 EP4240905A1 (de) | 2023-09-13 |

| EP4240905B1 true EP4240905B1 (de) | 2025-04-09 |

Family

ID=85037074

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP23701682.9A Active EP4240905B1 (de) | 2022-01-28 | 2023-01-20 | Segment für rauchartikel mit kalandrierter faserbahn |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20250127208A1 (pl) |

| EP (1) | EP4240905B1 (pl) |

| JP (1) | JP2025503872A (pl) |

| KR (1) | KR20240141769A (pl) |

| CN (1) | CN118742688A (pl) |

| DE (1) | DE102022102066B4 (pl) |

| ES (1) | ES3033607T3 (pl) |

| PL (1) | PL4240905T3 (pl) |

| WO (1) | WO2023144038A1 (pl) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3346682A (en) * | 1962-03-16 | 1967-10-10 | Du Pont | Method for making a filtering medium from plexifilamentary material |

| DE19753195A1 (de) * | 1997-11-21 | 1999-05-27 | Reemtsma H F & Ph | Biologisch abbaubarer Filter für Cigaretten |

| DE19951062C2 (de) * | 1999-10-22 | 2002-04-04 | Rhodia Acetow Gmbh | Hochleistungs-Zigarettenfilter |

| DE102004048651A1 (de) | 2004-10-06 | 2006-04-13 | Rhodia Acetow Gmbh | Tabakrauchfilter oder -filterelemente mit einem Gehalt an Zusatzstoffen |

-

2022

- 2022-01-28 DE DE102022102066.5A patent/DE102022102066B4/de active Active

-

2023

- 2023-01-20 ES ES23701682T patent/ES3033607T3/es active Active

- 2023-01-20 CN CN202380017260.7A patent/CN118742688A/zh active Pending

- 2023-01-20 US US18/730,602 patent/US20250127208A1/en active Pending

- 2023-01-20 PL PL23701682.9T patent/PL4240905T3/pl unknown

- 2023-01-20 JP JP2024541903A patent/JP2025503872A/ja active Pending

- 2023-01-20 EP EP23701682.9A patent/EP4240905B1/de active Active

- 2023-01-20 KR KR1020247027468A patent/KR20240141769A/ko active Pending

- 2023-01-20 WO PCT/EP2023/051409 patent/WO2023144038A1/de not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| DE102022102066B4 (de) | 2025-09-04 |

| WO2023144038A1 (de) | 2023-08-03 |

| PL4240905T3 (pl) | 2025-07-21 |

| KR20240141769A (ko) | 2024-09-27 |

| CN118742688A (zh) | 2024-10-01 |

| US20250127208A1 (en) | 2025-04-24 |

| JP2025503872A (ja) | 2025-02-06 |

| ES3033607T3 (en) | 2025-08-06 |

| DE102022102066A1 (de) | 2023-08-03 |

| EP4240905A1 (de) | 2023-09-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3861159B1 (de) | Wasserstrahlverfestigtes filtermaterial für rauchartikel | |

| DE69009103T2 (de) | Nichtgewebte Faserbahn für Tabakrauchfilter. | |

| EP1796488B1 (de) | Tabakrauchfilter oder-filterelemente mit einem gehalt an zusatzstoffen | |

| DE19951062C2 (de) | Hochleistungs-Zigarettenfilter | |

| DE69414938T2 (de) | Tabakrauchfiltermaterials und Verfahren zu dessen Herstellung | |

| DE69520816T2 (de) | Tabakrauchfiltermaterial und Tabakrauchfilter hergestellt aus diesem Material | |

| DE3855848T2 (de) | Verfahren und Einrichtung zur Bildung eines Stranges für die Herstellung von Rauchartikeln | |

| EP1299012B1 (de) | Rezessfilter und rauchbarer gegenstand mit einem rezessfilter | |

| EP3970521B1 (de) | Biologisch abbaubares segment eines rauchartikels | |

| EP0885321A1 (de) | Melt-blown-vlies, verfahren zu dessen herstellung und dessen verwendungen | |

| DE102021115456A1 (de) | Filtermaterial für segmente für rauchartikel mit reduzierter kriechneigung | |

| EP4064883B1 (de) | Strukturiertes filtermaterial für nikotinabgabeprodukte | |

| DE69015185T3 (de) | Konzentrischer Rauchfilter mit Filtriermedien aus Fadenmaterial und Bahnmaterial. | |

| EP4132303B1 (de) | Wasserstrahlverfestigtes filtermaterial für rauchartikel mit verbessertem dehnungsverhalten | |

| DE2744796A1 (de) | Filtermaterial, seine herstellung und verwendung | |

| EP4240905B1 (de) | Segment für rauchartikel mit kalandrierter faserbahn | |

| DE102021115450A1 (de) | Filtermaterial für rauchartikel mit verbessertem dehnungsverhalten | |

| EP4475696B1 (de) | Filterelement für mundstücke, mundstück zur verwendung mit rauchwaren oder hnb-produkten und zigarettenfilter | |

| DE1532152C (de) | Filtermaterial für Tabakrauchfilter od. dgl. und Verfahren zu dessen Herstellung | |

| DE1532152B (de) | Filtermaterial für Tabakrauchfilter od. dgl. und Verfahren zu dessen Herstellung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20230530 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20231030 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A24D 3/04 20060101ALN20240930BHEP Ipc: D21H 13/08 20060101ALI20240930BHEP Ipc: D21H 13/06 20060101ALI20240930BHEP Ipc: D21H 13/04 20060101ALI20240930BHEP Ipc: A24D 3/14 20060101ALI20240930BHEP Ipc: A24D 3/10 20060101ALI20240930BHEP Ipc: A24D 3/06 20060101ALI20240930BHEP Ipc: D21H 25/14 20060101AFI20240930BHEP |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20241104 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC ME MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502023000817 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 3033607 Country of ref document: ES Kind code of ref document: T3 Effective date: 20250806 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20250409 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20250401389 Country of ref document: GR Effective date: 20250808 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250409 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250811 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250709 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250409 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250709 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250409 |