EP4237782B1 - Metallisches wärmeaustauscherrohr - Google Patents

Metallisches wärmeaustauscherrohr Download PDFInfo

- Publication number

- EP4237782B1 EP4237782B1 EP21797938.4A EP21797938A EP4237782B1 EP 4237782 B1 EP4237782 B1 EP 4237782B1 EP 21797938 A EP21797938 A EP 21797938A EP 4237782 B1 EP4237782 B1 EP 4237782B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- projections

- channel

- heat exchange

- ribs

- rib

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/12—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element

- F28F1/34—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending obliquely

- F28F1/36—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being only outside the tubular element and extending obliquely the means being helically wound fins or wire spirals

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F1/00—Tubular elements; Assemblies of tubular elements

- F28F1/10—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses

- F28F1/42—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being both outside and inside the tubular element

- F28F1/422—Tubular elements and assemblies thereof with means for increasing heat-transfer area, e.g. with fins, with projections, with recesses the means being both outside and inside the tubular element with outside means integral with the tubular element and inside means integral with the tubular element

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F13/18—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by applying coatings, e.g. radiation-absorbing, radiation-reflecting; by surface treatment, e.g. polishing

- F28F13/185—Heat-exchange surfaces provided with microstructures or with porous coatings

- F28F13/187—Heat-exchange surfaces provided with microstructures or with porous coatings especially adapted for evaporator surfaces or condenser surfaces, e.g. with nucleation sites

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F2215/00—Fins

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F2215/00—Fins

- F28F2215/10—Secondary fins, e.g. projections or recesses on main fins

Definitions

- the invention relates to a metallic heat exchanger tube according to the preamble of claim 1.

- DE 10 2014 002829 A1 eg discloses such a heat exchanger tube.

- Shell-and-tube heat exchangers are often used in which liquids of pure substances or mixtures evaporate on the outside of the tube and cool a brine or water on the inside of the tube.

- the size of the evaporator can be reduced significantly. This reduces the manufacturing costs of such devices.

- the required amount of coolant is reduced, which can represent a significant proportion of the total system costs in the case of the chlorine-free safety coolants that are now predominantly used.

- the high-performance pipes commonly used today are already four times more efficient than smooth pipes of the same diameter.

- the most powerful commercially available finned tubes for flooded evaporators have a fin structure on the outside of the tube with a fin density of 55 to 60 fins per inch ( US 5,669,441 A ; US 5,697,430 A ; DE 197 57 526 C1 ). This corresponds to a fin pitch of approximately 0.45 to 0.40 mm. It is also known that evaporation structures with increased performance can be created with the same fin pitch on the outside of the tube by adding additional structural elements in the area of the groove base between the ribs.

- EP 1 223 400 B1 It is proposed to create undercut secondary grooves at the groove base between the ribs, which extend continuously along the primary groove.

- the cross-section of these secondary grooves can remain constant or be varied at regular intervals.

- EP 3 111 153 B1 Another approach with higher structures starting from the groove bottom is in EP 3 111 153 B1 , revealed.

- the structures are projections in the channel that cause segmentation. By segmenting between two ribs, the channel is repeatedly interrupted in the circumferential direction, thus at least reducing or completely preventing the migration of the bubbles and heat exchange fluid that are created in the channel. An exchange of liquid and vapor along the channel is increasingly less or no longer supported by the respective additional structure.

- the invention is based on the object of developing a performance-enhanced heat exchanger tube for the evaporation of liquids on the outside of the tube.

- the invention includes a metallic heat exchanger tube with integral fins formed on the outside of the tube with a fin base, fin flanks and fin tip, wherein the fin base protrudes radially from the tube wall and a channel with a channel base is formed between the fins, in which additional structures are arranged at a distance from one another.

- the additional structures divide the channel between the fins into segments.

- the additional structures locally reduce the cross-sectional area through which the flow can pass in the channel between two fins and thereby at least limit a fluid flow in the channel during operation.

- First additional structures are projections extending radially outwards from the channel base, which are each limited in the radial direction by an end surface located between the channel base and the fin tip, whereby a radial extension of the projections is defined.

- material projections are arranged radially outwards as second additional structures, which are formed from material from the fin flanks.

- the material projections are arranged in the radial direction between a closing surface and the rib tip, so that the material projections are formed around the radial extension of the projections above the channel base on the side of the rib flank.

- the material projections extend further in the axial and radial direction than in the circumferential direction.

- These metallic heat exchanger tubes are used in particular for the evaporation of liquids from pure substances or mixtures on the outside of the tube.

- Integrally rolled Finned tubes are finned tubes in which the fins are formed from the wall material of a smooth tube.

- Typical integral fins formed on the outside of the tube are, for example, spirally circumferential and have a fin base, fin flanks and fin tip, with the fin base protruding essentially radially from the tube wall.

- the number of fins is determined by counting successive bulges in the axial direction of a tube.

- the structures according to the invention can be produced by a sharp-edged toothed rolling disk, which forms both wall material at the channel base and material on the fin flank in the axial and radial directions.

- the invention is based on the idea that in order to increase the heat transfer during evaporation, the space between the fins is segmented by additional structures. This creates local overheating in the spaces and intensifies the process of bubble boiling. The formation of bubbles then takes place primarily within the segments and begins at the nucleation points. Small gas or vapor bubbles initially form at these nucleation points. When the growing bubble has reached a certain size, it detaches from the surface. As the bubble detaches, the remaining cavity in the segment is flooded with liquid again and the cycle begins again.

- the surface can be designed in such a way that when the bubble detaches, a small bubble remains behind, which then serves as the nucleation point for a new cycle of bubble formation.

- material projections as second additional structures in the form of radially outward-facing projections in the area of the first additional structures.

- the material projections are arranged laterally on the rib flank and extend essentially in the axial and radial directions.

- the material projections are formed from material from the rib flanks during the manufacturing process using rolling, which preferably sit directly on the projections while lying radially outward.

- the fluid flow of liquid heat exchanger fluid into the neighboring segments is promoted, almost from the side. Such fluid guidance thus contributes to the formation of bubbles in the segment.

- the projections can extend between the respective rib base of neighboring ribs in the axial direction over the entire channel base or only over part of the channel base. They represent a barrier running between two ribs, starting from the channel base, which extends radially outward and at least partially closes the channel in the circumferential direction.

- material projections according to the invention which are placed on a preferably solid projection of the basic channel structure, are formed as second additional structures from material of the rib flank and essentially form a flowing transition in the radial direction to the two side surfaces of the projection below.

- These therefore represent a fluid guide structure which guides liquid fluid into the segments from the side, so to speak.

- a radially externally arranged end surface of the projections can extend over the entire channel width.

- liquid fluid can be exchanged between adjacent segments and can also pass from one segment into an adjacent segment.

- the projections with The attached material projections therefore represent a threshold for the passage of fluid.

- the material projections in the axial direction can also have a smaller extension than that of the projections arranged underneath. Due to the size, shape and orientation of the material projections, the wetting behavior of the heat exchanger fluid is primarily the cause of an increase in fluid flow.

- the contour line of the material projections, which extend essentially in the axial and radial directions, can also be curved or irregular.

- this type of segmentation of the channel between two ribs means that it is repeatedly interrupted in the circumferential direction, thus at least reducing or completely preventing the migration of the bubbles that form in the channel.

- An exchange of liquid and vapor along the channel is increasingly less or no longer supported by the respective additional structure.

- the particular advantage of the invention is that the exchange of liquid and vapor is controlled locally and the flooding of the bubble nucleation point in the segment takes place locally and in particular through the material projections from the side.

- the evaporator tube structures can be optimized in a targeted manner depending on the application parameters, thereby increasing the heat transfer. Since the temperature of the fin base is higher in the area of the groove base than at the fin tip, structural elements for intensifying the bubble formation in the groove base are particularly effective.

- the additional structures locally reduce the flow-through cross-sectional area in the channel between two ribs.

- the evaporator tube structures can be further optimized depending on the application parameters to increase the heat transfer.

- the projections and the material protrusions can locally reduce the cross-sectional area through which the flow can pass in the channel between two ribs by at least 30%.

- the segments are locally sufficiently delimited for fluid to pass through.

- the channel section between two segments is thus sufficiently or largely separated from adjacent channel sections on the fluid side.

- the projections and the material protrusions can locally reduce the flow-through cross-sectional area in the channel between two ribs by 40 to 70%.

- the channel section between two segments forms a significant threshold on the fluid side compared to adjacent channel sections.

- the channel can be closed off radially to the outside except for individual local openings.

- the ribs can have a substantially T-shaped or ⁇ -shaped cross-section, whereby the channel between the ribs is closed off except for pores as local openings. The vapor bubbles created in the evaporation process can escape through these openings. The deformation of the rib tips takes place using methods that can be taken from the state of the art.

- the rib tips can also be folded in the axial direction or even be shaped to a certain extent towards the channel base.

- the channel can therefore also consist of a combination of several complementary structural elements from below and the side and/or from above can be tapered to the desired extent until completely closed. In any case, in such a way that the channel between the ribs is divided into discrete segments.

- the local openings are designed in such a way that liquid medium can also pass through and flow into the channel section. In order for the evaporation process to be maintained at a local opening, the same amounts of liquid and vapor must therefore be transported through the opening in opposite directions. Liquids that wet the pipe material well are usually used. Due to the capillary effect, such a liquid can penetrate into the channels through any opening in the outer pipe surface, even against excess pressure.

- the ratio of the number of local openings to the number of segments can be 1:1 to 6:1. More preferably, this ratio can be 1:1 to 3:1.

- the channels between the ribs are essentially closed by material from the upper rib regions, with the resulting cavities of the channel segments being connected to the surrounding space by openings.

- These openings can also be used as pores which can be the same size or in two or more size classes.

- pores with two size classes can be particularly suitable. According to a regular, repeating pattern, for example, every small opening follows a large opening along the channels. This structure creates a directed flow in the channels.

- Liquid is preferentially drawn in through the small pores with the help of capillary pressure and wets the channel walls, creating thin films.

- the vapor collects in the center of the channel and escapes at the points with the lowest capillary pressure.

- the large pores must be dimensioned so that the vapor can escape quickly enough without the channels drying out.

- the size and frequency of the vapor pores in relation to the smaller liquid pores must then be coordinated.

- the projections can be formed as first additional structures at least from material of the channel base between two integrally surrounding ribs. This maintains a material-locking connection for good heat exchange from the pipe wall to the respective structural elements.

- a projection can also consist of material from the rib flank. Segmenting the channel from a uniform material of the channel base is particularly favorable for the evaporation process.

- the projections as the first additional structures can have a height of between 0.15 and 1 mm. This dimensioning of the additional structures is particularly well suited to the high-performance finned tubes and expresses the fact that the structural sizes of the external structures are preferably in the submillimeter to millimeter range.

- the projections can advantageously have asymmetrical shapes.

- the asymmetry of the structures appears in a cutting plane that runs perpendicular to the longitudinal axis of the pipe.

- Asymmetrical shapes can make an additional contribution to the evaporation process, particularly if a larger surface is formed.

- the asymmetry can be pronounced both in additional structures at the channel base and at the fin tip.

- the projections can have a trapezoidal cross-section in a cutting plane running perpendicular to the longitudinal axis of the tube.

- Trapezoidal cross-sections are structural elements that are technologically easy to control in connection with integrally rolled finned tube structures. Minor manufacturing-related asymmetries of the otherwise parallel base sides of a trapezoid can occur here.

- opposing material projections can be formed at the location of the projections in the direction of the pipe's longitudinal axis.

- the projections with the opposing material projections therefore represent the threshold for the passage of fluid.

- Fig. 1 shows schematically a partial view of a cross section of a heat exchanger tube 1 according to the invention with segments 8 divided by additional structures 7.

- the integrally rolled heat exchanger tube 1 has helical fins 2 on the outside of the tube, between which a primary groove is formed as a channel 6.

- the fins 2 extend continuously without interruption along a helical line on the outside of the tube.

- the fin base 3 protrudes essentially radially from the tube wall 10.

- the fin height H is measured on the finished heat exchanger tube 1 from the lowest point of the channel base 61, starting from the fin base 3 over the fin flank 4 to the fin tip 5 of the fully formed finned tube.

- a heat exchanger tube 1 is proposed in which an additional structure 7 in the form of radially outward-directed projections 71 is arranged in the region of the channel base 61, which are each delimited in the radial direction by a closing surface 713 located between the channel base 61 and the fin tip 5.

- These projections 71 are referred to as the first additional structure and are formed from the material of the tube wall 10 from the channel base 61.

- the projections 71 are arranged at preferably regular intervals in the channel base 61 and extend transversely to the channel course from a fin base 3 of a fin 2 at least partially in the direction or completely to the above lying next rib foot.

- material projections 72 are arranged radially outward as a second additional structure 7, which are made from material of the rib flanks 4.

- the material projections 72 are arranged in the radial direction between a closing surface 713 and the rib tip 5, so that the material projections 72 are formed lying laterally on the rib flank 4 by the radial extent of the projections 71 above the channel base 61 of the channel 6.

- the material projections 72 extend further in the axial and radial direction than in the circumferential direction. In this way, the primary groove as channel 6 is at least partially tapered at regular intervals.

- the resulting segment 8 promotes bubble nucleation in conjunction with the material projections 72 as guide structures for the fluid flow in a special way.

- the direct exchange of liquid and vapor between the individual segments 8 is at least reduced.

- the rib tips 5 as the distal region of the ribs 2 are expediently deformed in such a way that they partially close the channel 6 in the radial direction with an axially folded rib tip 51.

- the connection between the channel 6 and the environment is designed in the form of pores 9 as local openings so that vapor bubbles can escape from the channel 6.

- the deformation of the rib tips 5 takes place using rolling methods that can be taken from the state of the art.

- the primary grooves 6 thus represent undercut grooves.

- a segment 8 in the form of a cavity is obtained, which is also characterized by the fact that it has a very high performance in the evaporation of liquids over a very wide range of operating conditions.

- the liquid evaporates within the segment 8 supported by material projections 72 as additional fluid conduction structures.

- the steam that is created exits the channel 6 at the local openings 9, through which liquid fluid also flows. Easily wettable pipe surfaces can also be helpful for the fluid to flow in.

- the solution according to the invention relates to structured tubes in which the heat transfer coefficient is increased on the outside of the tube.

- the heat transfer coefficient on the inside can also be intensified by a suitable internal structuring 11.

- the heat exchanger tubes 1 for tube bundle heat exchangers usually have at least one structured area as well as smooth end pieces and possibly smooth intermediate pieces. The smooth end or intermediate pieces delimit the structured areas. So that the heat exchanger tube 1 can be installed in the tube bundle heat exchanger without any problems, the outer diameter of the structured areas must not be larger than the outer diameter of the smooth end and intermediate pieces.

- Fig. 2 shows a schematic oblique view of part of the external structure of a heat exchanger tube 1 with folded fin tips 51.

- the fin tips 5 as the distal region of the fins 2 are deformed in such a way that they partially close the channel 6 in the radial direction with an axially folded fin tip 51.

- the connection between the channel 6 and the environment is designed as local openings 9 for the escape of vapor bubbles from the channel 6 and the flow of liquid fluid into the channel 6.

- the primary grooves 6 thus again represent undercut grooves.

- the axially folded fin tip 51 is formed from the fin 2 and thus extends in the axial direction over the channel 6.

- the flow-through cross-sectional area in the channel 6 between two ribs 2 is reduced locally particularly effectively in order to thereby limit the fluid flow in the channel 6 during operation.

- Fig. 3 shows a schematic detailed view of material projections 72 at the location of a projection 71.

- the material projections 72 which are placed radially on a preferably solid projection 71 of the channel base structure, are made from material of the rib flank 4 by a toothed rolling disk, which forms both wall material on the channel base 61 and material on the rib flank 4.

- projections 71 and material projections 72 are thus formed from different areas of the pipe wall, the material projections 72 can essentially form a radially flowing transition to the two side surfaces 711 of the underlying projection 71.

- the projection 71 only runs in part of the channel base 61 and ends in the axial pipe direction with an end face 712.

- the material projections 72 are designed like a partition wall and extend approximately radially and in the direction of the pipe's longitudinal axis A and, for example, in this axial direction up to approximately the middle of the channel.

- the end surface 713 of the projection 71 can also extend further in the direction of the pipe's longitudinal axis A or even over the entire channel width between opposing ribs. Starting in this area, the fluid flow can be controlled more precisely and contribute to the formation of bubbles in both adjacent segments 8 in the circumferential direction.

- the projections 71 with the attached material projections 72 therefore also represent a threshold for the passage of fluid.

- the axial extension of the material projections 72 is somewhat shorter than the axial extension of the projection 71 located underneath. This results in an opening to the pipe longitudinal axis A for the liquid heat exchange fluid, which can be more easily into the neighboring segments 8 to support bubble formation.

- Fig. 4 shows a schematic detailed view of another embodiment of material projections 72 at the location of a projection 71.

- the material projections 72 placed radially on a projection 71 of the channel base structure are made from material of the rib flank 4 by a toothed rolling disk, which forms both wall material on the channel base 61 and material on the rib flank 4.

- the contour line of the material projections extending essentially in the axial and radial directions can also be curved or irregular.

- the material projections 72 have a changing extension in the axial direction. In other words, viewed in the radial direction outwards, a smooth transition into the rib flank 4 is realized.

- the surfaces of the material projections 72 are also slightly curved. These shapes are certain variations of otherwise flat surfaces, which are particularly favorable with regard to the surface properties and the wetting behavior of the liquid heat exchanger fluid.

- Such structures particularly preferably guide the liquid heat exchange fluid from the side into the adjacent segments 8 to support bubble formation.

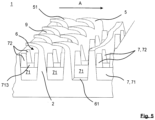

- Fig. 5 shows a schematic oblique view of a part of the external structure of a heat exchanger tube 1 with opposing material projections 72 at the location of a projection 71.

- the fin tips 5 as the distal region of the fins 2 are deformed in such a way that they partially close the channel 6 in the radial direction with an axially folded fin tip 51.

- the connection between the channel 6 and the environment is as local openings 9 for the escape of vapor bubbles from the channel 6 and the inflow of liquid fluid into the channel 6.

- the projections 71 and the material projections 72 as additional structures 7, the flow-through cross-sectional area in the channel 6 between two ribs 2 is reduced locally particularly effectively in order to thereby limit the fluid flow in the channel 6 during operation.

- the projections 71 extend over the entire channel width between adjacent ribs 2 in the direction of the pipe's longitudinal axis A. Radially outwardly, opposing material projections 72 are formed at the location of the projections 71.

- the projections 71 with the attached material projections 72 therefore represent a threshold for the passage of fluid.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Geometry (AREA)

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI202130232T SI4237782T1 (sl) | 2020-10-31 | 2021-10-07 | Kovinska cev prenosnika toplote |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102020006684 | 2020-10-31 | ||

| PCT/EP2021/000121 WO2022089773A1 (de) | 2020-10-31 | 2021-10-07 | Metallisches wärmeaustauscherrohr |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP4237782A1 EP4237782A1 (de) | 2023-09-06 |

| EP4237782B1 true EP4237782B1 (de) | 2024-10-23 |

Family

ID=78332748

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP21797938.4A Active EP4237782B1 (de) | 2020-10-31 | 2021-10-07 | Metallisches wärmeaustauscherrohr |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US12298089B2 (pl) |

| EP (1) | EP4237782B1 (pl) |

| JP (1) | JP7648747B2 (pl) |

| KR (1) | KR20230098132A (pl) |

| CN (1) | CN116507872A (pl) |

| CA (1) | CA3192303A1 (pl) |

| HU (1) | HUE069927T2 (pl) |

| MX (1) | MX2023004840A (pl) |

| PL (1) | PL4237782T3 (pl) |

| PT (1) | PT4237782T (pl) |

| SI (1) | SI4237782T1 (pl) |

| WO (1) | WO2022089773A1 (pl) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116507864A (zh) | 2020-10-31 | 2023-07-28 | 威兰德-沃克公开股份有限公司 | 金属热交换器管 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4313248A (en) | 1977-02-25 | 1982-02-02 | Fukurawa Metals Co., Ltd. | Method of producing heat transfer tube for use in boiling type heat exchangers |

| JPS5984095A (ja) | 1982-11-04 | 1984-05-15 | Hitachi Ltd | 熱交換壁 |

| EP0222100B1 (de) | 1985-10-31 | 1989-08-09 | Wieland-Werke Ag | Rippenrohr mit eingekerbtem Nutengrund und Verfahren zu dessen Herstellung |

| JPS6323778A (ja) | 1986-07-16 | 1988-02-01 | ヤンマー農機株式会社 | 籾摺選別機における制御装置 |

| JP2788793B2 (ja) | 1991-01-14 | 1998-08-20 | 古河電気工業株式会社 | 伝熱管 |

| US5597039A (en) | 1994-03-23 | 1997-01-28 | High Performance Tube, Inc. | Evaporator tube |

| DE69525594T2 (de) | 1994-11-17 | 2002-08-22 | Carrier Corp., Syracuse | Wärmeaustauschrohr |

| US5697430A (en) | 1995-04-04 | 1997-12-16 | Wolverine Tube, Inc. | Heat transfer tubes and methods of fabrication thereof |

| DE19757526C1 (de) | 1997-12-23 | 1999-04-29 | Wieland Werke Ag | Verfahren zur Herstellung eines Wärmeaustauschrohres, insbesondere zur Verdampfung von Flüssigkeiten aus Reinstoffen oder Gemischen auf der Rohraußenseite |

| DE10101589C1 (de) * | 2001-01-16 | 2002-08-08 | Wieland Werke Ag | Wärmeaustauscherrohr und Verfahren zu dessen Herstellung |

| US7254964B2 (en) | 2004-10-12 | 2007-08-14 | Wolverine Tube, Inc. | Heat transfer tubes, including methods of fabrication and use thereof |

| CN100365369C (zh) | 2005-08-09 | 2008-01-30 | 江苏萃隆铜业有限公司 | 蒸发器热交换管 |

| DE102008013929B3 (de) | 2008-03-12 | 2009-04-09 | Wieland-Werke Ag | Verdampferrohr mit optimierten Hinterschneidungen am Nutengrund |

| DE102009021334A1 (de) * | 2009-05-14 | 2010-11-18 | Wieland-Werke Ag | Metallisches Wärmeaustauscherrohr |

| DE102011121436A1 (de) * | 2011-12-16 | 2013-06-20 | Wieland-Werke Ag | Verflüssigerrohre mit zusätzlicher Flankenstruktur |

| CN102980431A (zh) * | 2012-11-12 | 2013-03-20 | 沃林/维兰德传热技术有限责任公司 | 蒸发传热管 |

| CN102980432A (zh) * | 2012-11-12 | 2013-03-20 | 沃林/维兰德传热技术有限责任公司 | 带空心腔体的蒸发传热管 |

| DE102014002829A1 (de) * | 2014-02-27 | 2015-08-27 | Wieland-Werke Ag | Metallisches Wärmeaustauscherrohr |

| CN116507864A (zh) | 2020-10-31 | 2023-07-28 | 威兰德-沃克公开股份有限公司 | 金属热交换器管 |

-

2021

- 2021-10-07 CN CN202180073791.9A patent/CN116507872A/zh active Pending

- 2021-10-07 HU HUE21797938A patent/HUE069927T2/hu unknown

- 2021-10-07 EP EP21797938.4A patent/EP4237782B1/de active Active

- 2021-10-07 SI SI202130232T patent/SI4237782T1/sl unknown

- 2021-10-07 MX MX2023004840A patent/MX2023004840A/es unknown

- 2021-10-07 CA CA3192303A patent/CA3192303A1/en active Pending

- 2021-10-07 JP JP2023517686A patent/JP7648747B2/ja active Active

- 2021-10-07 KR KR1020237008393A patent/KR20230098132A/ko active Pending

- 2021-10-07 PL PL21797938.4T patent/PL4237782T3/pl unknown

- 2021-10-07 US US18/245,405 patent/US12298089B2/en active Active

- 2021-10-07 WO PCT/EP2021/000121 patent/WO2022089773A1/de not_active Ceased

- 2021-10-07 PT PT217979384T patent/PT4237782T/pt unknown

Also Published As

| Publication number | Publication date |

|---|---|

| PT4237782T (pt) | 2024-12-04 |

| MX2023004840A (es) | 2023-05-10 |

| JP7648747B2 (ja) | 2025-03-18 |

| WO2022089773A1 (de) | 2022-05-05 |

| US20230341193A1 (en) | 2023-10-26 |

| US12298089B2 (en) | 2025-05-13 |

| JP2023545916A (ja) | 2023-11-01 |

| HUE069927T2 (hu) | 2025-04-28 |

| SI4237782T1 (sl) | 2025-02-28 |

| CA3192303A1 (en) | 2022-05-05 |

| CN116507872A (zh) | 2023-07-28 |

| PL4237782T3 (pl) | 2025-03-10 |

| EP4237782A1 (de) | 2023-09-06 |

| KR20230098132A (ko) | 2023-07-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69302668T2 (de) | Wärmetauscherrohr | |

| DE10101589C1 (de) | Wärmeaustauscherrohr und Verfahren zu dessen Herstellung | |

| DE69509976T2 (de) | Wärmeaustauschrohr | |

| DE69215988T2 (de) | Wärmeaustauschrohre und Verfahren zur Herstellung | |

| DE69525594T2 (de) | Wärmeaustauschrohr | |

| DE69200089T2 (de) | Wärmeübertragungsrohr. | |

| EP2795233B1 (de) | VERDAMPFERROHR MIT OPTIMIERTER AUßENSTRUKTUR | |

| DE102007009535A1 (de) | Wärmeaustauscher | |

| EP2101136B1 (de) | Metallisches Wärmeaustauscherrohr | |

| EP1711772B1 (de) | Wärmetauscher, insbesondere flachrohr-verdampfer für eine kraftfahrzeug-klimaanlage | |

| DE102015104180B4 (de) | Vorrichtung für einen Wärmeübertrager zum Sammeln und Verteilen eines Wärmeträgerfluids | |

| EP3111153B1 (de) | Metallisches wärmeaustauscherrohr | |

| EP4237782B1 (de) | Metallisches wärmeaustauscherrohr | |

| EP3465056B1 (de) | Wärmeübertragerrohr | |

| EP4237781B1 (de) | Metallisches wärmeaustauscherrohr | |

| EP1664655B1 (de) | Wärmetauscher | |

| DE10210016B9 (de) | Wärmeaustauschrohr mit berippter Innenoberfläche | |

| DE102016006967B4 (de) | Wärmeübertragerrohr | |

| DE202020005628U1 (de) | Metallisches Wärmeaustauscherrohr | |

| DE202020005625U1 (de) | Metallisches Wärmeaustauscherrohr | |

| EP3581871B1 (de) | Metallisches wärmeaustauscherrohr | |

| CH549193A (de) | Waermeaustauschrohr mit innenrippen und verfahren zu seiner herstellung. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: UNKNOWN |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20230405 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20240603 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502021005589 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Ref document number: 4237782 Country of ref document: PT Date of ref document: 20241204 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20241127 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20241023 Ref country code: SK Ref legal event code: T3 Ref document number: E 45639 Country of ref document: SK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250124 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E069927 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20250123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502021005589 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20241023 |

|

| 26N | No opposition filed |

Effective date: 20250724 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250922 Year of fee payment: 5 Ref country code: PL Payment date: 20250911 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250908 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20250912 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SI Payment date: 20250915 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20250929 Year of fee payment: 5 |