EP3591237A1 - Module structural pour un compresseur d'une turbomachine - Google Patents

Module structural pour un compresseur d'une turbomachine Download PDFInfo

- Publication number

- EP3591237A1 EP3591237A1 EP19181591.9A EP19181591A EP3591237A1 EP 3591237 A1 EP3591237 A1 EP 3591237A1 EP 19181591 A EP19181591 A EP 19181591A EP 3591237 A1 EP3591237 A1 EP 3591237A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- compressor

- structural assembly

- assembly according

- peripheral

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/52—Casings; Connections of working fluid for axial pumps

- F04D29/522—Casings; Connections of working fluid for axial pumps especially adapted for elastic fluid pumps

- F04D29/526—Details of the casing section radially opposing blade tips

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/66—Combating cavitation, whirls, noise, vibration or the like; Balancing

- F04D29/68—Combating cavitation, whirls, noise, vibration or the like; Balancing by influencing boundary layers

- F04D29/681—Combating cavitation, whirls, noise, vibration or the like; Balancing by influencing boundary layers especially adapted for elastic fluid pumps

- F04D29/685—Inducing localised fluid recirculation in the stator-rotor interface

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D27/00—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids

- F04D27/02—Surge control

- F04D27/0207—Surge control by bleeding, bypassing or recycling fluids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2260/00—Function

- F05D2260/40—Transmission of power

- F05D2260/403—Transmission of power through the shape of the drive components

- F05D2260/4031—Transmission of power through the shape of the drive components as in toothed gearing

- F05D2260/40311—Transmission of power through the shape of the drive components as in toothed gearing of the epicyclical, planetary or differential type

Definitions

- the invention relates to a structural assembly for a compressor of a turbomachine according to the preamble of claim 1.

- the invention is based on the object of providing a structural assembly for a compressor of a turbomachine which effectively realizes a housing structuring.

- the invention then considers a structural assembly for a compressor of a turbomachine that has an impeller with a plurality of blades that extend radially in a flow path of the turbomachine.

- a compressor housing is provided which forms a flow path boundary which delimits the flow path through the turbomachine radially on the outside.

- the compressor housing has a housing structure adjacent to the impeller. Housing structuring structures the flow path boundary, i. H. the wall area of the compressor housing, which delimits the flow path, it being possible in principle to use any housing structures known in the prior art.

- the compressor housing has a plurality of circumferential segments which extend in the circumferential direction. Only one or only some of the peripheral segments form a housing structure, while the other peripheral segments are designed without a housing structure.

- a circumferential segment is a segment of the compressor housing which extends in the circumferential direction and which adjoins the flow path. The individual circumferential segments adjoin one another in the circumferential direction. At least one scope segment, but not all Circumferential segments form a housing structure, so that the compressor housing has variations with respect to the housing structure.

- the invention effectively counteracts rotating detachment.

- the variation of the housing structuring in the circumferential direction provided by the invention in such a way that only one or only some of the circumferential segments have a housing structuring has the effect that the coherence of the rotating demolition patterns that are formed is disturbed.

- This counteracts a locally occurring flow separation at the respective blade tips.

- the invention thus suppresses the formation of coherent separation processes at the blade tip and thus of rotor vibrations. This significantly increases the stable working range of the compressor and the turbomachine overall.

- the compressor housing has an upper housing half and a lower housing half, each of which extends in the circumferential direction over a circumferential region of 180 °, and that the circumferential segment or the circumferential segments which form a housing structure are in the upper housing half of the Compressor housing are formed.

- This aspect of the invention therefore provides for the housing to be structured only in one or more peripheral segments which are formed in the upper housing half of the compressor housing. This ensures safe and effective operation of the compressor in which the structural assembly is integrated. By avoiding a housing structuring in the lower housing half of the compressor housing, the risk is avoided that the housing structuring is blocked by ice, for which case there is an at least temporary loss of functionality.

- the statement that the compressor housing has an upper housing half and a lower housing half is merely a geometric statement that does not say anything about the structure of the compressor housing of the housing half.

- the upper half of the housing is the upper region of the compressor housing and the lower half of the housing is the lower region of the compressor housing. It can only be imaginary areas, the two areas being separated from one another by a horizontal plane.

- the terms "upper” and “lower” take into account that the structural assembly and the compressor housing are in the gravitational field of the earth, which automatically results in a vertical direction is defined.

- the upper housing half Starting from a vector that points downwards according to the gravitational field and defines the angle of 0 °, the upper housing half extends in an angular range between 90 ° and 270 ° and the lower housing half in an angular range between 270 and 90 °.

- peripheral segments with the housing structure can have different housing structures, and of course an identical housing structure can also be provided.

- Exemplary embodiments provide that a plurality of adjoining circumferential segments are formed with different housing structuring, for example in the upper housing half, or that a plurality of circumferential segments with housing structuring are separated by regions without housing structuring.

- peripheral segments have the same extension angle in the peripheral direction. However, this is not necessarily the case. In embodiments of the invention, it can be provided that the extent of the circumferential segments varies in the circumferential direction, that is to say the extent angle.

- the sequence of the circumferential segments can furthermore be circumferentially symmetrical or circumferentially asymmetrical, whereby circumferential asymmetry means that apart from the angles 0 ° and 360 ° there are no angles at which the sequence of the circumferential segments is mapped onto itself during a rotation, i.e. leads to the same overall structuring.

- the compressor housing has exactly two peripheral segments, an upper peripheral segment being formed in the upper housing half and a lower peripheral segment being formed in the lower housing half.

- the housing structure is formed exclusively in the upper peripheral segment.

- both circumferential segments each extend over a circumferential angle of 180 °.

- the upper circumferential segment, which forms a housing structure extends over more or less than 180 ° in the circumferential direction, while the lower circumferential segment accordingly extends over less or more than 180 ° in the circumferential direction.

- both circumferential segments each extend over a circumferential angle of 180 °

- the two circumferential segments of the compressor housing are at least approximately designed as half cylinders.

- the compressor housing is formed by a two-part housing which forms two parts which each extend over 180 ° in the circumferential direction.

- a compressor housing is also drawn as a "split casing".

- the compressor housing has two circumferential segments with a circumferential angle of 180 ° in each case, the division plane between the two parts of the compressor housing simultaneously the boundary between the two circumferential segments with and without Representing housing structuring.

- two circumferential segments with a circumferential angle of 180 ° are formed in the case of compressor housings that are not divided into two.

- a further embodiment of the invention provides that at least one peripheral segment of the compressor housing has an inlet lining.

- the inlet lining forms the boundary of the flow path of the compressor housing.

- the inlet lining is part of the compressor housing.

- At least one circumferential segment that has a housing structure has an inlet lining, the housing structure being formed in the inlet lining.

- the upper circumferential segment has an inlet lining which forms a housing structure and the lower circumferential segment forms an inlet surface without a housing structure. This will along the The entire circumference of the compressor housing has narrow running gaps between the blade tips and the flow path limitation.

- Another variant provides that only the peripheral segment or only the peripheral segments that do not form a housing structure have an inlet lining, while the housing structure on the actual compressor housing, i.e. is formed in the housing wall of the compressor housing.

- the peripheral segments have two different housing radii (the housing radius referring to the housing wall of the actual compressor housing and not to the radius of the inlet lining).

- the radius of the housing of a peripheral segment that has an inlet lining is larger than the housing radius of a peripheral segment that has no inlet lining.

- the housing structuring is designed to be circumferentially discrete and, in this configuration, has circumferential grooves, for example, which each extend in the circumferential direction, the circumferential grooves being spaced apart in the axial direction.

- the housing structuring is designed to be circumferentially discrete.

- it has, for example, axial grooves which each extend over a defined length in the axial direction, the axial grooves being spaced apart in the circumferential direction.

- the housing structure is designed in the form of half-heart axial grooves.

- a case structure in the form of half-heart axial grooves is, for example, from the DE 10 2007 056 953 A1 known, to which extent reference is made.

- the circumferential grooves or axial grooves with a rectangular or parallelogram cross section are provided. It can also be provided that the housing is structured via recirculation channels instead of grooves. It is provided that a recirculation channel connects two openings at the flow path boundary, namely one removal opening with another upstream feed opening. Such circulation channels are for example from the DE 10 2008 037 154 A1 known, to which extent reference is made.

- the impeller of the structural assembly considered according to the invention can be a fan, the impeller of a low-pressure compressor, the impeller of a medium-pressure compressor or the impeller of a high-pressure compressor. It can be formed by the first stage (compressor input stage) or an embedded stage of the compressor.

- the impeller is designed in a BLISK design.

- problems arise due to a rotating detachment, which are counteracted by the present invention.

- the impeller is a BLISK-designed fan.

- the impeller is a BLISK-type impeller of a compressor input stage of a compressor.

- a compressor input stage further comprises a stator with stator blades adjustable in staggering angle, which is arranged in front of the first rotor of the compressor.

- a stator is referred to as an inlet guide vane or a guide vane or as an IGV (IGV - Inlet Guide Vane).

- IGV IGV - Inlet Guide Vane

- the housing structure is formed adjacent to the front edge of the blades in the compressor housing. It extends in a region that begins in front of the front edge of the blades in relation to the axial direction and ends behind the front edge of the blades.

- X indicates the axial direction, r the radial direction and ⁇ the angle in the circumferential direction.

- the axial direction is identical to the machine axis of a gas turbine engine in which the structural assembly is arranged. From the x-axis starting from, the radial direction points radially outwards. Terms such as “in front”, “behind”, “front” and “rear” refer to the axial direction or the direction of flow in the engine. Terms such as “outer” or “inner” refer to the radial direction.

- Such a gas turbine engine may include an engine core that includes a turbine, a combustion chamber, a compressor, and a core shaft connecting the turbine to the compressor.

- Such a gas turbine engine may include a fan (with fan blades) positioned upstream of the engine core.

- the gas turbine engine may include a transmission that receives an input from the core shaft and drives the fan to drive the fan at a lower speed than the core shaft.

- the input for the transmission can take place directly from the core shaft or indirectly from the core shaft, for example via a spur shaft and / or a spur gear.

- the core shaft may be rigidly connected to the turbine and compressor so that the turbine and compressor rotate at the same speed (with the fan rotating at a lower speed).

- the gas turbine engine described and / or claimed herein can have any suitable general architecture.

- the gas turbine engine may have any desired number of shafts connecting turbines and compressors, for example one, two or three shafts.

- the turbine connected to the core shaft may be a first turbine

- the compressor connected to the core shaft may be a first compressor

- the core shaft may be a first core shaft.

- the engine core may further include a second turbine, a second compressor, and a second core shaft connecting the second turbine to the second compressor.

- the second turbine, the second compressor, and the second core shaft may be arranged to rotate at a higher speed than the first core shaft.

- the second compressor may be positioned axially downstream of the first compressor.

- the second compressor can be arranged To receive flow from the first compressor (for example, to take up directly, for example through a generally annular channel).

- the transmission may be arranged to be driven by the core shaft configured to rotate at the lowest speed (e.g., in use) (e.g., the first core shaft in the example above).

- the transmission may be arranged to be driven only by the core shaft configured to rotate at the lowest speed (for example, in use) (for example, only the first core shaft and not the second core shaft in the example above) become.

- the transmission may be arranged to be driven by one or more shafts, for example the first and / or the second shaft in the example above.

- a combustion chamber may be provided axially downstream of the blower and the compressor (s).

- the combustion chamber can be located directly downstream of the second compressor (for example at the outlet thereof) if a second compressor is provided.

- the flow at the outlet of the compressor can be supplied to the inlet of the second turbine if a second turbine is provided.

- the combustion chamber can be provided upstream of the turbine (s).

- each compressor for example the first compressor and the second compressor as described above

- Each stage can include a series of rotor blades and a series of stator blades, which can be variable stator blades (in that their angle of attack can be variable).

- the row of rotor blades and the row of stator blades can be axially offset from one another.

- the or each turbine may include any number of stages, for example multiple stages.

- Each stage can include a series of rotor blades and a series of stator blades.

- the row of rotor blades and the row of stator blades can be axially offset from one another.

- Each fan blade may be defined with a radial span that extends from a foot (or hub) at a radially inner gas-flowed location or at a 0% span position to a tip at a 100% span position.

- the ratio of the radius of the fan blade on the hub to the radius of the fan blade on the tip may be less than (or on the order of): 0.4, 0.39, 0.38, 0.37, 0.36, 0, 35, 0.34, 0.33, 0.32, 0.31, 0.3, 0.29, 0.28, 0.27, 0.26 or 0.25.

- the ratio of the radius of the fan blade at the hub to the radius of the fan blade at the tip can be in an inclusive range limited by two of the values in the previous sentence (i.e. the values can form upper or lower limits).

- the hub-to-tip ratio can be commonly referred to as the hub-to-tip ratio.

- the radius at the hub and the radius at the tip can both be measured at the front edge portion (or the axially most forward edge) of the blade.

- the hub-to-tip ratio refers to the portion of the fan blade over which gas flows, i.e. H. the section that is radially outside of any platform.

- the radius of the fan can be measured between the center line of the engine and the tip of the fan blade at its front edge.

- the diameter of the blower (which can simply be twice the radius of the blower) can be greater than (or on the order of): 250 cm (about 100 inches), 260 cm, 270 cm (about 105 inches), 280 cm (about 110 inches), 290 cm (about 115 inches), 300 cm (about 120 inches), 310 cm, 320 cm (about 125 inches), 330 cm (about 130 inches), 340 cm (about 135 inches), 350 cm, About 360 cm (about 140 inches), 370 cm (about 145 inches), 380 cm (about 150 inches) or 390 cm (about 155 inches).

- the fan diameter can be in an inclusive range limited by two of the values in the previous sentence (i.e. the values can be upper or lower limits).

- the speed of the fan can vary in use. In general, the speed is lower for fans with a larger diameter.

- the fan speed may be less than 2500 rpm, for example less than 2300 rpm, under constant speed conditions.

- the speed of the fan under constant speed conditions for an engine with a fan diameter in the range from 320 cm to 380 cm can be in the range from 1200 rpm to 2000 rpm, for example in the range from 1300 rpm. min to 1800 rpm, for example in the range from 1400 rpm to 1600 rpm.

- a blower tip load can be defined as dH / U tip 2 , where dH is the enthalpy increase (e.g. the average 1-D enthalpy increase) across the blower and U tip is the (translation) speed of the blower tip, e.g. at the front edge of the tip , (which can be defined as the blower tip radius at the front edge multiplied by the angular velocity).

- the blower peak load under constant speed conditions can be more than (or on the order of): 0.3, 0.31, 0.32, 0.33, 0.34, 0.35, 0.36, 0.37, 0.38 , 0.39 or 0.4 are (lie) (all units in this section being Jkg -1 K -1 / (ms -1 ) 2 ).

- the blower peak load can be in an inclusive range limited by two of the values in the previous sentence (ie the values can be upper or lower limits).

- Gas turbine engines in accordance with the present disclosure may have any desired bypass ratio, the bypass ratio being defined as the ratio of the mass flow rate of flow through the bypass channel to the mass flow rate of flow through the core at constant speed conditions.

- the bypass ratio can be more than (on the order of): 10, 10.5, 11, 11.5, 12, 12.5, 13, 13.5, 14, 14.5, 15, 15.5 , 16, 16.5 or 17 are (lie).

- the bypass ratio can be in an inclusive range limited by two of the values in the previous sentence (ie the values can form upper or lower limits).

- the bypass channel can be essentially ring-shaped.

- the bypass channel can be located radially outside of the engine core.

- the radially outer surface of the bypass duct can be defined by an engine nacelle and / or a blower housing.

- the total pressure ratio of a gas turbine engine described and / or claimed herein can be defined as the ratio of the back pressure upstream of the fan to the back pressure at the output of the supercharger (prior to entering the combustion chamber).

- the total pressure ratio of a gas turbine engine described and / or claimed herein at constant speed may be more than (or on the order of): 35, 40, 45, 50, 55, 60, 65, 70, 75 (lie).

- the total pressure ratio can be in an inclusive range limited by two of the values in the previous sentence (i.e. the values can be upper or lower limits).

- the specific thrust of an engine can be defined as the net thrust of the engine divided by the total mass flow through the engine. Under constant speed conditions, the specific thrust of an engine described and / or claimed herein may be less than (or on the order of): 110 Nkg -1 s, 105 Nkg -1 s, 100 Nkg -1 s, 95 Nkg -1 s, 90 Nkg -1 s, 85 Nkg -1 s or 80 Nkg -1 s.

- the specific thrust can be in an inclusive range limited by two of the values in the previous sentence (ie the values can be upper or lower limits). Such engines can be particularly efficient compared to conventional gas turbine engines.

- a gas turbine engine described and / or claimed herein can have any desired maximum thrust.

- a gas turbine described and / or claimed herein can produce a maximum thrust of at least (or on the order of): 160kN, 170kN, 180kN, 190kN, 200kN, 250kN, 300kN, 350kN, 400kN , 450kN, 500kN or 550kN.

- the maximum thrust can be in an inclusive range limited by two of the values in the previous sentence (i.e. the values can be upper or lower limits).

- the thrust referred to above can be the maximum net thrust under standard atmospheric conditions at sea level plus 15 degrees C (ambient pressure 101.3 kPa, temperature 30 degrees C) for static engines.

- the temperature of the flow at the inlet of the high pressure turbine can be particularly high.

- This temperature which can be referred to as TET

- TET can be at the exit to the combustion chamber, for example immediately upstream of the first Turbine blade, which in turn can be referred to as a nozzle guide vane, are measured.

- the TET can be at least (or in the order of magnitude): 1400K, 1450K, 1500K, 1550K, 1600K or 1650K.

- the constant velocity TET can be in an inclusive range limited by two of the values in the previous sentence (ie the values can be upper or lower limits).

- the maximum TET in use of the engine may be at least (or on the order of): 1700K, 1750K, 1800K, 1850K, 1900K, 1950K or 2000K.

- the maximum TET can be in an inclusive range limited by two of the values in the previous sentence (ie the values can be upper or lower limits).

- the maximum TET can occur, for example, in a condition of high thrust, for example an MTO condition (MTO - maximum take-off thrust - maximum start thrust).

- a fan blade and / or a blade portion of a fan blade described and / or claimed herein can be made from any suitable material or combination of materials.

- at least a part of the fan blade and / or the blade can be made at least in part of a composite, for example a metal matrix composite and / or a composite with an organic matrix, such as, for example. B. carbon fiber.

- at least a portion of the fan blade and / or the blade may be at least partially made of a metal, such as. B. a titanium-based metal or an aluminum-based material (such as an aluminum-lithium alloy) or a steel-based material.

- the fan blade may include at least two areas made using different materials.

- the fan blade may have a protective front edge that is made using a material that is more resistant to impact (e.g., birds, ice, or other material) than the rest of the blade.

- a leading edge can be produced, for example, using titanium or a titanium-based alloy.

- the fan blade may include a carbon fiber or aluminum based body (such as an aluminum-lithium alloy) with a titanium leading edge.

- a fan described and / or claimed herein may include a central portion from which the fan blades may extend, for example in a radial direction.

- the fan blades can be any desired Way to be attached to the middle section.

- each fan blade can include a fixation device that can engage a corresponding slot in the hub (or disc).

- a fixing device in the form of a dovetail, which can be inserted and / or brought into engagement with a corresponding slot in the hub / disc for fixing the fan blade, can be present only as an example.

- the fan blades can be integrally formed with a central portion. Such an arrangement can be referred to as a blisk or a bling. Any suitable method can be used to make such a blisk or bling.

- at least some of the fan blades can be machined out of a block and / or at least some of the fan blades can be welded, e.g. B. linear friction welding, attached to the hub / disc.

- VAN Very Area Nozzle - nozzle with a variable cross-section

- Such a variable cross-section nozzle can allow the output cross-section of the bypass channel to be varied in use.

- the general principles of the present disclosure may apply to engines with or without a VAN.

- blower of a gas turbine which is described and / or claimed here, can have any desired number of blower blades, for example 16, 18, 20 or 22 blower blades.

- constant speed conditions may mean constant speed conditions of an aircraft to which the gas turbine engine is attached.

- Such constant speed conditions can conventionally be defined as the conditions during the middle part of the flight, for example the conditions to which the aircraft and / or the engine is exposed between (in terms of time and / or distance) the end of the climb and the start of the descent. become.

- the forward speed in the constant speed condition at any point may range from Mach 0.7 to 0.9, for example 0.75 to 0.85, for example 0.76 to 0.84, for example 0.77 to 0.83, for example 0.78 to 0.82, for example 0.79 to 0.81, for example in the order of Mach 0.8, in the order of Mach 0.85 or in the range of 0 , 8 to 0.85. Any speed within these ranges can be the constant travel condition. For some aircraft, constant speed conditions may be outside of these ranges, for example below Mach 0.7 or above Mach 0.9.

- the constant speed conditions may be standard atmospheric conditions at an altitude that is in the range of 10,000 m to 15,000 m, for example in the range of 10,000 m to 12,000 m, for example in the range of 10,400 m to 11,600 m (approximately 38,000 feet), for example in Range from 10,500 m to 11,500 m, for example in the range from 10,600 m to 11,400 m, for example in the range from 10,700 m (approximately 35,000 feet) to 11,300 m, for example in the range from 10,800 m to 11,200 m, for example in the range from 10,900 m to 11,100 m, for example in the order of 11,000 m, correspond.

- the constant speed conditions can correspond to standard atmospheric conditions at any given altitude in these areas.

- the constant speed conditions may correspond to: a forward Mach number of 0.8; a pressure of 23,000 Pa and a temperature of -55 degrees C.

- constant speed or “constant speed conditions” can mean the aerodynamic design point.

- Such an aerodynamic design point can correspond to the conditions (including, for example, the Mach number, ambient conditions and thrust requirement) for which the fan operation is designed. This can mean, for example, the conditions in which the blower (or the gas turbine engine) has the optimal efficiency by design.

- a gas turbine engine described and / or claimed herein may be operated at the constant speed conditions defined elsewhere herein.

- Such constant speed conditions may differ from the constant speed conditions (e.g. conditions during the middle part of the flight) of an aircraft on which at least one (For example, 2 or 4) gas turbine engine may be attached to provide thrust.

- Figure 1 represents a gas turbine engine 10 with a main axis of rotation 9.

- the engine 10 comprises an air inlet 12 and a thrust blower or fan 23, which generates two air streams: a core air stream A and a bypass air stream B.

- the gas turbine engine 10 comprises a core 11, which is the core air stream A. receives.

- the engine core 11 comprises, in axial flow order, a low-pressure compressor 14, a high-pressure compressor 15, a combustion device 16, a high-pressure turbine 17, a low-pressure turbine 19 and a core thrust nozzle 20.

- An engine nacelle 21 surrounds the gas turbine engine 10 and defines a bypass duct 22 and a bypass thruster nozzle 18.

- the bypass air flow B flows through the bypass duct 22.

- the fan 23 is connected to the low-pressure turbine 19 via a shaft 26 and an epicycloid gear 30 attached and is driven by this.

- the core air flow A is accelerated and compressed by the low pressure compressor 14 and passed into the high pressure compressor 15, where further compression takes place.

- the compressed air discharged from the high pressure compressor 15 is conducted into the combustion device 16, where it is mixed with fuel and the mixture is burned.

- the resulting hot combustion products then propagate through and drive the high pressure and low pressure turbines 17, 19 before being expelled through the nozzle 20 to provide some thrust.

- the high-pressure turbine 17 drives the high-pressure compressor 15 through a suitable connecting shaft 27.

- the blower 23 generally provides most of the thrust.

- the epicycloid gear 30 is a reduction gear.

- FIG Figure 2 An exemplary arrangement for a gear blower gas turbine engine 10 is shown in FIG Figure 2 shown.

- the low pressure turbine 19 (see Figure 1 ) drives the shaft 26, which is coupled to a sun gear 28 of the epicycloid gear arrangement 30.

- a plurality of planet gears 32 which are coupled to one another by a planet carrier 34, are located radially on the outside of the sun gear 28 and mesh with it.

- the planet carrier 34 limits the planet gears 32 to orbit synchronously around the sun gear 28 while allowing each planet gear 32 to rotate about its own axis.

- the planet carrier 34 is coupled to the blower 23 via linkages 36 to drive its rotation about the engine axis 9.

- An outer gear or ring gear 38 which is coupled to a stationary support structure 24 via linkages 40, is located radially outside of the planet gears 32 and meshes therewith.

- low pressure turbine and “low pressure compressor” as used herein can be understood to mean the lowest pressure turbine stage and the lowest pressure compressor stage (ie, they are not the blower 23) and / or the turbine and compressor stage connected by the lowest speed link shaft 26 in the engine (ie, not including the transmission output shaft that drives fan 23).

- the "low pressure turbine” and the “low pressure compressor” referred to herein will alternatively be known as the “medium pressure turbine” and “medium pressure compressor”.

- the blower 23 can be referred to as a first compression stage or compression stage with the lowest pressure.

- the epicycloid gear 30 is in Figure 3 shown in more detail by way of example.

- the sun gear 28, the planet gears 32 and the ring gear 38 each include teeth around their periphery for meshing with the other gears. However, for the sake of clarity, only exemplary sections of the teeth are shown in FIG Figure 3 shown.

- four planet gears 32 are shown, it is obvious to a person skilled in the art that more or fewer planet gears 32 can be provided within the scope of the claimed invention.

- Practical applications of an epicycloid gear 30 generally include at least three planet gears 32.

- Epicycloid gear 30 shown as an example is a planetary gear in which the planet carrier 34 is coupled to an output shaft via linkages 36, the ring gear 38 being fixed.

- any other suitable type of epicyclic gear 30 may be used.

- the epicycloid gear 30 may be a star configuration in which the planet carrier 34 is held in place, allowing the ring gear (or outer gear) 38 to rotate. With such an arrangement, the blower 23 is driven by the ring gear 38.

- transmission 30 may be a differential transmission that allows both ring gear 38 and planet carrier 34 to rotate.

- the present disclosure extends to a gas turbine engine with an arbitrary arrangement of the transmission types (for example star-shaped or planet-like), support structures, input and output shaft arrangement and bearing positions.

- the transmission types for example star-shaped or planet-like

- support structures for example star-shaped or planet-like

- input and output shaft arrangement and bearing positions for example star-shaped or planet-like

- the transmission can drive secondary and / or alternative components (e.g. the medium pressure compressor and / or a secondary compressor).

- secondary and / or alternative components e.g. the medium pressure compressor and / or a secondary compressor.

- Gas turbine engines to which the present disclosure may apply may have alternative configurations.

- such engines can have an alternative number of compressors and / or turbines and / or an alternative number of connecting shafts.

- Figure 1 Gas turbine engine shown a split stream nozzle 20, 22, which means that the flow through the bypass duct 22 has its own nozzle, which is separate from the engine core nozzle 20 and radially outside thereof.

- this is not limitative, and any aspect of the present disclosure may also apply to engines in which the flow through the bypass passage 22 and the flow through the core 11 are in front of (or upstream) a single nozzle, which may be referred to as a mixed flow nozzle, can be mixed or combined.

- One or both nozzles can have a fixed or variable range.

- the example described relates to a turbofan engine, the disclosure may be applicable to any type of gas turbine engine, such as a. B. in an open rotor (in which the blower stage is not surrounded by an engine nacelle) or a turboprop engine.

- the gas turbine engine 10 may not include a transmission 30.

- the geometry of the gas turbine engine 10 and components thereof is defined by a conventional axis system that has an axial direction (which is aligned with the axis of rotation 9), a radial direction (in the direction from the bottom to the bottom) up in Figure 1 ) and a circumferential direction (perpendicular to the view in Figure 1 ) includes.

- the axial, radial and circumferential directions are perpendicular to each other.

- the formation of a housing structure in the compressor housing is important.

- the invention can basically be implemented in the fan stage, in a low-pressure compressor, in a medium-pressure compressor (if present) and / or in a high-pressure compressor.

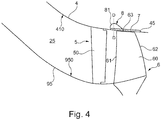

- the Figure 4 shows a sectional view of a structural assembly that defines a flow path 25 and includes an inlet stator 5, a rotor 6 and flow path boundaries.

- the flow path 25 conducts the core air flow A according to FIG Figure 1 through the core engine.

- the flow path 25 is delimited radially on the inside by inner wall or hub structures 95, which form an inner flow path boundary 950.

- the flow path 25 is delimited radially on the outside by a compressor housing 4 that forms a radially outer flow path boundary 410.

- the structural assembly is in the area of the first stage of a compressor.

- the compressor comprises the inlet guide wheel 5, which has stator blades 50 that can be adjusted in a staggered angle. The swirl in the flow is increased by the inlet guide wheel 5, and the subsequent rotor 6 is thereby striven for in a more effective manner.

- the rotor 6 comprises a series of rotor blades or rotor blades 60, which extend radially in the flow path 25.

- the blades 60 have a front edge 61, a rear edge 62 and a blade tip 63. A gap is realized between the blade tip 63 and the compressor housing 4.

- an inlet lining 7 is integrated in the compressor housing 4.

- the housing wall of the compressor housing 4 facing the flow path 25 forms a corresponding recess 45.

- the inlet lining 7 forms the flow path boundary 410.

- the inlet lining 7 is fastened in the recess 45 on its radially outer side.

- a housing structure 8 is integrated into the inlet lining 7. In the exemplary embodiment shown, this is implemented by axial grooves 81 in a half-heart shape.

- a such axial groove 81 in half-heart shape 81 is in the Figure 4 shown schematically.

- the illustration is not to be understood in such a way that the housing structuring 8 would protrude from the inlet lining 7 in the radial direction. The illustration only serves to display the axial course of the axial groove 81 in a half-heart shape.

- FIG. 5 shows a sectional view through a compressor housing 4 and an inlet lining 7 in a plane perpendicular to the axial direction, which is defined by the machine axis 9 (along the line DD of FIG Figure 4 ).

- the direction of rotation of the rotor 6 is marked with u.

- the compressor housing 4 has an upper compressor housing 410 and a lower compressor housing 420.

- the upper compressor housing 410 and the lower compressor housing 420 indicate spatial areas of the compressor housing 4. These are separated from one another by the horizontal plane 100.

- the upper compressor housing 410 and the lower compressor housing 420 can in principle be formed by any structures.

- the compressor housing comprises an upper peripheral segment 41 and a lower peripheral segment 42.

- the peripheral segments 41, 42 adjoin the flow path 25.

- the upper peripheral segment 41 extends, but not necessarily, in the region of the upper compressor housing 410.

- the lower peripheral segment 42 extends in the region of the lower compressor housing 420.

- the circumferential segments 41, 42 differ in any case in that only one of the circumferential segments forms a housing structure. It is thus provided that only the upper peripheral segment 41 has a housing structure 8, while the lower peripheral segment 42 has no housing structure.

- the housing structure in the illustrated embodiment is, but not necessarily in the inlet lining. Accordingly, the housing 4 has an upper inlet lining 71, in which a housing structure 8 is realized, and a lower inlet lining 72, which is realized without a housing structure.

- the two inlet linings 71, 72 each extend over 180 ° in the circumferential direction and adjoin one another in the horizontal plane 100.

- the housing 4 is a split housing which has two housing halves 411, 421, the division plane (ie the horizontal plane 100) between the two housing halves 411, 421 also representing the boundary between the two circumferential segments 41, 42 or inlet linings 71, 72.

- the upper inlet lining 71, in which a housing structure 8 is implemented, and the lower inlet lining 72, which is realized without a housing structure, consist, according to one embodiment, of the material Metco 601NS, Metco 320NS or Metco 314NS from Oerlikon Metco Switzerland in 8808 Pfäffikon, Switzerland , Metco 601 NS is a mixture of silicon-aluminum powders and polyester powders.

- Metco 320NS is an aluminum-silicon boron nitride powder.

- Metco 314NS is a thermal spray powder made from a nickel chrome aluminum bentonite mixture.

- high-temperature plastics, porous materials or metallic honeycomb structures are used as the material for the run-in coverings 71, 72.

- the radial thickness of the upper inlet lining 71 and the radial thickness of the lower inlet lining 72 are in any case identical in exemplary embodiments of the invention.

- the inlet linings 71, 72 are part of the compressor housing 4.

- the peripheral segments 41, 42 which are only partially provided with a housing structure, are shown in FIG Figure 5 formed by the inlet linings 71, 72 or in any case comprise these inlet linings 71, 72.

- the peripheral segments 41, 42 are formed by the actual compressor housing, ie the wall of the compressor housing facing the flow path 25.

- the corresponding structures such as axial grooves, are formed directly in the housing wall.

- the axial grooves 81 are shown in half-heart shape in a sectional view. As explained, the axial course of these axial grooves 81 is in the half-heart shape in FIG Figure 4 shown. According to the Figure 5 the axial grooves 81 are slightly inclined with respect to the radial direction. This can be done in one or the other circumferential direction. The axial grooves 81 can also run exactly in the radial direction.

- an inlet covering 72 is provided only in the lower circumferential segment 72.

- the casing structuring 8 is not realized in an upper inlet covering, but in an upper circumferential segment 41, which is through the casing wall of the compressor casing is realized. So that the flow path 25 does not have any cross-sectional change in such a case, it can be provided that the housing 4 has a larger housing radius in the lower compressor housing 420 than in the upper compressor housing 410 along the axial region in which it receives the lower inlet lining 72.

- neither the upper housing half 410 nor the lower housing half 420 has an inlet lining.

- a peripheral segment with a structuring of the housing is formed in the upper half of the housing.

- a peripheral segment without housing structuring is formed in the lower housing half.

- the Figure 6 shows a further embodiment of a structural assembly according to the present invention.

- the structural assembly comprises a compressor housing 4, which forms a flow path boundary 410.

- a rotor 6 comprises rotor blades 60, each of which has a front edge 61, a rear edge 62 and a blade tip 63. It can be seen that a gap is formed between the blade tip 63 and the flow path boundary 410.

- the machine axis 9 is also shown.

- a housing structure 8 is formed directly in the housing wall of the compressor housing 4 without the use of an inlet lining.

- a housing structure 8 is formed directly in the housing wall of the compressor housing 4 without the use of an inlet lining.

- formed by half-heart axial grooves 81 are in the DE 10 2007 056 953 A1 described, to which extent reference is made.

- the axial groove 81 with a half-heart shape can then be further defined by two angles ⁇ , ⁇ . These span the start and end of the cross-section curve specified by half the heart shape.

- the angle legs are arranged tangentially to the curve at the beginning or end.

- the angle ⁇ is, for example, in the range between 20 ° and 70 ° to the wall of the compressor housing and the angle ⁇ is, for example, in the range between 30 ° and 80 ° to the wall of the compressor housing.

- the Figure 6 furthermore shows that, in exemplary embodiments of the invention, the housing structure 8 in the region of the front edge 61 of the rotor blades 60 of the rotor 6 is formed.

- the axial extent of the axial grooves 81 is selected such that the axial grooves 81 extend from the front edge 630 of the blade tip 63 by a certain extension length opposite to the axial direction and from the front edge 630 by a certain extension length in the axial direction.

- the extension length in the two directions mentioned is, for example, a maximum of 50% of the axial length of the blade tip 63.

- Such an axial extension of the housing structuring can also be provided in the case of housing structuring designed in a different way.

- any of the features described can be used separately or in combination with any other features, provided that they are not mutually exclusive.

- the disclosure extends to and includes all combinations and subcombinations of one or more features described herein. If areas are defined, they include all values within these areas as well as all sub-areas that fall within one area.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102018116062.3A DE102018116062A1 (de) | 2018-07-03 | 2018-07-03 | Strukturbaugruppe für einen Verdichter einer Strömungsmaschine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3591237A1 true EP3591237A1 (fr) | 2020-01-08 |

| EP3591237B1 EP3591237B1 (fr) | 2021-05-19 |

Family

ID=67001586

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19181591.9A Active EP3591237B1 (fr) | 2018-07-03 | 2019-06-21 | Module structural pour un compresseur d'une turbomachine |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US11131322B2 (fr) |

| EP (1) | EP3591237B1 (fr) |

| DE (1) | DE102018116062A1 (fr) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3107917A1 (fr) * | 2020-03-04 | 2021-09-10 | Safran | Carter de roue mobile pour turbomachine |

| US12168983B1 (en) | 2024-06-28 | 2024-12-17 | Rolls-Royce North American Technologies Inc. | Active fan tip treatment using rotating drum array in fan track liner with axial and circumferential channels for distortion tolerance |

| US12209541B1 (en) | 2024-05-09 | 2025-01-28 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with dual slotted array active fan tip treatment for distortion tolerance |

| US12209502B1 (en) | 2024-06-28 | 2025-01-28 | Rolls-Royce North American Technologies Inc. | Active fan tip treatment using rotating drum array with axial channels in fan track liner for distortion tolerance |

| US12215712B1 (en) | 2024-05-09 | 2025-02-04 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with dual grooved array active fan tip treatment for distortion tolerance |

| US12258870B1 (en) | 2024-03-08 | 2025-03-25 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with slotted array active fan tip treatment for distortion tolerance |

| US12286936B1 (en) | 2024-05-09 | 2025-04-29 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with groove array active fan tip treatment for distortion tolerance |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11970985B1 (en) | 2023-08-16 | 2024-04-30 | Rolls-Royce North American Technologies Inc. | Adjustable air flow plenum with pivoting vanes for a fan of a gas turbine engine |

| US12066035B1 (en) | 2023-08-16 | 2024-08-20 | Rolls-Royce North American Technologies Inc. | Adjustable depth tip treatment with axial member with pockets for a fan of a gas turbine engine |

| US12078070B1 (en) | 2023-08-16 | 2024-09-03 | Rolls-Royce North American Technologies Inc. | Adjustable air flow plenum with sliding doors for a fan of a gas turbine engine |

| US12085021B1 (en) | 2023-08-16 | 2024-09-10 | Rolls-Royce North American Technologies Inc. | Adjustable air flow plenum with movable closure for a fan of a gas turbine engine |

| US12018621B1 (en) | 2023-08-16 | 2024-06-25 | Rolls-Royce North American Technologies Inc. | Adjustable depth tip treatment with rotatable ring with pockets for a fan of a gas turbine engine |

| US11965528B1 (en) | 2023-08-16 | 2024-04-23 | Rolls-Royce North American Technologies Inc. | Adjustable air flow plenum with circumferential movable closure for a fan of a gas turbine engine |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2504073A1 (de) * | 1974-02-15 | 1975-08-21 | Gen Electric | Akustischer kanal mit asymmetrischer akustischer behandlung |

| CN201152282Y (zh) * | 2007-09-26 | 2008-11-19 | 北京航空航天大学 | 一种非轴对称叶尖激励发生器 |

| CN201190695Y (zh) | 2007-11-09 | 2009-02-04 | 北京航空航天大学 | 一种非轴对称组合处理机匣 |

| DE102007053135A1 (de) * | 2007-11-08 | 2009-05-14 | Mtu Aero Engines Gmbh | Gasturbinenbauteil, insbesondere Flugtriebwerksbauteil bzw. Verdichterbauteil |

| DE102007056953A1 (de) | 2007-11-27 | 2009-05-28 | Rolls-Royce Deutschland Ltd & Co Kg | Strömungsarbeitsmaschine mit Ringkanalwandausnehmung |

| DE102008037154A1 (de) | 2008-08-08 | 2010-02-11 | Rolls-Royce Deutschland Ltd & Co Kg | Strömungsarbeitsmaschine |

| GB2477745A (en) * | 2010-02-11 | 2011-08-17 | Rolls Royce Plc | Compressor Casing |

| EP2514975A2 (fr) * | 2011-04-20 | 2012-10-24 | Rolls-Royce Deutschland Ltd & Co KG | Turbomachine |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3872966B2 (ja) * | 2001-06-29 | 2007-01-24 | 株式会社日立プラントテクノロジー | 軸流形流体機械 |

| GB2385378B (en) * | 2002-02-14 | 2005-08-31 | Rolls Royce Plc | Engine casing |

| DE102006048933A1 (de) * | 2006-10-17 | 2008-04-24 | Mtu Aero Engines Gmbh | Anordnung zur Strömungsbeeinflussung |

| FR2912789B1 (fr) * | 2007-02-21 | 2009-10-02 | Snecma Sa | Carter avec traitement de carter, compresseur et turbomachine comportant un tel carter. |

| DE102007037924A1 (de) * | 2007-08-10 | 2009-02-12 | Rolls-Royce Deutschland Ltd & Co Kg | Strömungsarbeitsmaschine mit Ringkanalwandausnehmung |

| DE102008010283A1 (de) * | 2008-02-21 | 2009-08-27 | Mtu Aero Engines Gmbh | Zirkulationsstruktur für einen Turboverdichter |

| FR2930590B1 (fr) * | 2008-04-23 | 2013-05-31 | Snecma | Carter de turbomachine comportant un dispositif empechant une instabilite lors d'un contact entre le carter et le rotor |

| JP4841680B2 (ja) * | 2010-05-10 | 2011-12-21 | 川崎重工業株式会社 | ガスタービン圧縮機の抽気構造 |

| DE102010036071A1 (de) | 2010-09-01 | 2012-03-01 | Mtu Aero Engines Gmbh | Gehäuseseitige Struktur einer Turbomaschine |

| FR2975735A1 (fr) | 2011-05-27 | 2012-11-30 | Snecma | Carter de soufflante de turbomachine et procede pour sa fabrication |

| GB201219617D0 (en) * | 2012-11-01 | 2012-12-12 | Rolls Royce Deutschland & Co Kg | Bleed flow passage |

| JP6109548B2 (ja) * | 2012-11-30 | 2017-04-05 | 三菱重工業株式会社 | 圧縮機 |

| DE102013210169A1 (de) * | 2013-05-31 | 2014-12-04 | Rolls-Royce Deutschland Ltd & Co Kg | Strukturbaugruppe für eine Strömungsmaschine |

| DE102013210171A1 (de) * | 2013-05-31 | 2014-12-04 | Rolls-Royce Deutschland Ltd & Co Kg | Strukturbaugruppe für eine Strömungsmaschine |

| US10047620B2 (en) * | 2014-12-16 | 2018-08-14 | General Electric Company | Circumferentially varying axial compressor endwall treatment for controlling leakage flow therein |

| GB201514896D0 (en) * | 2015-08-21 | 2015-10-07 | Rolls Royce Plc | Rotor tip clearance |

| US10472985B2 (en) * | 2016-12-12 | 2019-11-12 | Honeywell International Inc. | Engine case for fan blade out retention |

-

2018

- 2018-07-03 DE DE102018116062.3A patent/DE102018116062A1/de not_active Withdrawn

-

2019

- 2019-06-21 EP EP19181591.9A patent/EP3591237B1/fr active Active

- 2019-06-26 US US16/453,193 patent/US11131322B2/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2504073A1 (de) * | 1974-02-15 | 1975-08-21 | Gen Electric | Akustischer kanal mit asymmetrischer akustischer behandlung |

| CN201152282Y (zh) * | 2007-09-26 | 2008-11-19 | 北京航空航天大学 | 一种非轴对称叶尖激励发生器 |

| DE102007053135A1 (de) * | 2007-11-08 | 2009-05-14 | Mtu Aero Engines Gmbh | Gasturbinenbauteil, insbesondere Flugtriebwerksbauteil bzw. Verdichterbauteil |

| CN201190695Y (zh) | 2007-11-09 | 2009-02-04 | 北京航空航天大学 | 一种非轴对称组合处理机匣 |

| DE102007056953A1 (de) | 2007-11-27 | 2009-05-28 | Rolls-Royce Deutschland Ltd & Co Kg | Strömungsarbeitsmaschine mit Ringkanalwandausnehmung |

| DE102008037154A1 (de) | 2008-08-08 | 2010-02-11 | Rolls-Royce Deutschland Ltd & Co Kg | Strömungsarbeitsmaschine |

| GB2477745A (en) * | 2010-02-11 | 2011-08-17 | Rolls Royce Plc | Compressor Casing |

| EP2514975A2 (fr) * | 2011-04-20 | 2012-10-24 | Rolls-Royce Deutschland Ltd & Co KG | Turbomachine |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3107917A1 (fr) * | 2020-03-04 | 2021-09-10 | Safran | Carter de roue mobile pour turbomachine |

| US12258870B1 (en) | 2024-03-08 | 2025-03-25 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with slotted array active fan tip treatment for distortion tolerance |

| US12209541B1 (en) | 2024-05-09 | 2025-01-28 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with dual slotted array active fan tip treatment for distortion tolerance |

| US12215712B1 (en) | 2024-05-09 | 2025-02-04 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with dual grooved array active fan tip treatment for distortion tolerance |

| US12286936B1 (en) | 2024-05-09 | 2025-04-29 | Rolls-Royce North American Technologies Inc. | Adjustable fan track liner with groove array active fan tip treatment for distortion tolerance |

| US12168983B1 (en) | 2024-06-28 | 2024-12-17 | Rolls-Royce North American Technologies Inc. | Active fan tip treatment using rotating drum array in fan track liner with axial and circumferential channels for distortion tolerance |

| US12209502B1 (en) | 2024-06-28 | 2025-01-28 | Rolls-Royce North American Technologies Inc. | Active fan tip treatment using rotating drum array with axial channels in fan track liner for distortion tolerance |

Also Published As

| Publication number | Publication date |

|---|---|

| US11131322B2 (en) | 2021-09-28 |

| EP3591237B1 (fr) | 2021-05-19 |

| DE102018116062A1 (de) | 2020-01-09 |

| US20200011346A1 (en) | 2020-01-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3591237B1 (fr) | Module structural pour un compresseur d'une turbomachine | |

| EP3940200B1 (fr) | Roue à aubes d'une turbomachine | |

| DE102020103776A1 (de) | Getriebe-Gasturbinentriebwerk | |

| DE102020103780A1 (de) | Getriebe-Gasturbinentriebwerk | |

| DE102018113753A1 (de) | Planetengetriebe und Gasturbinentriebwerk | |

| WO2020260255A1 (fr) | Transmission et groupe motopropulseur à turbine à gaz | |

| DE102019106633A1 (de) | Getriebe und Gasturbinentriebwerk | |

| EP3599349A1 (fr) | Module structural avec aubes à calage variable inclinées pour un compresseur d'une turbomachine | |

| DE102020113053A1 (de) | Gasturbinentriebwerk | |

| EP4004407B1 (fr) | Roue dentée | |

| EP3543481B1 (fr) | Turbomoteur à gaz et procédé d'introduction de l'huile dans un agencement de transmission | |

| DE102018106864A1 (de) | Verfahren zum Zusammenbau eines Planetengetriebes, ein Planetenträger und ein Flugzeugtriebwerk | |

| EP4034756B1 (fr) | Turbine à gaz d'aéronef comprenant une transmission | |

| DE102018119463B4 (de) | Labyrinthdichtungssystem und Gasturbinentriebwerk mit einem Labyrinthdichtungssystem | |

| DE102021209552A1 (de) | Planetengetriebe | |

| DE102020215576A1 (de) | Strömungsleitvorrichtung und ein Gasturbinentriebwerk | |

| WO2021069186A1 (fr) | Engrenage à manchon en céramique | |

| DE102020122721A1 (de) | Getriebeteil | |

| DE102020116785B4 (de) | Strukturbaugruppe für ein Gasturbinentriebwerk | |

| WO2021008901A1 (fr) | Accouplement d'arbres pourvu d'une denture emboîtable | |

| DE102020116522A1 (de) | Planetengetriebe | |

| EP3597887A1 (fr) | Agencement de boîte de vitesse et son procédé de fabrication | |

| EP3670873A1 (fr) | Arbre de turbine à gaz | |

| DE102019200629A1 (de) | Wellenbauteil und Gasturbinentriebwerk mit einem Wellenbauteil | |

| DE102021209401A1 (de) | Planetengetriebe mit einem Dichtungssystem und Gasturbinentriebwerk mit einem Planetengetriebe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ROLLS-ROYCE DEUTSCHLAND LTD & CO KG |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20200707 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20201218 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BECKER, BERND Inventor name: GIERSCH, THOMAS Inventor name: GROTHE, PATRICK Inventor name: HEINICHEN, FRANK Inventor name: JUENGST, MAXIMILIAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502019001443 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1394246 Country of ref document: AT Kind code of ref document: T Effective date: 20210615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210819 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210820 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210919 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210920 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210819 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502019001443 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20210630 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210621 |

|

| 26N | No opposition filed |

Effective date: 20220222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210919 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20190621 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250626 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250624 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1394246 Country of ref document: AT Kind code of ref document: T Effective date: 20240621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210519 |