EP3590853B1 - Processing device for packaging machines - Google Patents

Processing device for packaging machines Download PDFInfo

- Publication number

- EP3590853B1 EP3590853B1 EP19172470.7A EP19172470A EP3590853B1 EP 3590853 B1 EP3590853 B1 EP 3590853B1 EP 19172470 A EP19172470 A EP 19172470A EP 3590853 B1 EP3590853 B1 EP 3590853B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- processing

- packaging machine

- processing units

- accordance

- adjustment

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000012545 processing Methods 0.000 title claims description 179

- 238000004806 packaging method and process Methods 0.000 title claims description 107

- 238000007639 printing Methods 0.000 claims description 12

- 230000008878 coupling Effects 0.000 claims description 10

- 238000010168 coupling process Methods 0.000 claims description 10

- 238000005859 coupling reaction Methods 0.000 claims description 10

- 235000013305 food Nutrition 0.000 claims description 7

- 238000002372 labelling Methods 0.000 claims description 7

- 238000003754 machining Methods 0.000 description 41

- 238000000034 method Methods 0.000 description 8

- 230000008569 process Effects 0.000 description 8

- 230000008859 change Effects 0.000 description 3

- 238000013461 design Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 238000004148 unit process Methods 0.000 description 2

- 208000027418 Wounds and injury Diseases 0.000 description 1

- 230000006378 damage Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 210000000056 organ Anatomy 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/02—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing

- E03D9/03—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing consisting of a separate container with an outlet through which the agent is introduced into the flushing water, e.g. by suction ; Devices for agents in direct contact with flushing water

- E03D9/033—Devices placed inside or dispensing into the cistern

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B61/00—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages

- B65B61/02—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for perforating, scoring, slitting, or applying code or date marks on material prior to packaging

- B65B61/025—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for perforating, scoring, slitting, or applying code or date marks on material prior to packaging for applying, e.g. printing, code or date marks on material prior to packaging

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B61/00—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages

- B65B61/02—Auxiliary devices, not otherwise provided for, for operating on sheets, blanks, webs, binding material, containers or packages for perforating, scoring, slitting, or applying code or date marks on material prior to packaging

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/02—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing

- E03D9/03—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing consisting of a separate container with an outlet through which the agent is introduced into the flushing water, e.g. by suction ; Devices for agents in direct contact with flushing water

- E03D9/033—Devices placed inside or dispensing into the cistern

- E03D9/035—Devices connected to the actuation mechanism

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/02—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing

- E03D9/03—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing consisting of a separate container with an outlet through which the agent is introduced into the flushing water, e.g. by suction ; Devices for agents in direct contact with flushing water

- E03D9/033—Devices placed inside or dispensing into the cistern

- E03D9/037—Active dispensers, i.e. comprising a moving dosing element

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/02—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing

- E03D2009/028—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing using a liquid substance

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/02—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing

- E03D9/03—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing consisting of a separate container with an outlet through which the agent is introduced into the flushing water, e.g. by suction ; Devices for agents in direct contact with flushing water

- E03D9/031—Devices connected to or dispensing into the flushing pipe

Definitions

- the invention relates to a processing device for packaging machines, in particular for labeling and / or printing packaging, with at least one upper processing unit for processing packaging tops and at least one lower processing unit for processing packaging undersides.

- the invention also relates to a packaging machine, in particular for food products, with at least one processing device according to the invention.

- Packaging machines such as are used in particular for packaging food products, typically comprise a multiplicity of work stations which are arranged one after the other along a work or transport direction. In such food processing lines with packaging machines, the products are often not only packaged, but the packs are actually produced in the first place.

- the packs are made from at least two material webs, in particular film webs, namely a so-called lower film and a so-called upper film.

- the lower film is reshaped by means of a deep-drawing process, in order, for example, to produce a shell-shaped lower part of a respective pack.

- the workflow in such a deep-drawing packaging machine is in particular clocked.

- a predetermined length of film is withdrawn and transported along the packaging machine, with one work cycle corresponding to at least one pack or, if the packaging machine is designed with multiple lanes, at least one row of packs lying transversely to the transport direction.

- the packs are provided with labels and / or printed, for example.

- this is often done on the packaging machines themselves, which are provided with appropriate processing devices for this purpose. These are usually arranged at an end region of the packaging machine in order to label or print the finished packs, which are still connected as a film web, for example.

- processing devices such as labelers and printers for packs have been known for a long time.

- the object of the invention is therefore to create a possibility for processing packs on packaging machines, which has the smallest possible space requirement and allows the simplest possible operation.

- a processing device with the features of claim 1.

- a common adjustment axis is provided for the processing units, along which the processing units can be adjusted manually or by means of a drive in an adjustment direction that runs parallel to a transport direction of the packaging machine.

- the object is also achieved by a packaging machine with at least one processing device according to the invention.

- the invention leaves the path taken so far in the prior art, in the case of several processing units, to consider them as separate, independent machines and to design and operate them accordingly, each of which requires a complete separate infrastructure in order to be attached to the packaging machine and in particular in the direction of transport Packaging machine to be adjusted.

- the common adjustment axis is not to be understood as an imaginary or virtual axis in the mathematical sense, but rather an objective component or structural unit that can be adjusted manually or by means of a drive of the processing units parallel to the transport direction of the packaging machine.

- the adjustment axis can be a component or unit, however specifically configured, extending over a suitable adjustment length parallel to the transport direction of the packaging machine, for example a guide rod, whereby this component or unit can consequently also fulfill a guiding function.

- this does not exclude additional guides for the machining units.

- the adjustment axis can form or comprise a common drive element for the processing units or be formed by such a drive element.

- This drive element can be, for example, a spindle, a toothed belt or a toothed rack.

- the concept of the invention makes it possible to shift the operation of all processing units completely to just one of the sides of the packaging machine.

- an additional guide for the processing units can be provided, which, however, does not need to be addressed by the operating personnel, at least while the packaging machine is in operation.

- Another advantage of a common adjustment axis for several processing units is that certain safety-related measures - insofar as they are fundamentally necessary - only need to be taken on one side of the packaging machine.

- the processing units can be adjusted in opposite directions with respect to the transport direction of the packaging machine, a risk of injury to the operating personnel, which is potentially due to this adjustability, must be carried out by means of suitable safety regulations Measures such as the provision of a cover can be avoided.

- the processing units can be adjusted via the central control of the packaging machine or the entire processing line into which the packaging machine is possibly integrated.

- inventive concept enables a variety of work variants, which will be discussed in more detail elsewhere, with at least certain variants not yet being able to be implemented, or at most with the acceptance of a considerable additional working length of the packaging machine.

- a single common adjustment axis can be provided for the machining units.

- At least one further common adjustment axis can be provided, in which case all the common adjustment axes of the processing units are arranged on the same side of the packaging machine.

- An adjustment axis which can also be referred to as the main adjustment axis, can primarily be provided for joint adjustment of the machining units.

- a machining unit that is decoupled from the main adjustment axis can be coupled to a further common adjustment axis and, for example, be brought into a non-working position along this further common adjustment axis, independently of the other machining unit or units.

- a common adjustment axis within the meaning of the invention can also be provided in such a way that one processing unit is not directly connected to the common one Adjusting axis interacts, but only indirectly via the respective other processing unit, which interacts directly with the common adjustment axis.

- the two machining units are consequently not adjustable independently of one another by means of the common adjustment axis.

- this does not preclude the processing units from being movable relative to one another in order, for example, to be able to change an offset in the transport direction of the packaging machine between the two processing units.

- Preferred embodiments can also be found in the following description, the dependent claims and the drawing.

- a common travel drive is provided for the two machining units, with which the machining units can be moved along the adjustment axis.

- the displacement drive can comprise an elongated drive element for the machining units that extends in the actuating direction.

- the drive element can be, for example, a spindle, a toothed belt or a toothed rack.

- the machining units can be coupled to the adjustment axis and decoupled from the adjustment axis independently of one another. This enables a highly flexible operation of the packaging machine with regard to the function of the processing units. If the processing units are all coupled to the adjustment axis, the processing units can be adjusted together.

- the processing units can, for example, jointly change their position along the packaging machine, and any offset that may be present between the two processing units in the transport direction can remain constant. However, an offset between the processing units does not have to be present and - if it is present - not constant be.

- a joint adjustment of processing units coupled to the adjustment axis can also be accompanied by an increasing or decreasing distance between the processing units in the transport direction of the packaging machine.

- each processing unit comprises a coupling device which can be actuated manually or controlled by means of a control device and is designed to couple and decouple the processing unit and the adjustment axis from one another.

- the control device can be assigned to the processing device and, in particular, integrated into the processing device and connected in a suitable manner to a central control device of the packaging machine.

- the control device used to control the coupling devices of the processing unit can be integrated into a central control device of the packaging machine or a higher-level processing line.

- a guide running parallel to the adjustment direction is provided for the machining devices.

- the guide can comprise a guide element or at least two guide elements extending at a distance from one another transversely to the setting direction.

- the guide element (s) can be, for example, simple, passive guide rods. If two spaced guide organs are provided, then these can be on opposite sides Be arranged sides of the packaging machine. This results in particularly stable and precise guidance and alignment of the processing units with respect to the respective packaging machine. While the or each common adjustment axis for the processing units is only arranged on one side of the machine, guide devices for the processing units can thus be provided on both sides of the packaging machine.

- At least one transverse axis running transversely to the transport direction is provided for at least one additional unit.

- the transverse axis can be moved manually or by means of a drive along the adjustment axis in the adjustment direction.

- the additional unit for which the additional transverse axis is provided can be, for example, a printing device for printing, for example, the top or bottom sides of the pack.

- the processing units are each a labeling unit, the upper labeling unit being used to label the tops of the pack and the lower labeling unit to be used to label the underside of the pack.

- the processing units can each be designed as printing units for printing the pack sides.

- "mixed" applications are also possible in which different processing units are used.

- the top of the pack can be labeled using an upper labeling unit and the bottom of the pack can be printed on using a lower printing unit.

- a packaging machine in particular a machine for packaging food products, which comprises at least one processing device according to the invention as disclosed herein, according to one

- the processing device is supported on a machine frame of the packaging machine. This does not exclude that an additional, but not sufficient, support takes place via another device that is not formed by the packaging machine or does not belong to the packaging machine or via a set-up area, in particular the floor.

- the processing device is preferably supported exclusively on the packaging machine and in particular on a rack or frame of the packaging machine.

- the adjustment axis of the packaging machine is preferably arranged on one side of a machine frame or a machine frame of the packaging machine.

- the adjustment axis is preferably supported on the machine frame or the machine frame. In particular, the adjustment axis is supported exclusively in this way.

- the processing units of the processing device can, viewed in the transport direction, be arranged in the same working section of the packaging machine that is assigned to a pack or to a row of packs lying transversely to the transport direction.

- the same pack is consequently processed by the processing units, ie the top processing unit processes the top side of the pack and the bottom processing unit processes the bottom side of the package.

- the processing units each process the same row of packs.

- An offset between the processing units in the transport direction of the packaging machine within the working section can be provided. This offset can result from the respectively desired processing positions, which can be different for the pack top and the pack bottom of a respective pack.

- a label for the top of the pack may be desirable to apply to a front region of the pack in the direction of transport, whereas a label or printing is to be applied to the underside of the pack, viewed in the direction of transport, in the rear area of the pack.

- an alternative configuration in which the processing units are arranged in different working sections offset from one another in the transport direction, which are each assigned to a pack or a row of packs lying transversely to the transport direction.

- the working sections can have one or more packs or pack rows offset from one another in the direction of transport or - in other words - be spaced from one another.

- This configuration can be advantageous, for example, as a function of the specific design and a possibly existing structure of the processing units that protrudes beyond the limitation of the actual packaging machine.

- the operation of the processing units can be made easier as a result.

- each comprising an upper processing unit and a lower processing unit can be provided, which are arranged in different working sections offset from one another in the transport direction, each working section being assigned to a pack or a row of packs lying transversely to the transport direction.

- the performance of the packaging machine with regard to the processing of the packs by means of the processing units can be multiplied in accordance with the number of pairs. For example, with two pairs of machining units, the machining performance can be doubled.

- Another possibility that results from the use of several pairs of processing units is to carry out additional processing on the packs, for example, to apply one or more additional labels that may only be required temporarily.

- processing units or pairs of processing units can be moved independently of one another from a work area into a non-work position.

- a pair of processing units can be serviced in the non-working position or provided with a new supply of labels, for example, without the packaging machine being shut down, but with a temporary reduction in processing performance.

- the temporarily inactive pair of processing units can be driven back into the respective work section, whereupon the original full capacity is available again.

- the processing units can each be moved within their working section in the adjusting direction in order to set a respectively desired working offset between an upper processing position and a lower processing position.

- a control device is preferably provided which is designed to control a travel drive of the machining device and the machining units, in particular coupling devices of the machining devices, depending on the respective operating situation, in order to adjust the machining units together or individually in the setting direction.

- the coupling units can serve to couple the respective machining unit and the adjustment axis to one another and to decouple them from one another. This is done independently of one another for the processing units.

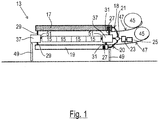

- Packaging machine 13 shown schematically in cross section, comprises a machine frame 37 which is supported on the floor via an underframe 49.

- a left transport chain 51 and a right transport chain 51 are supported by chain guides (not shown) on the respective frame element of the machine frame 37 extending in the transport direction and serve, as described in the introductory part, to transport a lower film through the packaging machine 13, from which, together with an upper film, packs 15 with food products (not shown) received therein.

- the packaging machine 13 has four lanes, ie in each row of packs 41 (cf. Figures 2 to 5 ) are four packs 15 next to each other, which are separated towards the end of the work process.

- the packaging machine 13 is provided with a processing device 11 which is used to process the top and bottom sides of the packs 15.

- the processing device 11 comprises at least one pair of processing units, namely an upper processing unit 17, which is located above the packs 15, and below the packs 15 a lower processing unit 19.

- the processing is the application of labels.

- Both processing units 17, 19, which are each designed as a labeler, are each assigned a structure which, among other things, includes a label supply roll 45 and a feed for the label web 47 rolled up in the supply 45. How out Fig. 1 As can be seen, these structures of the processing units 17, 19 protrude laterally and upwardly beyond the machine frame 37 of the packaging machine 13.

- These structures comprising the supply roll 45 and the label feed (not shown) are each connected to the respective processing unit 17, 19 in such a way that when the respective processing unit 17, 19 is adjusted, they move in the transport direction T of the packaging machine 13 and against the transport direction T - i.e. in the setting direction S (cf. Figures 2 to 5 ) - are always moved together with their respective processing unit 17, 19.

- the adjusting movements of the machining units 17, 19 are guided on the machine frame 37 in the exemplary embodiment shown here.

- guides 29, 31 are provided on the left side and on the right side of the machine frame 37, which are shown in FIG Fig. 1 only schematically and in the Figures 2 to 5 are each indicated as a dash-dotted line.

- the guides 29, 31 can only comprise passive guide elements, such as guide rods for example, which are carried by the machine frame 37 and have no drive function for the respective machining unit 17, 19.

- the provision of a guide for the machining device 11 is not mandatory.

- the adjustment axis 21 can be sufficient to ensure the required stability and guidance and to enable the machining units 17, 19 to be adjusted in the adjustment direction S.

- the illustrated position of the adjustment axis 21 relative to the packaging machine 13 is to be understood purely schematically.

- the adjustment axis 21 can be arranged at any point on one of the machine sides, depending on the specific structure of the packaging machine 13 and in particular of the machine frame 37. In the exemplary embodiments shown here, the adjustment axis 21 is located on the right-hand side of the machine - viewed in the transport direction T.

- the adjustment axis 21 is in the Figures 2 to 5 indicated by a dashed line that is thicker than the guides 29, 31.

- Fig. 1 shows, the upper machining unit 17 and the lower machining unit 19 are each connected to the common adjustment axis 21. This takes place in each case by means of a holder 18, 20, which is only indicated schematically.

- the adjustment axis 21 can be designed, for example, as a threaded spindle extending parallel to the transport direction T, with which spindle nuts formed on the brackets 18, 20 can be coupled.

- the threaded spindle acting as the adjustment axis 21 can be operated manually, for example.

- a preferred embodiment is an in Fig. 1 schematically represented drive 23 is provided, which is connected to a control device 25 and thus enables a controlled adjustment of the machining units 17, 19 by the threaded spindle forming the adjustment axis 21 is set in rotation accordingly.

- the control device 25 can only be assigned to the processing device 11 and connected to a higher-level control device, not shown, of the packaging machine 13. Alternatively, the control device 25 can be integrated into such a central control device.

- a differently configured travel drive can also be provided, which is based, for example, on the drive principle of a toothed belt or a toothed rack.

- each of the two processing units 17, 19 is provided with a coupling device 27, which allows the respective processing unit 17, 19 to be coupled with the adjustment axis 21 or decoupled from the adjustment axis 21 via its holder 18, 20 as required. In this way, an individual, mutually independent adjustment movement of the two processing units 17, 19 is possible.

- FIGS. 2 to 5 show examples of different configurations in which the processing units 17, 19 of the processing device 11 on the packaging machine 13 can be positioned and adjusted relative to one another with respect to the transport direction T and in particular with respect to the packaging 15 or packaging rows 41.

- FIG. 2 shows an additional option, which, however, can in principle also be used in all configurations possible according to the invention, namely the provision of an additional unit 35, which is, for example, a printing device can act for printing either the top of the pack or the bottom of the pack.

- a transverse axis 33 extending perpendicular to the transport direction T is provided for this additional unit 35, which - like the processing units 17, 19 - can be moved in the setting direction S by means of the common adjustment axis 21 in order to set the printing position on the top of the pack or on the top of the pack in relation to a pack row 41 To be able to adjust the undersides of the pack.

- the additional unit 35 is also adjustable along the transverse axis 33 in order to be able to reach all packs 15 of a pack row 41. The possible movements of the additional unit 35 thus given are shown in FIG Fig. 2 indicated by the double arrows.

- the upper processing unit 17 and the lower processing unit 19 are assigned to the same row of packs 41 and thus - as seen in the transport direction T - are assigned to the same working section.

- the two processing units 17, 19 are essentially one above the other.

- the offset existing within this same working section between the two processing units 17, 19 in the adjustment direction S can be adjusted by moving the processing units 17, 19 along the adjustment axis 21.

- the processing position with respect to the packs 15 of the relevant pack row 41 can be precisely specified for the upper processing unit 17 as well as for the lower processing unit 19.

- labels can be applied at any desired position on a pack top and a pack bottom, or the top and bottom sides of the packs 15 can be printed at basically any point if the processing units 17, 19 are not labelers, but Printer acts.

- the illustrated longitudinal offset of the machining units 17, 19 in the adjusting direction S can also be zero, ie the machining units 17, 19 can be positioned relative to one another in such a way that they are exactly lie on top of each other.

- the positions of the two processing units 17, 19 in the transport direction T compared to the arrangement in FIG Fig. 2 are interchanged, ie the upper processing unit 17 is further forward in the transport direction T than the lower processing unit 19.

- the two processing units 17, 19 are assigned to different rows of packs 41.

- a longitudinal offset in the adjusting direction S of the two processing units 17, 19 by precisely one row of packs 41 is shown.

- the offset can also be more than one row of packs 41.

- both processing units 17, 19 can only be moved together and are therefore positively coupled. It is also possible, for example, that only the lower machining unit 19 can be moved on the adjustment axis 21, but not the upper machining unit 17, which is for this purpose on a further adjustment axis 21, not shown, which is arranged on the same machine side as the common adjustment axis 21. can be adjusted relative to the lower processing unit 19. Since such a configuration enables joint adjustment by moving the lower machining unit 19 on the adjustment axis 21, the adjustment axis 21 is also a common adjustment axis for the two machining units 17, 19 in this configuration.

- the embodiment of the Fig. 4 is based on the configuration according to Fig. 2 , wherein the processing device 11 here comprises two pairs of processing units 17, 19 and each pair 43 is assigned to a row of packs 41, the two pairs 43 being offset from one another by a row of packs 41 in the transport direction T. It goes without saying that the offset can also be more than one row 41 of packs.

- this can double the processing performance or create the possibility of performing additional processing of the upper sides and / or lower sides of the packs 15, which may also only be done temporarily.

- so-called promotion labels or other additional labels or even printing can be applied to the packs 15 by means of the additional pair 43 of processing units 17, 19.

- FIG. 5 The illustrated embodiment is based on the concept of Fig. 4 .

- Two pairs 43 of processing units 17, 19 are again provided here.

- the above in connection with Fig. 1 The mentioned optional coupling and decoupling of the processing units 17, 19 by means of the coupling devices 27 can for example be used in this configuration for this purpose, for example the in Fig. 5 right pair 43 of processing units 17, 19 from a working position corresponding to the embodiment of FIG Fig. 4 in a non-work position in Fig. 5 to move to the right against the transport direction T, for example to carry out maintenance work or a label supply roll 45 (cf. Fig. 1 ) switch.

- the adjustment of the temporarily interrupted machining units 17, 19 in the state decoupled from the adjustment axis 21 can for example take place manually or by means of a travel drive which has an additional to the common adjustment axis 21 provided adjustment axis (not shown) includes.

- An additional adjustment axis can be assigned to both pairs 43 of machining units 17, 19. Alternatively, each pair 43 can have its own additional adjustment axis.

- an essential advantage of the invention is that the operation of the processing unit can be completely shifted to only one side of the packaging machine. Furthermore, the effort for any necessary safety measures can be reduced, in particular safety measures due to the mobility of the processing units and the associated potential risk of crushing. It is also advantageous that the working length required by the packaging machine for the processing unit according to the invention is comparatively small. In particular, when several pairs of machining units are provided, a saving in the required machine length of 50% and more can be achieved compared to an increase in performance achieved in a conventional manner, without having to accept any losses in functionality or performance.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Engineering & Computer Science (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Water Supply & Treatment (AREA)

- Mechanical Engineering (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

Description

Die Erfindung betrifft eine Bearbeitungsvorrichtung für Verpackungsmaschinen, insbesondere zum Etikettieren und/oder Bedrucken von Verpackungen, mit wenigstens einer oberen Bearbeitungseinheit zum Bearbeiten von Verpackungsoberseiten und wenigstens einer unteren Bearbeitungseinheit zum Bearbeiten von Verpackungsunterseiten. Die Erfindung betrifft außerdem eine Verpackungsmaschine, insbesondere für Lebensmittelprodukte, mit wenigstens einer erfindungsgemäßen Bearbeitungsvorrichtung.The invention relates to a processing device for packaging machines, in particular for labeling and / or printing packaging, with at least one upper processing unit for processing packaging tops and at least one lower processing unit for processing packaging undersides. The invention also relates to a packaging machine, in particular for food products, with at least one processing device according to the invention.

Verpackungsmaschinen, wie sie insbesondere zum Verpacken von Lebensmittelprodukten eingesetzt werden, umfassen typischerweise eine Vielzahl von Arbeitsstationen, die entlang einer Arbeits- oder Transportrichtung aufeinanderfolgend angeordnet sind. In derartigen Lebensmittelverarbeitungslinien mit Verpackungsmaschinen werden häufig die Produkte nicht nur verpackt, sondern es werden die Packungen überhaupt erst hergestellt. In sogenannten Tiefzieh-Verpackungsmaschinen, die zum Verpacken von Lebensmittelprodukten sehr häufig eingesetzt werden, werden die Packungen aus wenigstens zwei Materialbahnen, insbesondere Folienbahnen, hergestellt, nämlich einer sogenannten Unterfolie und einer sogenannten Oberfolie. Typischerweise wird an einer im Anfangsbereich der Verpackungsmaschine gelegenen Tiefziehstation eine Umformung der Unterfolie mittels eines Tiefziehvorgangs durchgeführt, um beispielsweise ein schalenförmiges Unterteil einer jeweiligen Packung herzustellen. An einer sich anschließenden Einlegestation werden die Produkte in die Packungsunterteile eingelegt. Anschließend wird die Oberfolie zugeführt, die auf die mit den Produkten gefüllten Verpackungsunterteile, also auf die Unterfolie, gelegt wird, woraufhin die beiden Folien in einer Siegelstation der Verpackungsmaschine versiegelt werden, um die Packungen zu verschließen. Während dieses Prozesses wird zumindest die die Unterfolie bildende Folienbahn jeweils nach dem Abwickeln von einer Vorratsrolle von mit Halteklammern versehenen Förderketten der Verpackungsmaschine gegriffen und entlang der Verpackungsmaschine durch die einzelnen Arbeitsstationen transportiert.

Der Arbeitsablauf in einer derartigen Tiefzieh-Verpackungsmaschine erfolgt insbesondere getaktet. In jedem Arbeitstakt wird eine vorgegebene Folienlänge abgezogen und längs der Verpackungsmaschine transportiert, wobei ein Arbeitstakt wenigstens einer Packung oder-wenn die Verpackungsmaschine mehrspurig ausgebildet ist - wenigstens einer quer zur Transportrichtung liegenden Packungsreihe entspricht.The workflow in such a deep-drawing packaging machine is in particular clocked. In each work cycle, a predetermined length of film is withdrawn and transported along the packaging machine, with one work cycle corresponding to at least one pack or, if the packaging machine is designed with multiple lanes, at least one row of packs lying transversely to the transport direction.

In der Praxis ist es häufig erforderlich, weitere Bearbeitungsvorgänge an den Packungen oder den Material- bzw. Folienbahnen durchzuführen. Insbesondere ist es vielfach erforderlich, die Packungen mit Informationen für die weitere Verarbeitung, den Transport, den Handel und vor allem den Endverbraucher der verpackten Produkte zu versehen. Hierzu werden die Packungen beispielsweise mit Etiketten versehen und/oder bedruckt. Dies erfolgt in der Praxis häufig an den Verpackungsmaschinen selbst, die hierzu mit entsprechenden Bearbeitungsvorrichtungen versehen sind. Diese sind üblicherweise an einem Endbereich der Verpackungsmaschine angeordnet, um die fertigen und noch als Folienbahn zusammenhängenden Packungen beispielsweise zu etikettieren oder zu bedrucken. Dabei ist es aber auch möglich, an einer anderen Stelle der Verpackungsmaschine die jeweiligen Materialbahnen mit Etiketten zu versehen oder zu bedrucken. Bearbeitungsvorrichtungen wie Etikettierer und Drucker für Packungen sind seit langem bekannt. Dabei ist es auch bekannt, derartige Bearbeitungsvorrichtungen direkt an der Verpackungsmaschine, insbesondere an einem sich in Transportrichtung erstreckenden Maschinenrahmen, abzustützen und in Transportrichtung manuell oder mittels eines Antriebs verfahrbar auszugestalten, um die jeweilige Bearbeitungsposition relativ zu der jeweiligen Packung bzw. Packungsreihe einstellen zu können. Um den Aufwand in Grenzen zu halten und um den Platzbedarf bzw. die Arbeitslänge der Verpackungsmaschine möglichst gering zu halten, wird in der Praxis häufig lediglich eine einzige Bearbeitungsvorrichtung vorgesehen, die entweder nur die Packungsoberseiten oder nur die Packungsunterseiten bearbeiten kann.In practice, it is often necessary to carry out further processing operations on the packs or the material or film webs. In particular, it is often necessary to provide the packs with information for further processing, transport, trade and, above all, the end user of the packaged products. For this purpose, the packs are provided with labels and / or printed, for example. In practice, this is often done on the packaging machines themselves, which are provided with appropriate processing devices for this purpose. These are usually arranged at an end region of the packaging machine in order to label or print the finished packs, which are still connected as a film web, for example. However, it is also possible to provide the respective material webs with labels or to print them at another point on the packaging machine. Processing devices such as labelers and printers for packs have been known for a long time. It is also known to support such processing devices directly on the packaging machine, in particular on a machine frame extending in the direction of transport, and to support them manually in the direction of transport or designed to be movable by means of a drive in order to be able to set the respective processing position relative to the respective pack or row of packs. In order to keep the effort within limits and to keep the space requirement or the working length of the packaging machine as low as possible, only a single processing device is often provided in practice, which can process either only the top of the pack or only the bottom of the pack.

Grundsätzlich ist es aber auch bekannt, zwei getrennte, eigenständige Bearbeitungsvorrichtungen vorzusehen, von denen die eine die Packungsoberseiten und die andere die Packungsunterseiten bearbeiten kann. Problematisch bei Bearbeitungsvorrichtungen für Verpackungsmaschinen, insbesondere bei Etikettierern, ist der große Platzbedarf der Aufbauten. Etikettierer beispielsweise benötigen unter anderem einen Etikettenvorrat und eine Etikettenzuführung. Dieser Aufbau steht typischerweise seitlich und nach oben über die eigentliche Begrenzung der Verpackungsmaschine vor. Wenn zwei separate Etikettiervorrichtungen zum Einsatz kommen sollen, so werden diese in der Praxis in Transportrichtung gegeneinander versetzt und zudem derart angeordnet, dass der Aufbau des einen Etikettierers auf der einen Seite der Verpackungsmaschine und der Aufbau des anderen Etikettierers auf der gegenüberliegenden Maschinenseite liegt. Dies erleichtert die Anordnung von zwei Etikettierern, hat allerdings den Nachteil, dass das Bedienpersonal ständig zwischen den beiden Maschinenseiten wechseln muss, um beispielsweise Etikettenvorratsrollen zu wechseln, die Vorratsrollen in die Etikettenzuführung einzufädeln, Feineinstellungen vorzunehmen oder andere während des laufenden Betriebs der Verpackungsmaschine notwendige Eingriffe zu erledigen. Dies ist vor allem auch deshalb problematisch, da Verpackungsmaschinen heutzutage eine enorme Länge besitzen und das Bedienpersonal folglich lange Wege in kurzer Zeit zurücklegen muss.In principle, however, it is also known to provide two separate, independent processing devices, one of which can process the top of the pack and the other of which can process the bottom of the pack. The problem with processing devices for packaging machines, in particular with labelers, is the large amount of space required by the superstructures. Labelers, for example, need, among other things, a label supply and a label feed. This structure typically projects laterally and upwardly beyond the actual boundary of the packaging machine. If two separate labeling devices are to be used, they are in practice offset from one another in the transport direction and also arranged in such a way that the structure of one labeler is on one side of the packaging machine and the structure of the other labeler is on the opposite side of the machine. This simplifies the arrangement of two labelers, but has the disadvantage that the operating personnel have to constantly switch between the two sides of the machine, for example to change label supply rolls, thread the supply rolls into the label feeder, make fine adjustments or make other interventions necessary while the packaging machine is in operation complete. This is particularly problematic because packaging machines nowadays are extremely long and the operating personnel consequently have to cover long distances in a short time.

Inbetriebnahme und Einstellung von Bearbeitungsvorrichtungen an Verpackungsmaschinen, insbesondere von Etikettierern und Druckern, sind folglich in der Praxis häufig mit einer umständlichen und schwierigen Bedienung verbunden. Dieses Problem wird aufgrund des immer weiter zunehmenden Automatisierungsgrades und der damit einhergehenden größeren Länge von Verpackungsmaschinen beständig größer.Commissioning and setting of processing devices on packaging machines, in particular of labelers and printers, are consequently often associated with cumbersome and difficult operation in practice. This problem is constantly increasing due to the ever increasing degree of automation and the associated greater length of packaging machines.

Aufgabe der Erfindung ist es daher, eine Möglichkeit zum Bearbeiten von Packungen an Verpackungsmaschinen zu schaffen, die einen möglichst geringen Platzbedarf besitzt und eine möglichst einfache Bedienung erlaubt.The object of the invention is therefore to create a possibility for processing packs on packaging machines, which has the smallest possible space requirement and allows the simplest possible operation.

Die Lösung dieser Aufgabe erfolgt durch eine Bearbeitungsvorrichtung mit den Merkmalen des Anspruchs 1. Erfindungsgemäß ist eine gemeinsame Verstellachse für die Bearbeitungseinheiten vorgesehen, entlang welcher die Bearbeitungseinheiten manuell oder mittels eines Antriebs in einer Stellrichtung verstellbar sind, die parallel zu einer Transportrichtung der Verpackungsmaschine verläuft. Die Aufgabe wird zudem durch eine Verpackungsmaschine mit wenigstens einer erfindungsgemäßen Bearbeitungsvorrichtung gelöst.This object is achieved by a processing device with the features of claim 1. According to the invention, a common adjustment axis is provided for the processing units, along which the processing units can be adjusted manually or by means of a drive in an adjustment direction that runs parallel to a transport direction of the packaging machine. The object is also achieved by a packaging machine with at least one processing device according to the invention.

Erfindungsgemäß ist lediglich eine gemeinsame Verstellachse für die Bearbeitungseinheiten vorgesehen. Damit verlässt die Erfindung den bislang im Stand der Technik eingeschlagenen Weg, im Falle mehrerer Bearbeitungseinheiten diese als separate, eigenständige Maschinen zu betrachten und entsprechend auszugestalten und zu betreiben, die jeweils eine vollständige eigene Infrastruktur benötigen, um an der Verpackungsmaschine angebracht und insbesondere in Transportrichtung der Verpackungsmaschine verstellt werden zu können.According to the invention, only a common adjustment axis is provided for the machining units. Thus, the invention leaves the path taken so far in the prior art, in the case of several processing units, to consider them as separate, independent machines and to design and operate them accordingly, each of which requires a complete separate infrastructure in order to be attached to the packaging machine and in particular in the direction of transport Packaging machine to be adjusted.

Unter der gemeinsamen Verstellachse ist keine gedachte oder virtuelle Achse im mathematischen Sinne zu verstehen, sondern eine gegenständliche Komponente oder Baueinheit, die ein manuelles oder mittels eines Antriebs erfolgendes Verstellen der Bearbeitungseinheiten parallel zur Transportrichtung der Verpackungsmaschine ermöglicht. Im Falle einer manuellen Verstellbarkeit kann die Verstellachse eine wie auch immer konkret ausgestaltete, sich über eine geeignete Stelllänge parallel zur Transportrichtung der Verpackungsmaschine erstreckende Komponente oder Baueinheit sein, beispielsweise eine Führungsstange, wobei diese Komponente oder Baueinheit folglich auch eine Führungsfunktion erfüllen kann. Zusätzliche Führungen für die Bearbeitungseinheiten sind hierdurch allerdings nicht ausgeschlossen.The common adjustment axis is not to be understood as an imaginary or virtual axis in the mathematical sense, but rather an objective component or structural unit that can be adjusted manually or by means of a drive of the processing units parallel to the transport direction of the packaging machine. In the case of manual adjustability, the adjustment axis can be a component or unit, however specifically configured, extending over a suitable adjustment length parallel to the transport direction of the packaging machine, for example a guide rod, whereby this component or unit can consequently also fulfill a guiding function. However, this does not exclude additional guides for the machining units.

Wenn ein Antrieb zum Verstellen der Bearbeitungseinheiten vorgesehen ist, dann kann die Verstellachse ein gemeinsames Antriebsorgan für die Bearbeitungseinheiten bilden oder umfassen bzw. von einem solchen Antriebsorgan gebildet sein. Bei diesem Antriebsorgan kann es sich beispielsweise um eine Spindel, einen Zahnriemen oder eine Zahnstange handeln.If a drive is provided for adjusting the processing units, then the adjustment axis can form or comprise a common drive element for the processing units or be formed by such a drive element. This drive element can be, for example, a spindle, a toothed belt or a toothed rack.

Das Konzept der Erfindung ermöglicht es, die Bedienung aller Bearbeitungseinheiten komplett auf nur eine der Seiten der Verpackungsmaschine zu verlagern. Auf der anderen Maschinenseite kann beispielsweise eine zusätzliche Führung für die Bearbeitungseinheiten vorgesehen sein, der sich allerdings das Bedienpersonal zumindest während des laufenden Betriebs der Verpackungsmaschine nicht zu widmen braucht.The concept of the invention makes it possible to shift the operation of all processing units completely to just one of the sides of the packaging machine. On the other side of the machine, for example, an additional guide for the processing units can be provided, which, however, does not need to be addressed by the operating personnel, at least while the packaging machine is in operation.

Ein weiterer Vorteil einer gemeinsamen Verstellachse für mehrere Bearbeitungseinheiten besteht darin, dass bestimmte sicherheitstechnische Maßnahmen - soweit sie grundsätzlich erforderlich sind - nur auf einer Seite der Verpackungsmaschine getroffen zu werden brauchen. Beispielsweise dann, wenn die Bearbeitungseinheiten gemäß einer bevorzugten Ausgestaltung bezüglich der Transportrichtung der Verpackungsmaschine gegenläufig verstellbar sind, muss gegebenenfalls aufgrund geltender Sicherheitsbestimmungen eine durch diese Verstellbarkeit potentiell gegebene Verletzungsgefahr für das Bedienpersonal durch geeignete Maßnahmen wie beispielsweise das Vorsehen einer Abdeckung vermieden werden.Another advantage of a common adjustment axis for several processing units is that certain safety-related measures - insofar as they are fundamentally necessary - only need to be taken on one side of the packaging machine. For example, if, according to a preferred embodiment, the processing units can be adjusted in opposite directions with respect to the transport direction of the packaging machine, a risk of injury to the operating personnel, which is potentially due to this adjustability, must be carried out by means of suitable safety regulations Measures such as the provision of a cover can be avoided.

Zudem wird bei einer gemeinsamen Verstellachse für die Bearbeitungseinheiten deren Integration insbesondere in steuerungstechnischer Hinsicht erleichtert oder sogar überhaupt erst ermöglicht. Beispielsweise Einstellungen der Bearbeitungseinheiten können über die zentrale Steuerung der Verpackungsmaschine bzw. der gesamten Verarbeitungslinie erfolgen, in welche die Verpackungsmaschine gegebenenfalls integriert ist.In addition, with a common adjustment axis for the machining units, their integration is facilitated, in particular in terms of control technology, or even made possible in the first place. For example, the processing units can be adjusted via the central control of the packaging machine or the entire processing line into which the packaging machine is possibly integrated.

Darüber hinaus ermöglicht das erfindungsgemäße Konzept vielfältige Arbeitsvarianten, auf die an anderer Stelle näher eingegangen wird, wobei zumindest bestimmte Varianten bislang nicht oder allenfalls unter Inkaufnahme eines beträchtlichen zusätzlichen Bedarfs an Arbeitslänge der Verpackungsmaschine realisiert werden konnten.In addition, the inventive concept enables a variety of work variants, which will be discussed in more detail elsewhere, with at least certain variants not yet being able to be implemented, or at most with the acceptance of a considerable additional working length of the packaging machine.

Es ist möglich, aber nicht zwingend, dass lediglich eine einzige gemeinsame Verstellachse für die Bearbeitungseinheiten vorgesehen ist. Es kann zumindest eine weitere gemeinsame Verstellachse vorgesehen sein, wobei dann alle gemeinsamen Verstellachsen der Bearbeitungseinheiten auf der gleichen Seite der Verpackungsmaschine angeordnet sind. Dabei kann eine Verstellachse, die auch als Hauptverstellachse bezeichnet werden kann, primär für ein gemeinsames Verstellen der Bearbeitungseinheiten vorgesehen sein. Eine von der Hauptverstellachse entkoppelte Bearbeitungseinheit kann mit einer weiteren gemeinsamen Verstellachse gekoppelt und entlang dieser weiteren gemeinsamen Verstellachse unabhängig von der oder den anderen Bearbeitungseinheiten beispielsweise in eine Nichtarbeitsposition gebracht werden.It is possible, but not mandatory, for only a single common adjustment axis to be provided for the machining units. At least one further common adjustment axis can be provided, in which case all the common adjustment axes of the processing units are arranged on the same side of the packaging machine. An adjustment axis, which can also be referred to as the main adjustment axis, can primarily be provided for joint adjustment of the machining units. A machining unit that is decoupled from the main adjustment axis can be coupled to a further common adjustment axis and, for example, be brought into a non-working position along this further common adjustment axis, independently of the other machining unit or units.

Eine gemeinsame Verstellachse im Sinne der Erfindung kann auch derart vorgesehen sein, dass die eine Bearbeitungseinheit nicht unmittelbar mit der gemeinsamen Verstellachse zusammenwirkt, sondern nur mittelbar über die jeweils andere Bearbeitungseinheit, die unmittelbar mit der gemeinsamen Verstellachse zusammenwirkt. Die beiden Bearbeitungseinheiten sind hierbei folglich, in einer nicht erfindungsgemäßen Ausführungsform, nicht unabhängig voneinander mittels der gemeinsamen Verstellachse verstellbar. Dies schließt aber nicht aus, dass die Bearbeitungseinheiten relativ zueinander bewegbar sind, um beispielsweise einen Versatz in Transportrichtung der Verpackungsmaschine zwischen den beiden Bearbeitungseinheiten verändern zu können. Bevorzugte Ausführungsformen sind auch der nachfolgenden Beschreibung, den abhängigen Ansprüchen sowie der Zeichnung zu entnehmen.A common adjustment axis within the meaning of the invention can also be provided in such a way that one processing unit is not directly connected to the common one Adjusting axis interacts, but only indirectly via the respective other processing unit, which interacts directly with the common adjustment axis. In an embodiment not according to the invention, the two machining units are consequently not adjustable independently of one another by means of the common adjustment axis. However, this does not preclude the processing units from being movable relative to one another in order, for example, to be able to change an offset in the transport direction of the packaging machine between the two processing units. Preferred embodiments can also be found in the following description, the dependent claims and the drawing.

Gemäß einem bevorzugten Ausführungsbeispiel ist ein gemeinsamer Verfahrantrieb für die beiden Bearbeitungseinheiten vorgesehen, mit welchem die Bearbeitungseinheiten entlang der Verstellachse verfahrbar sind.According to a preferred exemplary embodiment, a common travel drive is provided for the two machining units, with which the machining units can be moved along the adjustment axis.

Der Verfahrantrieb kann ein langgestrecktes, sich in Stellrichtung erstreckendes Antriebsorgan für die Bearbeitungseinheiten umfassen. Bei dem Antriebsorgan kann es sich beispielsweise um eine Spindel, einen Zahnriemen oder eine Zahnstange handeln.The displacement drive can comprise an elongated drive element for the machining units that extends in the actuating direction. The drive element can be, for example, a spindle, a toothed belt or a toothed rack.

Des Weiteren ist vorgesehen, dass die Bearbeitungseinheiten unabhängig voneinander mit der Verstellachse koppelbar und von der Verstellachse entkoppelbar sind. Dies ermöglicht einen hochgradig flexiblen Betrieb der Verpackungsmaschine hinsichtlich der Funktion der Bearbeitungseinheiten. Sind die Bearbeitungseinheiten alle mit der Verstellachse gekoppelt, können die Bearbeitungseinheiten gemeinsam verstellt werden. Die Bearbeitungseinheiten können beispielsweise gemeinsam ihre Position längs der Verpackungsmaschine ändern, wobei ein gegebenenfalls vorhandener Versatz zwischen den beiden Bearbeitungseinheiten in Transportrichtung konstant bleiben kann. Ein Versatz zwischen den Bearbeitungseinheiten muss jedoch nicht vorhanden und - wenn der vorhanden ist - nicht konstant sein. Alternativ kann ein gemeinsames Verstellen von jeweils mit der Verstellachse gekoppelten Bearbeitungseinheiten auch mit einem zunehmenden oder abnehmenden Abstand zwischen den Bearbeitungseinheiten in Transportrichtung der Verpackungsmaschine einhergehen.Furthermore, it is provided that the machining units can be coupled to the adjustment axis and decoupled from the adjustment axis independently of one another. This enables a highly flexible operation of the packaging machine with regard to the function of the processing units. If the processing units are all coupled to the adjustment axis, the processing units can be adjusted together. The processing units can, for example, jointly change their position along the packaging machine, and any offset that may be present between the two processing units in the transport direction can remain constant. However, an offset between the processing units does not have to be present and - if it is present - not constant be. Alternatively, a joint adjustment of processing units coupled to the adjustment axis can also be accompanied by an increasing or decreasing distance between the processing units in the transport direction of the packaging machine.

Des Weiteren ist es möglich, eine Bearbeitungseinheit von der Verstellachse zu entkoppeln. Die entkoppelte Bearbeitungseinheit kann - manuell oder über einen gegebenenfalls zusätzlich vorgesehenen Antrieb - in eine Nichtarbeitsposition an der Verpackungsmaschine gebracht werden, beispielsweise zu Wartungszwecken oder zum Aufbringen einer neuen Etikettenvorratsrolle, während die oder jede andere Bearbeitungseinheit ihren Bearbeitungsbetrieb fortsetzt. Des Weiteren kann erfindungsgemäß vorgesehen sein, dass jede Bearbeitungseinheit eine manuell betätigbare oder mittels einer Steuereinrichtung ansteuerbare Kopplungseinrichtung umfasst, die dazu ausgebildet ist, die Bearbeitungseinheit und die Verstellachse miteinander zu koppeln und voneinander zu entkoppeln. Die Steuereinrichtung kann der Bearbeitungsvorrichtung zugeordnet und insbesondere in die Bearbeitungsvorrichtung integriert und in geeigneter Weise mit einer zentralen Steuereinrichtung der Verpackungsmaschine verbunden sein. Alternativ kann die zur Ansteuerung der Kopplungseinrichtungen der Bearbeitungseinheit dienende Steuereinrichtung in eine zentrale Steuereinrichtung der Verpackungsmaschine oder einer übergeordneten Verarbeitungslinie integriert sein.It is also possible to decouple a processing unit from the adjustment axis. The decoupled processing unit can be brought into a non-working position on the packaging machine - manually or via a possibly additionally provided drive - for example for maintenance purposes or for applying a new label supply roll, while the or any other processing unit continues its processing operation. Furthermore, it can be provided according to the invention that each processing unit comprises a coupling device which can be actuated manually or controlled by means of a control device and is designed to couple and decouple the processing unit and the adjustment axis from one another. The control device can be assigned to the processing device and, in particular, integrated into the processing device and connected in a suitable manner to a central control device of the packaging machine. Alternatively, the control device used to control the coupling devices of the processing unit can be integrated into a central control device of the packaging machine or a higher-level processing line.

Gemäß einem weiteren Ausführungsbeispiel ist zusätzlich zu der gemeinsamen Verstellachse eine parallel zur Stellrichtung verlaufende Führung für die Bearbeitungsvorrichtungen vorgesehen. Die Führung kann ein Führungsorgan oder wenigstens zwei quer zur Stellrichtung mit Abstand voneinander verlaufende Führungsorgane umfassen. Bei dem oder den Führungsorganen kann es sich beispielsweise um einfache, passive Führungsstangen handeln. Wenn zwei beabstandete Führungsorgane vorgesehen sind, dann können diese auf gegenüberliegenden Seiten der Verpackungsmaschine angeordnet sein. Hierdurch ergibt sich eine besonders stabile und präzise Führung sowie Ausrichtung der Bearbeitungseinheiten bezüglich der jeweiligen Verpackungsmaschine. Während die oder jede gemeinsame Verstellachse für die Bearbeitungseinheiten lediglich auf einer Maschinenseite angeordnet ist, können somit Führungseinrichtungen für die Bearbeitungseinheiten auf beiden Seiten der Verpackungsmaschine vorhanden sein.According to a further exemplary embodiment, in addition to the common adjustment axis, a guide running parallel to the adjustment direction is provided for the machining devices. The guide can comprise a guide element or at least two guide elements extending at a distance from one another transversely to the setting direction. The guide element (s) can be, for example, simple, passive guide rods. If two spaced guide organs are provided, then these can be on opposite sides Be arranged sides of the packaging machine. This results in particularly stable and precise guidance and alignment of the processing units with respect to the respective packaging machine. While the or each common adjustment axis for the processing units is only arranged on one side of the machine, guide devices for the processing units can thus be provided on both sides of the packaging machine.

Gemäß einem weiteren möglichen Ausführungsbeispiel ist zusätzlich zu der Verstellachse für die Bearbeitungseinheiten wenigstens eine quer zur Transportrichtung verlaufende Querachse für zumindest eine Zusatzeinheit vorgesehen. Die Querachse kann manuell oder mittels eines Antriebs entlang der Verstellachse in Stellrichtung bewegbar sein. Bei der Zusatzeinheit, für welche die zusätzliche Querachse vorgesehen ist, kann es sich beispielsweise um eine Druckeinrichtung zum Bedrucken beispielsweise der Packungsoberseiten oder der Packungsunterseiten handeln.According to a further possible embodiment, in addition to the adjustment axis for the processing units, at least one transverse axis running transversely to the transport direction is provided for at least one additional unit. The transverse axis can be moved manually or by means of a drive along the adjustment axis in the adjustment direction. The additional unit for which the additional transverse axis is provided can be, for example, a printing device for printing, for example, the top or bottom sides of the pack.

Wie vorstehend bereits erwähnt, handelt es sich gemäß einer bevorzugten Ausgestaltung der Erfindung bei den Bearbeitungseinheiten jeweils um eine Etikettiereinheit, wobei die obere Etikettiereinheit zum Etikettieren von Packungsoberseiten und die untere Etikettiereinheit zum Etikettieren von Packungsunterseiten dient. Alternativ können die Bearbeitungseinheiten jeweils als Druckeinheiten zum Bedrucken der Packungsseiten ausgestaltet sein. Des Weiteren sind auch "gemischte" Anwendungen erfindungsgemäß möglich, bei denen unterschiedliche Bearbeitungseinheiten zum Einsatz kommen. So können beispielsweise mittels einer oberen Etikettiereinheit die Packungsoberseiten etikettiert und mittels einer unteren Bedruckungseinheit die Packungsunterseiten bedruckt werden.As already mentioned above, according to a preferred embodiment of the invention, the processing units are each a labeling unit, the upper labeling unit being used to label the tops of the pack and the lower labeling unit to be used to label the underside of the pack. Alternatively, the processing units can each be designed as printing units for printing the pack sides. Furthermore, according to the invention, "mixed" applications are also possible in which different processing units are used. For example, the top of the pack can be labeled using an upper labeling unit and the bottom of the pack can be printed on using a lower printing unit.

Bei einer erfindungsgemäßen Verpackungsmaschine, insbesondere einer Maschine zum Verpacken von Lebensmittelprodukten, die wenigstens eine erfindungsgemäße Bearbeitungsvorrichtung wie hierin offenbart umfasst, kann gemäß einer bevorzugten Ausgestaltung vorgesehen sein, dass die Bearbeitungsvorrichtung an einem Maschinenrahmen der Verpackungsmaschine abgestützt ist. Dies schließt nicht aus, dass eine zusätzliche, alleine jedoch nicht ausreichende Abstützung über eine andere, nicht von der Verpackungsmaschine gebildete bzw. nicht zur Verpackungsmaschine gehörende Einrichtung oder über eine Aufstellfläche, insbesondere den Boden, erfolgt. Bevorzugt ist die Bearbeitungsvorrichtung ausschließlich an der Verpackungsmaschine und insbesondere an einem Gestell oder Rahmen der Verpackungsmaschine abgestützt.In a packaging machine according to the invention, in particular a machine for packaging food products, which comprises at least one processing device according to the invention as disclosed herein, according to one In a preferred embodiment, the processing device is supported on a machine frame of the packaging machine. This does not exclude that an additional, but not sufficient, support takes place via another device that is not formed by the packaging machine or does not belong to the packaging machine or via a set-up area, in particular the floor. The processing device is preferably supported exclusively on the packaging machine and in particular on a rack or frame of the packaging machine.

Bevorzugt ist die Verstellachse der Verpackungsmaschine an einer Seite eines Maschinenrahmens oder eines Maschinengestells der Verpackungsmaschine angeordnet. Bevorzugt ist die Verstellachse an dem Maschinenrahmen bzw. dem Maschinengestell abgestützt. Insbesondere erfolgt die Abstützung der Verstellachse ausschließlich auf diese Weise.The adjustment axis of the packaging machine is preferably arranged on one side of a machine frame or a machine frame of the packaging machine. The adjustment axis is preferably supported on the machine frame or the machine frame. In particular, the adjustment axis is supported exclusively in this way.

Die Bearbeitungseinheiten der Bearbeitungsvorrichtung können, in Transportrichtung gesehen, in demselben Arbeitsabschnitt der Verpackungsmaschine angeordnet sein, der einer Packung oder einer quer zur Transportrichtung liegenden Packungsreihe zugeordnet ist. In dieser Konfiguration wird folglich von den Bearbeitungseinheiten jeweils die gleiche Packung bearbeitet, d.h. es wird jeweils von der oberen Bearbeitungseinheit die Packungsoberseite und von der unteren Bearbeitungseinheit die Packungsunterseite bearbeitet. Handelt es sich um eine mehrspurige Verpackungsmaschine, bearbeiten die Bearbeitungseinheiten jeweils die gleiche Packungsreihe. Ein Versatz zwischen den Bearbeitungseinheiten in Transportrichtung der Verpackungsmaschine innerhalb des Arbeitsabschnitts kann vorgesehen sein. Dieser Versatz kann sich aus den jeweils gewünschten Bearbeitungspositionen ergeben, die für die Packungsoberseite und die Packungsunterseite einer jeweiligen Packung unterschiedlich sein kann. So kann es beispielsweise gewünscht sein, ein Etikett für die Packungsoberseite an einem in Transportrichtung vorderen Bereich der Packung anzubringen, wohingegen ein Etikett oder eine Bedruckung an der Packungsunterseite in Transportrichtung gesehen im hinteren Packungsbereich angebracht werden soll.The processing units of the processing device can, viewed in the transport direction, be arranged in the same working section of the packaging machine that is assigned to a pack or to a row of packs lying transversely to the transport direction. In this configuration, the same pack is consequently processed by the processing units, ie the top processing unit processes the top side of the pack and the bottom processing unit processes the bottom side of the package. In the case of a multi-lane packaging machine, the processing units each process the same row of packs. An offset between the processing units in the transport direction of the packaging machine within the working section can be provided. This offset can result from the respectively desired processing positions, which can be different for the pack top and the pack bottom of a respective pack. For example, it may be desirable to apply a label for the top of the pack to a front region of the pack in the direction of transport, whereas a label or printing is to be applied to the underside of the pack, viewed in the direction of transport, in the rear area of the pack.

Gemäß einem weiteren Ausführungsbeispiel kann eine alternative Konfiguration vorgesehen sein, bei der die Bearbeitungseinheiten in verschiedenen, in Transportrichtung gegeneinander versetzten Arbeitsabschnitten angeordnet sind, die jeweils einer Packung oder einer quer zur Transportrichtung liegenden Packungsreihe zugeordnet sind. Die Arbeitsabschnitte können eine oder mehrere Packungen bzw. Packungsreihen in Transportrichtung gegeneinander versetzt oder - mit anderen Worten - voneinander beabstandet sein. Diese Konfiguration kann beispielsweise in Abhängigkeit von der konkreten Ausgestaltung und einem gegebenenfalls vorhandenen, über die Begrenzung der eigentlichen Verpackungsmaschine hinaus vorstehenden Aufbau der Bearbeitungseinheiten von Vorteil sein. Zudem lässt sich hierdurch gegebenenfalls die Bedienung der Bearbeitungseinheiten erleichtern.According to a further exemplary embodiment, an alternative configuration can be provided in which the processing units are arranged in different working sections offset from one another in the transport direction, which are each assigned to a pack or a row of packs lying transversely to the transport direction. The working sections can have one or more packs or pack rows offset from one another in the direction of transport or - in other words - be spaced from one another. This configuration can be advantageous, for example, as a function of the specific design and a possibly existing structure of the processing units that protrudes beyond the limitation of the actual packaging machine. In addition, the operation of the processing units can be made easier as a result.

Gemäß einem weiteren Ausführungsbeispiel der Erfindung können mehrere jeweils eine obere Bearbeitungseinheit und eine untere Bearbeitungseinheit umfassende Paare vorgesehen sein, die in verschiedenen, in Transportrichtung gegeneinander versetzten Arbeitsabschnitten angeordnet sind, wobei jeder Arbeitsabschnitt einer Packung oder einer quer zur Transportrichtung liegenden Packungsreihe zugeordnet ist.According to a further embodiment of the invention, several pairs each comprising an upper processing unit and a lower processing unit can be provided, which are arranged in different working sections offset from one another in the transport direction, each working section being assigned to a pack or a row of packs lying transversely to the transport direction.

Hierdurch lässt sich die Leistung der Verpackungsmaschine hinsichtlich der Bearbeitung der Packungen mittels der Bearbeitungseinheiten entsprechend der Anzahl der Paare vervielfachen. So lässt sich beispielsweise mit zwei Paaren von Bearbeitungseinheiten die Bearbeitungsleistung verdoppeln. Eine weitere Möglichkeit, die sich durch den Einsatz mehrerer Paare von Bearbeitungseinheiten ergibt, besteht darin, zusätzliche Bearbeitungen an den Packungen vorzunehmen, beispielsweise ein oder mehrere zusätzliche Etiketten anzubringen, die gegebenenfalls lediglich zeitweise gewünscht werden.As a result, the performance of the packaging machine with regard to the processing of the packs by means of the processing units can be multiplied in accordance with the number of pairs. For example, with two pairs of machining units, the machining performance can be doubled. Another possibility that results from the use of several pairs of processing units is to carry out additional processing on the packs, for example, to apply one or more additional labels that may only be required temporarily.

Des Weiteren kann vorgesehen sein, dass die Bearbeitungseinheiten oder Paare von Bearbeitungseinheiten unabhängig voneinander aus einem Arbeitsbereich in eine Nichtarbeitsposition bewegbar sind. So kann beispielsweise ohne Stillstand der Verpackungsmaschine, gleichwohl unter vorübergehender Verringerung der Bearbeitungsleistung, ein Paar von Bearbeitungseinheiten in der Nichtarbeitsposition gewartet oder beispielsweise mit einem neuen Etikettenvorrat versehen werden. Im Anschluss an diese Unterbrechung kann das vorübergehend nicht aktive Paar von Bearbeitungseinheiten wieder zurück in den jeweiligen Arbeitsabschnitt gefahren werden, woraufhin die ursprüngliche volle Leistung wieder zur Verfügung steht.Furthermore, it can be provided that the processing units or pairs of processing units can be moved independently of one another from a work area into a non-work position. For example, a pair of processing units can be serviced in the non-working position or provided with a new supply of labels, for example, without the packaging machine being shut down, but with a temporary reduction in processing performance. Following this interruption, the temporarily inactive pair of processing units can be driven back into the respective work section, whereupon the original full capacity is available again.

Unabhängig von der jeweiligen konkreten Konfiguration der erfindungsgemäßen Verpackungsmaschine kann vorgesehen sein, dass die Bearbeitungseinheiten jeweils innerhalb ihres Arbeitsabschnitts in Stellrichtung bewegbar sind, um einen jeweils gewünschten Arbeitsversatz zwischen einer oberen Bearbeitungsposition und einer unteren Bearbeitungsposition einzustellen.Regardless of the specific configuration of the packaging machine according to the invention, it can be provided that the processing units can each be moved within their working section in the adjusting direction in order to set a respectively desired working offset between an upper processing position and a lower processing position.

Des Weiteren ist bevorzugt eine Steuereinrichtung vorgesehen, die dazu ausgebildet ist, in Abhängigkeit von der jeweiligen Betriebssituation einen Verfahrantrieb der Bearbeitungsvorrichtung und die Bearbeitungseinheiten, insbesondere Kopplungseinrichtungen der Bearbeitungsvorrichtungen anzusteuern, um die Bearbeitungseinheiten gemeinsam oder einzeln in Stellrichtung zu verstellen.Furthermore, a control device is preferably provided which is designed to control a travel drive of the machining device and the machining units, in particular coupling devices of the machining devices, depending on the respective operating situation, in order to adjust the machining units together or individually in the setting direction.

Die Kopplungseinheiten können, wie vorstehend bereits erwähnt, dazu dienen, die jeweilige Bearbeitungseinheit und die Verstellachse miteinander zu koppeln und voneinander zu entkoppeln. Dies erfolgt für die Bearbeitungseinheiten unabhängig voneinander. Wie ebenfalls vorstehend bereits erwähnt, kann die Steuereinrichtung der Bearbeitungseinheit zugeordnet oder in eine zentrale Steuereinrichtung der Verpackungsmaschine integriert sein.As already mentioned above, the coupling units can serve to couple the respective machining unit and the adjustment axis to one another and to decouple them from one another. This is done independently of one another for the processing units. As already mentioned above, the control device assigned to the processing unit or integrated into a central control device of the packaging machine.

Die Erfindung wird im Folgenden beispielhaft unter Bezugnahme auf die Zeichnung beschrieben. Es zeigen:

- Fig. 1

- schematisch in einer senkrecht zur Transportrichtung der Verpackungsmaschine geschnittenen Ansicht die Anordnung zweier Bearbeitungseinheiten gemäß der Erfindung, und

- Fig. 2 bis 4

- jeweils schematisch eine mögliche Konfiguration einer erfindungsgemäßen Verpackungsmaschine.

- Fig. 1

- the arrangement of two processing units according to the invention, and

- Figs. 2 to 4

- each schematically shows a possible configuration of a packaging machine according to the invention.

Die in

Näher braucht im Hinblick auf die vorliegende Erfindung nicht auf den grundsätzlich bekannten Aufbau und die dem Fachmann ebenfalls hinlänglich bekannte Funktionsweise einer Verpackungsmaschine und insbesondere einer Tiefzieh-Verpackungsmaschine, wie es auch im Einleitungsteil erläutert ist, nicht eingegangen zu werden.With regard to the present invention, there is no need for more detail on the fundamentally known structure and the mode of operation of a packaging machine and in particular of a deep-drawing packaging machine, which is also sufficiently known to the person skilled in the art, as it is also explained in the introductory part, not to be discussed.