EP3333812B1 - Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés - Google Patents

Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés Download PDFInfo

- Publication number

- EP3333812B1 EP3333812B1 EP18154768.8A EP18154768A EP3333812B1 EP 3333812 B1 EP3333812 B1 EP 3333812B1 EP 18154768 A EP18154768 A EP 18154768A EP 3333812 B1 EP3333812 B1 EP 3333812B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- watermark

- security

- paper

- watermarks

- regions

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000835 fiber Substances 0.000 claims description 50

- 239000000463 material Substances 0.000 claims description 43

- 238000013461 design Methods 0.000 claims description 35

- 230000001965 increasing effect Effects 0.000 claims description 21

- 230000002708 enhancing effect Effects 0.000 claims description 12

- 238000009877 rendering Methods 0.000 claims description 7

- 239000010410 layer Substances 0.000 description 53

- 238000000034 method Methods 0.000 description 36

- 239000000126 substance Substances 0.000 description 21

- 229920000642 polymer Polymers 0.000 description 18

- 239000002861 polymer material Substances 0.000 description 16

- 239000012260 resinous material Substances 0.000 description 16

- 239000006185 dispersion Substances 0.000 description 13

- 239000000758 substrate Substances 0.000 description 13

- 230000003287 optical effect Effects 0.000 description 12

- 230000008569 process Effects 0.000 description 12

- 239000000853 adhesive Substances 0.000 description 11

- 230000001070 adhesive effect Effects 0.000 description 11

- 239000000049 pigment Substances 0.000 description 11

- 238000000576 coating method Methods 0.000 description 9

- 239000000976 ink Substances 0.000 description 9

- 239000000975 dye Substances 0.000 description 7

- 239000000243 solution Substances 0.000 description 7

- 238000009826 distribution Methods 0.000 description 6

- 238000004519 manufacturing process Methods 0.000 description 6

- 230000005540 biological transmission Effects 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- 229920005989 resin Polymers 0.000 description 5

- 239000011347 resin Substances 0.000 description 5

- 229920000742 Cotton Polymers 0.000 description 4

- 230000008901 benefit Effects 0.000 description 4

- 229920002678 cellulose Polymers 0.000 description 4

- 239000001913 cellulose Substances 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- -1 linen Polymers 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 239000011888 foil Substances 0.000 description 3

- 238000009432 framing Methods 0.000 description 3

- 239000011882 ultra-fine particle Substances 0.000 description 3

- 230000016776 visual perception Effects 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 229920001131 Pulp (paper) Polymers 0.000 description 2

- 238000013459 approach Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000012544 monitoring process Methods 0.000 description 2

- 230000008447 perception Effects 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 230000035945 sensitivity Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 238000004088 simulation Methods 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- 239000004925 Acrylic resin Substances 0.000 description 1

- 229920000178 Acrylic resin Polymers 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-L Carbonate Chemical compound [O-]C([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-L 0.000 description 1

- 229920000219 Ethylene vinyl alcohol Polymers 0.000 description 1

- RRHGJUQNOFWUDK-UHFFFAOYSA-N Isoprene Chemical compound CC(=C)C=C RRHGJUQNOFWUDK-UHFFFAOYSA-N 0.000 description 1

- 240000000907 Musa textilis Species 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 229920001328 Polyvinylidene chloride Polymers 0.000 description 1

- 229920001807 Urea-formaldehyde Polymers 0.000 description 1

- XTXRWKRVRITETP-UHFFFAOYSA-N Vinyl acetate Chemical compound CC(=O)OC=C XTXRWKRVRITETP-UHFFFAOYSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- GZCGUPFRVQAUEE-SLPGGIOYSA-N aldehydo-D-glucose Chemical compound OC[C@@H](O)[C@@H](O)[C@H](O)[C@@H](O)C=O GZCGUPFRVQAUEE-SLPGGIOYSA-N 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- DQXBYHZEEUGOBF-UHFFFAOYSA-N but-3-enoic acid;ethene Chemical compound C=C.OC(=O)CC=C DQXBYHZEEUGOBF-UHFFFAOYSA-N 0.000 description 1

- 230000003197 catalytic effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000003822 epoxy resin Substances 0.000 description 1

- 239000005038 ethylene vinyl acetate Substances 0.000 description 1

- 239000004715 ethylene vinyl alcohol Substances 0.000 description 1

- RZXDTJIXPSCHCI-UHFFFAOYSA-N hexa-1,5-diene-2,5-diol Chemical compound OC(=C)CCC(O)=C RZXDTJIXPSCHCI-UHFFFAOYSA-N 0.000 description 1

- 238000010191 image analysis Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 239000000696 magnetic material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000001590 oxidative effect Effects 0.000 description 1

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 1

- 229920000647 polyepoxide Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920001225 polyester resin Polymers 0.000 description 1

- 239000004645 polyester resin Substances 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920005749 polyurethane resin Polymers 0.000 description 1

- 239000011118 polyvinyl acetate Substances 0.000 description 1

- 229920002689 polyvinyl acetate Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 239000005033 polyvinylidene chloride Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 238000000859 sublimation Methods 0.000 description 1

- 230000008022 sublimation Effects 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

- 229920002994 synthetic fiber Polymers 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 239000012780 transparent material Substances 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/324—Reliefs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/333—Watermarks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/351—Translucent or partly translucent parts, e.g. windows

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/355—Security threads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

- B42D25/369—Magnetised or magnetisable materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

- B42D25/373—Metallic materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

- B42D25/378—Special inks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

- B42D25/378—Special inks

- B42D25/382—Special inks absorbing or reflecting infrared light

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/36—Identification or security features, e.g. for preventing forgery comprising special materials

- B42D25/378—Special inks

- B42D25/387—Special inks absorbing or reflecting ultraviolet light

-

- G—PHYSICS

- G07—CHECKING-DEVICES

- G07D—HANDLING OF COINS OR VALUABLE PAPERS, e.g. TESTING, SORTING BY DENOMINATIONS, COUNTING, DISPENSING, CHANGING OR DEPOSITING

- G07D7/00—Testing specially adapted to determine the identity or genuineness of valuable papers or for segregating those which are unacceptable, e.g. banknotes that are alien to a currency

Definitions

- the invention generally relates to a security sheet or document having one or more enhanced watermarks.

- Security papers are used for manufacturing security documents such as banknotes, passports, postage stamps and the like.

- security features are incorporated into such security papers or provided on their surface.

- Known examples of such security features include watermarks, embedded and windowed security threads, fluorescent pigments and the like.

- Watermarks which are recognizable images or patterns in paper that appear as various shades of lightness/darkness when viewed by transmitted light or by reflected light atop a dark background, have provided protection against counterfeiting security documents for hundreds of years.

- watermarks and their engaging designs are the most readily recognized security feature available to the general public for the authentication of security documents such as banknotes.

- US 2013/0255896 A1 discloses a sheet including a high-definition high-contrast multitone watermark having areas of pronounced brightness.

- Such watermark is particularly obtained by means of a part including a surface having a raised area and perforations. The perforations are such that making the cross-section thereof, at a given distance from the draining surface, directly depends on said distance.

- EP 1 743 778 A2 describes a method of producing coloured watermarks includes using a watermark applicator to which auxiliary coloured stock is supplied.

- the watermark applicator includes a cylinder with an open structure (similar to the open body of a dandy roll) and covered with an embossed wire mesh.

- the present invention addresses this need by providing enhanced and thus more counterfeit-resistant watermarks in paper and paper-like materials.

- the present invention provides a security sheet or document having one or more enhanced watermarks, the sheet or document comprising:

- the inventive security sheet or document is a single- or multi-ply paper that comprises:

- the film-like or foil-like security element preferably has a color different from the watermark(s) and the surrounding paper thereby enhancing the appearance of the underlying or overlying watermark(s) as well as enhancing the contrast between the underlying or overlying watermark(s) and the surrounding paper.

- the film-like or foil-like security element(s) is a micro-optic security device that projects one or more synthetic images such as the MOTIONTM micro-optic security device, which is described in, for example, U.S. Patent No. 7,333,268 .

- Such devices display colored images on a transparent or tinted background and thus are well suited for use in combination with underlying printed information. It has been observed that these security devices appear to provide the watermark(s) with a multi-tonal appearance. As will be readily appreciated by those skilled in the art, multi-tonal watermarks present an even greater challenge to a counterfeiter.

- the micro-optic security device is in the form of a surface-applied patch that covers all or part (e.g., one-half) of a watermark, the watermark containing one or more polymer or resinous materials within the first and/or second regions of the watermark, the one or more polymer or resinous materials having an index of refraction or combined (final) index of refraction substantially similar to that of cellulose.

- the region(s) also contains one or more features selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more so-called second level security features that are machine detectable or machine readable (e.g ., UV or IR reactive, luminescent, thermochromic, photochromic, electrochromic, metal, or magnetic security fibers, taggants, planchettes, dyes, pigments).

- one or more features selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more so-called second level security features that are machine detectable or machine readable (e.g ., UV or IR reactive, luminescent, thermochromic, photochromic, electrochromic, metal, or magnetic security fibers, taggants, planchettes, dyes, pigments).

- the micro-optic security device may also be in the form of a surface-applied elongate security band, strip, stripe, or thread, or a partially embedded elongate security band, strip, stripe, or thread that is present in window regions of a second paper layer (i.e ., windowed thread).

- Micro-optic devices such as the MOTIONTM device may be designed such that when registered with the watermark(s), synthetic images projected thereby are combined with the watermark design(s).

- the synthetic image(s) generated by each patch may coordinate or link in with the watermark design(s).

- the synthetic image(s) may also complete the watermark design(s) or locate within the design(s). As will be explained in more detail below, this may be a one-sided or two-sided feature.

- the micro-optic security device(s) which is also described in, for example, U.S. Patent No. 7,333,268 , displays colored images (of any color, including white and black) on a translucent or substantially opaque background of a different color.

- the micro-optic security device(s) at least partially covers and visually camouflages either the upper or face portion of the one or more watermarks, or the lower or back portion of the one or more watermarks.

- the watermark(s) is not visually discernible in reflected light from the covered side of the paper layer, but is visually evident in reflected light from the uncovered side of the paper layer, and in transmitted light from both sides of the paper layer.

- these watermarks may be made larger and that the total area within each watermark occupied by reduced fiber density regions (i.e ., first regions) may be increased and that these regions may be made even thinner.

- these reduced fiber density regions may be produced with thicknesses as low as 10 to 15 microns, with total thicknesses ranging from about 10 to about 60 microns.

- the total area occupied by these reduced fiber density regions within each such watermark ranges from about 5 to about 75 percent (%) of the total area of the watermark, preferably from about 20 to about 60%.

- the total area occupied by each such watermark within a banknote measuring approximately 10,000 square millimeters (mm 2 ) may range from about 5 to about 25%, which denotes an increase in size compared to conventional watermarks of about 5%.

- micro-optic devices such as the MOTIONTM device may also offer a machine detectable/readable feature in the form of enhanced IR-brightness, especially when measured in transmission.

- enhanced IR-brightness is intended to mean IR-transmission levels of at least 5% greater than (preferably, more than 10% greater than) the IR-transmission levels of the background paper. IR-transmission levels may be measured by using an optical sensor with a sensitivity at or above 830 nanometers (nm) and by projecting an IR light source with a wavelength greater than 800 nm through the sample.

- the micro-optic device be made using one or more IR-transparent elements (e.g ., an IR-transparent ink) and contain no IR-absorbing elements (e.g ., IR-absorbing inks). It is also preferred that no IR-absorbing elements be present in areas close to the device on the front and reverse side of the paper layer(s).

- the micro-optic device is a security thread (e.g ., MOTIONTM security thread) that contains no IR-absorbing elements.

- the micro-optic security thread is made using an IR-transparent ink (e.g ., ink comprising non-IR-absorbing pigments and/or dyes) for the microprint and areas on the front and reverse side of the paper layer(s) within at least two-thirds (2/3) of the security thread's length contain no IR-absorbing elements.

- an IR-transparent ink e.g ., ink comprising non-IR-absorbing pigments and/or dyes

- one or more additional security features may be contained on or within the first and/or second regions of the one or more watermarks.

- the watermark(s) does not contain one or more polymer or resinous materials within the first and/or second regions.

- the additional security features are selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more second level security features that are machine detectable or machine readable, as described above.

- the inventive security paper is a multi-ply paper that comprises:

- the second paper layer is windowed, the one or more through windows in the second paper layer being in register with either the upper or face portion or the lower or back portion of the one or more watermarks.

- the use of two paper layers and optionally one or more overlying or underlying through windows allows for a greater contrast between the one or more watermarks and the background.

- the one or more overlying or underlying through windows act in a manner similar to that of an electrotype, occupying paperless regions or regions of thinner paper which results in brighter-than-background regions in each paper/watermark region.

- one or more security elements in the form of one or more color-imparting substances are contained within the first and/or second regions of the one or more watermarks.

- the one or more color-imparting substances include both dyes and pigments (e.g ., ultra-fine particle size pigments).

- the security sheet or document does not include one or more film-like or foil-like security elements.

- the resulting watermarks have a tonality (i.e ., color scheme or range of tones) in a color or shade different from that of the bulk region of the material which surrounds the watermark.

- the inventive watermarks serve to increase the perception and resistance to simulation of existing watermarks.

- one or more polymer or resinous materials are contained within the first region(s) and optionally the second region(s) of the one or more watermarks.

- the security sheet or document in this exemplary embodiment does not include one or more film-like or foil-like security elements.

- the first and/or second regions in this embodiment may also contain one or more security features selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more second level security features that are machine detectable or machine readable, as described above.

- the inventive security sheet or document is a single-ply paper that comprises:

- watermarks formed on or within a security sheet or document are enhanced, rendering the security sheet or document more counterfeit-resistant.

- the inventive sheet or document comprises: a fibrous sheet material including one or more watermarks; and means for enhancing the one or more watermarks by rendering them visually enhanced, machine detectable/readable, or both.

- Fibrous sheet materials suitable for use in the present invention are paper or paper-like sheet materials. These sheet materials, which are single or multi-ply sheet materials, may be made from a range of fiber types including synthetic or natural fibers or a mixture of both. For example, these sheet materials may be made from fibers such as abaca, cotton, linen, wood pulp, and blends thereof. As is well known to those skilled in the art, cotton and cotton/linen or cotton/synthetic fiber blends are preferred for banknotes, while wood pulp is commonly used in non-banknote security documents.

- the watermarks may be formed in the fibrous sheet material using known methods and techniques.

- the watermarked sheet material may be manufactured on a cylinder mold papermaking machine (using an embossed wire cloth, or by applying a thin piece of metal, generally in the form of an image or letter, to the wire cloth), or on a Fourdrinier papermaking machine (using a dandy roll).

- the inventive security sheet or document is a single- or multi-ply paper that comprises (a) a first paper layer including one or more watermarks, each surface of the paper layer displaying either the upper or face portion of the watermark(s) or the lower or back portion thereof, (b) one or more film-like or foil-like security elements having a color different from the watermark(s) that at least partially covers the upper or face portion or the lower or back portion of the watermark(s), and optionally (c) a second paper layer having a reduced basis weight compared to the first paper layer ( e.g ., from about 10 to about 50 gsm) and optionally one or more through windows, the second paper layer covering either the upper or face portion or the lower or back portion of the watermark(s).

- a first paper layer including one or more watermarks, each surface of the paper layer displaying either the upper or face portion of the watermark(s) or the lower or back portion thereof

- one or more film-like or foil-like security elements having a color different from the

- the film-like or foil-like security element(s) used in the practice of the present invention is limited only by its film-like or foil-like structure, with contemplated structures having total thicknesses ranging from about 15 to about 100 microns (preferably, from about 15 to about 50 microns).

- the film-like or foil-like structures may take any shape including, but not limited to, bands, strips, stripes, threads, or patches. They may display or project information that is humanly perceivable either directly or with the aid of a device and/or embody information that is detectable/readable by machine.

- the structures may be segmented into regions, with the information being displayed or projected or otherwise contained in some or all of these regions being the same or different.

- Suitable film-like or foil-like security elements may employ one or more of the following: demetalized or selectively metalized, magnetic, combined magnetic and metallic, or embossed (e.g ., blind embossed) regions or layers, color changing coatings made up of color shift, iridescent, liquid crystal, photochromic and/or thermochromic materials, coatings of luminescent and/or magnetic materials, holographic and/or diffractive security features, and micro-optic security features.

- the security element(s) is a micro-optic structure.

- such structures project one or more synthetically magnified optical images, and generally comprise: (a) a light-transmitting polymeric substrate; (b) an arrangement of micro-sized image icons located on or within the polymeric substrate; and (c) an arrangement of microlenses.

- the icon and microlens arrangements are configured such that when the arrangement of icons is viewed through the arrangement of microlenses, one or more synthetically magnified optical images are projected. These projected images may show a number of different optical effects.

- Such structures are described in U.S. Patent No. 7,333,268 to Steenblik et al. , U.S. Patent No.

- the structure being formed from a polymeric substrate prepared using one or more essentially colorless polymers selected from the group including, but not limited to, polyester, polyethylene, polyethylene terephthalate, polypropylene, polyvinyl carbonate, polyvinylidene chloride, and combinations thereof.

- the micro-optic security device is in the form of a surface-applied patch that covers all or part ( e.g ., one-half) of a watermark, the watermark containing one or more polymer or resinous materials within the first and/or second regions thereof, the one or more polymer or resinous materials having an index of refraction or combined (final) index of refraction substantially similar to that of cellulose.

- the first and/or second regions of the watermark may also contain one or more features selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more second level security features that are machine detectable or machine readable, as described above.

- the micro-optic security device is in the form of a surface-applied elongate strip or thread, or a partially embedded elongate security strip or thread that is present in window regions of a second paper layer ( i.e ., windowed thread).

- the strip or thread in this embodiment covers all or part of the watermark(s).

- the micro-optic security device e.g ., the MOTIONTM device

- the micro-optic security device is designed such that when registered with the watermark, synthetic images projected thereby are combined with the watermark design.

- the synthetic image(s) generated by each patch or thread may coordinate or link in with the watermark design.

- the synthetic image(s) may also complete the watermark design(s) or locate within the design(s). This may be a one-sided or two-sided feature. In other words, complete information intended to be conveyed to the viewer is not supplied solely by the watermark or synthetic image(s), but requires that both be viewed simultaneously.

- the MOTIONTM patch when viewed at the optimal (perpendicular) viewing angle using visible spectrum-transmitted light, projects a synthetic image in the form of a coat of arms that overlays (in register) the watermark design in the form of a shield.

- the synthetic image and the watermark design are no longer in register with each other, and one would see the watermark design (shield and numeral 30) within the patch and the synthetic image would transition or switch from the coat of arms to, for example, an array of numerals.

- An inherent benefit in the exemplary embodiments of the present invention which employ a partially or fully overlying or underlying film-like or foil-like security element such as the MOTIONTM micro-optic security device is the increased durability of each watermark. Covering all or part of the watermark(s) with an applied film, foil, band, strip, stripe, thread, or patch serves to physically protect the watermark(s) from damage during circulation and handling, thus increasing its durability.

- these watermarks may be made larger and that the total area within each watermark occupied by reduced fiber density regions (i.e ., first regions) may be increased and that these regions may be made even thinner.

- these reduced fiber density regions may be produced with thicknesses as low as 10 to 15 microns, with total thicknesses ranging from about 10 to about 60 microns.

- the total area occupied by these reduced fiber density regions within each such watermark ranges from about 5 to about 75 percent (%) of the total area of the watermark, preferably from about 20 to about 60%.

- the total area occupied by each such watermark within a banknote measuring approximately 10,000 mm 2 may range from about 5 to about 25%, which denotes an increase in size compared to conventional watermarks of about 5%.

- micro-optic devices such as the MOTIONTM device may also offer a machine detectable/readable feature in the form of enhanced IR-brightness, especially when measured in transmission.

- the micro-optic device be made using one or more IR-transparent elements (e.g ., an IR-transparent ink) and contain no IR-absorbing elements (e.g ., IR-absorbing inks). It is also preferred that no IR-absorbing elements be present in areas close to the device on the front and reverse side of the paper layer(s).

- the micro-optic device is a MOTIONTM security patch 12 that contains no IR-absorbing elements.

- the patch 12 is located over a watermark 14 in the shape of a shield in which dark regions formed by more densely deposited fibers than the normal base fiber density (i.e ., second regions) 16 occupy the outer perimeter, light regions formed by less densely deposited fibers than the normal base fiber density ( i.e ., first regions) 18 occupy the area inside the shield design with the region occupied by the numeral 30 formed by even lighter or less dense regions.

- the watermark 14 with overlying MOTIONTM security patch 12 in FIG. 1 is shown in daylight and under IR-transmitted light, with the watermark and patch illustrated at an enlarged scale for clarity.

- IR-brightness correlates to the strength of the IR-signal, which as noted above is measured in transmission by using an optical sensor with a sensitivity at or above 830 nm and by projecting an IR light source with a wavelength of greater than 800 nm through the sample. IR-brightness may be controlled by the IR-properties of the ink used for the microprint of the security patch 12.

- the microprint in the form of micro-sized image icons located on or within a polymeric substrate is made using a printing method (e.g ., ink jet, laserjet, letterpress, flexo, gravure, intaglio, and dye sublimation printing methods), or using a microstructure approach.

- the image icons would be made as voids or recesses in the substrate (e.g ., recesses measuring, for example, from about 0.5 to about 8 microns in total depth), or as raised structures relative to the substrate (e.g ., raised structures (colored or colorless) measuring, for example, from about 0.5 to about 8 microns in total height).

- An IR-transparent material e.g ., ink comprising non-IR-absorbing pigments and/or dyes

- ink comprising non-IR-absorbing pigments and/or dyes

- areas on the front and reverse side of the paper layer(s) within a distance of approximately 5 millimeters from an outer edge of the patch would contain no IR-absorbing elements.

- FIGS. 2a -d and 3a-d In regard to the appearance of the FIG. 1 embodiment, and as shown in FIGS. 2a -d and 3a-d:

- one or more additional security features may be contained on or within the first and/or second regions of the one or more watermarks.

- the watermark(s) does not contain one or more polymer or resinous materials within the first and/or second regions.

- the additional security features are selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more second level security features that are machine detectable or machine readable, as described above.

- the film-like or foil-like security elements may be embedded (when in the form of, for example, a security strip or thread) in a second paper layer, or applied to a surface of the watermarked paper layer or second paper layer (when in the form of, for example, a thread or patch) using known methods and techniques.

- the security element(s) (with one or more adhesive layers) may be transferred to a surface of the watermarked or second paper layer as a transfer film using techniques including mechanical, chemical, thermal and photo-induced separation techniques.

- Activatable adhesives may be used to anchor or bond the film-like or foil-like security elements onto or within a surface of the fibrous sheet material.

- Suitable adhesives are not limited and include, but are not limited to, water-, heat- and/or pressure-activating adhesives that activate in the secondary dryer section of the papermaking machine, where temperatures reach between 100 °C and 160 °C. These coatings may be applied in the form of solvent-based polymer solutions or aqueous solutions or dispersions.

- Suitable dispersions are selected from the group of acrylic resin dispersions, epoxy resin dispersions, natural latex dispersions, polyurethane resin dispersions, polyvinyl acetate resin dispersions, polyvinyl alcohol resin dispersions, urea formaldehyde resin dispersions, vinyl acetate resin dispersions, ethylene vinyl acetate resin dispersions, ethylene vinyl alcohol resin dispersions, polyester resin dispersions, and mixtures thereof.

- Machine direction registration of security patches to watermarks contained on or formed in the sheet material may be achieved by indexing the relative position of the watermark(s) on the equipment used to produce the watermark(s) in the paper sheet.

- the watermark(s) position is then conveyed in a continuous manner to the equipment used to apply the security patch(es) to the paper surface.

- Pre-applied marks or indexes on the carrier film used to convey the patch(es) is used to control the speed of the carrier film and thus the patch(es), thereby ensuring registration of the watermark(s) with the patch(es).

- FIG. 4 a Fourdrinier process for making a single-ply embodiment of the fibrous sheet material of the present invention is shown.

- an adhesive coated security thread 20 (oriented such that the front side of the security thread and not the adhesive coated back side is an uppermost layer) is guided along a tube 22 with a variable speed advancing device 24 (e.g ., electric servomechanism with servo drive) and pushed into a surface of a partially consolidated advancing fibrous web 26 (e.g ., a fibrous slurry containing from about 1 to about 10 % by weight stock and from about 99 to about 90 % by weight water) at the wet end 28 of the paper-making machine after the web 26 has been watermarked by a dandy roll cylinder 30.

- a variable speed advancing device 24 e.g ., electric servomechanism with servo drive

- a partially consolidated advancing fibrous web 26 e.g ., a fibrous slurry containing from about 1 to about 10 %

- the security thread 20 may be positioned either partially or completely on top of the watermark(s) (i.e ., layered security features) on the surface of the web 26.

- the dandy roll cylinder 30 may be provided with raised and/or recessed areas on its surface, which may fully or partially overlap the area on the surface of the web 26 that will be occupied by the thread 20.

- this embodiment of the inventive method does not serve to disrupt fiber distribution around the surface applied security thread, resulting in a higher density fiber distribution with increased substrate density and stiffness which resists security thread deformation, distortion and creasing.

- the fibrous web 26 is passed through the press, main and secondary dryer and calender sections of the paper-making machine. While in the secondary dryer section of the paper-making machine, the web 26 is exposed to temperatures and/or pressures sufficient to activate the security thread's adhesive coating, causing it to firmly bond the thread in the fibrous sheet material, with the security thread continuously exposed on a front or upper surface of the sheet material partially or fully covering the formed watermark(s), while concealed from view on a back or lower surface of the sheet material.

- Machine directional registration of the security thread 20 to the formed watermark(s) is achieved using conventional techniques commonly used in the art.

- an automatic registration control system for a papermaking machine which includes the variable speed security thread advancing device 24, optical sensors 32a, 32b for tracking registration marks on the dandy roll cylinder 30 and on the security thread 20, and an encoder wheel 34 for tracking the speed of the paper being formed on the machine.

- the adhesive coated security thread 20 (again oriented such that the security thread and not the adhesive coating is an uppermost layer) is guided through the variable speed advancing device 24 and past optical sensor 32b and then pushed into a surface of the partially consolidated forming fibrous web 26 by the dandy roll 30 at the wet end 28 of the paper-making machine, the dandy roll 30 simultaneously or subsequently watermarking the web 26.

- fiber flows around the security thread resulting in a lower density fiber distribution with reduced substrate density and stiffness under the thread.

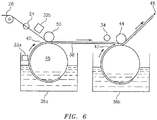

- FIG. 6 A cylinder mold process for making a two-ply embodiment of the fibrous sheet material of the present invention is shown in FIG. 6 .

- this process which employs two cylinder paper machines 36a, 36b, interconnected by pick-up felt 38, two paper webs 40, 42, are formed simultaneously, squeezed together in the area of roller 44, and then fed together to the press, dryer and calender sections of the paper-making machine.

- the resulting fibrous sheet material has the same physical characteristics as those noted above for sheet materials made using a Fourdrinier process.

- FIG. 6 shows cylinder paper machines of the wet vat type

- cylinder paper machines of the dry vat type may also be used to make the fibrous sheet material of the present invention.

- the two-ply paper web 46 formed by the cylinder paper machines shown in FIG. 6 , has adhesive coated security thread 20 recessed and one or more watermarks formed in a surface thereof, with the security thread 20 and the watermark(s) fully viewable from this surface.

- the watermark(s) is formed in paper web 40 by forming cylinder 48 and then the security thread 20 is integrated into the paper web by directing the thread through the variable speed advancing device 24 and past optical sensor 32b and then between roller 50 and a surface of the paper web exiting cylinder paper machine 36a.

- the security thread 20 may be positioned partially or completely on top of the watermark(s) on the surface of the paper web.

- Paper web 40 with surface applied security thread 20 and watermark(s) is then directed between roller 44 and a surface of the second paper web 42 exiting cylinder paper machine 36b, where the two paper webs are squeezed together.

- the second paper web 42 is homogeneous and serves to hide any irregularities in paper formation on a back or lower surface of the first paper web 40 that may have been caused by the presence of thread 20.

- forming cylinder 48 may be provided with raised and/or recessed areas on its surface, which may fully or partially overlap the area contacted by thread 20 during manufacture.

- machine directional registration between the security thread 20, the watermark(s) and the paper web 40 is achieved by the variable speed security thread advancing device 24, optical sensors 32a, 32b for tracking registration marks on the forming cylinder 48 and on the security thread 20, and an encoder wheel 34 for tracking the speed of the paper being formed on cylinder paper machine 36a.

- the inventive fibrous sheet material may be wound up and stored or directly introduced into another machine (e.g. , a printing machine) for further processing.

- the inventive security paper is a multi-ply paper that comprises:

- the second paper layer is windowed, the one or more through windows in the second paper layer being in register with the one or more watermarks.

- the use of two paper layers and optionally one or more overlying through windows allows for a greater contrast between the one or more watermarks and the background.

- one or more security elements in the form of one or more color-imparting substances are contained within the first and/or second regions of the one or more watermarks.

- the one or more color-imparting substances include both dyes and pigments (e.g ., ultra-fine particle size pigments).

- the security sheet or document does not include one or more film-like or foil-like security elements.

- the resulting watermarks have a tonality (i.e., color scheme or range of tones) in a color or shade different from that of the bulk region of the material which surrounds the watermarks, which serves to increase their perception and resistance to simulation.

- Watermarks have traditionally been the same color as the paper substrate on or within which they are carried. These marks are formed by localized variation in the thickness of the paper that changes the opacity of the paper, making the watermark visible in transmitted light or in reflected light atop a dark background.

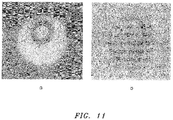

- FIG. 7 A prior art or standard watermark is shown against the same color paper substrate in FIG. 7 .

- the enhanced watermark of the present invention which includes one or more color-imparting substances in the form of one or more visible (colored) pigments (i.e ., blue), has improved quality in which the contrast between the light and dark areas in the watermark is significantly greater.

- the public's attention is therefore drawn more readily to the inventive watermark increasing the effectiveness of this security feature.

- the inventive watermark contains a second level security feature in the form of a UV excitable substance in addition to one or more color-imparting substances.

- the inventive watermark not only demonstrates a marked contrast between light and dark areas in transmitted light, but because it also contains a substance which can be excited by UV radiation, it also demonstrates a tonality of UV response that is difficult to reproduce, thereby rendering this watermark embodiment even more counterfeit resistant.

- the inventive method for manufacturing the security document involves making a continuous roll of watermarked paper 52 on a paper making machine 54 ( FIG. 9a ), watermarks or watermark regions 56 repeating along the length of the paper ( FIG. 9a ), watermarks or watermark regions 56 repeating along the length of the paper ( FIG. 9a ), watermarks or watermark regions 56 repeating along the length of the paper ( FIG. 9a ), watermarks or watermark regions 56 repeating along the length of the paper ( FIG.

- the watermarks are formed by well-known techniques on, for example, a cylinder mold papermaking machine or a Fourdrinier papermaking machine (using a dandy roll).

- a range of fiber types can be used in making the paper, including synthetic or natural fibers or a mixture of both.

- the "colored solution” used to impart tonality to the watermarks of the present invention comprises the one or more color-imparting substances referred to above, which include both dyes and pigments (e.g ., ultra-fine particle size pigments).

- the colored solution 58 is applied locally to the watermark regions 56 of the paper while the paper is still wet and on a forming wire and before any wet pressing occurs.

- the colored solution may be applied to the continuous roll of watermarked paper 52 using a low volume intermittent shower with nozzles 60 aligned to the watermark regions of the paper.

- the colored solution is drawn into the paper web using one or more vacuum boxes 62. Although two vacuum boxes are shown in FIG. 9b , one or more vacuum boxes may be used in the practice of the inventive method.

- one or more polymer or resinous materials are contained within the first region(s) and optionally the second region(s) of the one or more watermarks.

- the security sheet or document in this exemplary embodiment does not include one or more film-like or foil-like security elements.

- the first and/or second regions in this embodiment may also contain one or more security features selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more second level security features that are machine detectable or machine readable, as described above.

- the see-through watermark embodiment of the present invention provides an easily recognized public security feature for first-level authentication.

- the inventive watermark(s) which may be a paper-borne feature, allows for authentication by its transmissive properties.

- the inclusion of such a translucent or transparent region within a security document e.g ., banknote

- the inventive see-through watermark(s) is obtained as part of the papermaking process during sheet formation in the wet state.

- a paper web is made in a continuous manner on a Fourdrinier papermaking machine. Paper stock is deposited from a head box onto a continuous moving wire mesh. Water from the paper stock then drains through the wire mesh leaving a wet de-watered fiber mat.

- the inventive see-through watermark(s) is formed by first removing paper stock from select areas of the fiber mat with a resultant reduction in fiber density ( see FIG. 10 ). This may be done using conventional techniques such dandy roll (or cylinder vat) technology.

- the select areas with lower fiber density i.e ., the first regions

- the select areas with lower fiber density have reduced opacity relative to other areas of the watermark(s) ( i.e ., the second regions) and other areas of the fiber mat ( i.e ., the base sheet), though not transparent.

- the first and optionally the second regions of the watermark(s) are treated with one or more polymer or resinous materials chosen for a final refractive index which closely matches cellulose (e.g ., a UV curable, e-beam curable, or thermal curable polymer or resinous material).

- one or more polymer or resinous materials chosen for a final refractive index which closely matches cellulose e.g ., a UV curable, e-beam curable, or thermal curable polymer or resinous material.

- the first and second regions may be treated with the one or more polymer or resinous materials on the papermaking machine, in an off-line web process such as rewinding or respooling, in a dedicated off-line web process prior to sheet cutting, or on individual sheets.

- an off-line web process such as rewinding or respooling

- the one or more polymer or resinous materials which saturate the paper in the first and optionally the second regions of the watermark(s) (replacing air in the interstices between fibers), may optionally be applied in a pattern over these areas, and may further be cured via radiation, thermal/catalytic, or oxidative means.

- a polymer or resinous material(s) of appropriate modulus may also allow for embossing, applications within the translucent or transparent areas to be performed, for example, prior to printing, or during an intaglio printing process.

- the inventive see-through watermark(s) may also include one or more features within its perimeter selected from the group of increased fiber density areas in the form of recognizable or discernible indicia, one or more substances that are color-imparting, and one or more second level security features that are machine detectable or machine readable, as described above.

- fibers or planchettes may be added via random addition to the papermaking furnish, or selectively placed in-line in the position of the see-though security element. In addition, or alternatively, such inclusions could be concentrated in specific cross-direction areas of the paper.

- the inventive security sheet or document is a single-ply paper that comprises:

- Such frame-like areas may be formed in the watermarked paper layer by treating the areas surrounding each watermark with one or more transparentizing polymer or resinous materials, such as a UV curable, e-beam curable, or thermal curable polymer or resinous material.

- one or more transparentizing polymer or resinous materials such as a UV curable, e-beam curable, or thermal curable polymer or resinous material.

- These frame-like areas may be treated with the transparentizing material(s) on the papermaking machine, in an off-line web process such as rewinding or respooling, in a dedicated off-line web process prior to sheet cutting, or on individual sheets.

- the transparentizing material(s) saturates the paper in the applied areas replacing air in the interstices between fibers.

- This material(s) may be curable or non-curable. Treated areas of the watermarked paper layer allow for the transmission of visible light, thereby framing and thus enhancing the visual perception of watermark(s).

Claims (2)

- Feuille ou document de sécurité (10) ayant un ou plusieurs filigranes (14) ou dessins de filigrane améliorés, qui comprend:un matériau en feuille fibreuse comprenant un ou plusieurs filigranes ou dessins de filigrane, dans lequel chaque dessin de filigrane a une ou plusieurs premières zones (18) avec des densités de fibres réduites par rapport aux zones environnantes du matériau en feuille fibreuse et une ou plusieurs secondes zones (16) avec des densités de fibres similaires ou accrues par rapport aux zones environnantes du matériau en feuille, et dans lequel chaque dessin de filigrane a une partie supérieure ou recto et une partie inférieure ou verso; etdes moyens pour améliorer un ou plusieurs filigranes ou dessins de filigranes en les rendant visuellement améliorés, détectables ou lisibles par machine, ou les deux, lesdits moyens étant caractérisé en ce qu'ils comprennent:

une ou plusieurs zones transparentes ou translucides entourant chacun desdits un ou plusieurs motifs de filigrane. - Feuille ou document de sécurité (10) selon la revendication 1, qui est un papier multicouche comprenant: une première couche de papier ayant un grammage réduit d'environ 10 à environ 50 grammes par mètre carré et comprenant un ou plusieurs filigranes (14) ou dessins de filigrane, chaque surface de la première couche de papier présentant soit la partie supérieure ou recto desdits un ou plusieurs dessins de filigrane, soit la partie inférieure ou verso de ceux-ci; et

des moyens pour améliorer le ou les filigranes ou les dessins de filigrane sous la forme d'une seconde couche de papier ayant un poids de base réduit d'environ 10 à environ 50 grammes par mètre carré et, facultativement, une ou plusieurs fenêtres traversantes, la seconde couche de papier recouvrant soit la surface de la première couche de papier affichant la partie supérieure ou recto du ou des dessins de filigrane, soit la surface affichant la partie inférieure ou verso du ou des dessins de filigrane.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL18154768T PL3333812T3 (pl) | 2013-12-03 | 2014-12-02 | Arkusz lub dokument zabezpieczony mający jeden lub więcej udoskonalonych znaków wodnych |

| EP19219466.0A EP3690829B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

| EP22210172.7A EP4163888A1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité ayant un ou plusieurs filigranes améliorés |

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201361911141P | 2013-12-03 | 2013-12-03 | |

| US201361911831P | 2013-12-04 | 2013-12-04 | |

| US201361911885P | 2013-12-04 | 2013-12-04 | |

| US201461924000P | 2014-01-06 | 2014-01-06 | |

| PCT/US2014/068205 WO2015084872A2 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

| EP14821361.4A EP3078005B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14821361.4A Division EP3078005B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

Related Child Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP22210172.7A Division EP4163888A1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité ayant un ou plusieurs filigranes améliorés |

| EP19219466.0A Division EP3690829B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

| EP19219466.0A Division-Into EP3690829B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3333812A1 EP3333812A1 (fr) | 2018-06-13 |

| EP3333812B1 true EP3333812B1 (fr) | 2020-02-19 |

Family

ID=52273510

Family Applications (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP18154768.8A Active EP3333812B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

| EP19219466.0A Active EP3690829B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

| EP22210172.7A Pending EP4163888A1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité ayant un ou plusieurs filigranes améliorés |

| EP14821361.4A Active EP3078005B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

Family Applications After (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19219466.0A Active EP3690829B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

| EP22210172.7A Pending EP4163888A1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité ayant un ou plusieurs filigranes améliorés |

| EP14821361.4A Active EP3078005B1 (fr) | 2013-12-03 | 2014-12-02 | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés |

Country Status (12)

| Country | Link |

|---|---|

| EP (4) | EP3333812B1 (fr) |

| JP (1) | JP6534679B2 (fr) |

| KR (1) | KR102336078B1 (fr) |

| CN (1) | CN106163822B (fr) |

| AU (1) | AU2014360693B2 (fr) |

| BR (1) | BR112016012684B1 (fr) |

| CA (1) | CA2932257A1 (fr) |

| ES (3) | ES2938837T3 (fr) |

| MX (1) | MX358966B (fr) |

| PL (2) | PL3690829T3 (fr) |

| RU (1) | RU2680329C9 (fr) |

| WO (1) | WO2015084872A2 (fr) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6545116B2 (ja) * | 2015-03-31 | 2019-07-17 | 特種東海製紙株式会社 | 偽造防止用紙及びその製造方法 |

| JP6732175B2 (ja) * | 2016-11-28 | 2020-07-29 | 独立行政法人 国立印刷局 | 色彩を有するセルロース要素を用いたすき入れ紙及びその製造方法 |

| KR101875566B1 (ko) * | 2017-01-25 | 2018-07-09 | 그린비월드(주) | 위조방지용 보안필름 |

| CA3051841A1 (fr) | 2017-02-10 | 2018-08-16 | Crane & Co., Inc. | Dispositif de securite optique lisible par machine |

| FR3080630B1 (fr) * | 2018-04-25 | 2021-10-08 | Honnorat Rech & Services | Papier de securite avec inserts manuels |

| EP3763539A1 (fr) * | 2019-07-11 | 2021-01-13 | Gemalto Sa | Personnalisation multi-pages pour un document de sécurité multi-pages |

| KR102214523B1 (ko) * | 2019-07-31 | 2021-02-10 | (주) 나노메카 | 위조 방지용 필름 구조물 |

| CN111625854B (zh) * | 2020-05-25 | 2022-10-14 | 聚好看科技股份有限公司 | 文档加密方法、访问方法、服务器及系统 |

| PT117491B (pt) | 2021-09-30 | 2024-03-12 | Univ De Coimbra | Copolímero cromogénico, seu método de obtenção, produtos que o incorporam e método de deteção de contrafação e autenticaçao de produtos |

| KR102632898B1 (ko) * | 2023-04-27 | 2024-02-05 | 엔비에스티(주) | 위변조 방지용 보안필름 및 이를 활용한 위변조 인증방법 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1489084A (en) | 1975-10-28 | 1977-10-19 | Tullis Russell Co Ltd | Simulated watermarking |

| EP0091341A1 (fr) | 1982-03-25 | 1983-10-12 | ARJOMARI-PRIOUX Société anonyme dite | Matières cellulosiques rendues transparentes et leurs applications, leur procédé de fabrication et les compositions de traitement correspondantes |

| WO1995009275A1 (fr) | 1993-09-27 | 1995-04-06 | Portals Limited | Ameliorations relatives aux caracteristiques de securite du papier |

| WO2005038135A1 (fr) | 2003-10-15 | 2005-04-28 | Arjowiggins | Papier de securite multijet |

| EP1743778A2 (fr) | 2005-07-13 | 2007-01-17 | Colin Austin Harris | Fabrication de papier anti-falsification |

| US20090001709A1 (en) | 2005-03-23 | 2009-01-01 | Giesecke & Devrient Gmbh | Multi-Ply Security Paper |

| US20090301676A1 (en) | 2006-02-09 | 2009-12-10 | Arjowiggins | Sheet material comprising at least one watermark having a colored shade |

| US20100001508A1 (en) | 2007-02-07 | 2010-01-07 | Wayne Robert Tompkin | Security document |

Family Cites Families (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH287332A (de) | 1948-10-01 | 1952-11-30 | Herbig Wolfgang Ing Dr | Eine unbefugte Vervieltältigung erschwerendes Dokument. |

| CH607170A5 (fr) | 1976-10-28 | 1978-11-30 | Sodeco Compteurs De Geneve | |

| FR2542472B1 (fr) | 1983-03-11 | 1985-06-21 | Thomson Brandt | Carte a lecture optique portant des informations numeriques et systeme de controle d'acces a des informations diffusees utilisant une telle carte |

| DE4314380B4 (de) * | 1993-05-01 | 2009-08-06 | Giesecke & Devrient Gmbh | Sicherheitspapier und Verfahren zu seiner Herstellung |

| EP1377853B1 (fr) * | 2001-04-10 | 2008-09-17 | President And Fellows of Harvard College | Microlentille pour gravure par projection et son procede de preparation |

| US8543823B2 (en) * | 2001-04-30 | 2013-09-24 | Digimarc Corporation | Digital watermarking for identification documents |

| EP1308485A1 (fr) | 2001-10-31 | 2003-05-07 | Sicpa Holding S.A. | Assortiment d' encres avec un marquage d'infrarouge |

| EP2397883B1 (fr) | 2003-11-21 | 2018-10-24 | Visual Physics, LLC | Sécurité micro-optique et système de présentation d'images |

| ATE495222T1 (de) | 2004-02-11 | 2011-01-15 | Basf Se | Schwarze perylenpigmente |

| GB0409747D0 (en) * | 2004-04-30 | 2004-06-09 | Rue De Int Ltd | Improvements in substrates incorporating security devices |

| WO2005106601A2 (fr) | 2004-04-30 | 2005-11-10 | De La Rue International Limited | Dispositifs optiquement variables ameliores |

| DE102004031118A1 (de) * | 2004-06-28 | 2006-01-19 | Infineon Technologies Ag | Schein, Lese-Vorrichtung und Schein-Identifikations-System |

| US7351277B2 (en) | 2004-09-08 | 2008-04-01 | E. I. Du Pont De Nemours And Company | IR transparent cyan inkjet ink |

| US7407538B2 (en) | 2004-09-08 | 2008-08-05 | E.I. Du Pont De Nemours And Company | IR transparent inkjet ink set |

| ES2794076T3 (es) | 2005-05-18 | 2020-11-17 | Visual Physics Llc | Sistema de presentación de imágenes y de seguridad micro-óptico |

| JP2007136907A (ja) | 2005-11-21 | 2007-06-07 | Dainippon Printing Co Ltd | 印刷物および真偽判定用媒体 |

| DE102005062132A1 (de) | 2005-12-23 | 2007-07-05 | Giesecke & Devrient Gmbh | Sicherheitselement |

| JP2007261112A (ja) | 2006-03-29 | 2007-10-11 | Dainippon Printing Co Ltd | 偽造防止印刷物 |

| WO2007133613A2 (fr) * | 2006-05-12 | 2007-11-22 | Crane & Co., Inc. | Structure de film micro-optique qui seule ou conjointement avec un document ou étiquette de sécurité projette des images en coordination spatiale avec des images statiques et/ou d'autres images projetées |

| EP2410370A1 (fr) | 2006-06-28 | 2012-01-25 | Visual Physics, LLC | Sécurité micro-optique et système de présentation d'images |

| ES2338353T3 (es) * | 2006-08-11 | 2010-05-06 | National Bank Of Belgium | Imagen escondida. |

| DE102007057658A1 (de) * | 2007-02-07 | 2009-06-04 | Leonhard Kurz Stiftung & Co. Kg | Sicherheitselement |

| GB201003397D0 (en) | 2010-03-01 | 2010-04-14 | Rue De Int Ltd | Moire magnification security device |

| FR2957943B1 (fr) * | 2010-03-24 | 2021-11-05 | Arjowiggins Security | Filigrane, procedes de fabrication d'une piece pour la formation d'un filigrane et piece obtenue selon ledit procede |

| FR2984799A1 (fr) * | 2011-12-22 | 2013-06-28 | Arjowiggins Security | Structure multicouche comportant au moins une couche diffusante. |

-

2014

- 2014-12-02 EP EP18154768.8A patent/EP3333812B1/fr active Active

- 2014-12-02 PL PL19219466.0T patent/PL3690829T3/pl unknown

- 2014-12-02 RU RU2016125988A patent/RU2680329C9/ru active

- 2014-12-02 KR KR1020167017511A patent/KR102336078B1/ko active IP Right Grant

- 2014-12-02 EP EP19219466.0A patent/EP3690829B1/fr active Active

- 2014-12-02 WO PCT/US2014/068205 patent/WO2015084872A2/fr active Application Filing

- 2014-12-02 ES ES19219466T patent/ES2938837T3/es active Active

- 2014-12-02 JP JP2016557524A patent/JP6534679B2/ja active Active

- 2014-12-02 PL PL18154768T patent/PL3333812T3/pl unknown

- 2014-12-02 BR BR112016012684-0A patent/BR112016012684B1/pt active IP Right Grant

- 2014-12-02 ES ES14821361.4T patent/ES2664785T3/es active Active

- 2014-12-02 EP EP22210172.7A patent/EP4163888A1/fr active Pending

- 2014-12-02 CN CN201480074261.6A patent/CN106163822B/zh active Active

- 2014-12-02 EP EP14821361.4A patent/EP3078005B1/fr active Active

- 2014-12-02 AU AU2014360693A patent/AU2014360693B2/en not_active Ceased

- 2014-12-02 CA CA2932257A patent/CA2932257A1/fr not_active Abandoned

- 2014-12-02 ES ES18154768T patent/ES2779923T3/es active Active

- 2014-12-02 MX MX2016007197A patent/MX358966B/es active IP Right Grant

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1489084A (en) | 1975-10-28 | 1977-10-19 | Tullis Russell Co Ltd | Simulated watermarking |

| EP0091341A1 (fr) | 1982-03-25 | 1983-10-12 | ARJOMARI-PRIOUX Société anonyme dite | Matières cellulosiques rendues transparentes et leurs applications, leur procédé de fabrication et les compositions de traitement correspondantes |

| WO1995009275A1 (fr) | 1993-09-27 | 1995-04-06 | Portals Limited | Ameliorations relatives aux caracteristiques de securite du papier |

| WO2005038135A1 (fr) | 2003-10-15 | 2005-04-28 | Arjowiggins | Papier de securite multijet |

| US20090001709A1 (en) | 2005-03-23 | 2009-01-01 | Giesecke & Devrient Gmbh | Multi-Ply Security Paper |

| EP1743778A2 (fr) | 2005-07-13 | 2007-01-17 | Colin Austin Harris | Fabrication de papier anti-falsification |

| US20090301676A1 (en) | 2006-02-09 | 2009-12-10 | Arjowiggins | Sheet material comprising at least one watermark having a colored shade |

| US20100001508A1 (en) | 2007-02-07 | 2010-01-07 | Wayne Robert Tompkin | Security document |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2779923T3 (es) | 2020-08-20 |

| CA2932257A1 (fr) | 2015-06-11 |

| JP6534679B2 (ja) | 2019-06-26 |

| EP3690829A1 (fr) | 2020-08-05 |

| EP4163888A1 (fr) | 2023-04-12 |

| WO2015084872A3 (fr) | 2015-08-13 |

| EP3078005B1 (fr) | 2018-02-07 |

| WO2015084872A2 (fr) | 2015-06-11 |

| BR112016012684A2 (fr) | 2017-08-08 |

| AU2014360693B2 (en) | 2019-07-04 |

| KR20160098293A (ko) | 2016-08-18 |

| AU2014360693A1 (en) | 2016-06-16 |

| EP3078005A2 (fr) | 2016-10-12 |

| PL3333812T3 (pl) | 2020-07-13 |

| RU2680329C9 (ru) | 2019-04-04 |

| EP3333812A1 (fr) | 2018-06-13 |

| JP2016540335A (ja) | 2016-12-22 |

| CN106163822B (zh) | 2018-05-08 |

| MX358966B (es) | 2018-09-11 |

| CN106163822A (zh) | 2016-11-23 |

| KR102336078B1 (ko) | 2021-12-08 |

| EP3690829B1 (fr) | 2022-11-30 |

| ES2664785T3 (es) | 2018-04-23 |

| MX2016007197A (es) | 2016-10-28 |

| ES2938837T3 (es) | 2023-04-17 |

| BR112016012684B1 (pt) | 2022-01-11 |

| PL3690829T3 (pl) | 2023-04-11 |

| RU2680329C1 (ru) | 2019-02-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10344431B2 (en) | Security sheet or document having one or more enhanced watermarks | |

| EP3333812B1 (fr) | Feuille ou document de sécurité comportant un ou plusieurs filigranes améliorés | |

| AU2008315842B2 (en) | Sheet having at least one watermark or pseudo-watermark observable only on one side of the sheet | |

| RU2386541C2 (ru) | Усовершенствование способов изготовления защитных подложек | |

| RU2360060C2 (ru) | Усовершенствование подложек, включающих в себя защитные устройства | |

| US8268128B2 (en) | Security substrates | |

| EP1965986A2 (fr) | Substrats de securite ameliores | |

| EP1567713B1 (fr) | Procede de fabrication de substrat fibreux incorporant un element effile a profil d'arete variable | |

| JP2008111203A (ja) | スレッド及び偽造防止用紙及び偽造防止印刷物 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 3078005 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20181213 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B42D 25/333 20140101ALI20190528BHEP Ipc: B42D 25/36 20140101ALI20190528BHEP Ipc: B42D 25/29 20140101ALI20190528BHEP Ipc: B42D 25/373 20140101ALI20190528BHEP Ipc: G07D 7/00 20160101AFI20190528BHEP Ipc: B42D 25/351 20140101ALI20190528BHEP Ipc: B42D 25/382 20140101ALI20190528BHEP Ipc: B42D 25/355 20140101ALI20190528BHEP Ipc: B42D 25/324 20140101ALI20190528BHEP Ipc: B42D 25/387 20140101ALI20190528BHEP Ipc: B42D 25/378 20140101ALI20190528BHEP Ipc: B42D 25/369 20140101ALI20190528BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190904 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 3078005 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014061398 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1235833 Country of ref document: AT Kind code of ref document: T Effective date: 20200315 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200519 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200219 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200219 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2779923 Country of ref document: ES Kind code of ref document: T3 Effective date: 20200820 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |