EP3239015B1 - Kraftgeregelte spurführung für ein schienenfahrzeug - Google Patents

Kraftgeregelte spurführung für ein schienenfahrzeug Download PDFInfo

- Publication number

- EP3239015B1 EP3239015B1 EP17164999.9A EP17164999A EP3239015B1 EP 3239015 B1 EP3239015 B1 EP 3239015B1 EP 17164999 A EP17164999 A EP 17164999A EP 3239015 B1 EP3239015 B1 EP 3239015B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rail vehicle

- actuator unit

- actuating force

- axle

- elastic bearing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61F—RAIL VEHICLE SUSPENSIONS, e.g. UNDERFRAMES, BOGIES OR ARRANGEMENTS OF WHEEL AXLES; RAIL VEHICLES FOR USE ON TRACKS OF DIFFERENT WIDTH; PREVENTING DERAILING OF RAIL VEHICLES; WHEEL GUARDS, OBSTRUCTION REMOVERS OR THE LIKE FOR RAIL VEHICLES

- B61F5/00—Constructional details of bogies; Connections between bogies and vehicle underframes; Arrangements or devices for adjusting or allowing self-adjustment of wheel axles or bogies when rounding curves

- B61F5/38—Arrangements or devices for adjusting or allowing self- adjustment of wheel axles or bogies when rounding curves, e.g. sliding axles, swinging axles

- B61F5/383—Adjustment controlled by non-mechanical devices, e.g. scanning trackside elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61F—RAIL VEHICLE SUSPENSIONS, e.g. UNDERFRAMES, BOGIES OR ARRANGEMENTS OF WHEEL AXLES; RAIL VEHICLES FOR USE ON TRACKS OF DIFFERENT WIDTH; PREVENTING DERAILING OF RAIL VEHICLES; WHEEL GUARDS, OBSTRUCTION REMOVERS OR THE LIKE FOR RAIL VEHICLES

- B61F5/00—Constructional details of bogies; Connections between bogies and vehicle underframes; Arrangements or devices for adjusting or allowing self-adjustment of wheel axles or bogies when rounding curves

- B61F5/38—Arrangements or devices for adjusting or allowing self- adjustment of wheel axles or bogies when rounding curves, e.g. sliding axles, swinging axles

- B61F5/386—Arrangements or devices for adjusting or allowing self- adjustment of wheel axles or bogies when rounding curves, e.g. sliding axles, swinging axles fluid actuated

Definitions

- the invention relates to a method for axle control of at least one first axle of a rail vehicle, the axle control having an actuator unit, a passive elastic bearing connected mechanically in parallel to this and a control device, and the control device being connected at least to the actuator unit for the purpose of data transmission.

- Running gears for rail vehicles must have a high level of driving safety. This can be improved, for example, by arranging an active axle or wheel or wheel set control.

- the targeted positioning of axles or wheels or wheel sets by actively rotating them about their vertical axes is used in a known manner to prevent unstable driving conditions. Furthermore, this increases driving comfort by avoiding disruptive vibrations in a rail vehicle.

- the wheel-rail contact has a special, safety-relevant importance. Irregularities in the wheel-rail contact, e.g. due to damage to a wheel, can lead to considerable consequential damage and even derailment. Even slight damage, such as fine cracks, can cause great difficulties, since they require maintenance work, which can result in high costs and limited availability of the rail vehicles.

- an active axle or wheel or wheel set control reduces wear and tear or rolling contact fatigue (RCF) and thus of irregularities in the wheel-rail contact on wheels and rails.

- RCF rolling contact fatigue

- EP 0 870 664 B1 a method for wheel set guidance of rail vehicles.

- a device is shown, among other things, in which a two-chamber fluid bushing is arranged between a swing arm and a chassis frame, which generates a relative movement between the swing arm and the chassis frame and thereby sets a wheel set adjustment angle.

- a turning angle between the chassis frame and a car body or a turning angle between two wheelsets and the car body are used as the control variable for the wheel set adjustment angle.

- the aforementioned approach has the disadvantage that measuring and evaluation units must be provided in connection with the processing of the aforementioned turning angles, that is to say, for example, angle sensors.

- the DE 198 61 086 B4 shows a method for a steering alignment of wheels of a rail vehicle that are rotatably fastened to a chassis in a track, a target steering angle of the wheels being determined as a function of a curvature of the track.

- the aforementioned approach has the disadvantage that the method is designed as a steering angle control which, for checking whether a target steering angle has been reached or maintained, is sensors for the Angle detection, e.g. angle encoder, required.

- a regulation with regard to a wheel adjusting force is not disclosed in this document.

- the wishbones have hydraulic sockets with which the longitudinal rigidity of the chassis is controlled.

- hydraulic pressures of the hydraulic bushings are set by means of an adjusting device on the basis of a measurement of wheel set accelerations.

- the DE 10 2006 025773 A1 shows a method for regulating an active chassis of a rail vehicle, for which actuators are provided, which compensate for driving dynamics effects by setting steering angles of wheel sets. For this purpose, steering angles and values representative of loads on the actuators are recorded by means of sensors.

- the EP 0 600 172 A1 known, in which a bogie with wheelsets is described. Force or displacement-regulated actuators are arranged on the wheelsets, which act on wheelset bearings in order to ensure that the wheelsets are turned out in a controlled manner.

- the actuators are controlled based on distance measurements. Unscrewing angles between a bogie frame and a vehicle frame are determined from distances measured by a sensor. Setpoint specifications for the actuators are formed from these turning angles.

- the invention is therefore based on the object of specifying a method which is improved over the prior art.

- this object is achieved by a method according to claim 1.

- the first wheel 8 is connected via a mechanical coupling, not shown, to a second wheel 9, not shown, whose center point is also arranged on the first axle 2 and which rests on a second rail 23, not shown.

- a wheel bearing 14, a swing arm 15 and a wheel bearing housing 16 are shown.

- a passive elastic bearing 5 designed as a hydraulic bushing with frequency and amplitude-dependent static and increased dynamic rigidity is provided to generate dynamic rigidity.

- the hydraulic bushing has a stabilizing, resilient and damping effect primarily in the plane of its base area, ie the rigidity acts in the direction of a longitudinal axis 17 of the chassis and in the direction of a vertical axis 18 of the chassis.

- An actuator unit 4 is connected in parallel to the elastic bearing 5 with regard to the mechanical mode of operation. With regard to its position, it is arranged in such a way that it generates an actual actuating force 7, which acts parallel to the direction of the longitudinal axis 17 of the chassis and, via the mechanical coupling with the second wheel 9, rotates the first wheel 8 about the vertical axis 18 or the chassis . about an axis of rotation parallel to this.

- the actuator unit 4 has a pneumatic actuator 19, which is supplied with compressed air via units, lines and valves (not shown) and generates a defined, controllable or regulatable actual actuating force 7.

- Fig. 2 represents an exemplary variant of a method according to the invention. Functional relationships between an actuator unit 4, an elastic bearing 5, a control device 6, a rotation rate sensor 20 and a translational speed sensor 21 are shown. The actuator unit 4 generates via an in Fig. 2 Pneumatic actuator 19, not shown, an actual actuating force 7 for setting steering angles ⁇ for an axle or wheel or wheel set control.

- the elastic bearing 5 has a stiffness characteristic c which mathematically corresponds to a non-linear function. A yaw rate ⁇ of a chassis is measured via the yaw rate sensor 20. Its use represents an advantageous solution for the determination of

- a translation speed v of the chassis is measured via the translation speed sensor 21. Their detection can, however, also take place via other means, for example via a multifunction vehicle bus system (MVB), from which corresponding data can be read out.

- the control device 6 comprises software modules (not shown) for the implementation of control algorithms.

- the actuator unit 4, the elastic bearing 5, the rotation rate sensor 20 and the translational speed sensor 21 have data interfaces to the control device 6 as well as devices (not shown) for processing the information to be transmitted via the data interfaces mentioned.

- the control device 6 receives information about the actual actuating force 7 at a frequency greater than or equal to 10 Hz or corresponding actual actuating force data DFIst from the actuator unit 4, information about the stiffness characteristic c or corresponding stiffness data Dc from the elastic bearing 5, information about the yaw rate ⁇ or corresponding yaw rate data D ⁇ from the yaw rate sensor 20 and information about the translational speed v or corresponding Translation speed data Dv from the translation speed sensor 21.

- the aforementioned transfer of stiffness data Dc is a particularly advantageous solution. According to the invention, however, in the case of bearings with known stiffness behavior, it is also conceivable to implement stiffness curves in the software modules of the control device 6 and thus to dispense with data interfaces and devices for processing the information to be transmitted.

- setpoint actuating force data DFSoll are formed from the received actual actuating force data DFIst, the rigidity data Dc, the yaw rate data D ⁇ and the translational speed data Dv. From the yaw rate data D ⁇ or a yaw rate ⁇ and from the Translation speed data Dv or the translation speed v using the known rule, according to which a radius of curvature of the circle results as the quotient of a translation speed v and a yaw rate ⁇ , first of all a track curve radius R is determined.

- a travel s for the in Fig. 1 shown pneumatic actuator 19 of the actuator unit 4 is formed.

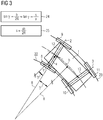

- the corresponding relationships are in Fig. 3 shown.

- Corresponding values for half the wheelset length a and the center distance b are implemented in the software modules of the control device 6.

- a target actuating force or target actuating force data DFSoll for the actuator unit is formed from the stiffness data Dc or the stiffness characteristic c of the elastic bearing 5 and the actuating path s 4 generated.

- the target actuating force is that force which is required to overcome the rigidity of the elastic bearing 5 and to generate the actuating path s of the pneumatic actuator 19 of the actuator unit 4.

- the in Fig. 1 illustrated pneumatic actuator 19 controlled.

- the actuator unit 4 includes devices not shown. Via the known relationship between a force, a piston area and a pressure, a pressure is generated in the pneumatic actuator 19, which generates the setpoint actuating force.

- the method for determining the target actuating force, the control of the actuator unit 4 for generating the target actuating force and the processing and transmission of the actual actuating force data DFIst, the target actuating force data DFSoll, the stiffness data Dc, the yaw rate data D ⁇ and the translational speed data Dv occur cyclically with a frequency greater than or equal to 10 Hz.

- Fig. 3 shows a running gear of a rail vehicle with a running gear frame 1, a first set of wheels 12 with a first wheel 8, a second wheel 9 and a first axle 2 as well as with a second set of wheels 13 with a third wheel 10, a fourth wheel 11 and a second axle 3 in a curved track.

- a first rail 22 and a second rail 23 are shown.

- a track curve radius R of the track curve, a steering angle ⁇ based on a rotation of the first wheel set 12 about its vertical axis, a center distance b and half a wheel set length a of the first wheel set 12 are shown.

- An adjustment path s for the in Fig. 1 shown pneumatic actuator 19 of the actuator unit 4 is determined.

- the formation formula 24 uses the permissible linearization, according to which, for small angles, the sine function and the tangent function of an angle can be set equal to the angle itself.

- the sine of the steering angle ⁇ is formed as the quotient of half the center distance b and the track curve radius R, the tangent of the steering angle ⁇ from the travel s and half the wheelset length a.

- the term for the sine of the steering angle ⁇ and the term for the tangent of the steering angle ⁇ are equated, ie the steering angle ⁇ is a pure calculation variable and does not have to be measured and processed.

- the travel s is determined as the quotient of the product of half the wheelset length a in the numerator and the center distance b as well as twice the track curve radius R in the denominator.

- the travel s is used in connection with Fig. 2 described method used for the determination of a target actuating force.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Vehicle Body Suspensions (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL17164999T PL3239015T3 (pl) | 2016-04-28 | 2017-04-05 | Prowadzenie pojazdu wzdłuż zadanego toru z regulowaną siłą dla pojazdu szynowego |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ATA50377/2016A AT518698B1 (de) | 2016-04-28 | 2016-04-28 | Kraftgeregelte Spurführung für ein Schienenfahrzeug |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3239015A1 EP3239015A1 (de) | 2017-11-01 |

| EP3239015B1 true EP3239015B1 (de) | 2021-05-26 |

Family

ID=58536741

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17164999.9A Active EP3239015B1 (de) | 2016-04-28 | 2017-04-05 | Kraftgeregelte spurführung für ein schienenfahrzeug |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP3239015B1 (pl) |

| AT (1) | AT518698B1 (pl) |

| ES (1) | ES2875525T3 (pl) |

| PL (1) | PL3239015T3 (pl) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102017114421A1 (de) * | 2017-06-28 | 2019-01-03 | Rheinisch-Westfälische Technische Hochschule (Rwth) Aachen | Gelenktes Losradpaar für Schienenfahrzeuge |

| PT110903B (pt) * | 2018-08-03 | 2021-08-02 | Inst Superior Tecnico | Dispositivo de guiamento ferroviário e o seu método de operar. |

| DE102020123592A1 (de) | 2020-09-10 | 2022-03-10 | Liebherr-Transportation Systems Gmbh & Co Kg | Aktive Radsatzsteuerung für ein Schienenfahrzeug |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4240098A1 (de) * | 1992-11-28 | 1994-06-01 | Krupp Verkehrstechnik Gmbh | Fahrwerk für Schienenfahrzeuge |

| AT407140B (de) * | 1993-11-26 | 2000-12-27 | Integral Verkehrstechnik Ag | Einrichtung zur steuerung eines rades, insbesondere eines radsatzes eines schienenfahrzeuges |

| DE19861086B4 (de) * | 1998-06-13 | 2004-04-15 | Bombardier Transportation Gmbh | Verfahren zur Achsausrichtung bei Schienenfahrzeugen |

| DE102006025773A1 (de) * | 2006-05-31 | 2007-12-06 | Bombardier Transportation Gmbh | Verfahren zur Regelung eines aktiven Fahrwerks eines Schienenfahrzeugs |

| DE102014214055A1 (de) * | 2014-07-18 | 2016-01-21 | Siemens Aktiengesellschaft | Fahrwerk für ein Schienenfahrzeug |

-

2016

- 2016-04-28 AT ATA50377/2016A patent/AT518698B1/de not_active IP Right Cessation

-

2017

- 2017-04-05 EP EP17164999.9A patent/EP3239015B1/de active Active

- 2017-04-05 ES ES17164999T patent/ES2875525T3/es active Active

- 2017-04-05 PL PL17164999T patent/PL3239015T3/pl unknown

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2875525T3 (es) | 2021-11-10 |

| PL3239015T3 (pl) | 2021-11-15 |

| AT518698A1 (de) | 2017-12-15 |

| AT518698B1 (de) | 2021-06-15 |

| EP3239015A1 (de) | 2017-11-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0877694B1 (de) | Verfahren zur beeinflussung des knickwinkels von schienenfahrzeug-wagenkästen und schienenfahrzeug zur durchführung des verfahrens | |

| EP2414207B1 (de) | Fahrzeug mit wankkompensation | |

| DE102013001973B3 (de) | Spurführung eines Schienenfahrzeugs | |

| EP2021223A2 (de) | Verfahren zur regelung eines aktiven fahrwerks eines schienenfahrzeugs | |

| DE69510871T2 (de) | Steuerverfahren zur Lenkung von Laufwerken mit einstellbaren Rädern einer auf Schienen fahrenden Einheit und dieses Verfahren nutzende Einheit | |

| EP0655378B1 (de) | Einrichtung und Verfahren von Radsätzen von Schienenfahrzeugen | |

| EP3239015B1 (de) | Kraftgeregelte spurführung für ein schienenfahrzeug | |

| EP1412240B1 (de) | Verfahren und vorrichtung zur aktiven radialsteuerung von radpaaren oder radsätzen von fahrzeugen | |

| EP0870664B1 (de) | Verfahren und Einrichtung zur Radsatzführung von Schienen-Fahrzeugen | |

| EP1451030B1 (de) | Positionseinstellung eines fahrzeug-wagenkörpers | |

| DE2606702C3 (de) | Einrichtung zum Einstellen von Drehgestellen | |

| DE2614166A1 (de) | Radsatz fuer ein schienenfahrzeug | |

| EP0833766A1 (de) | Schienenfahrzeug mit einem einachsigen laufwerk | |

| EP3544875B1 (de) | Fahrwerk für schienenfahrzeuge | |

| WO2010113045A2 (de) | Fahrzeug mit wankkompensation | |

| EP0736439A1 (de) | Fahrwerk für Schienenfahrzeuge | |

| DE102016226072A1 (de) | Sicherheitsfunktion und Steuergerät zur Überwachung sowie Steuerung von Wankstabilisatoren | |

| DE102016215004B4 (de) | Verfahren zum Betreiben eines elektrischen Stellmotors, Wankstabilisatoreinrichtung und Fahrzeug | |

| EP3934960A1 (de) | Vorrichtung und verfahren zur bestimmung von abständen zwischen wagenkästen und fahrwerken von fahrzeugen | |

| DE2848398B1 (de) | Spurfuehrung eines Radsatzes fuer Schienenfahrzeuge | |

| AT524550B1 (de) | Fahrwerk für ein Schienenfahrzeug | |

| EP1193154A1 (de) | Verfahren und Vorrichtung zur Stabilisierung des Wellenlaufes von Eisenbahnradsätzen | |

| DE102019213272A1 (de) | Verfahren zum Betreiben eines verstellbaren Wankstabilisators | |

| EP4227188B1 (de) | Schienenfahrzeugfahrwerk mit einer vorrichtung zum steuern einer radachse | |

| EP3241716B1 (de) | Fahrwerk für ein schienenfahrzeug |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN PUBLISHED |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20180430 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SIEMENS MOBILITY GMBH |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SIEMENS MOBILITY AUSTRIA GMBH |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B61F 5/38 20060101AFI20201030BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20201123 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502017010442 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1395950 Country of ref document: AT Kind code of ref document: T Effective date: 20210615 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210826 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20210526 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2875525 Country of ref document: ES Kind code of ref document: T3 Effective date: 20211110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210827 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210926 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210927 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210826 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502017010442 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20220301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210926 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20220430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20170405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20210526 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20250327 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250620 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250507 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250411 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20250307 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20250401 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20250721 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250709 Year of fee payment: 9 |