EP3122863B1 - Verfahren zum reinigen von anlagen - Google Patents

Verfahren zum reinigen von anlagen Download PDFInfo

- Publication number

- EP3122863B1 EP3122863B1 EP15726856.6A EP15726856A EP3122863B1 EP 3122863 B1 EP3122863 B1 EP 3122863B1 EP 15726856 A EP15726856 A EP 15726856A EP 3122863 B1 EP3122863 B1 EP 3122863B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- value

- color

- composition

- cleaning

- determined

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/39—Organic or inorganic per-compounds

- C11D3/3902—Organic or inorganic per-compounds combined with specific additives

- C11D3/3905—Bleach activators or bleach catalysts

- C11D3/3907—Organic compounds

- C11D3/391—Oxygen-containing compounds

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/39—Organic or inorganic per-compounds

- C11D3/3947—Liquid compositions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B9/00—Cleaning hollow articles by methods or apparatus specially adapted thereto

- B08B9/02—Cleaning pipes or tubes or systems of pipes or tubes

- B08B9/027—Cleaning the internal surfaces; Removal of blockages

- B08B9/032—Cleaning the internal surfaces; Removal of blockages by the mechanical action of a moving fluid, e.g. by flushing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/07—Cleaning beverage-dispensing apparatus

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/39—Organic or inorganic per-compounds

- C11D3/3942—Inorganic per-compounds

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/395—Bleaching agents

- C11D3/3956—Liquid compositions

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D2111/00—Cleaning compositions characterised by the objects to be cleaned; Cleaning compositions characterised by non-standard cleaning or washing processes

- C11D2111/10—Objects to be cleaned

- C11D2111/14—Hard surfaces

- C11D2111/20—Industrial or commercial equipment, e.g. reactors, tubes or engines

Definitions

- the present invention relates to a method for cleaning plants while simultaneously detecting the purity of the plant.

- EP 1,343,864 A1 and EP 1,730,258 A1 (equivalent to WO 2005/044968 A1 ) also discloses the Applicant water-soluble, permanganate-containing detergents and disinfectants, which in addition to permanganate a second oxidizing agent is used, which sometimes serves as the main oxidizing agent, while the permanganate predominantly indicator function plays.

- the base color value of the cleaning composition herein simultaneously referred to as F B prior to entering the system to be cleaned, does not serve as a benchmark for determining the purity of the system. Rather, according to the present invention, so to speak for the "calibration" of the process, the system is first flushed through to the surface until a constant color value is obtained.

- the constancy of the plant-specific color value named F A indicates that no more oxidisable impurities are contained in the plant.

- this "self-degradation" is temperature dependent and, moreover, is still strongly dependent on the size of the plant, i. of its inner surface and the residence time therein, as well as of course depends on the accuracy in the preparation of the composition.

- the value for F A can be determined several times using different water temperatures, as they are within the natural fluctuation range-during the corresponding season or over the entire calendar year-in order to bring out the influence of temperature.

- inaccuracies in mixing the usually commercially available concentrates for the cleaning composition can be averaged out by the sample weighed in steps of 1% ⁇ 5 wt .-% is varied and the respective color values are determined and used for averaging.

- these are preferably carried out in each case in the course of cleaning operations after interim operation of the system.

- the color value of the exiting composition can be measured to constancy, so that over time an ever more accurate average for F A is obtained, are taken into account in the temperature, air and concentration fluctuations or influences.

- a base color value F B of the composition without passage of the plant can be determined Value for F A , so as to obtain an increasingly accurate general correlation between F B and F A over time in an iterating manner.

- this value for F B does not serve, as in the prior art, as a reference point for the determination of the desired value, but merely represents an alternative or preferably Also in addition to the multiple determinations described above. Rather than over time to obtain an increasingly accurate average for F A , in which temperature and other factors are taken into account, according to this preferred embodiment of the invention, the "Ausstoffn" these influences ad hoc respectively. After repeated, in particular frequent, implementation of steps a) to e) and the resulting receipt of a reliable correlation between F B and F A , only the basic color value F B needs to be determined for a particular installation in step c), while the inherent investment value F A of the correlation between F and B F A can be calculated. This therefore simplifies and accelerates the process of the invention significantly and at the same time ensures high accuracy in the determination of purity.

- the target value ⁇ F A which is determined based on the inherent plant value F A determined initially at the "calibration" of the plant and serves as a reference for the measurement during the following cleaning operations, is not particularly limited and may vary depending on several factors. These include above all the intended use of the plant itself, for example, whether this is for drinks or other food or not for food, the frequency of cleaning, the costs necessary to achieve a certain purity and the time required for it, but also the reliability of the inherent Asset value F A. The latter depends above all on whether the value is based on multiple determinations, if so, on their number and on which influences were taken into account in the mean value (eg temperature, water quality, etc.).

- the last difference .DELTA.F can be given greater zero before reaching the values constant as the desired value .DELTA.F A, or a certain percentage deviation from the inherent investment value F A, for example 95% thereof, or the like. Since the method according to the invention primarily results in a saving of cleaning composition, a relatively large deviation of F A can sometimes be specified as the setpoint, as long as this is possible, for example, without infringing relevant hygiene regulations.

- a digital camera is preferably used in accordance with the present invention, and a color comparison software, for example for calculating the difference values .DELTA.F, is used.

- software capable of converting RBG values recorded by the camera (unless the camera directly captures RGB values) and comparing these RGB values, e.g. by a vector subtraction method, wherein the magnitude of the difference vector is the respective difference ⁇ F.

- the colorant-containing cleaning composition in preferred embodiments comprises permanganate as a color indicator and at least one further oxidizing agent whose oxidation potential is above that of permanganate as described above, more preferably peroxodisulfate, hypochlorite or a mixture thereof, v. due to the high sensitivity and strong oxidation effect of such systems.

- permanganate as a color indicator

- at least one further oxidizing agent whose oxidation potential is above that of permanganate as described above, more preferably peroxodisulfate, hypochlorite or a mixture thereof, v. due to the high sensitivity and strong oxidation effect of such systems.

- oxidizing agent e.g. e.g. Potassium iodide, dichromate or dichlorophenolindophenol in combination with hydrogen peroxide or ferroin for persulfate.

- color value is not necessarily an RGB value.

- the principle of the invention works with all physical data that allow conclusions to be drawn on the concentration of manganese ion species in the cleaning composition leaving the unit - and consequently on the amount of impurities oxidized in the just-done passage of the unit. These include, for example, photometrically measured extinction values, the refractive index or else the pH of the cleaning composition emerging from the plant.

- the principle of the invention works not only with difference values, but also with other relations between two temporally successive color value measurements. Instead of differences, it is also possible, for example, to form quotients of the two last measured values obtained, in which case consistency of the cleaning composition not at a difference value of 0, but at a quotient of 1 vorläge.

- the setpoint may be a percentage deviation thereof, eg, a value of 0.95 or 1.05, depending on whether the color value increases or decreases as it approaches the constant inherent plant value F A. See also the explanations in the later examples, especially in connection with the Fig. 5 and 6 ,

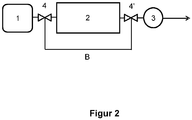

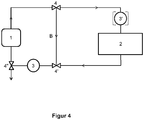

- FIG. 1 to 4 schematic representations of three different embodiments of the method of the invention

- Fig. 5 and 6 are graphical representations of color values measured in one embodiment of the method according to the invention.

- FIG. 1 A simplest embodiment of the method according to the invention is in Fig. 1 shown.

- a reservoir 1 for the cleaning composition it is continuously passed through a system 2 to be cleaned, whereafter it passes through a sensor 3 in which color values and their differences are determined at regular intervals.

- the length of the time interval depends significantly on the size of the system and the associated residence time of the composition in the system - from entry to re-exit - from.

- the residence time may be around 15 minutes, in which case the color value may be determined, for example, every 2 minutes or every 5 minutes.

- a maximum allowable deviation ⁇ F A is defined, which can be reached at the next cleaning of the system after its operation in order to be able to treat the system as sufficiently pure.

- the size of this setpoint depends on various considerations and circumstances. For example, the last measured difference> 0 can be used as the desired value ⁇ F A. This would mean that, according to the method of the invention, flushing of the equipment could be stopped a few minutes earlier, saving material costs (for the cleaning composition), energy and time.

- a greater difference than ⁇ F A is set to increase the savings potential, eg, a difference between F A and that measured before the complete last run of the equipment, ie, 15, for example measured before reaching the zero difference value, or, as already mentioned, a percentage deviation of F A.

- the reliability of the inherent plant value F A it is preferably determined several times: be it several times on the same day, eg with different temperatures of the water used to prepare the cleaning composition and / or slightly varying concentrations of the cleaning composition, or on different days, in addition to the parameters mentioned also the influences of the ambient air to include.

- the value for F A is first determined for each cleaning of the system over a certain period of time.

- F A becomes an average value obtained in which several variables have been taken into account, so you can always be sure to have the plant actually sufficiently cleaned during demolition of the cleaning process by measuring a color value difference ⁇ .DELTA.F A.

- the length of this "certain period" depends on the frequency of cleaning and various other conditions. For example, in a weekly cleaning, the F A value may be determined for several months or even a whole year to obtain a representative mean.

- the self-degradation of the cleaning composition in the plant is taken into account in the assessment of plant purity, which has hitherto never been the case in the prior art.

- Fig. 2 shows a preferred embodiment of the method Fig. 1 in which, parallel to the line through the plant 2, a bypass line B is provided, through which the cleaning composition - by means of actuation of the in the drawing by reference numerals 4 and 4 'indicated three-way valves can be passed without first to pass the plant itself.

- F B a so-called basic color value

- F B according to the present invention is not measured by its own sensor before it enters the system but by the same sensor 3 downstream of the system as in the course of the actual cleaning.

- F B does not serve as a set point in the cleaning, but only for more accurate determination of the inherent plant value F A or the difference ⁇ F A based thereon.

- the base color value F B measured in this way can furthermore be compared with F A , preferably with a value for F A measured in each case on the same day, so as to obtain a more and more precise correlation between F B and F A over time, for example a can be defined calculation formula or a calibration curve derived therefrom.

- a corresponding value for F A can be estimated from a measured value for F B from the correlation obtained with high precision, without having to determine this separately. Namely a value for F A , in which daily fluctuations (see above) are already taken into account.

- Fig. 3 a variant of the method according to the invention is shown schematically, in which in contrast to the embodiment of the Fig. 1 and 2 the composition leaving the unit is not completely removed (and sometimes discarded), but is at least partially recycled and blended with fresh detergent composition.

- a three-way valve is indicated, by means of which the ratio between recycled and to be discarded cleaning composition is adjustable.

- Fig. 4 is a similar variant as in Fig. 2 shown with bypass, in addition to the arrangement of Fig. 3 in a bypass circuit B between the valves 4 and 4 ', the basic color value FB of the cleaning composition at sensor 3 can be measured and in turn correlated with the inherent plant value F A. After determining the basic color value F B , the bypass B is switched off, so that the cleaning composition as in Fig. 3 shown is performed. By means of valve 4 "is again the ratio between recycled and discarded cleaning composition adjustable.

- an additional sensor 3 ' may be provided which is similar to DE 10 2006 060 204 A1 measures another base color value F B ' before entering the system. This value can also be correlated with either F A or F B, or both, to further increase the accuracy of the calibration.

- the method of the invention works well even without such a second sensor.

- Fig. 5 shows the results of the measurements at both temperatures as well as at 535 nm wavelength, ie the change in violet coloration due to permanganate, which is a measure of the presence of manganese (VII) in the composition.

- a similar course was observed at both temperatures: after addition of the impurity, the content of manganese (VII) dropped abruptly from the inherent plant value F A applied as starting point, which in this case was at an extinction of about 0.1. but recovered quickly - due to the small dimensions of the test system after a few seconds - again and then slowly approached the initial value F A again.

- a differential value .DELTA.F drawn ie .DELTA.F RT or .DELTA.F 40 ° C , each of which corresponds to about 5% of the original extinction, ie of F A , and which can be used as setpoint .DELTA.F A for the system used here.

- the impurities remaining in hard-to-reach places would consist of components of a normal operation of the plant, which as such could not disturb the process itself (at least as long as it is not perishable food), especially since (ii) these residual impurities are generally contained only in extremely small amounts but are sufficient to initiate the self-degradation of the permanganate.

- ⁇ F A can have a positive or negative value depending on the type of color value measured.

- the decisive factor is therefore only the amount of this difference, ie the extent of Farbwerts- and thus the concentration change of the cleaning composition, but not the sign.

- the invention thus obviously provides a new process by which plants, such as e.g. Dispensing or bottling plants can be cleaned in a significantly more economical manner than in the prior art.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Wood Science & Technology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Inorganic Chemistry (AREA)

- Mechanical Engineering (AREA)

- Investigating Or Analysing Materials By The Use Of Chemical Reactions (AREA)

- Investigating Or Analysing Materials By Optical Means (AREA)

- Cleaning In General (AREA)

- Investigating Or Analyzing Non-Biological Materials By The Use Of Chemical Means (AREA)

- Detergent Compositions (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RS20180599A RS57251B1 (sr) | 2014-03-26 | 2015-03-24 | Postupak za čišćenje sistema |

| PL15726856T PL3122863T3 (pl) | 2014-03-26 | 2015-03-24 | Sposób czyszczenia urządzeń |

| HRP20180895TT HRP20180895T1 (hr) | 2014-03-26 | 2015-03-24 | Postupak za čišćenje sustava |

| SI201530271T SI3122863T1 (en) | 2014-03-26 | 2015-03-24 | Procedure for cleaning plants |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ATA217/2014A AT515571B1 (de) | 2014-03-26 | 2014-03-26 | Verfahren zum Reinigen von Anlagen |

| PCT/AT2015/050073 WO2015143468A1 (de) | 2014-03-26 | 2015-03-24 | Verfahren zum reinigen von anlagen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3122863A1 EP3122863A1 (de) | 2017-02-01 |

| EP3122863B1 true EP3122863B1 (de) | 2018-03-14 |

Family

ID=53283944

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP15726856.6A Active EP3122863B1 (de) | 2014-03-26 | 2015-03-24 | Verfahren zum reinigen von anlagen |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US10190080B2 (pl) |

| EP (1) | EP3122863B1 (pl) |

| CN (1) | CN106459848B (pl) |

| AT (1) | AT515571B1 (pl) |

| DK (1) | DK3122863T3 (pl) |

| ES (1) | ES2671477T3 (pl) |

| HR (1) | HRP20180895T1 (pl) |

| HU (1) | HUE038035T2 (pl) |

| PL (1) | PL3122863T3 (pl) |

| PT (1) | PT3122863T (pl) |

| RS (1) | RS57251B1 (pl) |

| SI (1) | SI3122863T1 (pl) |

| TR (1) | TR201807247T4 (pl) |

| WO (1) | WO2015143468A1 (pl) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102019100961A1 (de) | 2019-01-15 | 2020-07-16 | Ossberger Gmbh + Co Kg | Bewertungsverfahren für einen Reinigungszustand eines Werkstücks sowie eine Vorrichtung zur Durchführung des Verfahrens |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK180559B1 (en) * | 2020-04-14 | 2021-06-17 | Habi Tech I/S | CIP control surveillance system and application of the system |

| US11982630B2 (en) * | 2020-04-29 | 2024-05-14 | DataGarden, Inc. | Method and apparatus for cleanliness determination of areas and objects via video monitoring |

| DE102022128131A1 (de) | 2022-09-20 | 2024-03-21 | Liebherr-Hausgeräte Lienz Gmbh | Verfahren zur Reinigung eines Rohrleitungssystems eines Kühl- und/oder Ge-friergeräts |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1510452A (en) * | 1977-03-04 | 1978-05-10 | Colgate Palmolive Co | Cleaning compositions |

| JPH0210124A (ja) * | 1988-06-28 | 1990-01-12 | Nec Corp | 洗浄装置 |

| US6663902B1 (en) | 2000-09-19 | 2003-12-16 | Ecolab Inc. | Method and composition for the generation of chlorine dioxide using Iodo-Compounds, and methods of use |

| AT408987B (de) * | 2000-10-13 | 2002-04-25 | Thonhauser Gmbh Dipl Ing | Reinigungs- und desinfektionsmittel |

| AT413032B (de) * | 2003-11-11 | 2005-10-15 | Thonhauser Gmbh Dipl Ing | Reinigungs-, desinfektions- und indikatormittel |

| US20060228801A1 (en) * | 2005-03-30 | 2006-10-12 | Ben Fryer | Integator system and method for rapidly determining effectiveness of a germicidal treatment |

| DE102006060204A1 (de) * | 2006-12-18 | 2008-06-19 | Krones Ag | Verfahren zur Reinigung einer Anlage |

| CN101226157A (zh) * | 2007-01-19 | 2008-07-23 | 鸿富锦精密工业(深圳)有限公司 | 滤光片洁净度的检测设备及方法 |

| RU2505607C2 (ru) * | 2007-03-22 | 2014-01-27 | Нанолоджикс, Инк. | Способ быстрого выращивания, детекции и идентификации или подсчета микроколоний микроорганизмов ранней стадии |

| US9091010B2 (en) * | 2007-05-07 | 2015-07-28 | Whirlpool Corporation | Washer and washer control with cycles for laundry additives and color safe bleaches/in-wash stain removers |

| CN103063167B (zh) * | 2012-12-28 | 2015-11-18 | 江苏大学 | 一种自动判断激光清洗效果的方法 |

| EP2764776A1 (de) * | 2013-02-07 | 2014-08-13 | Thonhauser GmbH | Detektion von Oberflächenverschmutzung |

| CN104076027A (zh) * | 2013-03-25 | 2014-10-01 | 内蒙古伊利实业集团股份有限公司 | 一种食品生产设备清洗效果评估方法 |

-

2014

- 2014-03-26 AT ATA217/2014A patent/AT515571B1/de active

-

2015

- 2015-03-24 HU HUE15726856A patent/HUE038035T2/hu unknown

- 2015-03-24 WO PCT/AT2015/050073 patent/WO2015143468A1/de not_active Ceased

- 2015-03-24 DK DK15726856.6T patent/DK3122863T3/en active

- 2015-03-24 RS RS20180599A patent/RS57251B1/sr unknown

- 2015-03-24 PL PL15726856T patent/PL3122863T3/pl unknown

- 2015-03-24 ES ES15726856.6T patent/ES2671477T3/es active Active

- 2015-03-24 PT PT157268566T patent/PT3122863T/pt unknown

- 2015-03-24 TR TR2018/07247T patent/TR201807247T4/tr unknown

- 2015-03-24 SI SI201530271T patent/SI3122863T1/en unknown

- 2015-03-24 HR HRP20180895TT patent/HRP20180895T1/hr unknown

- 2015-03-24 EP EP15726856.6A patent/EP3122863B1/de active Active

- 2015-03-24 CN CN201580027467.8A patent/CN106459848B/zh active Active

- 2015-03-24 US US15/128,549 patent/US10190080B2/en active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102019100961A1 (de) | 2019-01-15 | 2020-07-16 | Ossberger Gmbh + Co Kg | Bewertungsverfahren für einen Reinigungszustand eines Werkstücks sowie eine Vorrichtung zur Durchführung des Verfahrens |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2015143468A1 (de) | 2015-10-01 |

| CN106459848B (zh) | 2020-04-17 |

| DK3122863T3 (en) | 2018-06-14 |

| ES2671477T3 (es) | 2018-06-06 |

| AT515571A1 (de) | 2015-10-15 |

| EP3122863A1 (de) | 2017-02-01 |

| US20170191006A1 (en) | 2017-07-06 |

| HUE038035T2 (hu) | 2018-09-28 |

| RS57251B1 (sr) | 2018-08-31 |

| SI3122863T1 (en) | 2018-07-31 |

| TR201807247T4 (tr) | 2018-06-21 |

| AT515571B1 (de) | 2018-01-15 |

| CN106459848A (zh) | 2017-02-22 |

| PT3122863T (pt) | 2018-05-29 |

| HRP20180895T1 (hr) | 2018-07-13 |

| US10190080B2 (en) | 2019-01-29 |

| PL3122863T3 (pl) | 2018-08-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3122863B1 (de) | Verfahren zum reinigen von anlagen | |

| EP1947168B1 (de) | Verfahren zur Reinigung einer Anlage | |

| DE4342787C1 (de) | Verfahren zur quantitativen Bestimmung elektrochemisch reduzierbarer oder oxidierbarer Stoffe, insbesondere von Peroxiessigsäure im Gemisch mit anderen oxidierenden Stoffen | |

| EP1068525B1 (de) | Automatische kontrolle und steuerung des tensidgehalts in wässrigen prozesslösungen | |

| EP2533036B1 (de) | Verfahren zum Betrieb eines Leitfähigkeitssensors, insbesondere zur Reinigung der Elektrodenoberflächen des Leitfähigkeitssensors, und Wasserenthärter enthaltend einen solchen Leitfähigkeitssensor | |

| DE102013104203B4 (de) | Verfahren und Vorrichtung zur Bestimmung einer Restbetriebsdauer eines Messaufnehmers | |

| EP2947426B1 (de) | Verfahren zum betreiben einer messstelle | |

| EP3321668A2 (de) | Verfahren und vorrichtung zur beurteilung der qualität eines längsbewegten strangförmigen gutes | |

| EP2350758B1 (de) | Verfahren zur überwachung einer potentiometrischen messsonde | |

| WO2000009780A1 (de) | Automatische kontrolle und steuerung von reinigerbädern | |

| EP2605007B2 (de) | Verfahren zum Reinigen von Elektrodenoberflächen | |

| WO2008068196A1 (de) | Verfahren zur überwachung der konzentration eines wasserinhaltsstoffes in einem wässrigen medium | |

| EP1144996B1 (de) | Automatische bestimmung der belastung von wässrigen reinigungslösungen mit kohlenstoffhaltigen verbindungen | |

| DE102015016742A1 (de) | Verfahren zur Überprüfung der Reagierfähigkeit unter Berücksichtigung des Neuzustandes (Basiseigenschaften) eines elektronischen Sensors sowie Vorrichtung zur Durchführung des Verfahrens mit der Bezeichnung Basiskurven-Vergleichsverfahren | |

| EP3359490B1 (de) | Online analytik mittels nahinfrarotspektroskopie-analytik nir zur herstellung von polyaluminiumchloridhydroxid | |

| EP3588074A2 (de) | Verfahren zur reinigung, konditionierung, kalibration und/oder justage eines amperometrischen sensors | |

| DE102022130510A1 (de) | Überwachungsverfahren zur Qualitätsüberwachung von Messspektren | |

| EP3556447A1 (de) | Prozessmonitoring einer filtration durch filtratmessungen | |

| DE3841367A1 (de) | Prozessleitverfahren fuer eine kontinuierliche walzstrasse | |

| DE102018133232A1 (de) | Verfahren zur Überwachung eines Prozesses | |

| DE102010010715B4 (de) | Wirtschaftliche Kesselanalytik | |

| DE102019120442A1 (de) | Verfahren zur Kalibration eines Analysenmessgerätes sowie Messstelle zur Analyse eines Prozessmediums und zur Kalibration eines Analysenmessgerätes | |

| DE202011102629U1 (de) | Leitfähigkeitssensorstation mit Reinigungsfunktion für die Elektrodenoberflächen des Leitfähigkeitssensors | |

| EP3875950A1 (de) | Bestimmung von chlorat mit einer elektrode sowie verfahren und vorrichtung zur kalibrierung der elektrode | |

| DE102019120415A1 (de) | Verfahren zur Bestimmung einer chemischen Aufnahmekapazität eines Prozessmediums in einer Messstelle sowie Messstelle zur Bestimmung einer chemischen Aufnahmekapazität eines Prozessmediums |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20160927 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20171013 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 978875 Country of ref document: AT Kind code of ref document: T Effective date: 20180315 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502015003448 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Ref document number: 3122863 Country of ref document: PT Date of ref document: 20180529 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20180522 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 4 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: GACHNANG AG PATENTANWAELTE, CH |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2671477 Country of ref document: ES Kind code of ref document: T3 Effective date: 20180606 Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: TUEP Ref document number: P20180895 Country of ref document: HR |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 Effective date: 20180607 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: T1PR Ref document number: P20180895 Country of ref document: HR |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: NO Ref legal event code: T2 Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180615 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E038035 Country of ref document: HU |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T3 Ref document number: E 27534 Country of ref document: SK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502015003448 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180324 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180314 |

|

| 26N | No opposition filed |

Effective date: 20181217 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20190227 Year of fee payment: 5 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20200316 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180714 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20210120 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 978875 Country of ref document: AT Kind code of ref document: T Effective date: 20200324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200324 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20220214 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20230323 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NO Payment date: 20230327 Year of fee payment: 9 Ref country code: IE Payment date: 20230320 Year of fee payment: 9 Ref country code: FI Payment date: 20230324 Year of fee payment: 9 Ref country code: DK Payment date: 20230323 Year of fee payment: 9 Ref country code: BG Payment date: 20230327 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20230324 Year of fee payment: 9 Ref country code: SE Payment date: 20230331 Year of fee payment: 9 Ref country code: PT Payment date: 20230322 Year of fee payment: 9 Ref country code: PL Payment date: 20230323 Year of fee payment: 9 Ref country code: DE Payment date: 20220617 Year of fee payment: 9 Ref country code: BE Payment date: 20230330 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20230328 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20240322 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PK Free format text: BERICHTIGUNGEN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502015003448 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240924 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20240331 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240924 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 Ref country code: BG Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20240401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240401 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20240331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241001 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240331 |

|

| REG | Reference to a national code |

Ref country code: HR Ref legal event code: ODRP Ref document number: P20180895 Country of ref document: HR Payment date: 20250306 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HR Payment date: 20250306 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240331 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RO Payment date: 20250311 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20250320 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SI Payment date: 20250306 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240324 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250325 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20250306 Year of fee payment: 11 Ref country code: GB Payment date: 20250324 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: RS Payment date: 20250310 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20250401 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250331 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250401 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240325 |