EP2986527B1 - Récipient, notamment à usage alimentaire - Google Patents

Récipient, notamment à usage alimentaire Download PDFInfo

- Publication number

- EP2986527B1 EP2986527B1 EP14721981.0A EP14721981A EP2986527B1 EP 2986527 B1 EP2986527 B1 EP 2986527B1 EP 14721981 A EP14721981 A EP 14721981A EP 2986527 B1 EP2986527 B1 EP 2986527B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- container body

- container

- apertured

- maneuvering member

- sleeve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 235000013305 food Nutrition 0.000 title claims description 5

- 238000000576 coating method Methods 0.000 claims description 22

- 239000011248 coating agent Substances 0.000 claims description 15

- 239000000463 material Substances 0.000 claims description 11

- 229920000642 polymer Polymers 0.000 claims description 4

- 230000002441 reversible effect Effects 0.000 claims description 2

- 230000002093 peripheral effect Effects 0.000 description 7

- 238000010411 cooking Methods 0.000 description 4

- 210000000056 organ Anatomy 0.000 description 4

- 208000031968 Cadaver Diseases 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 3

- 230000006866 deterioration Effects 0.000 description 2

- 208000035193 Ring chromosome 10 syndrome Diseases 0.000 description 1

- 208000032822 Ring chromosome 11 syndrome Diseases 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 235000015504 ready meals Nutrition 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D43/00—Lids or covers for rigid or semi-rigid containers

- B65D43/14—Non-removable lids or covers

- B65D43/18—Non-removable lids or covers pivoted for movement in plane of container mouth

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D43/00—Lids or covers for rigid or semi-rigid containers

- B65D43/14—Non-removable lids or covers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D25/00—Details of other kinds or types of rigid or semi-rigid containers

- B65D25/14—Linings or internal coatings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

Definitions

- the present invention relates to a container, particularly for food use.

- a container comprising a container body, an operating ring and a flexible sleeve for closing / releasing the opening of the container body, this sleeve being connected to the container body, on the one hand, and to the maneuver ring, on the other hand.

- the operating ring is adapted to be pivoted with respect to the container body so as to twist / unscrew the sleeve, between a twisting state, in which this sleeve closes the opening of the container body, and a non-twisting state, in which he releases this opening.

- Such containers have always been made in cylindrical shapes with circular cross-sections and with mounting of the operating ring on the container body.

- Such a shape is indeed easy to handle by the user, and the operating ring, immobilized in a given angular position by means provided for this purpose, can be placed in a large number of angular positions relative to the container body and thus ensure various degrees of partial opening of the container.

- this circular shape allows uniform deformation of the sleeve on the periphery of the container body and the ring, and thus allows to control the movement of the ring relative to the container body.

- the document EP 2050679 describes such a container, according to the preamble of claim 1.

- this circular form has the disadvantage of limiting the possible capacity of the container and not being very suitable for containing food products other than liquids or the like. In particular, this form is hardly suitable for containing cooked dishes.

- the present invention aims to overcome this disadvantage while providing a container adapted to be perfectly closed by the twisting of the sleeve.

- the invention also aims to provide a container allowing wide access to the product contained by this container.

- Another object of the invention is to provide a container which maintains the closed state reliably.

- the invention also aims to provide a container that can be quickly and easily adapted for cooking for example in a microwave oven.

- This part makes it possible to generate friction between the container body and said openwork actuating member so as to ensure the engagement of this body on said wall. The risk of untimely escape of the openwork member relative to the container body is thus greatly reduced.

- square or rectangular general shape means that it is possible on said body and said actuator, to distinguish sides and angles. This notion of a square general form or Rectangular must however be interpreted very broadly, including sides that may not be rectilinear, but particularly curved, and not necessarily very marked corners, but rounded.

- axially movable is meant that said operating member can be moved freely with respect to the container body, along the axis according to which said perforated member is able to pivot relative to the body container for twisting or unscrewing the sleeve.

- this or these parts are preferably each in the form of a coating fixed on said wall of the container body or on said openwork member.

- This coating is preferably overmoulded on this wall or this openwork member actuating.

- both said wall of the container body and said openwork member comprise a coating as mentioned above

- the two coatings may comprise surfaces shaped to interpenetrate with each other.

- these coatings may each have alternating ribs and grooves, and the ribs and grooves of a coating are offset from the ribs and grooves of the other coating, so that the respective ribs and grooves of these coatings come into interpenetration with each other when said perforated operating member is in the engagement position on the container body.

- said wall of the container body and / or the openwork actuating member form snap-fastening means allowing a reversible snap of this openwork actuating member in the engagement position on this wall of the container body.

- This latching helps to ensure the conservation of the closed state notwithstanding the non-uniform deformation of the sleeve due to the shape of the container in cross section.

- the openwork member in the state of non-twisting of the sleeve, is arranged so that its diagonals are offset relative to the diagonals of the container body, so that the race of pivoting necessary to effect a twisting of the sleeve is greater than 180 ° and less than 270 °.

- the inventor has been able to determine that it was possible to apply the aforementioned closure principle to a container of generally square or rectangular shape, provided, however, to provide a perforated actuating member movable axially relative to the container body, thus engageable / disengageable with respect to the latter, and a pivoting stroke greater than 180 ° and less than 270 °.

- the passage from a circular shape to a square or rectangular shape certainly has the favorable result of allowing the angular setting of said openwork member on the container body, but also has the disadvantage of greatly reducing the number of positions. possible angles of this organ on this body, distant 90 ° in the case of a square box and 180 ° in the case of a rectangular box.

- the aforementioned reference to the diagonals of the openwork member and the diagonals of the container body is used to cover the fact that the body and said member may be of square or rectangular shapes; in the case of a rectangular body and organ, it would be possible to simply refer to the length of this body and this organ: the length of the organ is offset with respect to the length of the body, so that these lengths form between them an angle such that the aforementioned pivoting stroke is made possible.

- the container according to the invention can be either sealed, without risk of deterioration of the sleeve, when said openwork member is pivoted in the direction that causes it to run over more than 180 °, be left partially open for example for cooking in a microwave oven, when said openwork member is rotated in the direction that causes it to operate a race on less than 180 °.

- the aforementioned offset of the diagonals of the openwork member is such that each diagonal of the openwork member forms an angle of the order of 20 ° with the corresponding diagonal of the container body.

- the twisting / unscrewing of the sleeve is thus of the order of 200 ° in a pivoting direction and of the order of 160 ° in the opposite pivoting direction.

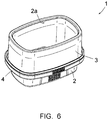

- the container body 2 comprises a bottom and a peripheral wall delimiting the opening 2a, and has a generally rectangular cross-sectional shape, giving the container 1 the appearance of a box.

- This notion of rectangular general shape is to be interpreted very broadly, as being the fact that it is possible, on the body 2, to distinguish sides and angles; as visible on the figure 2 , the sides of the body 2 are not rectilinear but curved, and the angles are not very marked and are rounded.

- the peripheral wall of the body 2 comprises a peripheral coating 5 on its outer face, below its free edge delimiting the opening 2a.

- This coating 5 is made of a material with a high coefficient of friction, such as a polymer, overmolded on the body 2. It has an irregular surface appearance, and in particular, as in the example shown, has alternating ribs and grooves .

- the two main lateral faces of the body 2 also comprise, molded on them, gripping areas 6 on which are also overmolded ribs of a material with a high coefficient of friction.

- the sleeve 3 is made of a material with a high coefficient of stretching, in particular latex. It is intimately connected to the free edge of the body 2, on the one hand, and to said openwork member 4, on the other hand, that is to say with a sealed connection to the entire periphery of this free edge and of this body. 4. As visible on the figure 4 , this sealed connection is made by the arrangement of a peripheral groove in said free edge, receiving in force a peripheral ring 10 of imprisoning the corresponding edge of the sleeve 3 (the latter is not shown in this figure for reasons of clarity), and by the arrangement of a peripheral groove in the perforated member 4, receiving in force a peripheral ring 11 for enclosing the corresponding edge of the sleeve 3.

- connection can also be achieved by other means, for example by overmolding the sleeve on the body 2 and the member 4.

- the side wall of the body 2 and the opening delimited by the member 4 are mutually shaped so that this side wall fits into this opening, and this side wall is free of roughness or other likely obstacle, while the sleeve 3 is not twisted, to prevent a displacement of the member 4 along this wall to a position remote from the opening 2a formed by the body 2.

- the member 4 comprises a coating 12 overmolded on its inner face, also in a material with a high coefficient of friction, such as a polymer.

- This coating also has alternating ribs and grooves, offset from the ribs and grooves of the coating 5 so that the respective ribs and grooves of these coatings 5 and 12 interpenetrate in the engagement position of the member 4 on the body 2.

- the member 4 is adapted to be pivoted in the clockwise direction, that is to say on a stroke of 200 ° with respect to this position, until it is engaged on the edge of the body 2.

- this position of commitment represented on the figure 3

- the sleeve 3 is completely twisted and the container 1 is thus sealed, without the twisting of the sleeve 3 is excessive, and therefore without risk of deterioration of this sleeve 3.

- the member 4 is able to be pivoted in the counterclockwise direction, that is to say on a stroke of 160 ° with respect to this position, to be also engaged on the edge of the body 2.

- this engagement position shown on the figure 5 , the sleeve 3 is not completely twisted, leaving a central opening 20 allowing for example a cooking in a microwave oven.

- the invention has been described above with reference to an exemplary embodiment. It goes without saying that it is not limited to this embodiment but that it extends to all the embodiments covered by the appended claims.

- the aforementioned reference to the diagonals of the member 4 and the diagonals of the body 2 is intended to cover the possibility of a body 2 and a member 4 of square shape; in the case of a body 2 and a more or less rectangular body 4, as shown, it is possible to simply refer to the length of this body 2 and to the length of this body 4: the length of the body member 4 forms an angle of the order of 20 ° with respect to the length of the body 2.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Details Of Rigid Or Semi-Rigid Containers (AREA)

- Packages (AREA)

- Cookers (AREA)

- Packging For Living Organisms, Food Or Medicinal Products That Are Sensitive To Environmental Conditiond (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1353419A FR3004426B1 (fr) | 2013-04-16 | 2013-04-16 | Recipient, notamment a usage alimentaire |

| PCT/IB2014/060620 WO2014170805A1 (fr) | 2013-04-16 | 2014-04-10 | Récipient, notamment à usage alimentaire |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2986527A1 EP2986527A1 (fr) | 2016-02-24 |

| EP2986527B1 true EP2986527B1 (fr) | 2017-06-21 |

Family

ID=48656152

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14721981.0A Not-in-force EP2986527B1 (fr) | 2013-04-16 | 2014-04-10 | Récipient, notamment à usage alimentaire |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US9745108B2 (enExample) |

| EP (1) | EP2986527B1 (enExample) |

| JP (1) | JP2016523772A (enExample) |

| KR (1) | KR20150143509A (enExample) |

| CN (1) | CN105473461B (enExample) |

| AU (1) | AU2014255400B2 (enExample) |

| CA (1) | CA2909398A1 (enExample) |

| FR (1) | FR3004426B1 (enExample) |

| WO (1) | WO2014170805A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3069529A1 (fr) * | 2017-07-31 | 2019-02-01 | Neolid | Recipient, notamment a usage alimentaire |

| TWI862180B (zh) * | 2023-09-20 | 2024-11-11 | 本物股份有限公司 | 可感受飲品不同風味之杯子 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4214957Y1 (enExample) * | 1966-01-29 | 1967-08-25 | ||

| IT7922714U1 (it) * | 1979-09-28 | 1981-03-28 | Artsana Spa | Astuccio contenitore particolarmente per termometri. |

| US4733794A (en) * | 1983-06-23 | 1988-03-29 | Johnson & Johnson Products, Inc. | Hinged plastic container |

| ATA197486A (de) * | 1986-07-22 | 2001-05-15 | Teich Ag | Packung mit stückigem verpackungsgut sowie verfahren zum herstellen solcher packungen |

| US5148912A (en) * | 1991-02-27 | 1992-09-22 | Yoshino Kogyosho Co., Ltd. | Cap closing member for container opening |

| US5165593A (en) * | 1992-02-21 | 1992-11-24 | Emily Chuang | Packing box with a unitary, resealable cap |

| JPH05305992A (ja) * | 1992-04-20 | 1993-11-19 | Kuraray Co Ltd | フレキシブルバッグ及びその布筒口の閉塞方法 |

| JP3751194B2 (ja) * | 2000-02-01 | 2006-03-01 | 三洋エンジニアリング株式会社 | 電子レンジ対応の包装容器 |

| US20030124316A1 (en) * | 2001-09-20 | 2003-07-03 | Huang Yan C. | Repulpable, water repellant paperboard |

| US20050082248A1 (en) * | 2003-10-21 | 2005-04-21 | Omar Al-Jadda | Elastic membrane container closure |

| KR100715622B1 (ko) * | 2005-10-20 | 2007-05-09 | 양영근 | 오이절임 용기 |

| MX2010003910A (es) * | 2007-10-09 | 2010-08-02 | Folgers Coffee Co | Indicador visual de vacio. |

| FR2922195A1 (fr) * | 2007-10-16 | 2009-04-17 | Nocolas Frolin | Moyens d'ouverture/fermeture d'un conduit delimite par deux pieces. |

| CN201329991Y (zh) * | 2008-12-05 | 2009-10-21 | 顾新君 | 一种便于运输及存放的工具箱 |

-

2013

- 2013-04-16 FR FR1353419A patent/FR3004426B1/fr not_active Expired - Fee Related

-

2014

- 2014-04-10 JP JP2016508261A patent/JP2016523772A/ja not_active Ceased

- 2014-04-10 CA CA2909398A patent/CA2909398A1/fr not_active Abandoned

- 2014-04-10 EP EP14721981.0A patent/EP2986527B1/fr not_active Not-in-force

- 2014-04-10 AU AU2014255400A patent/AU2014255400B2/en not_active Ceased

- 2014-04-10 US US14/782,648 patent/US9745108B2/en not_active Expired - Fee Related

- 2014-04-10 KR KR1020157029921A patent/KR20150143509A/ko not_active Withdrawn

- 2014-04-10 CN CN201480021046.XA patent/CN105473461B/zh not_active Expired - Fee Related

- 2014-04-10 WO PCT/IB2014/060620 patent/WO2014170805A1/fr not_active Ceased

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20150143509A (ko) | 2015-12-23 |

| WO2014170805A1 (fr) | 2014-10-23 |

| FR3004426B1 (fr) | 2015-05-15 |

| CN105473461A (zh) | 2016-04-06 |

| CA2909398A1 (fr) | 2014-10-23 |

| JP2016523772A (ja) | 2016-08-12 |

| CN105473461B (zh) | 2017-10-13 |

| AU2014255400B2 (en) | 2017-09-14 |

| US9745108B2 (en) | 2017-08-29 |

| FR3004426A1 (fr) | 2014-10-17 |

| AU2014255400A1 (en) | 2015-10-29 |

| EP2986527A1 (fr) | 2016-02-24 |

| US20160090219A1 (en) | 2016-03-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2704961B1 (fr) | Bouchon pour un col de récipient | |

| EP3200645B1 (fr) | Pot de cosmétique comportant un couvercle à élément d'accrochage basculant | |

| EP3456226B1 (fr) | Ensemble de préparation et/ou de cuisson d'aliments pour robot ménager de cuisine | |

| EP3256021B1 (fr) | Pot de cosmétique comportant un couvercle à élément d'accrochage guidé | |

| EP3160291B1 (fr) | Pot de cosmétique comportant un couvercle à élément d'accrochage translaté | |

| FR2866819A1 (fr) | Distributeur-applicateur typiquement a tete massante | |

| FR2750022A1 (fr) | Distributeur de produit a organe de manoeuvre rotatif et procede de fabrication | |

| EP3435812B1 (fr) | Boîte a usage alimentaire | |

| EP1512637A1 (fr) | Couvercle de fermeture de pots alimentaires | |

| CA3072412A1 (fr) | Dispositif de conditionnement d'objet, ensemble et procede d'extraction correspondant | |

| FR2953107A1 (fr) | Dispositif d'application d'un fluide | |

| EP3634173B1 (fr) | Pot pour produit cosmétique | |

| EP2986527B1 (fr) | Récipient, notamment à usage alimentaire | |

| EP4106576A1 (fr) | Pot pour produit cosmétique ayant un col non cylindrique | |

| CA2041711C (fr) | Dispositif d'actionnement d'une valve de distribution | |

| EP1722453B1 (fr) | Boîte d'encastrement | |

| EP2178415A2 (fr) | Dispositif de produit cosmetique comprenant un reservoir et un applicateur | |

| FR3004425A1 (fr) | Recipient, notamment a usage alimentaire | |

| BE1010977A4 (fr) | Dispositif releveur de produits, notamment de condiments, disposes dans un recipient. | |

| FR3056280A1 (fr) | Embout pour gaine tubulaire de matiere plastique souple | |

| FR2710902A1 (fr) | Récipient perfectionné pour contenir un produit. | |

| EP4595808A1 (fr) | Pot destiné à recevoir une cartouche amovible de produit cosmétique | |

| FR3032692A1 (fr) | Dispositif de fermeture d'un recipient a moyens de securite empechant une ouverture non desiree. | |

| WO2010046567A1 (fr) | Bouchon muni d'un dispositif anti-rotation d'un anneau de garantie | |

| EP4029416A1 (fr) | Infuseur amovible à thé ou autre plante pour infusion apte et destiné à équiper un récipient infuseur et récipient infuseur équipé d'un infuseur |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20151012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20161103 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| INTC | Intention to grant announced (deleted) | ||

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20170418 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 902711 Country of ref document: AT Kind code of ref document: T Effective date: 20170715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602014010986 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: MEYER AND KOLLEGEN, CH |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170922 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170921 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 902711 Country of ref document: AT Kind code of ref document: T Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170921 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20171021 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602014010986 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 5 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| 26N | No opposition filed |

Effective date: 20180322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180522 Year of fee payment: 5 Ref country code: CH Payment date: 20180523 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180427 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20180518 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180430 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180410 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602014010986 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191101 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190410 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170621 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140410 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170621 |