EP2934234B1 - Monofil aus kunststoff und zahnbürsten-borste aus einem entsprechenden monofil - Google Patents

Monofil aus kunststoff und zahnbürsten-borste aus einem entsprechenden monofil Download PDFInfo

- Publication number

- EP2934234B1 EP2934234B1 EP14724307.5A EP14724307A EP2934234B1 EP 2934234 B1 EP2934234 B1 EP 2934234B1 EP 14724307 A EP14724307 A EP 14724307A EP 2934234 B1 EP2934234 B1 EP 2934234B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- monofilament

- matrix

- accordance

- area

- rib

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/023—Bristles with at least a core and at least a partial sheath

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0238—Bristles with non-round cross-section

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0253—Bristles having a shape which is not a straight line, e.g. curved, "S", hook, loop

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0269—Monofilament bristles

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/253—Formation of filaments, threads, or the like with a non-circular cross section; Spinnerette packs therefor

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/28—Formation of filaments, threads, or the like while mixing different spinning solutions or melts during the spinning operation; Spinnerette packs therefor

- D01D5/30—Conjugate filaments; Spinnerette packs therefor

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/14—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyester as constituent

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/10—For human or animal care

- A46B2200/1066—Toothbrush for cleaning the teeth or dentures

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

- Y10T428/2922—Nonlinear [e.g., crimped, coiled, etc.]

- Y10T428/2924—Composite

Definitions

- the invention relates to a plastic monofilament and a toothbrush bristle made from a corresponding monofilament.

- the cleaning effect of a brush depends essentially on the geometry of the individual bristles and the material of which the bristles are made. In particular, it has proved to be advantageous to structure or profile the bristles on their lateral surface so that the bristles have a scraping action.

- bristles which have a plurality of axially parallel ribs, which are integrally formed at their radially inner end on a core forming the matrix.

- the core and the rib may be made of different plastics, on the one hand to adapt the strength and bending property of the bristle and on the other hand, the cleaning effect by the rib to the desired application.

- the bristle is used on a toothbrush, the choice of materials should ensure that the user can not be injured.

- a monofilament according to the preamble of claim 1 is known from US 2008 0221618 known.

- the invention has for its object to provide a monofilament for producing a bristle or a toothbrush bristle made therefrom, in which for the material of the rib and the matrix improved selection and combination options are given.

- the monofilament has a matrix which, at least in a first region, consists of a first plastic material and has at least one rib extending in the longitudinal direction of the monofilament, which consists of a second plastic material and which is in the first region of the matrix is held positively.

- the materials and the parameters in the extrusion of the monofilament are chosen so that the rib is also welded to the first region of the matrix in addition to the positive connection. Alternatively or additionally, however, it may also be provided that the rib is adhesively bonded to the first region of the matrix in addition to the positive connection.

- the rib has a radially outwardly tapering cross-section, for example a triangular or drop-shaped cross-section, so that it tapers in its radially outer cross-sectional area.

- the rib In order to ensure a good positive connection between the rib and the first region of the matrix, the rib should be provided with undercuts at its radially inner end region embedded in the first area of the matrix. It is preferably provided that in the radially inner end region of the rib, a widespread foot is formed, which is encompassed by the first plastic material of the first region of the matrix.

- the monofilament has a plurality of ribs, which should preferably be distributed equally over the circumference of the monofilament.

- the ribs run in the form of a Wendel around the matrix. This can be achieved in particular if the monofilament is twisted after the extrusion in a manner known per se. According to the twisting takes place with 50 to 400 revolutions per meter.

- the 1st area forms the entire matrix, i. the matrix consists exclusively of the first plastic material, in which the rib or the ribs are held in a form-fitting manner.

- the first area of the matrix has an annular cross-section and surrounds at least one inner, second area of the matrix, which consists of a third plastic material. In this way, the performance characteristics of the monofilament or bristle made therefrom can be better adapted to the desired application.

- the ribs are connected to one another by means of the inner, second region of the matrix.

- the plastic materials can be chosen largely freely due to the positive connection.

- the first plastic material of the first area of the matrix is a rigid thermoplastic polyester and in particular PBT (polybutylene terephthalate).

- the second synthetic material of the rib according to the invention is a soft thermoplastic material and in particular a thermoplastic elastomer.

- the 3rd plastic material of the inner 2nd area of the matrix can also be freely selected within wide limits. If the ribs are connected together at their radially inner ends by means of the second region of the matrix, it is preferably provided that the third plastic material of the second region of the matrix is equal to the second plastic material of the ribs.

- At least one rib is colored at least in sections and thereby stands out in terms of color from the rest of the monofilament. In this way, it is possible to visualize to the user that the monofilament is twisted, thereby avoiding confusion when using the monofilament.

- bristles can be produced in the usual way, which are preferably used as toothbrush bristles.

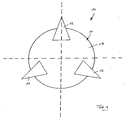

- FIG. 1 shows a cross section through a monofilament 10 made of plastic, which has a consisting of a 1st area 13 matrix 11 with a circular cross section, which consists entirely of a first plastic material, such as a rigid thermoplastic polyester.

- the monofilament 10 has three in the longitudinal direction, ie perpendicular to the plane extending radially outwardly from the matrix 11 protruding ribs 12.

- Each rib 12 has a triangular, radially outwardly tapering cross-section and is with its radially inner, wide end portion in a form-fitting manner held in the matrix 11. Due to the positive connection, the material of the ribs 12 can be chosen freely, ie it is not dependent on the type of the first plastic material of the matrix 11.

- the second plastic material of the ribs 12 is a soft thermoplastic material.

- the ribs 12 may be held in the matrix 11 by means of gluing or welding in addition to the positive locking.

- FIG. 2 shows a FIG. 1 similar embodiment and differs from this only in that in the radially inner end portion of the ribs 12 each have a common foot 15 is provided which substantially improves the holding forces to be achieved via the positive locking.

- FIG. 3 shows a further embodiment of the monofilament 10 according to the invention.

- the matrix 11 has a first region 13 of a first plastic material which has an annular cross-section. Within the first annular region 13, a second region 14 of the matrix is arranged, which consists of a third plastic material.

- the ribs 12 are held in a form-fitting manner in the annular first region 13 of the matrix 11 and lie with their radially inner ends on the inner second region 14 of the matrix 11 at.

- the ribs 12 are connected to the inner second region 14 of the matrix 11 by gluing or welding.

- FIG. 4 shows an embodiment according to FIG. 3 corresponding embodiment, which only differs therefrom in that the ribs 12 and the inner second region 14 of the matrix consist of a uniform material and are formed as a monolithic body.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Brushes (AREA)

- Multicomponent Fibers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013007870.9A DE102013007870A1 (de) | 2013-05-08 | 2013-05-08 | Monofil aus Kunststoff und Zahnbürsten-Borste aus einem entsprechenden Monofil |

| PCT/EP2014/001200 WO2014180560A1 (de) | 2013-05-08 | 2014-05-06 | Monofil aus kunststoff und zahnbürsten-borste aus einem entsprechenden monofil |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2934234A1 EP2934234A1 (de) | 2015-10-28 |

| EP2934234B1 true EP2934234B1 (de) | 2016-06-15 |

Family

ID=50732092

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14724307.5A Active EP2934234B1 (de) | 2013-05-08 | 2014-05-06 | Monofil aus kunststoff und zahnbürsten-borste aus einem entsprechenden monofil |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20150354098A1 (enExample) |

| EP (1) | EP2934234B1 (enExample) |

| JP (1) | JP2016524481A (enExample) |

| KR (1) | KR20160006661A (enExample) |

| CN (1) | CN105188475B (enExample) |

| DE (1) | DE102013007870A1 (enExample) |

| WO (1) | WO2014180560A1 (enExample) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015205265A1 (de) * | 2015-03-24 | 2016-09-29 | Pedex Gmbh | Filament aus Kunststoff |

| US10136723B2 (en) * | 2015-12-14 | 2018-11-27 | Colgate-Palmolive Company | Oral care implement |

| CN107041622A (zh) * | 2017-05-23 | 2017-08-15 | 湖北瑞特威日化有限公司 | 一种塑料牙刷毛及其制造方法 |

| DE102018000663A1 (de) * | 2018-01-29 | 2019-08-01 | Pedex Gmbh | Filament und Zahnbürste mit zumindest einem entsprechenden Filament |

| KR102197602B1 (ko) | 2019-09-04 | 2020-12-31 | 주식회사 케이앤케이 | 이형 단면을 갖는 필라멘트 제조용 방사구금 및 이에 의해 제조된 필라멘트 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2317485A (en) * | 1940-04-27 | 1943-04-27 | Pepsodent Co | Brush |

| US3209402A (en) * | 1962-03-07 | 1965-10-05 | Celanese Corp | Apparatus for producing multicom-ponent filaments and yarns |

| US4457973B1 (en) * | 1980-06-06 | 1995-05-09 | Kanebo Synthetic Fibert Ltd | Conductive composite filaments and methods for producing said composite filaments |

| JPS62170509A (ja) * | 1986-01-20 | 1987-07-27 | Teijin Ltd | 伸縮性合成繊維糸条およびその製造方法 |

| DE19533815A1 (de) * | 1995-09-13 | 1997-03-20 | Coronet Werke Gmbh | Zahnbürste und Verfahren zu ihrer Herstellung |

| DE19533816A1 (de) | 1995-09-13 | 1997-03-20 | Coronet Werke Gmbh | Verfahren zur Herstellung spiraliger Borsten |

| US5707735A (en) * | 1996-03-18 | 1998-01-13 | Midkiff; David Grant | Multilobal conjugate fibers and fabrics |

| AU3868397A (en) * | 1996-08-27 | 1998-03-19 | Chisso Corporation | A non-woven fabric and an absorbent article using thereof |

| US5879801A (en) * | 1997-01-10 | 1999-03-09 | Basf Corporation | Multiple domain fibers having inter-domain boundary compatibilizing layer and methods and apparatus for making the same |

| DE19932368A1 (de) * | 1999-07-13 | 2001-02-08 | Pedex & Co Gmbh | Verfahren zur Herstellung von mehrschichtigem Borstenmaterial, mehrschichtige Borste und deren Verwendung |

| KR100760797B1 (ko) * | 2000-09-29 | 2007-10-04 | 이 아이 듀폰 디 네모아 앤드 캄파니 | 신축성 중합체 섬유, 이 섬유의 제조에 유용한 방사구금,및 이로부터 제조한 용품 |

| JP4816037B2 (ja) * | 2005-12-02 | 2011-11-16 | サンスター株式会社 | 歯ブラシ |

| JP4992285B2 (ja) * | 2006-04-21 | 2012-08-08 | サンスター株式会社 | 歯ブラシ |

| US20080221618A1 (en) * | 2007-03-09 | 2008-09-11 | Gaoyuan Chen | Co-extruded tissue grasping monofilament |

| JP5338233B2 (ja) * | 2008-09-30 | 2013-11-13 | サンスター株式会社 | 歯ブラシ用フィラメント及びこれを植設した歯ブラシ |

| JP5387352B2 (ja) * | 2009-11-13 | 2014-01-15 | 東レ・モノフィラメント株式会社 | 歯ブラシ用モノフィラメント |

| MY194080A (en) * | 2012-09-25 | 2022-11-11 | Lion Corp | Tapered bristles, method for manufacturing same, and toothbrush provided with tapered bristles |

-

2013

- 2013-05-08 DE DE102013007870.9A patent/DE102013007870A1/de not_active Withdrawn

-

2014

- 2014-05-06 EP EP14724307.5A patent/EP2934234B1/de active Active

- 2014-05-06 US US14/763,232 patent/US20150354098A1/en not_active Abandoned

- 2014-05-06 CN CN201480025042.9A patent/CN105188475B/zh active Active

- 2014-05-06 WO PCT/EP2014/001200 patent/WO2014180560A1/de not_active Ceased

- 2014-05-06 KR KR1020157021099A patent/KR20160006661A/ko not_active Ceased

- 2014-05-06 JP JP2016512244A patent/JP2016524481A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| WO2014180560A1 (de) | 2014-11-13 |

| US20150354098A1 (en) | 2015-12-10 |

| JP2016524481A (ja) | 2016-08-18 |

| CN105188475B (zh) | 2017-07-04 |

| EP2934234A1 (de) | 2015-10-28 |

| CN105188475A (zh) | 2015-12-23 |

| KR20160006661A (ko) | 2016-01-19 |

| DE102013007870A1 (de) | 2014-11-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2934234B1 (de) | Monofil aus kunststoff und zahnbürsten-borste aus einem entsprechenden monofil | |

| DE102008027279B4 (de) | Filterelement und Verfahren zur Herstellung eines Filterelements | |

| EP1593321B1 (de) | Bürstenkopf | |

| EP2268168B1 (de) | Bürste, insbesondere für haushalt oder industrielle anwendungen | |

| EP1992251B1 (de) | Kosmetikbürstchen mit vielen Borsten zum Auftragen eines Kosmetikums | |

| DE102015215832B4 (de) | Haarstylingutensil | |

| WO1997009907A1 (de) | Zahnbürste und verfahren zu ihrer herstellung | |

| EP2862478B1 (de) | Zahnbürste und Verfahren zur Herstellung | |

| WO2014023395A1 (de) | Interdental-reiniger | |

| EP3709929B1 (de) | Interdentalreiniger | |

| DE102008007105A1 (de) | Schraubrad mit Dämpfung | |

| DE102010015836A1 (de) | Abstandhalter | |

| EP4146969A1 (de) | Brauseschlauch, baureihe von brauseschläuchen, verwendung einer umflechtung und verfahren zur herstellung eines brauseschlauchs | |

| EP1030937A1 (de) | Monofil für und zur herstellung von borsten oder interdentalreiniger, sowie borstenware mit solchen borsten und interdentalreiniger | |

| EP1983104B1 (de) | Kunstrasen | |

| DE102011114916B4 (de) | Radialbürste | |

| DE102016123422A1 (de) | Hohlwelle aus einem Faserverbundwerkstoff und Wickelwelle für die Herstellung einer derartigen Hohlwelle | |

| EP1381719A1 (de) | Thermoplastisches monofilament für borsten | |

| DE102005055771B4 (de) | Kupplungsnabe | |

| DE3438379C2 (enExample) | ||

| DE102011105698B4 (de) | Grasbesen | |

| DE102009018443A1 (de) | Rotationsbürste mit unterschiedlichem Borstenbesatz | |

| DE102015205265A1 (de) | Filament aus Kunststoff | |

| DE29704122U1 (de) | Sanitärschlauch | |

| EP2683975B1 (de) | Wendelumhüllter schlauch |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20150627 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D01F 8/04 20060101ALI20160111BHEP Ipc: D01D 5/253 20060101ALI20160111BHEP Ipc: A46D 1/00 20060101AFI20160111BHEP Ipc: D01D 5/30 20060101ALI20160111BHEP Ipc: D01F 8/14 20060101ALI20160111BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20160225 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 806047 Country of ref document: AT Kind code of ref document: T Effective date: 20160715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502014000951 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160915 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160916 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161017 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502014000951 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170506 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 806047 Country of ref document: AT Kind code of ref document: T Effective date: 20190506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190506 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230509 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20250522 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250512 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20250530 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250601 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20250521 Year of fee payment: 12 |