EP2934234B1 - Plastics monofilament and toothbrush bristle produced from a corresponding monofilament - Google Patents

Plastics monofilament and toothbrush bristle produced from a corresponding monofilament Download PDFInfo

- Publication number

- EP2934234B1 EP2934234B1 EP14724307.5A EP14724307A EP2934234B1 EP 2934234 B1 EP2934234 B1 EP 2934234B1 EP 14724307 A EP14724307 A EP 14724307A EP 2934234 B1 EP2934234 B1 EP 2934234B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- monofilament

- matrix

- accordance

- area

- rib

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/023—Bristles with at least a core and at least a partial sheath

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0238—Bristles with non-round cross-section

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0253—Bristles having a shape which is not a straight line, e.g. curved, "S", hook, loop

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0269—Monofilament bristles

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/253—Formation of filaments, threads, or the like with a non-circular cross section; Spinnerette packs therefor

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/28—Formation of filaments, threads, or the like while mixing different spinning solutions or melts during the spinning operation; Spinnerette packs therefor

- D01D5/30—Conjugate filaments; Spinnerette packs therefor

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/14—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyester as constituent

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46B—BRUSHES

- A46B2200/00—Brushes characterized by their functions, uses or applications

- A46B2200/10—For human or animal care

- A46B2200/1066—Toothbrush for cleaning the teeth or dentures

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

- Y10T428/2922—Nonlinear [e.g., crimped, coiled, etc.]

- Y10T428/2924—Composite

Definitions

- the invention relates to a plastic monofilament and a toothbrush bristle made from a corresponding monofilament.

- the cleaning effect of a brush depends essentially on the geometry of the individual bristles and the material of which the bristles are made. In particular, it has proved to be advantageous to structure or profile the bristles on their lateral surface so that the bristles have a scraping action.

- bristles which have a plurality of axially parallel ribs, which are integrally formed at their radially inner end on a core forming the matrix.

- the core and the rib may be made of different plastics, on the one hand to adapt the strength and bending property of the bristle and on the other hand, the cleaning effect by the rib to the desired application.

- the bristle is used on a toothbrush, the choice of materials should ensure that the user can not be injured.

- a monofilament according to the preamble of claim 1 is known from US 2008 0221618 known.

- the invention has for its object to provide a monofilament for producing a bristle or a toothbrush bristle made therefrom, in which for the material of the rib and the matrix improved selection and combination options are given.

- the monofilament has a matrix which, at least in a first region, consists of a first plastic material and has at least one rib extending in the longitudinal direction of the monofilament, which consists of a second plastic material and which is in the first region of the matrix is held positively.

- the materials and the parameters in the extrusion of the monofilament are chosen so that the rib is also welded to the first region of the matrix in addition to the positive connection. Alternatively or additionally, however, it may also be provided that the rib is adhesively bonded to the first region of the matrix in addition to the positive connection.

- the rib has a radially outwardly tapering cross-section, for example a triangular or drop-shaped cross-section, so that it tapers in its radially outer cross-sectional area.

- the rib In order to ensure a good positive connection between the rib and the first region of the matrix, the rib should be provided with undercuts at its radially inner end region embedded in the first area of the matrix. It is preferably provided that in the radially inner end region of the rib, a widespread foot is formed, which is encompassed by the first plastic material of the first region of the matrix.

- the monofilament has a plurality of ribs, which should preferably be distributed equally over the circumference of the monofilament.

- the ribs run in the form of a Wendel around the matrix. This can be achieved in particular if the monofilament is twisted after the extrusion in a manner known per se. According to the twisting takes place with 50 to 400 revolutions per meter.

- the 1st area forms the entire matrix, i. the matrix consists exclusively of the first plastic material, in which the rib or the ribs are held in a form-fitting manner.

- the first area of the matrix has an annular cross-section and surrounds at least one inner, second area of the matrix, which consists of a third plastic material. In this way, the performance characteristics of the monofilament or bristle made therefrom can be better adapted to the desired application.

- the ribs are connected to one another by means of the inner, second region of the matrix.

- the plastic materials can be chosen largely freely due to the positive connection.

- the first plastic material of the first area of the matrix is a rigid thermoplastic polyester and in particular PBT (polybutylene terephthalate).

- the second synthetic material of the rib according to the invention is a soft thermoplastic material and in particular a thermoplastic elastomer.

- the 3rd plastic material of the inner 2nd area of the matrix can also be freely selected within wide limits. If the ribs are connected together at their radially inner ends by means of the second region of the matrix, it is preferably provided that the third plastic material of the second region of the matrix is equal to the second plastic material of the ribs.

- At least one rib is colored at least in sections and thereby stands out in terms of color from the rest of the monofilament. In this way, it is possible to visualize to the user that the monofilament is twisted, thereby avoiding confusion when using the monofilament.

- bristles can be produced in the usual way, which are preferably used as toothbrush bristles.

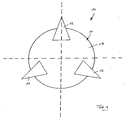

- FIG. 1 shows a cross section through a monofilament 10 made of plastic, which has a consisting of a 1st area 13 matrix 11 with a circular cross section, which consists entirely of a first plastic material, such as a rigid thermoplastic polyester.

- the monofilament 10 has three in the longitudinal direction, ie perpendicular to the plane extending radially outwardly from the matrix 11 protruding ribs 12.

- Each rib 12 has a triangular, radially outwardly tapering cross-section and is with its radially inner, wide end portion in a form-fitting manner held in the matrix 11. Due to the positive connection, the material of the ribs 12 can be chosen freely, ie it is not dependent on the type of the first plastic material of the matrix 11.

- the second plastic material of the ribs 12 is a soft thermoplastic material.

- the ribs 12 may be held in the matrix 11 by means of gluing or welding in addition to the positive locking.

- FIG. 2 shows a FIG. 1 similar embodiment and differs from this only in that in the radially inner end portion of the ribs 12 each have a common foot 15 is provided which substantially improves the holding forces to be achieved via the positive locking.

- FIG. 3 shows a further embodiment of the monofilament 10 according to the invention.

- the matrix 11 has a first region 13 of a first plastic material which has an annular cross-section. Within the first annular region 13, a second region 14 of the matrix is arranged, which consists of a third plastic material.

- the ribs 12 are held in a form-fitting manner in the annular first region 13 of the matrix 11 and lie with their radially inner ends on the inner second region 14 of the matrix 11 at.

- the ribs 12 are connected to the inner second region 14 of the matrix 11 by gluing or welding.

- FIG. 4 shows an embodiment according to FIG. 3 corresponding embodiment, which only differs therefrom in that the ribs 12 and the inner second region 14 of the matrix consist of a uniform material and are formed as a monolithic body.

Description

Die Erfindung betrifft ein Monofil aus Kunststoff und eine aus einem entsprechenden Monofil hergestellte Zahnbürsten-Borste.The invention relates to a plastic monofilament and a toothbrush bristle made from a corresponding monofilament.

Die Reinigungswirkung einer Bürste ist wesentlich von der Geometrie der einzelnen Borsten und dem Material abhängig, aus dem die Borsten bestehen. Insbesondere hat es sich als vorteilhaft erwiesen, die Borsten auf ihrer Mantelfläche zu strukturieren oder zu profilieren, so dass die Borsten eine Schabewirkung haben.The cleaning effect of a brush depends essentially on the geometry of the individual bristles and the material of which the bristles are made. In particular, it has proved to be advantageous to structure or profile the bristles on their lateral surface so that the bristles have a scraping action.

Aus der

Es hat sich herausgestellt, dass die Materialauswahl einerseits für die Rippe und andererseits für die Matrix dadurch stark beschränkt ist, dass die beiden Materialien bei der Herstellung des entsprechenden Monofils eine starke Verbindung eingehen müssen, um zu verhindern, dass sich die Rippe bei Benutzung der Borste von der Matrix löst. Diese Beschränkung in der Materialwahl ist sehr nachteilig, so dass eine optimierte Reinigungswirkung selten erreicht werden kann.It has been found that the material selection on the one hand for the rib and on the other hand for the matrix is strongly limited by the fact that the two materials must make a strong connection in the production of the corresponding monofilament, in order to prevent the rib from using the bristle detached from the matrix. This restriction in the choice of material is very disadvantageous, so that an optimized cleaning effect can rarely be achieved.

Ein Monofil gemäß dem Oberbegriff des Anspruchs 1 ist aus der

Der Erfindung liegt die Aufgabe zugrunde, ein Monofil zur Herstellung einer Borste bzw. eine daraus hergestellte Zahnbürsten-Borste zu schaffen, bei dem für das Material der Rippe und der Matrix verbesserte Auswahl- und Kombinationsmöglichkeiten gegeben sind.The invention has for its object to provide a monofilament for producing a bristle or a toothbrush bristle made therefrom, in which for the material of the rib and the matrix improved selection and combination options are given.

Diese Aufgabe wird erfindungsgemäß durch ein Monofil mit den Merkmalen des Anspruchs 1 gelöst. Das Monofil besitzt eine Matrix, die zumindest in einem 1. Bereich aus einem 1. Kunststoff-Material besteht und zumindest eine in Längsrichtung des Monofils verlaufende Rippe aufweist, die aus einem 2. Kunststoff-Material besteht und die in dem 1. Bereich der Matrix formschlüssig gehalten ist.This object is achieved by a monofilament having the features of

Aufgrund des Formschlusses zwischen der Rippe und dem 1. Bereich der Matrix kann eine sichere Halterung der Rippe in der Matrix unabhängig davon erreicht werden, ob zwischen dem 1. Kunststoff-Material des 1. Bereichs der Matrix und dem 2. Kunststoff-Material der Rippe zusätzlich eine stoffschlüssige und/oder kraftschlüssige Verbindung gegeben ist. Es ist einerseits möglich, die Rippe allein über Formschluss in dem 1. Bereich der Matrix zu halten, alternativ ist es jedoch auch möglich, zusätzlich zwischen den genannten Materialien insbesondere eine stoffschlüssige oder kraftschlüssige Verbindung vorzusehen. In bevorzugter Ausgestaltung der Erfindung sind die Materialien und die Parameter bei der Extrusion des Monofils so gewählt, dass die Rippe mit dem 1. Bereich der Matrix zusätzlich zu dem Formschluss auch verschweißt ist. Alternativ oder zusätzlich dazu kann aber auch vorgesehen sein, dass die Rippe mit dem 1. Bereich der Matrix zusätzlich zu dem Formschluss verklebt ist.Due to the positive connection between the rib and the first area of the matrix, secure retention of the rib in the matrix can be achieved independently of whether between the 1st plastic material of the first area of the matrix and the second plastic material of the rib in addition, a cohesive and / or non-positive connection is given. On the one hand, it is possible to hold the rib alone in the first area of the matrix by means of positive locking, but alternatively it is also possible to intervene between To provide the materials mentioned in particular a cohesive or non-positive connection. In a preferred embodiment of the invention, the materials and the parameters in the extrusion of the monofilament are chosen so that the rib is also welded to the first region of the matrix in addition to the positive connection. Alternatively or additionally, however, it may also be provided that the rib is adhesively bonded to the first region of the matrix in addition to the positive connection.

In einer möglichen Ausgestaltung der Erfindung ist vorgesehen, dass die Rippe einen sich radial nach außen verjüngenden Querschnitt, beispielsweise einen dreieckigen oder tropfenförmigen Querschnitt aufweist, so dass sie in ihrem radial äußeren Querschnittsbereich spitzt zuläuft.In one possible embodiment of the invention it is provided that the rib has a radially outwardly tapering cross-section, for example a triangular or drop-shaped cross-section, so that it tapers in its radially outer cross-sectional area.

Um eine gute formschlüssige Verbindung zwischen der Rippe und dem ersten Bereich der Matrix zu gewährleisten, sollte die Rippe an ihrem radial inneren, in den 1. Bereich der Matrix eingebetteten Endbereich mit Hinterschneidungen versehen sein. Vorzugsweise ist vorgesehen, dass im radial inneren Endbereich der Rippe ein verbreiteter Fuß aufgebildet ist, der von dem 1. Kunststoffmaterial des 1. Bereichs der Matrix umgriffen ist.In order to ensure a good positive connection between the rib and the first region of the matrix, the rib should be provided with undercuts at its radially inner end region embedded in the first area of the matrix. It is preferably provided that in the radially inner end region of the rib, a widespread foot is formed, which is encompassed by the first plastic material of the first region of the matrix.

Erfindungsgemäß weist das Monofil mehrere Rippen auf, die vorzugsweise über den Umfang des Monofils gleich verteilt sein sollten.According to the invention, the monofilament has a plurality of ribs, which should preferably be distributed equally over the circumference of the monofilament.

Erfindungsgemäß laufen die Rippen in Form einer Wendel um die Matrix um. Dies kann insbesondere dann erreicht werden, wenn das Monofil nach der Extrusion in an sich bekannter Weise verdrillt wird. Erfindungsgemäß erfolgt das Verdrillen mit 50 bis 400 Umdrehungen pro laufendem Meter.According to the invention, the ribs run in the form of a Wendel around the matrix. This can be achieved in particular if the monofilament is twisted after the extrusion in a manner known per se. According to the twisting takes place with 50 to 400 revolutions per meter.

In einer möglichen Ausgestaltung der Erfindung kann vorgesehen, dass der 1. Bereich die gesamte Matrix bildet, d.h. die Matrix ausschließlich aus dem 1. Kunststoff-Material besteht, in dem die Rippe oder die Rippen formschlüssig gehalten sind.In a possible embodiment of the invention, it is provided that the 1st area forms the entire matrix, i. the matrix consists exclusively of the first plastic material, in which the rib or the ribs are held in a form-fitting manner.

Alternativ kann vorgesehen sein, dass der 1. Bereich der Matrix einen ringförmigen Querschnitt aufweist und zumindest einen innen liegenden 2. Bereich der Matrix umgibt, der aus einem 3. Kunststoffmaterial besteht. Auf diese Weise können die Gebrauchseigenschaften des Monofils bzw. der daraus hergestellten Borste noch besser an den gewünschte Einsatzzweck angepasst werden.Alternatively, it can be provided that the first area of the matrix has an annular cross-section and surrounds at least one inner, second area of the matrix, which consists of a third plastic material. In this way, the performance characteristics of the monofilament or bristle made therefrom can be better adapted to the desired application.

Um die Halterung der Rippen in der Matrix zu verstärken, kann in Weiterbildung der Erfindung vorgesehen sein, dass die Rippen mittels des innen liegenden 2. Bereichs der Matrix miteinander verbunden sind.In order to reinforce the retention of the ribs in the matrix, it can be provided in a development of the invention that the ribs are connected to one another by means of the inner, second region of the matrix.

Die Kunststoffmaterialien können aufgrund des Formschlusses weitestgehend frei gewählt werden. Erfindungsgemäß ist das 1. Kunststoff-Material des 1. Bereichs der Matrix ein steifes thermoplastisches Polyester und insbesondere PBT (Polybutylenterephthalat).The plastic materials can be chosen largely freely due to the positive connection. According to the invention, the first plastic material of the first area of the matrix is a rigid thermoplastic polyester and in particular PBT (polybutylene terephthalate).

Das 2. Kunstostoff-Material der Rippe ist erfindungsgemäß ein weicher thermoplastischer Kunststoff und insbesondere ein thermoplastisches Elastomer.The second synthetic material of the rib according to the invention is a soft thermoplastic material and in particular a thermoplastic elastomer.

Auch das 3. Kunststoff-Material des innen liegenden 2. Bereichs der Matrix kann in weiten Grenzen frei gewählt werden. Wenn die Rippen an ihren radial innen liegenden Enden mittels des 2. Bereichs der Matrix miteinander verbunden sind, ist vorzugsweise vorgesehen, dass das 3. Kunststoff-Material des 2. Bereichs der Matrix gleich dem 2. Kunststoff-Material der Rippen ist.The 3rd plastic material of the inner 2nd area of the matrix can also be freely selected within wide limits. If the ribs are connected together at their radially inner ends by means of the second region of the matrix, it is preferably provided that the third plastic material of the second region of the matrix is equal to the second plastic material of the ribs.

In bevorzugter Ausgestaltung der Erfindung ist vorgesehen, dass zumindest eine Rippe zumindest abschnittsweise eingefärbt ist und sich dadurch farblich von dem Rest des Monofils abhebt. Auf diese Weise ist es möglich, dem Benutzer zu visualisieren, dass das Monofil verdrillt ist, um dadurch Verwechslungen bei der Verwendung des Monofils zu vermeiden.In a preferred embodiment of the invention it is provided that at least one rib is colored at least in sections and thereby stands out in terms of color from the rest of the monofilament. In this way, it is possible to visualize to the user that the monofilament is twisted, thereby avoiding confusion when using the monofilament.

Aus dem erfindungsgemäßen Monofil können in üblicher Weise Borsten hergestellt werden, die vorzugsweise als Zahnbürsten-Borste Verwendung finden.From the monofilament according to the invention bristles can be produced in the usual way, which are preferably used as toothbrush bristles.

Weitere Einzelheiten und Merkmale der Erfindung sind aus der folgenden Beschreibung von Ausführungsbeispiel unter Bezugnahme auf die Zeichnung ersichtlich. Es zeigen:

- Fig. 1

- den Querschnitt einer 1. Ausführungsform des erfindungsgemäßen Monofils,

- Fig. 2

- eine Abwandlung der Ausführungsform gemäß

Figur 1 - Fig. 3

- den Querschnitt einer 2. Ausführungsform des erfindungsgemäßen Monofils und

- Fig. 4

- eine Abwandlung der Ausführungsform gemäß

Figur 3 .

- Fig. 1

- the cross section of a first embodiment of the monofilament according to the invention,

- Fig. 2

- a modification of the embodiment according to

FIG. 1 . - Fig. 3

- the cross section of a second embodiment of the monofilament according to the invention and

- Fig. 4

- a modification of the embodiment according to

FIG. 3 ,

Die Rippen 12 können zusätzlich zu dem Formschluss auch mittels einer Klebung oder einer Schweißung in der Matrix 11 gehalten sein.The

Claims (13)

- Plastic monofilament (10) with a matrix (11), which consists of a first plastic material at least in a first area, and with at least one rib (12), which extends in the longitudinal direction of the monofilament (10) and which consists of a second plastic material and which is held in the first area (13) of the matrix (11) in a positive-locking manner, wherein a plurality of ribs (12) arranged distributed over the circumference of the monofilament (10) are provided, characterized in that the first plastic material of the first area (13) of the matrix (11) is a rigid thermoplastic polyester, that the second plastic material of the ribs (12) is a soft thermoplastic plastic, and that the monofilament is twisted with 50 to 400 revolutions per running meter, so that the ribs (12) extend around the matrix (11) in the form of a coil.

- Monofilament in accordance with claim 1, characterized in that the rib (12) is additionally welded to the first area (13) of the matrix (11).

- Monofilament in accordance with claim 1 or 2, characterized in that the rib (12) has a radially outwardly tapering cross section.

- Monofilament in accordance with claim 3, characterized in that the rib has a triangular or drop-shaped cross section.

- Monofilament in accordance with one of the claims 1 through 4, characterized in that a broadened foot (15) is formed in the radially inner end area of the rib (12).

- Monofilament in accordance with one of the claims 1 through 5, characterized in that the first area (13) forms the entire matrix (11).

- Monofilament in accordance with one of the claims 1 through 5, characterized in that the first area (13) of the matrix (11) has a ring-shaped cross section and surrounds an inner, second area (14) of the matrix (11), which consists of a third plastic material.

- Monofilament in accordance with claim 7, characterized in that the ribs (12) are connected to one another by means of the second area (14) of the matrix (11).

- Monofilament in accordance with one of the claims 1 through 8, characterized in that the first plastic material of the first area (13) of the matrix (11) is PBT (polybutylene terephthalate).

- Monofilament in accordance with one of the claims 1 through 9, characterized in that the second plastic material of the rib (12) is a thermoplastic elastomer.

- Monofilament in accordance with one of the claims 7 through 10, characterized in that the third plastic material of the second area (14) is identical to the second plastic material of the rib (12).

- Monofilament in accordance with one of the claims 1 through 11, characterized in that at least one rib (12) is colored at least in some sections.

- Toothbrush bristle consisting of a monofilament in accordance with one of the claims 1 through 12.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013007870.9A DE102013007870A1 (en) | 2013-05-08 | 2013-05-08 | Monofilament of plastic and toothbrush bristle of a corresponding monofilament |

| PCT/EP2014/001200 WO2014180560A1 (en) | 2013-05-08 | 2014-05-06 | Plastics monofilament and toothbrush bristle produced from a corresponding monofilament |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2934234A1 EP2934234A1 (en) | 2015-10-28 |

| EP2934234B1 true EP2934234B1 (en) | 2016-06-15 |

Family

ID=50732092

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP14724307.5A Active EP2934234B1 (en) | 2013-05-08 | 2014-05-06 | Plastics monofilament and toothbrush bristle produced from a corresponding monofilament |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20150354098A1 (en) |

| EP (1) | EP2934234B1 (en) |

| JP (1) | JP2016524481A (en) |

| KR (1) | KR20160006661A (en) |

| CN (1) | CN105188475B (en) |

| DE (1) | DE102013007870A1 (en) |

| WO (1) | WO2014180560A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102015205265A1 (en) * | 2015-03-24 | 2016-09-29 | Pedex Gmbh | Plastic filament |

| US10136723B2 (en) * | 2015-12-14 | 2018-11-27 | Colgate-Palmolive Company | Oral care implement |

| CN107041622A (en) * | 2017-05-23 | 2017-08-15 | 湖北瑞特威日化有限公司 | A kind of acrylic resin tooth bristle and its manufacture method |

| DE102018000663A1 (en) * | 2018-01-29 | 2019-08-01 | Pedex Gmbh | Filament and toothbrush with at least one corresponding filament |

| KR102197602B1 (en) | 2019-09-04 | 2020-12-31 | 주식회사 케이앤케이 | Spinneret to manufacture filaments with modified cross-section and filaments by this |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2317485A (en) * | 1940-04-27 | 1943-04-27 | Pepsodent Co | Brush |

| US3209402A (en) * | 1962-03-07 | 1965-10-05 | Celanese Corp | Apparatus for producing multicom-ponent filaments and yarns |

| US4457973B1 (en) * | 1980-06-06 | 1995-05-09 | Kanebo Synthetic Fibert Ltd | Conductive composite filaments and methods for producing said composite filaments |

| JPS62170509A (en) * | 1986-01-20 | 1987-07-27 | Teijin Ltd | Stretchable synthetic filament yarn and production thereof |

| DE19533815A1 (en) | 1995-09-13 | 1997-03-20 | Coronet Werke Gmbh | Toothbrush and process for its manufacture |

| DE19533816A1 (en) | 1995-09-13 | 1997-03-20 | Coronet Werke Gmbh | Process for the production of spiral bristles |

| US5707735A (en) * | 1996-03-18 | 1998-01-13 | Midkiff; David Grant | Multilobal conjugate fibers and fabrics |

| WO1998009010A1 (en) * | 1996-08-27 | 1998-03-05 | Chisso Corporation | A non-woven fabric and an absorbent article using thereof |

| US5879801A (en) * | 1997-01-10 | 1999-03-09 | Basf Corporation | Multiple domain fibers having inter-domain boundary compatibilizing layer and methods and apparatus for making the same |

| DE19932368A1 (en) * | 1999-07-13 | 2001-02-08 | Pedex & Co Gmbh | Process for the production of multilayer bristle material, multilayer bristle and their use |

| ATE302865T1 (en) * | 2000-09-29 | 2005-09-15 | Invista Tech Sarl | STRETCHABLE POLYMER FIBERS, SPINNING NUTS FOR THE PRODUCTION THEREOF AND ARTICLES MADE THEREFROM |

| JP4816037B2 (en) * | 2005-12-02 | 2011-11-16 | サンスター株式会社 | toothbrush |

| JP4992285B2 (en) * | 2006-04-21 | 2012-08-08 | サンスター株式会社 | toothbrush |

| US20080221618A1 (en) * | 2007-03-09 | 2008-09-11 | Gaoyuan Chen | Co-extruded tissue grasping monofilament |

| JP5338233B2 (en) * | 2008-09-30 | 2013-11-13 | サンスター株式会社 | Toothbrush filament and toothbrush in which the filament is implanted |

| JP5387352B2 (en) * | 2009-11-13 | 2014-01-15 | 東レ・モノフィラメント株式会社 | Monofilament for toothbrush |

| MY194080A (en) * | 2012-09-25 | 2022-11-11 | Lion Corp | Tapered bristles, method for manufacturing same, and toothbrush provided with tapered bristles |

-

2013

- 2013-05-08 DE DE102013007870.9A patent/DE102013007870A1/en not_active Withdrawn

-

2014

- 2014-05-06 KR KR1020157021099A patent/KR20160006661A/en not_active Application Discontinuation

- 2014-05-06 US US14/763,232 patent/US20150354098A1/en not_active Abandoned

- 2014-05-06 JP JP2016512244A patent/JP2016524481A/en active Pending

- 2014-05-06 WO PCT/EP2014/001200 patent/WO2014180560A1/en active Application Filing

- 2014-05-06 EP EP14724307.5A patent/EP2934234B1/en active Active

- 2014-05-06 CN CN201480025042.9A patent/CN105188475B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2014180560A1 (en) | 2014-11-13 |

| CN105188475A (en) | 2015-12-23 |

| CN105188475B (en) | 2017-07-04 |

| KR20160006661A (en) | 2016-01-19 |

| DE102013007870A1 (en) | 2014-11-13 |

| US20150354098A1 (en) | 2015-12-10 |

| JP2016524481A (en) | 2016-08-18 |

| EP2934234A1 (en) | 2015-10-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2934234B1 (en) | Plastics monofilament and toothbrush bristle produced from a corresponding monofilament | |

| EP1593321B1 (en) | Brush head | |

| EP1992251B1 (en) | Small cosmetic brush with many bristles for applying make-up | |

| EP2268168B1 (en) | Broom, in particular for industrial or household use | |

| WO1997009907A1 (en) | Toothbrush and the process for its manufacture | |

| DE102015215832B4 (en) | Hairstyling utensil | |

| EP2862478B1 (en) | Toothbrush and method for its manufacture | |

| DE102008007105B4 (en) | Worm wheel with damping | |

| EP3709929B1 (en) | Interdental cleaner | |

| DE102010015836A1 (en) | spacer | |

| WO1999024649A1 (en) | Monofil for and for producing bristles or interdental cleaning elements, bristle products with bristles of this type and interdental cleaning elements | |

| DE102005055771B4 (en) | clutch | |

| EP1983104B1 (en) | Synthetic turf | |

| WO2021223921A1 (en) | Shower hose, series of shower hoses, use of a braiding and method for producing a shower hose | |

| DE102011114916B4 (en) | radial brush | |

| EP1381719A1 (en) | Thermoplastic monofilament for bristles | |

| DE102013209439A1 (en) | torsion | |

| DE3438379C2 (en) | ||

| DE102011105698B4 (en) | grass broom | |

| DE102015205265A1 (en) | Plastic filament | |

| DE102007021314A1 (en) | toothbrush | |

| EP1001075A2 (en) | Sheathless conveyor cable for cable or municipal railways | |

| EP2683975B1 (en) | Spiral-bound hose | |

| EP3713445B1 (en) | Toothbrush | |

| WO2019145114A1 (en) | Filament and toothbrush with at least one corresponding filament |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20150627 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D01F 8/04 20060101ALI20160111BHEP Ipc: D01D 5/253 20060101ALI20160111BHEP Ipc: A46D 1/00 20060101AFI20160111BHEP Ipc: D01D 5/30 20060101ALI20160111BHEP Ipc: D01F 8/14 20060101ALI20160111BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20160225 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 806047 Country of ref document: AT Kind code of ref document: T Effective date: 20160715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502014000951 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160915 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160916 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161015 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161017 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502014000951 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20170316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20180131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170506 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20140506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160615 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 806047 Country of ref document: AT Kind code of ref document: T Effective date: 20190506 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190506 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230509 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20230519 Year of fee payment: 10 Ref country code: IT Payment date: 20230531 Year of fee payment: 10 Ref country code: IE Payment date: 20230516 Year of fee payment: 10 Ref country code: DE Payment date: 20230510 Year of fee payment: 10 Ref country code: CH Payment date: 20230605 Year of fee payment: 10 |