EP2912151B1 - Use of viscosity modifier in high viscosity index lubricating oil base stock combinations - Google Patents

Use of viscosity modifier in high viscosity index lubricating oil base stock combinations Download PDFInfo

- Publication number

- EP2912151B1 EP2912151B1 EP13773574.2A EP13773574A EP2912151B1 EP 2912151 B1 EP2912151 B1 EP 2912151B1 EP 13773574 A EP13773574 A EP 13773574A EP 2912151 B1 EP2912151 B1 EP 2912151B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- viscosity

- group

- copolymer

- acid

- oil

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- UAEPNZWRGJTJPN-UHFFFAOYSA-N CC1CCCCC1 Chemical compound CC1CCCCC1 UAEPNZWRGJTJPN-UHFFFAOYSA-N 0.000 description 1

- ALHGTRBFOGTTAW-UHFFFAOYSA-O [IH]=CCC1[NH2+]C1 Chemical compound [IH]=CCC1[NH2+]C1 ALHGTRBFOGTTAW-UHFFFAOYSA-O 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M149/00—Lubricating compositions characterised by the additive being a macromolecular compound containing nitrogen

- C10M149/02—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C10M149/06—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to an amido or imido group

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M145/00—Lubricating compositions characterised by the additive being a macromolecular compound containing oxygen

- C10M145/02—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C10M145/10—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. acrylate

- C10M145/12—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. acrylate monocarboxylic

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M145/00—Lubricating compositions characterised by the additive being a macromolecular compound containing oxygen

- C10M145/02—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C10M145/10—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. acrylate

- C10M145/16—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. acrylate polycarboxylic

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M149/00—Lubricating compositions characterised by the additive being a macromolecular compound containing nitrogen

- C10M149/02—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C10M149/04—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to an amino group

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M169/00—Lubricating compositions characterised by containing as components a mixture of at least two types of ingredient selected from base-materials, thickeners or additives, covered by the preceding groups, each of these compounds being essential

- C10M169/04—Mixtures of base-materials and additives

- C10M169/041—Mixtures of base-materials and additives the additives being macromolecular compounds only

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2205/00—Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions

- C10M2205/02—Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions containing acyclic monomers

- C10M2205/028—Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions containing acyclic monomers containing aliphatic monomers having more than four carbon atoms

- C10M2205/0285—Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions containing acyclic monomers containing aliphatic monomers having more than four carbon atoms used as base material

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2209/00—Organic macromolecular compounds containing oxygen as ingredients in lubricant compositions

- C10M2209/02—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C10M2209/08—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. acrylate type

- C10M2209/084—Acrylate; Methacrylate

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10M—LUBRICATING COMPOSITIONS; USE OF CHEMICAL SUBSTANCES EITHER ALONE OR AS LUBRICATING INGREDIENTS IN A LUBRICATING COMPOSITION

- C10M2217/00—Organic macromolecular compounds containing nitrogen as ingredients in lubricant compositions

- C10M2217/06—Macromolecular compounds obtained by functionalisation op polymers with a nitrogen containing compound

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2020/00—Specified physical or chemical properties or characteristics, i.e. function, of component of lubricating compositions

- C10N2020/01—Physico-chemical properties

- C10N2020/019—Shear stability

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/02—Pour-point; Viscosity index

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/04—Detergent property or dispersant property

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/06—Oiliness; Film-strength; Anti-wear; Resistance to extreme pressure

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/08—Resistance to extreme temperature

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/10—Inhibition of oxidation, e.g. anti-oxidants

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2030/00—Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g. multifunctional additives

- C10N2030/68—Shear stability

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2040/00—Specified use or application for which the lubricating composition is intended

- C10N2040/04—Oil-bath; Gear-boxes; Automatic transmissions; Traction drives

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10N—INDEXING SCHEME ASSOCIATED WITH SUBCLASS C10M RELATING TO LUBRICATING COMPOSITIONS

- C10N2040/00—Specified use or application for which the lubricating composition is intended

- C10N2040/04—Oil-bath; Gear-boxes; Automatic transmissions; Traction drives

- C10N2040/044—Oil-bath; Gear-boxes; Automatic transmissions; Traction drives for manual transmissions

Definitions

- This disclosure relates to the use of high viscosity index lubricating oil base stock (metallocene catalyzed polyalphaolefin and polyalphaolefin fluid) and viscosity modifier (e.g., ester-containing copolymer) combinations, and of lubricating oils derived therefrom.

- This disclosure relates to lubricating driveline devices, e.g., gears and transmissions, using the lubricating oils to improve fuel efficiency without sacrificing driveline device durability.

- Lubricants in commercial use today are prepared from a variety of natural and synthetic base stocks admixed with various additive packages and solvents depending upon their intended application.

- the base stocks typically include mineral oils, polyalphaolefins (PAO), gas-to-liquid base oils (GTL), silicone oils, phosphate esters, diesters, polyol esters, and the like.

- WO2007/145924 discloses lubricating oils comprising metallocene catalyzed PAO.

- Viscosity index improvers are known to be added to lubricating oil compositions to reduce the change in viscosity of the lubricant as a function of temperature.

- the most conventional types of viscosity index improvers used in axle and transmission oil applications include polyisobutylene and polymers of methacrylates.

- More recent viscosity index improver technologies consist of olefins (such as copolymers of alpha-olefins and maleic anhydride and esterified derivatives thereof). These viscosity index improvers tend to incorporate ester functional groups in pendant/grafted/branched groups.

- the ester functional groups may be derived from linear alkyl alcohols with 1 to 40 carbon atoms.

- Lubricants capable of performing at lower viscosity typically provide increased fuel economy (thus improving corporate average fuel efficiency (CAFE), NEDC (European Driving Cycle), or FTP-75 (Federal Test Procedure), or Japanese test cycle (JC-08)). Conversely, higher viscosity fluids contribute to elevated gear and transmission operating temperatures, which are believed to reduce fuel economy and diminish durability.

- CAFE corporate average fuel efficiency

- NEDC European Driving Cycle

- FTP-75 Federal Test Procedure

- JC-08 Japanese test cycle

- Driveline power transmitting devices such as axles and transmissions-present highly complex technological challenges for axle and manual transmission lubricants.

- These lubricants are required to ensure hardware durability in the form wear protection and high load-carrying capacity, while delivering enhanced fuel efficiency benefits over extended periods.

- transmissions typically require specific frictional characteristics of fluids that are compatible with synchronizer material or design.

- One of the important parameters influencing performance is lubricant viscosity.

- Lubricants capable of performing at lower viscosity typically provide increased fuel economy. However viscosity that is too low to maintain sufficient and stable oil film between surface asperities results in elevated gear and transmission operating temperatures, which are believed to reduce fuel economy due to higher friction in contact zones. Therefore, increasing lubricant viscosity is conventionally believed to provide better wear protection and durability to gears and transmissions.

- a viscosity modifier comprising a copolymer having units derived from monomers of (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with an alcohol in a driveline device lubricated with a lubricating composition comprising:

- the above lubricating composition can be produced by a, process comprising:

- a method of lubricating a mechanical device comprises supplying to the device the above lubricating composition.

- the mechanical device comprises a driveline device, e.g., gears or transmissions.

- fuel efficiency can be improved, while maintaining or improving wear control, load carrying capacity and/or traction reduction in a driveline device, e.g., gears or transmissions, lubricated with a lubricating composition.

- a driveline device e.g., gears or transmissions

- higher viscosity fluids can result in lower fuel efficiency due to churning losses.

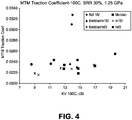

- the internal friction of the fluid measured by its traction properties is an indicator of its efficiency benefits in high pressure contact areas within axles.

- the method of blending of this disclosure delivers lower traction and lower viscosity fluids.

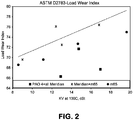

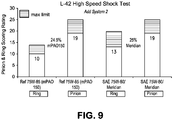

- the lubricating compositions used in this disclosure exhibit improved wear control (as determined by ASTM D4172), load carrying capacity (as determined by ASTM D2783) and/or traction reduction (as determined by Mini-Traction Machine (MTM) Ball-on-Disc apparatus) with said lubricating composition as compared to wear control, load carrying capacity and traction reduction achieved, at an equal or lower kinematic viscosity (Kv@100°C), with a lubricating composition containing a viscosity modifier other than a viscosity modifier comprising a copolymer having units derived from monomers of (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with an alcohol.

- a polymer is referred to as comprising homopolymers and copolymers, where copolymers include any polymer having two or more chemically distinct monomers.

- polyalphaolefin or “PAO” includes homopolymers and copolymers of C 3 or greater alphaolefin monomers.

- the lubricating compositions used according to this disclosure exhibit improved wear control (as determined by ASTM D4172), improved load carrying capacity (as determined by ASTM D2783) and/or improved traction reduction (as determined by Mini-Traction Machine (MTM) Ball-on-Disc apparatus) as compared to wear control, load carrying capacity and traction reduction achieved, at an equal or lower kinematic viscosity (Kv@100°C), with a lubricating composition containing a viscosity modifier other than a viscosity modifier comprising a copolymer having units derived from monomers of (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with an alcohol.

- the lubricating compositions used according to this disclosure are also capable of providing at least one of improved oxidative stability, reduced mechanical device operating temperatures, increased mechanical device durability, improved shear stability, improved viscosity index, improved low temperature viscometrics and improved high temperature viscometrics.

- this disclosure relates to the use of a combination of a high viscosity synthetic base stock and an ester-containing viscosity modifier that enables improvement in wear control, load carrying capacity and traction and provides improved efficiency at equal or lower kinematic viscosity (Kv @100°C).

- Current high performance commercial axle fluids are blended with low viscosity synthetic base stocks (such as ⁇ 10 cSt PAO) in combination with conventional viscosity modifiers.

- higher viscosity fluids can result in lower fuel efficiency due to churning losses.

- the internal friction of the fluid measured by its traction properties provides an indicator of its efficiency benefits in high pressure contact areas within axles.

- the method of blending a high viscosity synthetic base stock and an ester-containing viscosity modifier in accordance with this disclosure provides lower traction and lower viscosity fluids.

- This disclosure relates to lubricating driveline devices, e.g., gears and transmissions, using the lubricating oils to improve fuel efficiency without sacrificing driveline device durability.

- Lubricating oils that are useful in the present disclosure are both natural oils and synthetic oils. Natural and synthetic oils (or mixtures thereof) can be used unrefined, refined, or rerefined (the latter is also known as reclaimed or reprocessed oil). Unrefined oils are those obtained directly from a natural or synthetic source and used without added purification. These include shale oil obtained directly from retorting operations, petroleum oil obtained directly from primary distillation, and ester oil obtained directly from an esterification process. Refined oils are similar to the oils discussed for unrefined oils except refined oils are subjected to one or more purification steps to improve the at least one lubricating oil property.

- Groups I, II, III, IV, V and VI are broad categories of base oil stocks developed and defined by the American Petroleum Institute (API Publication 1509; www.API.org) to create guidelines for lubricant base oils.

- Group I base stocks generally have a viscosity index of between 80 to 120 and contain greater than 0.03% sulfur and less than 90% saturates.

- Group II base stocks generally have a viscosity index of between 80 to 120, and contain less than or equal to 0.03% sulfur and greater than or equal to 90% saturates.

- Group III stock generally has a viscosity index greater than 120 and contains less than or equal to 0.03% sulfur and greater than 90% saturates.

- Group IV includes polyalphaolefins (PAO).

- Group V base stocks include base stocks not included in Groups I-IV. The table below summarizes properties of each of these six groups.

- Group VI are polyinternal olefins ("PIO").

- Polyinternal olefins are long-chain hydrocarbons, typically a linear backbone with some branching randomly attached; they are obtained by oligomerization of internal n-olefins.

- the catalyst is usually a BF3 complex with a proton source that leads to a cationic polymerization, or promoted BF3 or AlCl3 catalyst system.

- the process to produce polyinternal olefins (PIO) consists of four steps: reaction, neutralization/washing, hydrogenation and distillation. These steps are somewhat similar to PAO process.

- PIO are typically available in low viscosity grades, 4 cSt, 6 cSt and 8 cSt.

- n-olefins used as starting material are n-C 12 -C 18 internal olefins, more preferably, n-C 14 -C 16 olefins are used.

- PIO can be made with VI and pour points very similar to PAO, only slightly inferior. They can be used in engine and industrial lubricant formulations. For more detailed discussion, see Chapter 2, Polyintemalolefins in the book, "Synthetics, Mineral Oils, and Bio-Based Lubricants-Chemistry and Technology" Edited by Leslie R. Rudnick, p.

- PIO was classified by itself as Group VI fluid in API base stock classification

- Base Stock Properties Saturates Sulfur Viscosity Index Group I ⁇ 90 and/or >0.03% and ⁇ 80 and ⁇ 120

- Group IV Includes polyalphaolefins (PAO) Group V All other base oil stocks not included in Groups I, II, III or IV Group VI Polyinternal olefins (PIO)

- Natural oils include animal oils, vegetable oils (castor oil and lard oil, for example), and mineral oils. Animal and vegetable oils possessing favorable thermal oxidative stability can be used. Of the natural oils, mineral oils are preferred. Mineral oils vary widely as to their crude source, for example, as to whether they are paraffinic, naphthenic, or mixed paraffinic-naphthenic. Oils derived from coal or shale are also useful in the present disclosure. Natural oils vary also as to the method used for their production and purification, for example, their distillation range and whether they are straight run or cracked, hydrorefined, or solvent extracted.

- Group II and/or Group III hydroprocessed or hydrocracked base stocks as well as synthetic oils such as polyalphaolefins, alkyl aromatics and synthetic esters, i.e., Group IV and Group V oils are also well known base stock oils.

- Synthetic oils include hydrocarbon oil such as polymerized and interpolymerized olefins (polybutylenes, polypropylenes, propylene isobutylene copolymers, ethylene-olefin copolymers, and ethylene-alphaolefin copolymers, for example).

- Polyalphaolefin (PAO) oil base stocks the Group IV API base stocks, are a commonly used synthetic hydrocarbon oil.

- PAOs derived from C 8 , C 10 , C 12 , C 14 olefins or mixtures thereof may be utilized. See U.S. Patent Nos. 4,956,122 ; 4,827,064 ; and 4,827,073 .

- Group IV oils, that is, the PAO base stocks have viscosity indices preferably greater than 130, more preferably greater than 135, still more preferably greater than 140.

- Esters in a minor amount may be useful in the lubricating oils of this disclosure. Additive solvency and seal compatibility characteristics may be secured by the use of esters such as the esters of dibasic acids with monoalkanols and the polyol esters of monocarboxylic acids.

- Esters of the former type include, for example, the esters of dicarboxylic acids such as phthalic acid, succinic acid, sebacic acid, fumaric acid, adipic acid, linoleic acid dimer, malonic acid, alkyl malonic acid, alkenyl malonic acid, etc., with a variety of alcohols such as butyl alcohol, hexyl alcohol, dodecyl alcohol, 2-ethylhexyl alcohol, etc.

- dicarboxylic acids such as phthalic acid, succinic acid, sebacic acid, fumaric acid, adipic acid, linoleic acid dimer, malonic acid, alkyl malonic acid, alkenyl malonic acid, etc.

- alcohols such as butyl alcohol, hexyl alcohol, dodecyl alcohol, 2-ethylhexyl alcohol, etc.

- esters include dibutyl adipate, di(2-ethylhexyl) sebacate, di-n-hexyl fumarate, dioctyl sebacate, diisooctyl azelate, diisodecyl azelate, dioctyl phthalate, didecyl phthalate, dieicosyl sebacate, etc.

- Particularly useful synthetic esters are those which are obtained by reacting one or more polyhydric alcohols, preferably the hindered polyols such as the neopentyl polyols; e.g., neopentyl glycol, trimethylol ethane, 2-methyl-2-propyl-1,3-propanediol, trimethylol propane, pentaerythritol and dipentaerythritol with alkanoic acids containing at least 4 carbon atoms, preferably C 5 to C 30 acids such as saturated straight chain fatty acids including caprylic acid, capric acids, lauric acid, myristic acid, palmitic acid, stearic acid, arachic acid, and behenic acid, or the corresponding branched chain fatty acids or unsaturated fatty acids such as oleic acid, or mixtures of any of these materials.

- the hindered polyols such as the neopentyl polyols

- Esters should be used in an amount such that the improved wear and corrosion resistance provided by the lubricating oils of this disclosure are not adversely affected.

- the esters preferably have a D5293 viscosity of less than 10,000 cP at -35°C.

- Non-conventional or unconventional base stocks and/or base oils include one or a mixture of base stock(s) and/or base oil(s) derived from: (1) one or more Gas-to-Liquids (GTL) materials, as well as (2) hydrodewaxed, or hydroisomerized/cat (and/or solvent) dewaxed base stock(s) and/or base oils derived from synthetic wax, natural wax or waxy feeds, mineral and/or non-mineral oil waxy feed stocks such as gas oils, slack waxes (derived from the solvent dewaxing of natural oils, mineral oils or synthetic oils; e.g., Fischer-Tropsch feed stocks), natural waxes, and waxy stocks such as gas oils, waxy fuels hydrocracker bottoms, waxy raffinate, hydrocrackate, thermal crackates, foots oil or other mineral, mineral oil, or even non-petroleum oil derived waxy materials such as waxy materials recovered from coal liquefaction or shale oil, linear or

- GTL materials are materials that are derived via one or more synthesis, combination, transformation, rearrangement, and/or degradation/deconstructive processes from gaseous carbon-containing compounds, hydrogen-containing compounds and/or elements as feed stocks such as hydrogen, carbon dioxide, carbon monoxide, water, methane, ethane, ethylene, acetylene, propane, propylene, propyne, butane, butylenes, and butynes.

- GTL base stocks and/or base oils are GTL materials of lubricating viscosity that are generally derived from hydrocarbons; for example, waxy synthesized hydrocarbons, that are themselves derived from simpler gaseous carbon-containing compounds, hydrogen-containing compounds and/or elements as feed stocks.

- GTL base stock(s) and/or base oil(s) include oils boiling in the lube oil boiling range (1) separated/fractionated from synthesized GTL materials such as, for example, by distillation and subsequently subjected to a final wax processing step which involves either or both of a catalytic dewaxing process, or a solvent dewaxing process, to produce lube oils of reduced/low pour point; (2) synthesized wax isomerates, comprising, for example, hydrodewaxed or hydroisomerized cat and/or solvent dewaxed synthesized wax or waxy hydrocarbons; (3) hydrodewaxed or hydroisomerized cat and/or solvent dewaxed Fischer-Tropsch (F-T) material (i.e., hydrocarbons, waxy hydrocarbons, waxes and possible analogous oxygenates); preferably hydrodewaxed or hydroisomerized/followed by cat and/or solvent dewaxing dewaxed F-T waxy hydrocarbons, or hydrodewaxed

- GTL base stock(s) and/or base oil(s) derived from GTL materials are characterized typically as having kinematic viscosities at 100°C of from 2 mm 2 /s to 50 mm 2 /s (ASTM D445). They are further characterized typically as having pour points of -5°C to -40°C or lower (ASTM D97). They are also characterized typically as having viscosity indices of 80 to 140 or greater (ASTM D2270).

- GTL base stock(s) and/or base oil(s) are typically highly paraffinic (>90% saturates), and may contain mixtures of monocycloparaffins and multicycloparaffins in combination with non-cyclic isoparaffins.

- the ratio of the naphthenic (i.e., cycloparaffin) content in such combinations varies with the catalyst and temperature used.

- GTL base stock(s) and/or base oil(s) typically have very low sulfur and nitrogen content, generally containing less than 10 ppm, and more typically less than 5 ppm of each of these elements.

- the sulfur and nitrogen content of GTL base stock(s) and/or base oil(s) obtained from F-T material, especially F-T wax, is essentially nil.

- the absence of phosphorous and aromatics make this materially especially suitable for the formulation of low SAP products.

- GTL base stock and/or base oil and/or wax isomerate base stock and/or base oil is to be understood as embracing individual fractions of such materials of wide viscosity range as recovered in the production process, mixtures of two or more of such fractions, as well as mixtures of one or two or more low viscosity fractions with one, two or more higher viscosity fractions to produce a blend wherein the blend exhibits a target kinematic viscosity.

- the GTL material, from which the GTL base stock(s) and/or base oil(s) is/are derived is preferably an F-T material (i.e., hydrocarbons, waxy hydrocarbons, wax).

- Base oils for use in the formulated lubricating oils useful in the present disclosure are any of the variety of oils corresponding to API Group I, Group II, Group III, Group IV, Group V and Group VI oils and mixtures thereof, preferably API Group II, Group III, Group IV, Group V and Group VI oils and mixtures thereof, more preferably the Group III to Group VI base oils due to their exceptional volatility, stability, viscometric and cleanliness features.

- Minor quantities of Group I stock such as the amount used to dilute additives for blending into formulated lube oil products, can be tolerated but should be kept to a minimum, i.e. amounts only associated with their use as diluent/carrier oil for additives used on an "as-received" basis.

- Even in regard to the Group II stocks it is preferred that the Group II stock be in the higher quality range associated with that stock, i.e. a Group II stock having a viscosity index in the range 100 ⁇ VI ⁇ 120.

- GTL base stock(s) and/or base oil(s) are typically highly paraffinic (>90% saturates), and may contain mixtures of monocycloparaffins and multicycloparaffins in combination with non-cyclic isoparaffins.

- the ratio of the naphthenic (i.e., cycloparaffin) content in such combinations varies with the catalyst and temperature used.

- GTL base stock(s) and/or base oil(s) and hydrodewaxed, or hydroisomerized/cat (and/or solvent) dewaxed base stock(s) and/or base oil(s) typically have very low sulfur and nitrogen content, generally containing less than 10 ppm, and more typically less than 5 ppm of each of these elements.

- the sulfur and nitrogen content of GTL base stock(s) and/or base oil(s) obtained from F-T material, especially F-T wax, is essentially nil.

- the absence of phosphorous and aromatics make this material especially suitable for the formulation of low sulfur, sulfated ash, and phosphorus (low SAP) products.

- Polyalphaolefins are preferred lubricating oil basestocks of this disclosure.

- the PAOs can preferably comprise one or more C 8 to C 12 monomers.

- the PAOs have a viscosity (Kv 100 ) from 2 to 700 cSt at 100°C, preferably from 3 to 155 cSt at 100°C, and more preferably from 4 to 150 cSt at 100°C; and a viscosity index (VI) from 130 to 207, preferably from 140 to 200, and more preferably from 150 to 197.

- viscosity (Kv 100 ) is determined by ASTM D 445-01

- viscosity index (VI) is determined by ASTM D 2270-93 (1998).

- the PAOs useful in this disclosure can have a pour point (PP) less than -25°C; a molecular weight distribution (Mw/Mn) less than 2.0; and a glass transition temperature T g less than -60°C.

- any PAO described herein may have a kinematic viscosity (Kv) at 100°C in any of the following ranges: from 65 to 1,000 cSt, from 100 to 950 cSt, from 250 cSt to 900 cSt, from 400 cSt to 800 cSt, wherein all values are measured by ASTM D445-01.

- Kv kinematic viscosity

- the PAOs useful in this disclosure have a high viscosity index and a Kv 100 of 2 cSt or more, alternatively 3 cSt or more, alternatively 4 cSt or more, with a VI of 130 or more, alternatively 140 or more, alternatively 150 or more.

- base stock VI is a function of fluid viscosity. Usually, the higher the VI, the better it is for lube application. Base stock VI also depends on feed composition. Fluids made from single 1-octene, 1-nonene, 1-decene, or 1-dodecene have excellent VI and good low pour point.

- Fluids made from two or more olefins selected from C 8 to C 12 alphaolefins generally have excellent high VI and superior low pour points if the average carbon chain length of feed LAOs is kept within 8 to 12 carbons.

- a relatively much lower average chain length in the feed (much below 6 carbons) of the mixed LAO would result in lower VI. Too high of a average chain length in the feed (much above 12 carbons) of the mixed LAO would result in very high pour point, around room temperature.

- Viscosity Index is an empirical, unitless number which indicates the rate of change in the viscosity of an oil within a given temperature range and is related to kinematic viscosities measured at 40°C and 100°C (typically using ASTM Method D 445). Fluids exhibiting a relatively large change in viscosity with temperature are said to have a low viscosity index.

- the low VI oil for example, will thin out at elevated temperatures faster than the high VI oil.

- the high VI oil is more desirable because it has higher viscosity at higher temperature, which translates into better or thicker lubrication film and better protection of the contacting machine elements.

- the viscosity of the high VI oil will not increase as much as the viscosity of low VI oil. This is advantageous because the excessive high viscosity of the low VI oil will decrease the efficiency of the operating machine.

- high VI oil has performance advantages in both high and low temperature operation.

- the PAOs useful in this disclosure have low pour points (PP) less than -25°C, preferably less than -30°C, and more preferably less than -35°C. As used herein, pour point is determined by ASTM D97.

- any PAO described herein may have a pour point of less than -25°C (as measured by ASTM D97), preferably less than -35°C, preferably less than -45°C, preferably less than -55°C, preferably less than -65°C, and preferably between -25°C and -75°C.

- the PAOs useful in this disclosure have a narrow molecular weight distribution (Mw/Mn) less than 2.0, preferably less than 1.95, and more preferably less than 1.9 as synthesized.

- Mw/Mn molecular weight distribution

- Mw/Mn is determined by GPC using a column for medium to low molecular weight polymers, tetrahydrofuran as solvent and polystyrene as calibration standard.

- the PAOs useful in this disclosure have a Mw of 100,000 g/mol or less, or between 2000 and 80,000 g/mol, or between 2500 and 60,000 g/mol, or between 2800 and 50,000 g/mol, or between 3360 and 40,000 g/mol.

- Preferred Mw's include those from 840 to 55,100 g/mol, or from 900 to 45,000 g/mol, or 1000 to 40,000 g/mol, or 2,000 to 37,500 g/mol.

- preferred Mw's include 2240 to 67900 g/mol and 2240 to 37200 g/mol.

- the PAOs useful in this disclosure preferably have an Mn of 50,000 g/mol or less, or 40,000 g/mol or less, or between 2000 and 40,000 g/mol, or between 2500 and 30,000 g/mol, preferably between 5000 and 20,000 g/mol.

- Preferred Mn ranges include those from 2800 to 10,000 g/mol or from 2800 to 8,000 g/mol.

- preferred Mn ranges are from 2000 to 20,900 g/mol, or 2800 to 20,000 g/mol, or 2000 to 17000 g/mol, or 2000 to 12000 g/mol, or 2800 to 29000 g/mol, or 2800 to 17000 g/mol, or 2000 to 5000 g/mol.

- the Mw and Mn are measured by GPC using a column for medium to low molecular weight polymers, tetrahydrofuran as solvent and polystyrene as calibration standard, correlated with the fluid viscosity according to a power equation.

- the PAOs described herein have a narrow molecular weight distribution of greater than 1 and less than 2, alternatively less than 1.95, alternatively less than 1.90, alternatively less than 1.85.

- the Mn and Mw are measured by gel permeation chromatography (GPC) using a column for medium to low molecular weight polymers, tetrahydrofuran as solvent and narrow molecular weight distribution polystyrene as calibration standard, correlated with the fluid viscosity according to a power equation.

- the MWD of PAO is a function of fluid viscosity.

- any of the polyalphaolefins described herein preferably have an Mw/Mn of between 1 and 2.0, alternatively between 1 and 1.95, depending on fluid viscosity.

- the PAOs useful in this disclosure have low glass transition temperature T g less than -60°C, preferably less than -70°C, and more preferably less than -80°C.

- glass transition temperature T g is determined by differential scanning calorimetry (DSC).

- DSC differential scanning calorimetry

- the polyolefin products produced in accordance with the process of this disclosure have no crystallization peak as measured by differential scanning calorimetry and high thermal stability.

- the PAOs useful in this disclosure can comprise a single alphaolefin monomer type, or may comprise two or more different alphaolefin monomers.

- this disclosure relates to PAOs comprising a molar amount of C 8 to C 12 alphaolefin monomers selected from the group consisting of 55 mol% or more, 60 mol% or more, 65 mol% or more, 70 mol% or more, 75 mol% or more, 80 mol% or more, 85 mol% or more, 90 mol% or more, 95 mol% or more, 100 mol%, all based on the total moles of monomers present in the polyalphaolefin, as measured by 13 CNMR.

- the PAOs comprise polymers of one or more alphaolefins (also known as 1-olefins) with carbon numbers of C 8 to C 12 .

- at least one of the alphaolefins is a linear alphaolefin (LAO); more preferably, all the alphaolefins are LAOS.

- LAOs include 1-octene, 1-nonene, 1-decene, 1-undecene, and 1-dodecene, and blends thereof.

- the PAO comprises polymers of two or more C 8 to C 12 LAOs to make 'copolymer' or 'terpolymer' or higher-order copolymer combinations.

- Other embodiments involve polymerization of a mixture of LAOs selected from C 8 to C 12 LAOs with even carbon numbers, preferably a mixture of two or three LAOs selected from 1-octene, 1-decene, and 1-dodecene.

- the PAO comprises polymers of a single alphaolefin species having a total carbon count of 8 to 12. In other embodiments, the PAO comprises polymers of mixed (i.e., two or more) alphaolefin species, wherein each alphaolefin species has a carbon number of 8 to 12. In other embodiments, the PAO comprises polymers of mixed alphaolefin species wherein the molar-average carbon number (“C LAO ") is 8 to 12 or 9 to 11.

- C LAO molar-average carbon number

- any PAO described herein may have a density of 0.75 to 0.96 g/cm 3 , preferably 0.80 to 0.94 g/cm 3 , alternatively from 0.76 to 0.855 g/cm 3 .

- the high viscosity PAOs useful in this disclosure are desirable for use as lubricating oil base stocks and also blend stocks with API Groups I to V or gas-to-liquid (GTL) derived lube base stocks for use in industrial and automotive engine or gear oil, especially certain high Kv 100 grades of 65 to 155 cSt which are especially desirable for use as lubricating oil base stocks or blend stocks with Groups I to V or GTL-derived lube base stocks for use in industrial and automotive engine or gear oil.

- GTL gas-to-liquid

- PAOs can be used as lubricating oil base stocks and also superior blend stocks. They can be blend stocks with any of the API Group I to V and GTL fluids to give the optimum viscometrics, solvency, high and low temperature lubricity, etc.

- the PAOs can be further blended with proper additives, including antioxidants, antiwear additives, friction modifiers, dispersants, detergents, corrosion inhibitors, defoamants, extreme pressure additives, seal swell additives, and optionally viscosity modifiers, etc. Description of typical additives can be found in the book " Lubricant Additives: Chemistry and Applications," L.R. Rudnick, ed. Marcel Dekker Inc., New York, 2001 .

- the PAOs can be produced by conventional methods known in the art.

- the high viscosity PAOs used in this disclosure is prepared from different feed olefins using metallocene catalysts.

- the metallocene catalyst system, products, process and feeds are described, for example, in U.S. Application Publication No. 2011/0136714 .

- the basestock component of the present lubricating oils will typically be from 80 to 99 weight percent of the total composition (all proportions and percentages set out in this specification are by weight unless the contrary is stated) and more usually in the range of 90 to 99 weight percent.

- the viscosity modifiers useful in the lubricating compositions of the disclosure include substantially linear polymers with a weight average molecular weight of 45,000 or less, or 35,000 or less, or 25,000 or less, or 8000 to 25,000, or 12,000 to 20,000.

- the substantially linear polymers are copolymers comprising units derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with an alcohol.

- the substantially linear polymer may be a copolymer comprising units derived from monomers (i) one or more alpha olefins and (ii) one or more alkyl (meth) acrylate esters.

- the ethylenically unsaturated carboxylic acid may be esterified with alcohol before or after polymerization with the ⁇ -olefin.

- the ethylenically unsaturated carboxylic acid may be esterified with alcohol before polymerization with the ⁇ -olefin. In one embodiment the ethylenically unsaturated carboxylic acid may be esterified with alcohol after polymerization with the ⁇ -olefin.

- a commercially available copolymer prepared by esterification before polymerization is available from Akzo Nobel sold under the tradename Ketjenlube®3700.

- the alcohol may have 1 to 40, or 1 to 30, or 4 to 20, or 6 to 16 carbon atoms.

- Examples of a suitable alcohol include 2-ethylhexanol, 2- butyloctanol, 2-hexyldecanol, 2-octyldodecanol, 2-decyltetradecanol, butanol, pentanol, hexanol, heptanol, octanol, nonanol, decanol, undecanol, dodecanol, tridecanol, tetradecanol, pentadecanol, hexadecanol, heptadecanol, octadecanol, eicosanol, or mixtures thereof.

- a copolymer of this type is described in more detail in U.S. Patent Nos. 4,526,950 , 6,419,714 , 6,573,224 , or 6,174,843 .

- the ethylenically unsaturated carboxylic acid may be esterified with alcohol after polymerization with the ⁇ -olefin.

- a copolymer of this type may be a substantially linear polymer that may in one embodiment be (a) a copolymer comprising units derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with a primary alcohol branched at the ⁇ - or higher position, wherein the copolymer typically has a reduced specific viscosity of up to 0.2, (b) a poly(meth)acrylate, or mixtures thereof.

- the substantially linear polymer may be present in the lubricating compositions described herein at 0.1 wt% to 50 wt%, or 2 wt% to 40 wt%, or 5 wt% to 30 wt%, or 8 wt% to 20 wt% of the lubricating composition.

- the lubricating composition contains 65 to 99 wt % of synthetic base stock and 1 to 35 wt % of substantially linear polymer.

- the lubricating composition contains 75 to 98 wt% of synthetic base stock and 2 to 25 wt% of substantially linear polymer.

- the substantially linear polymer may be a copolymer comprising units derived from monomers (i) one or more alpha olefins and (ii) one or more alkyl (meth)acrylate esters.

- the substantially linear polymer includes a mixtures of (a) a copolymer comprising units derived from monomers of (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with a primary alcohol, and (b) a poly(meth)acrylate.

- the poly(meth)acrylate (typically a polymethacrylate) can have units derived from a mixture of alkyl (meth)acrylate ester monomers containing (a) 8 to 24, or 12 to 18, or to 15 carbon atoms in the alcohol-derived portion of the ester group and (b) 6 to 11, or 8 to 11, or 8 carbon atoms in the alcohol-derived portion of the ester group, and which have 2-(C 1-4 alkyl)-substituents, and optionally, at least one monomer selected from the group consisting of (meth)acrylic acid esters containing 1 to 7 carbon atoms in the alcohol-derived portion of the ester group and which are different from (meth)acrylic acid esters (a) and (b), vinyl aromatic compounds (or vinyl aromatic monomers); and nitrogen-containing vinyl monomers; provided that no more than 60% by weight, or no more than 50% by weight, or no more than 35% by weight of the esters contain not more than 10 carbon atoms in the alcohol-derived portion of the ester group

- the linear polymer of this type is described in more detail in US 6,124,249 or EP 0 937 769 A1 .

- the linear polymer may further contain a third monomer.

- the third monomer may be styrene, or mixtures thereof.

- the third monomer may be present in an amount 0% to 25% of the polymer composition, or from 1% to 15% of the composition, 2% to 10% of the composition, or even from 1% to 3% of the composition.

- the mole ratio of esters (a) to esters (b) in the copolymer ranges from 95:5 to 35:65, or 90:10 to 60:40, or 80:20 to 50:50.

- the esters are usually aliphatic esters, typically alkyl esters.

- the ester of (a) may be a C 12-15 alkyl methacrylate and the ester of (b) may be 2-ethylhexyl methacrylate.

- ester groups in ester (a) contain branched alkyl groups.

- the ester groups may contain 2 to 65%, or 5 to 60% or greater of the ester groups having branched alkyl groups.

- the C 1-4 alkyl substituents may be methyl, ethyl, and any isomers of propyl and butyl.

- the weight average molecular weight of the poly(meth)acrylate may be 45,000 or less, or 35,000 or less, or 25,000 or less, or 8000 to 25,000, or 12,000 to 20,000.

- the substantially linear polymer includes a copolymer comprising units derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with a primary alcohol branched at the ⁇ - or higher position, wherein the copolymer typically has a reduced specific viscosity of up to 0.2, or up to 0.15, or up to 0.10, or up to 0.08.

- the reduced specific viscosity may be up to 0.08 (or 0.02 to 0.08 (or 0.02 to 0.07, 0.03 to 0.07 or 0.04 to 0.06).

- a measurement correlating with molecular weight of the copolymer (or interpolymer such as an alternating copolymer) may be expressed in terms of the "reduced specific viscosity" of the copolymer which is a recognized means of expressing the molecular size of a polymeric substance.

- the copolymer may be derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof, wherein 0.1 to 99.89% of the carboxylic acid units are esterified with a primary alcohol branched at the ⁇ - or higher position, wherein 0.1 to 99.89% of the carboxylic acid units are esterified with a linear alcohol or an alpha-branched alcohol (e.g., a secondary alcohol), wherein 0.01 to 10% of the carboxylic acid units has at least one of an amino-, amido- and/or imido- group, and wherein the copolymer has a reduced specific viscosity (prior to esterification) of up to 0.08.

- monomers i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof, wherein 0.1 to 99.89% of the carboxylic acid units are esterified with

- the copolymer may be derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof, wherein 0.1 to 99.89% of the carboxylic acid units are esterified with a primary alcohol branched at the ⁇ - or higher position, wherein 0.1 to 99.9% of the carboxylic acid units are esterified with a linear alcohol or an alpha-branched alcohol, wherein 0 to 10% of the carboxylic acid units has at least one of an amino-, amido- and/or imido- group, and wherein the copolymer has a reduced specific viscosity of up to 0.08.

- a linear alcohol may include methanol, ethanol, propanol, butanol, pentanol, hexanol, heptanol, octanol, nonanol, decanol, undecanol, dodecanol, tridecanol, tetradecanol, pentadecanol, hexadecanol, heptadecanol, octadecanol, nonadecanol, eicosanol, or mixtures thereof.

- the linear alcohol contains 6 to 30, or 8 to 20, or 8 to 15 carbon atoms (typically 8 to 15 carbon atoms).

- the linear alcohol may include commercially available materials such as Oxo Alcohol® 7911, Oxo Alcohol® 7900 and Oxo Alcohol® 1 100 of Monsanto; Alphanol® 79 of ICI; Nafol® 1620, Alfol® 610 and Alfol® 810 of Condea (now Sasol); Epal® 610 and Epal® 810 of Ethyl Corporation (now Afton); Linevol® 79, Linevol® 911 and Dobanol® 25 L of Shell AG; Lial® 125 of Condea Augusta, Milan; Dehydad® and Lorol® of Henkel KGaA (now Cognis) as well as Linopol® 7-11 and Acropol® 91 of Ugine Kuhlmann.

- Commercially available materials such as Oxo Alcohol® 7911, Oxo Alcohol® 7900 and Oxo Alcohol® 1 100 of Monsanto; Alphanol® 79 of ICI; Nafol® 1620, Alfol® 610 and Alfo

- the copolymer may be derived from monomers of (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof, wherein 5 to 15% of the carboxylic acid units are esterified with a primary alcohol branched at the ⁇ - or higher position, wherein 0.1 to 95% of the carboxylic acid units are esterified with a linear alcohol or an alpha-branched alcohol, wherein 0 to less than 2% of the carboxylic acid units has at least one of an amino-, amido- and/or imido- group, and wherein the copolymer has a reduced specific viscosity of up to 0.08.

- the copolymer comprises units derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof esterified with a primary alcohol branched at the ⁇ - or higher position.

- the copolymer may be represented by the formula below. Ester or other groups with the primary alcohol-derived moiety branched at the ⁇ - or higher position may be represented within the ( ) w shown in the formula: wherein

- the copolymer with pendant groups may contain 0.10% to 100%, or 0.5% to 20%, or 0.75% to 10%, branched hydrocarbyl groups represented by a group within ( ) y of the formula (I) above, expressed as a percentage of the total number of pendant groups .

- the pendant groups of formula (1) may also be used to define the ester groups as defined above by the phrase "esterified with a primary alcohol branched at the ⁇ - or higher position".

- X may be derived from an ethylenically unsaturated carboxylic acid or derivatives thereof.

- a suitable carboxylic acid or derivatives thereof typically include maleic anhydride, maleic acid, (meth)acrylic acid, itaconic anhydride or itaconic acid.

- the ethylenically unsaturated carboxylic acid or derivatives thereof may be at least one of maleic anhydride or maleic acid.

- X is other than an alkylene group, connecting the copolymer backbone and the branched hydrocarbyl groups.

- the pendant groups may be esterified, amidated or imidated functional groups.

- the pendant groups may be derived from esterified and/or amidated functional groups.

- the copolymer includes esterified pendant groups.

- the pendant groups may be derived from Guerbet alcohols.

- the Guerbet alcohols may contain 10 to 60, or 12 to 60, or 16 to 40 carbon atoms.

- the primary alcohol branched at the ⁇ - or higher position described herein may be a Guerbet alcohol. Methods to prepare Guerbet alcohols are disclosed in U.S. Patent No. 4,767,815 .

- the pendant groups may contain a total combined number of carbon atoms on R' and R"in the range of 12 to 60, or 14 to 50, or 16 to 40, or 18 to 40, or 20 to 36.

- Each of R' and R" may individually contain 5 to 25, or 8 to 32, or 10 to 18 methylene carbon atoms. In one embodiment the number of carbon atoms on each R' and R"group maybe 10 to 24.

- Suitable primary alcohol branched at the ⁇ - or higher position examples include 2-ethylhexanol, 2-propyl heptanol, 2-butyloctanol, 2-hexyldecanol, 2-octyldodecanol, 2-decyltetradecanol, or mixtures thereof.

- the ethylenically unsaturated carboxylic acid or derivatives thereof may be an acid or anhydride or derivatives thereof that may be wholly esterified, partially esterified or mixtures thereof.

- other functional groups include acids, salts or mixtures thereof.

- Suitable salts include alkali metals, alkaline earth metals or mixtures thereof.

- the salts include lithium, sodium, potassium, magnesium, calcium or mixtures thereof.

- the unsaturated carboxylic acid or derivatives thereof includes acrylic acid, methyl acrylate, methacrylic acid, maleic acid or anhydride, fumaric acid, itaconic acid or anhydride or mixtures thereof, or substituted equivalents thereof.

- Suitable examples of the ethylenically unsaturated carboxylic acid or derivatives thereof include itaconic anhydride, maleic anhydride, methyl maleic anhydride, ethyl maleic anhydride, dimethyl maleic anhydride or mixtures thereof.

- the ethylenically unsaturated carboxylic acid or derivatives thereof includes maleic anhydride or derivatives thereof.

- Examples of an alpha-olefin include 1-decene, 1-undecene, 1-dodecene, 1-tridecene, 1-tetradecene, 1-pentadecene, 1-hexadecene, 1-hepta-decene, 1-octadecene, or mixtures thereof.

- An example of a useful alpha-olefm is 1-dodecene.

- the alpha-olefin may be a branched alpha-olefin, or mixtures thereof. If the ⁇ -olefin is branched, the number of carbon atoms of the ⁇ -olefin may range from 4 to 32, or 6 to 20, or 8 to 16.

- the copolymer of the disclosure further includes a nitrogen containing group such as those disclosed above.

- the nitrogen containing group may be derived from a nitrogen containing compound capable of being incorporated during copolymerization.

- the copolymer of the disclosure further includes a nitrogen containing group that may be capable of reacting with the functionalized copolymer backbone, typically for capping the copolymer backbone. The capping may result in the copolymer having ester, amide, imide or amine groups.

- the nitrogen group is described in more detail in PCT Patent Application No. PCT/US09/052028 .

- the copolymer comprises units derived from monomers (i) an ⁇ -olefin and (ii) an ethylenically unsaturated carboxylic acid or derivatives thereof may be further reacted with an amine to additionally provide oxidation control.

- the copolymer with oxidation control contains an incorporated residue of an amine-containing compound such as morpholines, pyrrolidinones, imidazolidinones, acetamides, ⁇ -alanine alkyl esters, or mixtures thereof.

- nitrogen-containing compounds examples include 3-morpholin-4-yl-propylamine, 3-morpholin-4-yl-ethylamine, [beta]-alanine alkyl esters (typically alkyl esters have 1 to 30, or 6 to 20 carbon atoms), or mixtures thereof.

- the compounds based on imidazolidinones, cyclic carbamates or pyrrolidinones may be derived from a compound of general structure: wherein:

- the imidazolidinone includes 1-(2-amino-ethyl)-imidazolidin-2-one (may also be called aminoethylethyleneurea), 1-(3-amino-propyl)-imidazolidin-2-one, 1-(2-hydroxy-ethyl)-imidazolidin-2-one, 1-(3-amino-propyl)-pyrrolidin-2-one, 1-(3-amino-ethyl)-pyrrolidin-2-one, or mixtures thereof.

- 1-(2-amino-ethyl)-imidazolidin-2-one may also be called aminoethylethyleneurea

- 1-(3-amino-propyl)-imidazolidin-2-one 1-(2-hydroxy-ethyl)-imidazolidin-2-one

- 1-(3-amino-propyl)-pyrrolidin-2-one 1-(3-amino-ethyl)-pyrrolidin-2-one

- the copolymer may be reacted with an amine-containing compound selected from morpholines, imidazolidinones, and mixtures thereof.

- the formulated lubricating oil useful in the present disclosure may additionally contain one or more of the other commonly used lubricating oil performance additives including but not limited to dispersants, other detergents, corrosion inhibitors, rust inhibitors, metal deactivators, other antiwear agents and/or extreme pressure additives, anti-seizure agents, wax modifiers, viscosity index improvers, fluid-loss additives, seal compatibility agents, other friction modifiers, lubricity agents, antistaining agents, chromophoric agents, defoamants, demulsifiers, emulsifiers, densifiers, wetting agents, gelling agents, tackiness agents, colorants, and others.

- dispersants including but not limited to dispersants, other detergents, corrosion inhibitors, rust inhibitors, metal deactivators, other antiwear agents and/or extreme pressure additives, anti-seizure agents, wax modifiers, viscosity index improvers, fluid-loss additives, seal compatibility agents, other friction

- Typical antioxidant include phenolic antioxidants, aminic antioxidants and oil-soluble copper complexes.

- the phenolic antioxidants include sulfurized and non-sulfurized phenolic antioxidants.

- the terms "phenolic type” or “phenolic antioxidant” used herein includes compounds having one or more than one hydroxyl group bound to an aromatic ring which may itself be mononuclear, e.g., benzyl, or poly-nuclear, e.g., naphthyl and spiro aromatic compounds.

- phenol type includes phenol per se, catechol, resorcinol, hydroquinone, naphthol, etc., as well as alkyl or alkenyl and sulfurized alkyl or alkenyl derivatives thereof, and bisphenol type compounds including such bi-phenol compounds linked by alkylene bridges sulfuric bridges or oxygen bridges.

- Alkyl phenols include mono- and poly-alkyl or alkenyl phenols, the alkyl or alkenyl group containing from 3-100 carbons, preferably 4 to 50 carbons and sulfurized derivatives thereof, the number of alkyl or alkenyl groups present in the aromatic ring ranging from 1 to up to the available unsatisfied valences of the aromatic ring remaining after counting the number of hydroxyl groups bound to the aromatic ring.

- the phenolic anti-oxidant may be represented by the general formula: (R) x -Ar-(OH) y where Ar is selected from the group consisting of: wherein R is a C 3 -C 100 alkyl or alkenyl group, a sulfur substituted alkyl or alkenyl group, preferably a C 4 -C 50 alkyl or alkenyl group or sulfur substituted alkyl or alkenyl group, more preferably C 3 -C 100 alkyl or sulfur substituted alkyl group, most preferably a C 4 -C 50 alkyl group, R g is a C 1 -C 100 alkylene or sulfur substituted alkylene group, preferably a C 2 -C 50 alkylene or sulfur substituted alkylene group, more preferably a C 2 -C 2 alkylene or sulfur substituted alkylene group, y is at least 1 to up to the available valences of Ar, x ranges from 0 to up to the available valences of Ar

- Preferred phenolic antioxidant compounds are the hindered phenolics and phenolic esters which contain a sterically hindered hydroxyl group, and these include those derivatives of dihydroxy aryl compounds in which the hydroxyl groups are in the o- or p-position to each other.

- Typical phenolic anti-oxidants include the hindered phenols substituted with C 1 + alkyl groups and the alkylene coupled derivatives of these hindered phenols.

- phenolic materials of this type 2-t-butyl-4-heptyl phenol; 2-t-butyl-4-octyl phenol; 2-t-butyl-4-dodecyl phenol; 2,6-di-t-butyl-4-heptyl phenol; 2,6-di-t-butyl-4-dodecyl phenol; 2-methyl-6-t-butyl-4-heptyl phenol; 2-methyl-6-t-butyl-4-dodecyl phenol; 2,6-di-t-butyl-4 methyl phenol; 2,6-di-t-butyl-4-ethyl phenol; and 2,6-di-t-butyl 4 alkoxy phenol; and

- Phenolic type antioxidants are well known in the lubricating industry and commercial examples such as Ethanox® 4710, Irganox® 1076, Irganox® L1035, Irganox® 1010, Irganox® L109, Irganox® L118, Irganox® L135 and the like are familiar to those skilled in the art. The above is presented only by way of exemplification, not limitation on the type of phenolic anti-oxidants which can be used.

- the phenolic antioxidant can be employed in an amount in the range of 0.1 to 3 wt%, preferably 0.25 to 2.5 wt%, more preferably 0.5 to 2 wt% on an active ingredient basis.

- Aromatic amine antioxidants include phenyl- ⁇ -naphthyl amine which is described by the following molecular structure: wherein R z is hydrogen or a C 1 to C 14 linear or C 3 to C 14 branched alkyl group, preferably C 1 to C 10 linear or C 3 to C 10 branched alkyl group, more preferably linear or branched C 6 to C 8 and n is an integer ranging from 1 to 5 preferably 1.

- R z is hydrogen or a C 1 to C 14 linear or C 3 to C 14 branched alkyl group, preferably C 1 to C 10 linear or C 3 to C 10 branched alkyl group, more preferably linear or branched C 6 to C 8 and n is an integer ranging from 1 to 5 preferably 1.

- a particular example is Irganox L06.

- aromatic amine antioxidants include other alkylated and non-alkylated aromatic amines such as aromatic monoamines of the formula R 8 R 9 R 10 N where R 8 is an aliphatic, aromatic or substituted aromatic group, R 9 is an aromatic or a substituted aromatic group, and R 10 is H, alkyl, aryl or R 11 S(O) x R 12 where R 11 is an alkylene, alkenylene, or aralkylene group, R 12 is a higher alkyl group, or an alkenyl, aryl, or alkaryl group, and x is 0, 1 or 2.

- the aliphatic group R 8 may contain from 1 to 20 carbon atoms, and preferably contains from 6 to 12 carbon atoms.

- the aliphatic group is a saturated aliphatic group.

- both R 8 and R 9 are aromatic or substituted aromatic groups, and the aromatic group may be a fused ring aromatic group such as naphthyl.

- Aromatic groups R 8 and R 9 may be joined together with other groups such as S.

- Typical aromatic amines anti-oxidants have alkyl substituent groups of at least 6 carbon atoms.

- Examples of aliphatic groups include hexyl, heptyl, octyl, nonyl, and decyl. Generally, the aliphatic groups will not contain more than 14 carbon atoms.

- the general types of such other additional amine antioxidants which may be present include diphenylamines, phenothiazines, imidodibenzyls and diphenyl phenylene diamines. Mixtures of two or more of such other additional aromatic amines may also be present. Polymeric amine antioxidants can also be used.

- oil-soluble copper compounds are oil-soluble copper compounds. Any oil-soluble suitable copper compound may be blended into the lubricating oil.

- suitable copper antioxidants include copper dihydrocarbyl thio- or dithio-phosphates and copper salts of carboxylic acid (naturally occurring or synthetic).

- suitable copper salts include copper dithiacarbamates, sulphonates, phenates, and acetylacetonates.

- Basic, neutral, or acidic copper Cu(I) and or Cu(II) salts derived from alkenyl succinic acids or anhydrides are known to be particularly useful.

- antioxidants may be used individually or as mixtures of one or more types of antioxidants, the total amount employed being an amount of 0.50 to 5 wt%, preferably 0.75 to 3 wt% (on an as-received basis).

- alkali or alkaline earth metal salicylate detergent which is an optional component in the present disclosure

- other detergents may also be present. While such other detergents can be present, it is preferred that the amount employed be such as to not interfere with the synergistic effect attributable to the presence of the salicylate. Therefore, most preferably such other detergents are not employed.

- additional detergents can include alkali and alkaline earth metal phenates, sulfonates, carboxylates, phosphonates and mixtures thereof.

- These supplemental detergents can have total base number (TBN) ranging from neutral to highly overbased, i.e. TBN of 0 to over 500, preferably 2 to 400, more preferably 5 to 300, and they can be present either individually or in combination with each other in an amount in the range of from 0 to 10 wt%, preferably 0.5 to 5 wt% (active ingredient) based on the total weight of the formulated lubricating oil.

- TBN total base number

- Such additional other detergents include by way of example and not limitation calcium phenates, calcium sulfonates, magnesium phenates, magnesium sulfonates and other related components (including borated detergents).

- Dispersants help keep these byproducts in solution, thus diminishing their deposition on metal surfaces.

- Dispersants may be ashless or ash-forming in nature.

- the dispersant is ashless.

- So called ashless dispersants are organic materials that form substantially no ash upon combustion.

- non-metal-containing or borated metal-free dispersants are considered ashless.

- metal-containing detergents discussed above form ash upon combustion.

- Suitable dispersants typically contain a polar group attached to a relatively high molecular weight hydrocarbon chain.

- the polar group typically contains at least one element of nitrogen, oxygen, or phosphorus.

- Typical hydrocarbon chains contain 50 to 400 carbon atoms.

- a particularly useful class of dispersants are the alkenylsuccinic derivatives, typically produced by the reaction of a long chain substituted alkenyl succinic compound, usually a substituted succinic anhydride, with a polyhydroxy or polyamino compound.

- the long chain group constituting the oleophilic portion of the molecule which confers solubility in the oil, is normally a polyisobutylene group.

- Hydrocarbyl-substituted succinic acid compounds are popular dispersants.

- succinimide, succinate esters, or succinate ester amides prepared by the reaction of a hydrocarbon-substituted succinic acid compound preferably having at least 50 carbon atoms in the hydrocarbon substituent, with at least one equivalent of an alkylene amine are particularly useful.

- Succinimides are formed by the condensation reaction between alkenyl succinic anhydrides and amines. Molar ratios can vary depending on the amine or polyamine. For example, the molar ratio of alkenyl succinic anhydride to TEPA can vary from 1:1 to 5:1.

- Succinate esters are formed by the condensation reaction between alkenyl succinic anhydrides and alcohols or polyols. Molar ratios can vary depending on the alcohol or polyol used. For example, the condensation product of an alkenyl succinic anhydride and pentaerythritol is a useful dispersant.

- Succinate ester amides are formed by condensation reaction between alkenyl succinic anhydrides and alkanol amines.

- suitable alkanol amines include ethoxylated polyalkylpolyamines, propoxylated polyalkylpolyamines and polyalkenylpolyamines such as polyethylene polyamines.

- propoxylated hexamethylenediamine is propoxylated hexamethylenediamine.

- the molecular weight of the alkenyl succinic anhydrides will typically range between 800 and 2,500.

- the above products can be post-reacted with various reagents such as sulfur, oxygen, formaldehyde, carboxylic acids such as oleic acid, and boron compounds such as borate esters or highly borated dispersants.

- the dispersants can be borated with from 0.1 to 5 moles of boron per mole of dispersant reaction product.

- Mannich base dispersants are made from the reaction of alkylphenols, formaldehyde, and amines. Process aids and catalysts, such as oleic acid and sulfonic acids, can also be part of the reaction mixture. Molecular weights of the alkylphenols range from 800 to 2,500 or more.

- Typical high molecular weight aliphatic acid modified Mannich condensation products can be prepared from high molecular weight alkyl-substituted hydroxyaromatics or HN(R) 2 group-containing reactants.

- high molecular weight alkyl-substituted hydroxyaromatic compounds are polypropylphenol, polybutylphenol, and other polyalkylphenols. These polyalkylphenols can be obtained by the alkylation, in the presence of an alkylating catalyst, such as BF 3 , of phenol with high molecular weight polypropylene, polybutylene, and other polyalkylene compounds to give alkyl substituents on the benzene ring of phenol having an average 600-100,000 molecular weight.

- an alkylating catalyst such as BF 3

- HN(R) 2 group-containing reactants are alkylene polyamines, principally polyethylene polyamines.

- Other representative organic compounds containing at least one HN(R) 2 group suitable for use in the preparation of Mannich condensation products are well known and include the mono- and di-amino alkanes and their substituted analogs, e.g., ethylamine and diethanol amine; aromatic diamines, e.g., phenylene diamine, diamino naphthalenes; heterocyclic amines, e.g., morpholine, pyrrole, pyrrolidine, imidazole, imidazolidine, and piperidine; melamine and their substituted analogs.

- alkylene polyamine reactants include ethylenediamine, diethylene triamine, triethylene tetraamine, tetraethylene pentaamine, pentaethylene hexamine, hexaethylene heptaamine, heptaethylene octaamine, octaethylene nonaamine, nonaethylene decamine, and decaethylene undecamine and mixture of such amines having nitrogen contents corresponding to the alkylene polyamines, in the formula H 2 N-(Z-NH-) n H, mentioned before, Z is a divalent ethylene and n is 1 to 10 of the foregoing formula.

- propylene polyamines such as propylene diamine and di-, tri-, tetra-, pentapropylene tri-, tetra-, penta- and hexaamines are also suitable reactants.

- the alkylene polyamines are usually obtained by the reaction of ammonia and dihalo alkanes, such as dichloro alkanes.

- the alkylene polyamines obtained from the reaction of 2 to 11 moles of ammonia with 1 to 10 moles of dichloroalkanes having 2 to 6 carbon atoms and the chlorines on different carbons are suitable alkylene polyamine reactants.

- Aldehyde reactants useful in the preparation of the high molecular products useful in this disclosure include the aliphatic aldehydes such as formaldehyde (also as paraformaldehyde and formalin), acetaldehyde and aldol ( ⁇ -hydroxybutyraldehyde). Formaldehyde or a formaldehyde-yielding reactant is preferred.

- Preferred dispersants include borated and non-borated succinimides, including those derivatives from mono-succinimides, bis-succinimides, and/or mixtures of mono- and bis-succinimides, wherein the hydrocarbyl succinimide is derived from a hydrocarbylene group such as polyisobutylene having a Mn of from 500 to 5000 or more or a mixture of such hydrocarbylene groups.

- Other preferred dispersants include succinic acid-esters and amides, alkylphenol-polyamine-coupled Mannich adducts, their capped derivatives, and other related components.

- Such additives may be used in an amount of 0.1 to 20 wt%, preferably 0.1 to 8 wt%, more preferably 1 to 6 wt% (on an as-received basis) based on the weight of the total lubricant.

- pour point depressants also known as lube oil flow improvers

- Pour point depressant may be added to lower the minimum temperature at which the fluid will flow or can be poured.

- suitable pour point depressants include alkylated naphthalenes polymethacrylates, polyacrylates, polyarylamides, condensation products of haloparaffin waxes and aromatic compounds, vinyl carboxylate polymers, and terpolymers of dialkylfumarates, vinyl esters of fatty acids and allyl vinyl ethers.

- Such additives may be used in amount of 0.0 to 0.5 wt%, preferably 0 to 0.3 wt%, more preferably 0.001 to 0.1 wt% on an as-received basis.

- Corrosion inhibitors are used to reduce the degradation of metallic parts that are in contact with the lubricating oil composition.

- Suitable corrosion inhibitors include aryl thiazines, alkyl substituted dimercapto thiodiazoles thiadiazoles and mixtures thereof.

- Such additives may be used in an amount of 0.01 to 5 wt%, preferably 0.01 to 1.5 wt%, more preferably 0.01 to 0.2 wt%, still more preferably 0.01 to 0.1 wt% (on an as-received basis) based on the total weight of the lubricating oil composition.

- Seal compatibility agents help to swell elastomeric seals by causing a chemical reaction in the fluid or physical change in the elastomer.

- Suitable seal compatibility agents for lubricating oils include organic phosphates, aromatic esters, aromatic hydrocarbons, esters (butylbenzyl phthalate, for example), and polybutenyl succinic anhydride and sulfolane-type seal swell agents such as Lubrizol 730-type seal swell additives. Such additives may be used in an amount of 0.01 to 3 wt%, preferably 0.01 to 2 wt% on an as-received basis.

- Anti-foam agents may advantageously be added to lubricant compositions. These agents retard the formation of stable foams. Silicones and organic polymers are typical anti-foam agents. For example, polysiloxanes, such as silicon oil or polydimethyl siloxane, provide antifoam properties. Anti-foam agents are commercially available and may be used in conventional minor amounts along with other additives such as demulsifiers; usually the amount of these additives combined is less than 1 percent, preferably 0.001 to 0.5 wt%, more preferably 0.001 to 0.2 wt%, still more preferably 0.0001 to 0.15 wt% (on an as-received basis) based on the total weight of the lubricating oil composition.

- Antirust additives are additives that protect lubricated metal surfaces against chemical attack by water or other contaminants.

- One type of antirust additive is a polar compound that wets the metal surface preferentially, protecting it with a film of oil.

- Another type of antirust additive absorbs water by incorporating it in a water-in-oil emulsion so that only the oil touches the surface.

- Yet another type of antirust additive chemically adheres to the metal to produce a nonreactive surface.

- suitable additives include zinc dithiophosphates, metal phenolates, basic metal sulfonates, fatty acids and amines. Such additives may be used in an amount of 0.01 to 5 wt%, preferably 0.01 to 1.5 wt% on an as-received basis.

- organo molybdenum-nitrogen complexes embraces the organo molybdenum-nitrogen complexes described in U.S. Patent 4,889,647 .

- the complexes are reaction products of a fatty oil, dithanolamine and a molybdenum source. Specific chemical structures have not been assigned to the complexes.

- U.S. Patent 4,889,647 reports an infrared spectrum for a typical reaction product of that disclosure; the spectrum identifies an ester carbonyl band at 1740 cm -1 and an amide carbonyl band at 1620 cm -1 .

- the fatty oils are glyceryl esters of higher fatty acids containing at least 12 carbon atoms up to 22 carbon atoms or more.

- the molybdenum source is an oxygen-containing compound such as ammonium molybdates, molybdenum oxides and mixtures.

- organo molybdenum complexes which can be used in the present disclosure are tri-nuclear molybdenum-sulfur compounds described in EP 1 040 115 and WO 99/31113 and the molybdenum complexes described in U.S. Patent No. 4,978,464 .

- the lubricating composition may optionally further contain other known viscosity modifiers.

- the viscosity modifiers may be hydrogenated styrene-butadiene rubbers, ethylenepropylene copolymers, hydrogenated styrene-isoprene polymers, hydrogenated diene polymers, polyalkyl styrenes, polyolefins, esters of maleic anhydride-styrene copolymers, or mixtures thereof.

- the lubricating compositions can include at least one antiwear agent.

- suitable antiwear agents include oil soluble amine salts of phosphorus compounds, sulphurised olefins, metal dihydrocarbyldithio-phosphates (such as zinc dialkyldithiophosphates), thiocarbamate-containing compounds, such as thiocarbamate esters, thiocarbamate amides, thiocarbamic ethers, alkylene-coupled thiocarbamates, and bis(S-alkyldithiocarbamyl) disulphides.

- the oil soluble phosphorus amine salt antiwear agent includes an amine salt of a phosphorus acid ester or mixtures thereof.

- the amine salt of a phosphorus acid ester includes phosphoric acid esters and amine salts thereof; dialkyldithiophosphoric acid esters and amine salts thereof; amine salts of phosphites; and amine salts of phosphorus-containing carboxylic esters, ethers, and amides; and mixtures thereof.

- the amine salt of a phosphorus acid ester may be used alone or in combination.

- the oil soluble phosphorus amine salt includes partial amine salt-partial metal salt compounds or mixtures thereof.

- the phosphorus compound further includes a sulphur atom in the molecule.

- the amine salt of the phosphorus compound may be ashless, i.e., metal-free (prior to being mixed with other components).

- the amines which may be suitable for use as the amine salt include primary amines, secondary amines, tertiary amines, and mixtures thereof.

- the amines include those with at least one hydrocarbyl group, or, in certain embodiments, two or three hydrocarbyl groups.