EP2869782B1 - Système d'ancrage - Google Patents

Système d'ancrage Download PDFInfo

- Publication number

- EP2869782B1 EP2869782B1 EP13732835.7A EP13732835A EP2869782B1 EP 2869782 B1 EP2869782 B1 EP 2869782B1 EP 13732835 A EP13732835 A EP 13732835A EP 2869782 B1 EP2869782 B1 EP 2869782B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- soft tissue

- abutment

- tissue level

- abutment part

- screw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 210000004872 soft tissue Anatomy 0.000 claims description 100

- 239000004053 dental implant Substances 0.000 claims description 46

- 210000000988 bone and bone Anatomy 0.000 claims description 21

- 210000003128 head Anatomy 0.000 description 9

- 239000007943 implant Substances 0.000 description 9

- 230000010485 coping Effects 0.000 description 7

- 230000035876 healing Effects 0.000 description 6

- 238000000034 method Methods 0.000 description 6

- 210000001519 tissue Anatomy 0.000 description 4

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 2

- 239000004568 cement Substances 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 210000000214 mouth Anatomy 0.000 description 1

- 238000010883 osseointegration Methods 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C8/00—Means to be fixed to the jaw-bone for consolidating natural teeth or for fixing dental prostheses thereon; Dental implants; Implanting tools

- A61C8/0048—Connecting the upper structure to the implant, e.g. bridging bars

- A61C8/005—Connecting devices for joining an upper structure with an implant member, e.g. spacers

- A61C8/0068—Connecting devices for joining an upper structure with an implant member, e.g. spacers with an additional screw

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C8/00—Means to be fixed to the jaw-bone for consolidating natural teeth or for fixing dental prostheses thereon; Dental implants; Implanting tools

- A61C8/0048—Connecting the upper structure to the implant, e.g. bridging bars

- A61C8/005—Connecting devices for joining an upper structure with an implant member, e.g. spacers

- A61C8/0066—Connecting devices for joining an upper structure with an implant member, e.g. spacers with positioning means

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C8/00—Means to be fixed to the jaw-bone for consolidating natural teeth or for fixing dental prostheses thereon; Dental implants; Implanting tools

- A61C8/0048—Connecting the upper structure to the implant, e.g. bridging bars

- A61C8/0078—Connecting the upper structure to the implant, e.g. bridging bars with platform switching, i.e. platform between implant and abutment

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C8/00—Means to be fixed to the jaw-bone for consolidating natural teeth or for fixing dental prostheses thereon; Dental implants; Implanting tools

- A61C8/008—Healing caps or the like

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C8/00—Means to be fixed to the jaw-bone for consolidating natural teeth or for fixing dental prostheses thereon; Dental implants; Implanting tools

- A61C8/0048—Connecting the upper structure to the implant, e.g. bridging bars

- A61C8/005—Connecting devices for joining an upper structure with an implant member, e.g. spacers

- A61C8/006—Connecting devices for joining an upper structure with an implant member, e.g. spacers with polygonal positional means, e.g. hexagonal or octagonal

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C8/00—Means to be fixed to the jaw-bone for consolidating natural teeth or for fixing dental prostheses thereon; Dental implants; Implanting tools

- A61C8/0048—Connecting the upper structure to the implant, e.g. bridging bars

- A61C8/005—Connecting devices for joining an upper structure with an implant member, e.g. spacers

- A61C8/0069—Connecting devices for joining an upper structure with an implant member, e.g. spacers tapered or conical connection

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2270/00—Control; Monitoring or safety arrangements

- F04C2270/04—Force

- F04C2270/042—Force radial

- F04C2270/0421—Controlled or regulated

Definitions

- the present invention relates to an abutment system.

- US5810592 discloses a dental implant system made from four pieces: a rounded equilateral triangle shaped healing abutment, a large bolt member, a matching abutment head, and a small bolt member.

- the healing abutment has an intermediate shoulder for accommodating the gingival tissues which surround the patient's jawbone. Further, the matching abutment head is secured on the healing abutment for supporting a tooth analogue.

- the large bolt member is used for fastening the healing abutment to an implant fixture.

- the small bolt member is for securing the abutment head to the healing abutment.

- the dental implant system in US5810592 appears only to support a cement-retained tooth analogue.

- US5040983 (Binon ) discloses a coping fixed on a dental implant fixture installed in a jawbone.

- a transmucosal component, penetrating the overlying gum tissue, is fixed to the implant fixture with a screw, the head portion of which has an internally-threaded socket which receives a bolt cooperating with a shoulder to fix the coping on the transmucosal component.

- the coping is intended for use in removably fixing a temporary dental restoration on the support consisting of the dental implant fixture and its transmucosal component, where a permanent prosthodontic restoration will eventually be fixed.

- the temporary dental restoration is mounted on and around the coping.

- the system in US5040983 supports only a screw-retained prosthodontic restoration.

- US 5,439,380 A discloses abutment posts, gingival collars, and universal adaptors along with their fixation screws that are used for insertion into dental implants.

- the adaptor is universal in that it matches to many different shaped, sized, and styled implants, and standardizes their restoration with uniform gingival collars and abutment posts.

- a gingival collar of varying sizes which extends from the top of the flange of the adaptor to the height of the gingival tissue, is used to bring the restoration of the implant into the oral cavity.

- a post becomes connected to the gingival collar. The post and the gingival collar are cast into metal to create a restoration for the placement of a crown or coping over the implant.

- an abutment system comprising: a soft tissue level abutment part adapted to be attached to a bone level dental implant by means of an abutment screw, wherein the abutment system is adapted to selectively support both a cement-retained final restoration and a screw-retained prosthetic component. That is, either a cement-retained final restoration or a screw-retained prosthetic component can be supported using the same soft tissue level abutment part. This makes the abutment system flexible to use.

- the abutment system may further comprise a coronal abutment part adapted to be attached to the soft tissue level abutment part by means of a further screw, wherein the coronal abutment part further is adapted to support the cement-retained final restoration.

- the prosthetic component may be a screw-retained final restoration adapted to be directly attached to the soft tissue level abutment part by means of a further screw.

- the abutment screw has a coronal internally threaded portion, wherein the further screw has an apical externally threaded portion for engagement with the coronal internally threaded portion of the abutment screw.

- the soft tissue level abutment part has a flat circumferential top surface at the outer perimeter of the coronal end of the soft tissue level abutment part.

- the soft tissue level abutment part has at least one indexing element exposed to the coronal end of the soft tissue level abutment part for preventing rotation of a component attached to the soft tissue level abutment part.

- the flat circumferential top surface has an inner circular perimeter, wherein the at least one indexing element is at least one lobe extending apically from the inner circular perimeter.

- the soft tissue level abutment part has an outer surface devised for exposure to soft tissue.

- the outer surface is curved in the coronal-apical direction of the soft tissue level abutment part.

- the curved outer surface may extend from a larger coronal diameter to a smaller apical diameter first in a convex shape and then in a concave shape.

- the soft tissue level abutment part has an external surface adapted to abut against an internal connection surface of the bone level dental implant.

- the abutment system may comprise several soft tissue level abutment parts (of the general type described above) with different diameters and/or heights.

- Another aspect not being part of the claimed invention relates to the use of an abutment system as described above to selectively support both a cement-retained final restoration and a screw-retained prosthetic component.

- This aspect may exhibit the same or similar features and advantages as the previously described aspect, and vice versa.

- a dental method which comprises: providing an abutment system including a universal soft tissue level abutment part adapted to be attached to a bone level dental implant; and attaching the universal soft tissue level abutment part to the bone level dental implant installed in the jawbone of a patient, wherein the abutment system is adapted to selectively support both a cement-retained final restoration and a screw-retained final restoration.

- This aspect may exhibit the same or similar features and advantages as the previously described aspects, and vice versa.

- the universal soft tissue level abutment part may remain attached to the bone level dental implant during subsequent steps of the method, which include: selecting one of a cement-retained final restoration and a screw- retained final restoration; and attaching the selected final restoration to the abutment system.

- the universal soft tissue level abutment part may be attached to the bone level dental implant immediately after the bone level dental implant is installed in the jawbone of the patient.

- the bone level dental implant may be allowed to at least partly osseointegrate before the selected final restoration is attached.

- the bone level dental implant may be installed in the jawbone such that the coronal end of the bone level dental implant is substantially in level with the edge of the jawbone.

- the attached universal soft tissue level abutment part may have an outer surface exposed to soft tissue.

- a dental method wherein a universal soft tissue level abutment part of an abutment system is attached to a bone level dental implant installed in the jawbone of a patient, and wherein the abutment system is adapted to selectively support both a cement-retained final restoration and a screw-retained final restoration, which method comprises: selecting one of a cement-retained final restoration and a screw-retained final restoration; and attaching the selected final restoration to the abutment system.

- This aspect may exhibit the same or similar features and advantages as the previously described aspects, and vice versa.

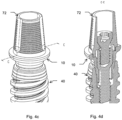

- Figs, la-b show a (universal) soft tissue level abutment part 10 of an abutment system 12.

- the soft tissue level abutment part 10 is 'universal' in that it can be used with both a cement-retained final restoration and a screw-retained prosthetic component, as will be explained further below.

- the soft tissue level abutment part 10 is preferably made in one piece, and it can be made of for example titanium or ceramic material (e.g. zirconia).

- the soft tissue level abutment part 10 has a coronal end 14 and an apical end 16. At the coronal end 14, the soft tissue level abutment part 10 has a flat circumferential top surface 18 at the outer perimeter of the soft tissue level abutment part 10.

- the flat circumferential top surface 18 allows for an effective seal without any cement or the like against another component having a corresponding flat surface.

- the flat circumferential top surface 18 has an inner perimeter 20 which may be circular.

- the inner circular perimeter 20 accommodates at least one indexing element, here in the form of three concave lobes 22a-c uniformly distributed about the inner circular perimeter 20.

- the three concave lobes 22a-c extends apically from the inner circular perimeter 20, in an inner side wall 24 of the soft tissue level abutment part 10.

- the indexing elements prevents rotation (around the longitudinal axis 26 of the soft tissue level abutment part 10) of a component having corresponding indexing elements being attached to the soft tissue level abutment part 10.

- Such a component may for instance be a screw-retained single restoration (crown). However, a component without corresponding indexing elements may not be prevented to rotate.

- Such a component may (only) have a circular interface corresponding to the inner circular perimeter 20. It is appreciated that other indexing elements are possible, for example convex lobes (not shown) instead of the concave lobes 22a-c. Also, the number of indexing elements may be varied.

- the soft tissue level abutment part 10 Extending apically from the flat circumferential top surface 18, the soft tissue level abutment part 10 further has an outer surface 28 devised for exposure to soft tissue or gum. Hence the term 'soft tissue level' abutment part 10.

- the outer surface 28 may have a length L that is greater than its height H, in order to increase the soft tissue contact length and improve soft tissue health.

- the length may for example be about 2.5 mm, while the height may be about 2 mm.

- the limited height or low profile of the soft tissue level abutment part 10 also enables healing without unnecessary loading of the dental implant (see below).

- the outer surface 28 is at least partly curved between its coronal and apical ends.

- the curved outer surface 28 extends from a larger coronal diameter DI to a smaller coronal diameter D2, first in a convex shape 30a and then in a concave shape 30b.

- the outer surface 28 can comprise straight portions that are inclined in relation to each other.

- the outer surface 28 may be provided with one or several circumferential or ring-shaped grooves (not shown), whereby sufficient length and additional geometrical locking of the soft tissue may be established.

- a lower (apical) portion of the outer surface 28 may be roughened for improved stabilization.

- the outer surface 28 transitions apically into an external surface 32 of the soft tissue level abutment part 10.

- the external surface 32 is generally adapted to abut against an internal connection surface of a bone level dental implant, as will be explained further below.

- the external surface 32 may be straight but inclined with respect to the longitudinal axis 26 of the soft tissue level abutment part 10, with a decreasing diameter towards the apical end 16 of the soft tissue level abutment part 10. In other words, a conical portion is formed on the soft tissue level abutment part 10.

- the external surface may be parallel to the longitudinal axis 26 of the soft tissue level abutment part 10, depending on what implant the soft tissue level abutment part 10 should be attached to.

- the soft tissue level abutment part 10 may comprise an interlock portion 34.

- the interlock portion 34 may comprise an external, generally hexagonal shape that is sized to fit within an interlock recess of the bone level dental implant.

- the soft tissue level abutment part 10 further comprises an internal bore 36 extending from the coronal end 14 to the apical end 16 and coinciding with the longitudinal axis 26 of the soft tissue level abutment part 10.

- an internal bore 36 In the internal bore 36, there is a seat 38.

- Figs. 2a-b show the soft tissue level abutment part 10 attached to a dental implant 40.

- the dental implant 40 is a 'bone level' dental implant, meaning that its coronal end 42 is substantially in level with the edge or crest 44 of the jawbone 46 of a patient, when the dental implant 40 is installed in the jawbone 46.

- the dental implant 40 may for example be of the type disclosed in WO 2008/128757 A2 . However, other (bone level) implants may be used as well.

- the dental implant 40 comprises an internal connection interface that is open to the coronal (or proximal) end 42 of the dental implant 40.

- the internal connection interface comprises a conical chamber 48, a hexagonal interlock recess 50, and an internally threaded portion 52.

- the conical chamber 48 has an inclined internal connection surface 54 matching the external surface 32 of the tissue level abutment part 10.

- the soft tissue level abutment part 10 is attached to the bone level dental implant 40 by means of an abutment screw 56, as shown in figs. 2a-b .

- the abutment screw 56 may be comprised in the abutment system 12.

- the abutment screw 56 has an apical external threaded portion 58 for engaging the internally threaded portion 52 of the dental implant 40.

- the abutment screw 56 has a head 60 that rests against the seat 38 of the soft tissue level abutment part 10.

- the head 60 may have a coronal internally threaded portion 62.

- the height H of the outer surface 28 of the soft tissue level abutment part 10 may correspond to the height of soft tissue 64 adjacent the installed bone level dental implant 38.

- the present abutment system 12 selectively supports both a cement-retained final restoration 66 (see figs. 4a- d and 6 ) and a screw-retained final restoration 68 (see figs. 5a-c and 6). In other words, either of a cement- retained final restoration and a screw-retained final restoration can be supported using the same soft tissue level abutment part 10. Also, the abutment system 12 can support other screw-retained prosthetic components, such as a cover screw 70 (see fig. 3 ), an impression coping, a bar, etc.

- the present invention could also be regarded as a two-piece soft tissue level dental implant, wherein the two pieces are the (bone level) dental implant 40 and the (soft tissue level) abutment part 10.

- a cover screw 70 is attached to the soft tissue level abutment part 10.

- the cover screw 70 may have an externally threaded portion (not shown) for engagement with the internally threaded portion 62 of the abutment screw 56.

- the cover screw 70 may further have flat circumferential surface matching the flat circumferential top surface 18 of the soft tissue level abutment part 10, for creating an effective seal between the cover screw 70 and the soft tissue level abutment part 10.

- the top of the cover screw 70 can be slightly rounded not to damage soft tissue.

- the abutment system 12 further comprises a coronal abutment part 72.

- the coronal abutment part 72 is adapted to be attached to the soft tissue level abutment part 10 by means of a further screw 74.

- the further screw 74 may also be comprised in the abutment system 12.

- the coronal abutment part 72 has an apical end 76 at least partly matching the coronal end 14 of the soft tissue level abutment part 10, as seen in figs. 4b and 4d , such that an effective seal between the abutment parts 10 and 72 can be achieved.

- the coronal abutment part 72 further comprises an internal bore 78 extending between its coronal end 80 and the apical end 76. In the internal bore 78, there is a seat 82.

- the coronal abutment part 72 is further adapted to support a cement-retained final restoration (not shown in figs. 4a-d ), such as a crown or bridge.

- an outer surface 84 of the coronal abutment part 72 may include one or several longitudinal grooves 86 for accommodating cement.

- the outer surface 84 may also comprise a plurality of (smaller) transversal grooves and ridges 87.

- the coronal abutment part 72 may be designed such that a portion of the flat circumferential top surface 18 remains exposed when the coronal abutment part 72 is attached to the soft tissue level abutment part 10.

- the exposed portion of the flat circumferential top surface 18 may also serve as a support for the cement-retained final restoration.

- the coronal abutment part 72 is attached to the soft tissue level abutment part 10 by means of the further screw 74.

- the further screw 74 has an apical external threaded portion 88 for engaging the internally threaded portion 62 of the abutment screw 56.

- the further screw 74 has a head 90 that rests against the seat 82 of the coronal abutment part 72.

- the head 90 may have a coronal tool socket 92.

- Figs. 5a-c show a screw-retained final restoration 68 attached to the soft tissue level abutment part 10 by means of a further screw 74.

- the screw-retained final restoration 68 in figs. 5a-c is embodied as a crown, but it can also be a bridge, etc.

- the screw-retained final restoration 68 has an apical end 94 at least partly matching the coronal end 14 of the soft tissue level abutment part 10, as seen particularly in figs. 5b-c , such that an effective seal between the soft tissue level abutment part 10 and the screw-retained final restoration 68 can be achieved.

- the screw-retained final restoration 68 may be designed such that no portion of the flat circumferential top surface 18 remains exposed when the screw-retained final restoration 68 is attached to the soft tissue level abutment part 10. This ensures a smooth transition between the screw-retained final restoration 68 and the soft tissue level abutment part 10.

- the screw-retained final restoration 68 further comprises an internal bore 96 extending between its coronal end 98 and the apical end 94. In the internal bore 96, there is a seat 100.

- the screw-retained final restoration 68 is directly attached to the soft tissue level abutment part 10 by means of the further screw 74.

- the further screw 74 has an apical external threaded portion 88 for engaging the internally threaded portion 62 of the abutment screw 56.

- the further screw 74 has a head 90 that rests against the seat 100 of the screw-retained final restoration 68.

- the head 90 may have a coronal tool socket 92.

- the abutment system 12 may be used in the following way: First, the bone level dental implant 40 is installed (a) by a surgeon in the jawbone 46 of a patient in a manner known per se. The dental implant 40 should be installed such that the coronal end 42 of the dental implant 40 is substantially in level with the upper edge 44 of the jawbone 46.

- the soft tissue level abutment part 10 is attached (b) to the dental implant 40 by the surgeon by means of the abutment screw 56.

- This soft tissue level abutment part 10 will normally not be removed after it has been attached to the implant 40.

- the outer surface 28 is here exposed to soft tissue 64.

- the soft tissue level abutment part 10 may be attached to the dental implant 40 immediately after the dental implant 40 has been installed.

- a prosthodontist which typically is not the same person as the surgeon, is thereafter free to decide or select (c) which one of a cement-retained final restoration 66 and a screw-retained final restoration 68 that should be used. This makes the present system very flexible.

- the selected final restoration may then be attached (d) as described in relation to figs. 4a-d or figs. 5a-c , i.e. without having to remove the soft tissue level abutment part 10, and without breaking any soft tissue seal.

- any intermediate operations such as attaching the cover screw or an impression coping to the soft tissue level abutment part 10 can be carried out without breaking any soft tissue seal.

- Step (d) may be performed several weeks or months after step (b) (attachment of soft tissue level abutment part 10), to allow for osseointegration of the dental implant 40.

- an immediate/early loading protocol can be used.

- soft tissue level abutment parts 10 with different diameters (widths) and/or different heights may be provided, to cater for various clinical situations. This makes the present system and method more flexible than a one-piece soft tissue level dental implant system.

Landscapes

- Health & Medical Sciences (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Orthopedic Medicine & Surgery (AREA)

- Dentistry (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Dental Prosthetics (AREA)

- Vehicle Body Suspensions (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

- Vehicle Step Arrangements And Article Storage (AREA)

Claims (7)

- Système d'ancrage (12), comprenant :une partie d'ancrage universelle au niveau des tissus mous (10),une vis d'ancrage (56) pour fixer la partie d'ancrage universelle au niveau des tissus mous (10) à l'implant dentaire au niveau osseux (40), la vis d'ancrage ayant une partie filetée intérieurement coronale (62),dans lequel la partie d'ancrage universelle au niveau des tissus mous (10) a une extrémité coronale (14) et une extrémité apicale (16), est réalisée en une seule pièce et comporte :une surface externe (32) étant formée en tant que partie conique pour venir en butée contre et former un joint d'étanchéité efficace avec une surface de connexion interne (54) de l'implant dentaire au niveau osseux,une surface externe (28), la surface externe étant incurvée dans la direction coronale-apicale de la partie d'ancrage universelle au niveau des tissus mous et faisant une transition apicale dans la surface externe (32), etune surface supérieure circonférentielle plate (18) ayant un périmètre circulaire interne (20) ;au moins un élément d'indexation (22a-c) exposé à l'extrémité coronale de la partie d'ancrage au niveau des tissus mous pour empêcher la rotation d'un composant fixé à la partie d'ancrage au niveau des tissus mous, dans lequel l'au moins un élément d'indexation est au moins un lobe s'étendant apicalement depuis le périmètre circulaire interne, etdans lequel le système d'ancrage est conçu pour supporter sélectivement à la fois- une restauration finale scellée (66) supportée par une partie d'ancrage coronale (72) fixée à la partie d'ancrage au niveau des tissus mous au moyen d'une autre vis ayant une partie filetée extérieurement apicale (88) pour une mise en prise avec la partie filetée intérieurement coronale de la vis d'ancrage, et- une restauration définitive vissée (68) directement fixée à la partie d'ancrage au niveau des tissus mous au moyen de l'autre vis.

- Système d'ancrage selon la revendication 1, dans lequel le système d'ancrage comporte en outre un autre composant ayant une surface plate qui correspond à la surface supérieure circonférentielle plate (18) de la partie d'ancrage universelle au niveau des tissus mous (10).

- Système d'ancrage selon la revendication 1 ou 2, dans lequel la partie d'ancrage au niveau des tissus mous a la surface supérieure circonférentielle plate (18) au niveau du périmètre externe de l'extrémité coronale (14) de la partie d'ancrage au niveau des tissus mous.

- Système d'ancrage selon l'une quelconque des revendications précédentes, dans lequel la surface externe incurvée s'étend d'un plus grand diamètre coronal (Dl) à un plus petit diamètre apical (D2), en particulier d'abord sous une forme convexe (30a) et puis sous une forme concave (30b).

- Système d'ancrage selon l'une quelconque des revendications précédentes, comprenant plusieurs parties d'ancrage au niveau des tissus mous avec des diamètres et/ou hauteurs différents.

- Système d'ancrage selon l'une quelconque des revendications précédentes, dans lequel la surface externe (28) a une longueur (L) supérieure à sa hauteur (H).

- Système d'ancrage selon l'une quelconque des revendications précédentes, dans lequel la surface externe (28) est pourvue d'une ou de plusieurs rainures circonférentielles.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GBGB1212125.7A GB201212125D0 (en) | 2012-07-09 | 2012-07-09 | Abutment system and dental methods |

| PCT/EP2013/001901 WO2014008987A1 (fr) | 2012-07-09 | 2013-06-28 | Système d'ancrage et méthodes dentaires |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2869782A1 EP2869782A1 (fr) | 2015-05-13 |

| EP2869782B1 true EP2869782B1 (fr) | 2023-04-19 |

Family

ID=46766320

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP13732835.7A Active EP2869782B1 (fr) | 2012-07-09 | 2013-06-28 | Système d'ancrage |

Country Status (11)

| Country | Link |

|---|---|

| US (2) | US10441387B2 (fr) |

| EP (1) | EP2869782B1 (fr) |

| JP (1) | JP6259822B2 (fr) |

| KR (1) | KR102278335B1 (fr) |

| CN (1) | CN104540470B (fr) |

| BR (1) | BR112015000549B1 (fr) |

| CA (1) | CA2878188C (fr) |

| ES (1) | ES2945328T3 (fr) |

| GB (1) | GB201212125D0 (fr) |

| WO (1) | WO2014008987A1 (fr) |

| ZA (1) | ZA201500037B (fr) |

Families Citing this family (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2509135A (en) | 2012-12-21 | 2014-06-25 | Nobel Biocare Services Ag | An abutment with conical metal adapter |

| GB2509136A (en) | 2012-12-21 | 2014-06-25 | Nobel Biocare Services Ag | Dental component with metal adapter |

| GB2509138A (en) | 2012-12-21 | 2014-06-25 | Nobel Biocare Services Ag | Dental component with screw fixation |

| US20150044638A1 (en) * | 2013-08-07 | 2015-02-12 | Ebless Victor Baez | Dental implant |

| KR101388846B1 (ko) * | 2013-09-10 | 2014-04-23 | 왕제원 | 일체형 임플란트 |

| JP5706976B1 (ja) * | 2014-01-30 | 2015-04-22 | 敏弘 中塚 | 歯肉賦形キャップ及び歯肉賦形キャップキット |

| IL230833A0 (en) * | 2014-02-05 | 2014-09-30 | Ophir Fromovich | bone graft |

| US10743966B2 (en) * | 2015-01-21 | 2020-08-18 | Kwang Seob Kim | Implant unit |

| ES2611760B1 (es) * | 2015-11-06 | 2018-02-13 | Biotechnology Institute, I Mas D, S.L. | Conjunto de implante dental y componentes protésicos, que incluye una camisa transepitelial con conexión superior antirrotacional |

| US11219510B2 (en) | 2015-11-20 | 2022-01-11 | Nobel Biocare Services Ag | Healing cap with scannable features |

| IL242816B (en) | 2015-11-26 | 2020-06-30 | Mis Implants Tech Ltd | A supporting structure, a covering and a method for connecting them in a multi-unit dental system |

| KR101695612B1 (ko) * | 2016-01-21 | 2017-01-13 | 김영재 | 육각형 고정홈을 가지는 픽스쳐 |

| CN109069234B (zh) | 2016-05-20 | 2022-02-08 | 诺贝尔生物服务公司 | 装卸工具、牙科套件和用于组装牙科部件的方法 |

| BR112019025239B1 (pt) | 2017-05-29 | 2022-12-20 | Mis Implants Technologies Ltd | Base de unidade única para prender uma superestrutura a um implante ósseo dentário |

| USD840038S1 (en) | 2017-09-05 | 2019-02-05 | MIS Implants Technologies Ltd. | Dental connector |

| USD840037S1 (en) | 2017-09-05 | 2019-02-05 | MIS Implants Technologies Ltd. | Dental connector |

| USD840039S1 (en) | 2017-09-05 | 2019-02-05 | MIS Implants Technologies Ltd. | Dental connector |

| US20210220095A1 (en) * | 2018-05-16 | 2021-07-22 | Valoc Ag | Gingiva former, bite support and dental healing system |

| DE102018113237A1 (de) * | 2018-06-04 | 2019-12-05 | TRI Dental Implants Int. AG | Zahnimplantat und Zahnprothese |

| US11730565B1 (en) * | 2019-07-12 | 2023-08-22 | Todd E. Shatkin | Sleeve for installing a crown on a miniature dental implant |

| KR20210088884A (ko) | 2020-01-07 | 2021-07-15 | 권현정 | 어버트먼트 |

| BR112022013787A2 (pt) * | 2020-01-24 | 2022-09-13 | Inst Straumann Ag Ch | Sistema de restauração dentária e método para construir uma restauração |

| CN111658197B (zh) * | 2020-06-23 | 2022-02-11 | 西安交通大学口腔医院 | 一种牙种植体 |

| DE102020209688A1 (de) * | 2020-07-31 | 2022-02-03 | Frank Zastrow | Implantationssystem und Aufbauelement für ein Implantationssystem |

| KR102464000B1 (ko) * | 2020-09-22 | 2022-11-04 | 김정환 | 임플란트 어셈블리 |

| WO2022109412A1 (fr) * | 2020-11-23 | 2022-05-27 | Instarisa Digital Dental Technologies, Llc | Système et procédé de flux de travail numérique pour soins de restauration et de chirurgie dentaires |

| KR102528601B1 (ko) | 2021-03-31 | 2023-05-10 | 경북대학교 산학협력단 | 3d 스캔을 이용한 영구 치아 보철물 제조 방법 |

| US20220378555A1 (en) * | 2021-06-01 | 2022-12-01 | Yao-Tsung Wu | All-Zirconium One-piece Dental Implant |

| KR20240041945A (ko) | 2021-08-08 | 2024-04-01 | 아쥐스뜨 에스에이알엘 | 임플란트 상의 치아 복원용 연결 디바이스 및 연결 시스템, 임플란트 상의 치아 복원물 및 임플란트 상의 치아 복원을 수행하기 위한 방법 |

| FR3125960B1 (fr) | 2021-08-08 | 2024-06-21 | Tanimura Remy | Dispositif de liaison et système de liaison pour reconstruction dentaire sur implant, reconstruction dentaire sur implant, procédé de réalisation de reconstruction dentaire sur implant |

| WO2023108247A1 (fr) | 2021-12-17 | 2023-06-22 | M3 Health Indústria E Comércio De Produtos Médicos, Odontológicos E Correlatos S.A. | Composant prothétique et procédé de fabrication d'un composant prothétique par des moyens de fabrication additive |

Family Cites Families (89)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH604674A5 (fr) | 1975-07-17 | 1978-09-15 | Straumann Inst Ag | |

| DE2733394C3 (de) | 1977-07-23 | 1984-10-25 | Riess, Guido, Prof. Dr.med.dent., 8100 Garmisch-Partenkirchen | Kunstzahn mit implantierbarer Zahnwurzel |

| US5071351A (en) * | 1986-07-02 | 1991-12-10 | Collagen Corporation | Dental implant system |

| US4713004A (en) * | 1986-09-04 | 1987-12-15 | Vent Plant Corporation | Submergible screw-type dental implant and method of utilization |

| US5015186A (en) * | 1987-09-24 | 1991-05-14 | Detsch Steven G | Dental implant attachment system |

| DE3839837A1 (de) * | 1988-11-25 | 1990-05-31 | Lauks Nikola | Vorrichtung zur befestigung eines zahnersatzes an einem menschlichen kiefer |

| US5040983A (en) * | 1989-01-23 | 1991-08-20 | Implant Innovations, Inc. | Temporary dental coping |

| US5035619A (en) | 1989-10-20 | 1991-07-30 | Fereidoun Daftary | Anatomical restoration dental implant system with improved healing cap and abutment |

| US5169309A (en) | 1990-01-12 | 1992-12-08 | Attachments International, Inc. | Abutment for dental appliances and the like |

| US5040982A (en) * | 1990-06-28 | 1991-08-20 | Stefan Dogar Sorin | Dental implant and conversion assembly |

| US5350302A (en) * | 1990-07-05 | 1994-09-27 | Marlin Gerald M | Implant collar and post system |

| US5135395A (en) | 1990-07-05 | 1992-08-04 | Marlin Gerald M | Implant collar and post system |

| JP3001300B2 (ja) * | 1990-09-08 | 2000-01-24 | イー・エム・ツエツト・フエルテイグングス−ウント・フエアトリープスゲゼルシヤフト・フエーア・デンタール・テヒノロギー・エムベーハー | 骨に取付ける単一歯植込み部材 |

| US5281140A (en) | 1991-01-02 | 1994-01-25 | Core-Vent Corporation | Multi-part, multi-positionable abutment for use with dental implants |

| US5108288A (en) * | 1991-06-14 | 1992-04-28 | Perry William L | Non-rotational prosthodontic restoration |

| US5662476A (en) | 1992-06-29 | 1997-09-02 | Nobel Biocare Ab | Prosthetic implant restoration method |

| US5362235A (en) * | 1993-05-17 | 1994-11-08 | Fereidoun Daftary | Anatomical restoration dental implant system with interlockable angled abutment assembly |

| US5527182A (en) * | 1993-12-23 | 1996-06-18 | Adt Advanced Dental Technologies, Ltd. | Implant abutment systems, devices, and techniques |

| US5873721A (en) * | 1993-12-23 | 1999-02-23 | Adt Advanced Dental Technologies, Ltd. | Implant abutment systems, devices, and techniques |

| US5417568A (en) * | 1994-02-25 | 1995-05-23 | Giglio; Graziano D. | Gingival contoured abutment |

| AT400804B (de) * | 1994-10-10 | 1996-03-25 | Mke Metall Kunststoffwaren | Implantat |

| US5674069A (en) | 1995-01-13 | 1997-10-07 | Osorio; Julian | Customized dental abutment |

| EP0814724B1 (fr) * | 1995-03-20 | 1998-09-16 | Institut Straumann Ag | Attache d'un implant dentaire dote d'une partie secondaire conique |

| US5829977A (en) | 1995-05-25 | 1998-11-03 | Implant Innovations, Inc. | Two-piece dental abutment |

| AU7123896A (en) | 1995-10-13 | 1997-05-07 | Institut Straumann Ag | Connector between an implant and an abutment |

| US5904483A (en) * | 1995-11-17 | 1999-05-18 | Wade; Curtis K. | Dental implant systems and methods |

| BR9707334A (pt) | 1996-02-02 | 1999-07-20 | Implant Innovations Inc | Sistema de perfil de emergéncia tendo um reforço de curativo e de crista de impressão |

| WO1997028755A1 (fr) | 1996-02-08 | 1997-08-14 | Institut Straumann Ag | Systeme d'empreinte pour extremite d'implant emergeant d'une structure tissulaire humaine |

| US5810592A (en) * | 1996-05-06 | 1998-09-22 | Daftary; Fereidoun | Anatomical restoration dental implant system with healing abutment member and matching abutment member |

| US5759036A (en) | 1996-07-29 | 1998-06-02 | Hinds; Kenneth F. | Complete dental implant system and method |

| EP0966236A4 (fr) | 1997-01-27 | 2002-06-12 | Implant Innovations Inc | Pilier et chaperon a utiliser avec des implants dentaires |

| EP0868889B1 (fr) | 1997-03-21 | 1998-11-04 | Dinkelacker, Wolfgang, Dr. med. dent. | Implant dentaire |

| US6619958B2 (en) * | 1997-04-09 | 2003-09-16 | Implant Innovations, Inc. | Implant delivery system |

| ATE322223T1 (de) | 1997-07-25 | 2006-04-15 | Nobel Biocare Ab | Abdruckkappensystem für knochenintegrierte implantate |

| SE9702981D0 (sv) | 1997-08-19 | 1997-08-19 | Astra Ab | Dental implant systems |

| US5890902A (en) * | 1997-09-19 | 1999-04-06 | Sapian; Schubert L. | Implant bone locking mechanism and artificial periodontal ligament system |

| US6540514B1 (en) | 1998-02-26 | 2003-04-01 | Theodore S. Falk | Method for isolating a dental implant |

| US6168435B1 (en) * | 1998-10-26 | 2001-01-02 | Implant Innovations, Inc. | Ceramic dental abutments with a metallic core |

| US6358052B1 (en) | 1999-07-15 | 2002-03-19 | L. Paul Lustig | Dental implant system and method for effecting a dental restoration using the same |

| WO2001034057A1 (fr) | 1999-11-10 | 2001-05-17 | Implant Innovations, Inc. | Composants de cicatrisation a utiliser lors de la prise d'empreinte et leurs procedes de fabrication |

| US6790040B2 (en) | 1999-11-10 | 2004-09-14 | Implant Innovations, Inc. | Healing components for use in taking impressions and methods for making the same |

| GB9929662D0 (en) | 1999-12-15 | 2000-02-09 | Sethi Ashok | Impression jig |

| US6769913B2 (en) | 2000-08-30 | 2004-08-03 | Nobel Biocare Ab | Impression cap |

| US20070037123A1 (en) * | 2000-10-26 | 2007-02-15 | Mansueto Robert F | High-strength dental-implant w/curvilinear-indexing and tool-free delivery-system |

| US20070072150A1 (en) * | 2000-10-26 | 2007-03-29 | Mansueto Robert F | High-strength dental-implant w/cone-locking & swaging abutment |

| US6386876B1 (en) | 2000-11-29 | 2002-05-14 | Kenneth K. S. Lee | Universal tissue emergence profile shaping healing abutment, provisional and restoration abutments, impression coping and ceramic crown base system |

| US20040063069A1 (en) * | 2002-09-30 | 2004-04-01 | Lombardi Steven B. | External locking dental implant system |

| US6786391B2 (en) * | 2002-10-16 | 2004-09-07 | Kac Holdings, Inc. | Method of controlling solder deposition utilizing two fluxes and preform |

| SE534830C2 (sv) | 2004-01-29 | 2012-01-10 | Nobel Biocare Services Ag | Anordning vid dentalt implantat |

| US7632096B2 (en) | 2004-10-18 | 2009-12-15 | Gittleman Neal B | Rotating winged low profile impression transfer cap |

| EP2119414B1 (fr) | 2005-06-03 | 2013-04-24 | Straumann Holding AG | Couplage pour système d'implants dentaires à plusieurs parties |

| US8430668B2 (en) * | 2005-06-17 | 2013-04-30 | Zimmer Dental, Inc. | Dental restorative system and components |

| WO2007005490A2 (fr) | 2005-06-30 | 2007-01-11 | Implant Innovations, Inc. | Procede de fabrication de composants d'implants dentaires |

| EP1757245B1 (fr) * | 2005-08-22 | 2010-07-21 | Riemser Arzneimittel AG | Implant dentaire |

| EP1757246A1 (fr) * | 2005-08-22 | 2007-02-28 | Novident SA | Superstructure pour implant dentaire |

| US20070059666A1 (en) * | 2005-09-15 | 2007-03-15 | Albert Zickman | Dental implant system |

| US20070099152A1 (en) | 2005-10-31 | 2007-05-03 | Albert Busch | Dental implant system |

| CN101940503B (zh) | 2005-11-30 | 2014-07-09 | 3形状股份有限公司 | 用于牙齿修复物制造的印模扫描 |

| DE102006018726B4 (de) | 2006-04-20 | 2019-01-31 | Holger Zipprich | Verfahren zur Herstellung eines Dentalimplantats |

| KR100677870B1 (ko) | 2006-05-29 | 2007-02-02 | 주식회사 메가젠 | 치유 지대주 및 그를 구비한 치과용 임플란트 |

| FR2908629B1 (fr) | 2006-11-20 | 2009-11-27 | Anthogyr Sa | Dispositif d'impression a coiffe de prise d'empreinte pour prothese dentaire |

| EP1967158A1 (fr) * | 2007-03-06 | 2008-09-10 | Astra Tech AB | Implant dentaire, structure de butée et procédé de mise en place d'un implant dentaire |

| WO2008129512A1 (fr) | 2007-04-23 | 2008-10-30 | Avinent Implant System, S. L. | Dispositif d'espacement trans-épithélial pour implants dentaires |

| US7806693B2 (en) * | 2007-04-23 | 2010-10-05 | Nobel Biocare Services Ag | Dental implant |

| US8038442B2 (en) | 2007-04-23 | 2011-10-18 | Nobel Biocare Services Ag | Dental implant and dental component connection |

| US7632095B2 (en) * | 2007-08-13 | 2009-12-15 | Biomet 3I, Inc. | Method for forming a dental prosthesis |

| US9833300B2 (en) | 2007-10-26 | 2017-12-05 | Council Of Scientific & Industrial Research | Dental implant system |

| US8033826B2 (en) | 2007-11-15 | 2011-10-11 | Biomet 3I, Llc | Two-piece dental abutment system |

| EP2090263A1 (fr) | 2008-02-13 | 2009-08-19 | Straumann Holding AG | Butée dotée d'un inlay pour implants dentaires |

| US20090298015A1 (en) | 2008-05-28 | 2009-12-03 | Global Implant Solutions, Llc | Digital Abutment For Dental Implant System |

| ITGE20080054A1 (it) | 2008-06-11 | 2009-12-12 | Alberto Rebaudi | Impianto per il fissaggio di protesi dentarie |

| JP2011528927A (ja) | 2008-07-24 | 2011-12-01 | クフィール,ピンカス | 歯科インプラント埋め込み方法およびシステム |

| WO2010056330A1 (fr) | 2008-11-13 | 2010-05-20 | Robert Zena | Modèles de tissu mou et procédés de fabrication pour des applications dentaires |

| KR100948074B1 (ko) | 2009-03-23 | 2010-03-16 | 주식회사 이노바이오써지 | 임플란트 보철 부품세트 및 상기 부품세트를 이용하여 지대주가 포함된 복제 석고모델의 제작방법 |

| US8794966B2 (en) | 2009-05-09 | 2014-08-05 | William Hung | Dental implant fixture mount-abutment and ball impression screw |

| US8867800B2 (en) | 2009-05-27 | 2014-10-21 | James R. Glidewell Dental Ceramics, Inc. | Method of designing and fabricating patient-specific restorations from intra-oral scanning of a digital impression |

| WO2011056452A2 (fr) | 2009-10-28 | 2011-05-12 | 3M Innovative Properties Company | Articles de type ébauches pour implants dentaires et procédés associés |

| EP2347729A1 (fr) * | 2010-01-21 | 2011-07-27 | Camlog Biotechnologies AG | Implant dentaire, butée pour un implant dentaire et combinaison des deux ainsi qu'un kit d'implantation |

| US20110200968A1 (en) | 2010-02-17 | 2011-08-18 | Procerex Dental Lab Llc | System and method for fabricating a dental healing abutment |

| US20120237899A1 (en) * | 2011-03-03 | 2012-09-20 | Astra Tech Ab | Dental implant assembly |

| WO2012126475A1 (fr) | 2011-03-18 | 2012-09-27 | Elos Medtech Pinol A/S | Butée dentaire pour le balayage buccal |

| US20130196290A1 (en) | 2011-05-16 | 2013-08-01 | Biomet 3I, Llc | Healing Abutment Assembly With Combination Of Scanning Features |

| EP3777760B1 (fr) | 2011-05-16 | 2024-06-19 | Biomet 3I, LLC | Capuchon de pilier temporaire avec marqueurs d'informations |

| TW201318604A (zh) | 2012-11-14 | 2013-05-16 | Chen Yi Lin | 口內取模套件與口內取模方法 |

| WO2014081843A1 (fr) | 2012-11-20 | 2014-05-30 | Advanced Implant Intellectual Properties, Llc | Système et procédés d'adaptateur d'alignement universel |

| GB2509135A (en) * | 2012-12-21 | 2014-06-25 | Nobel Biocare Services Ag | An abutment with conical metal adapter |

| US20170056132A1 (en) * | 2013-08-05 | 2017-03-02 | Norman Ho Kwong Kwan | Method for simultaneously installing a monolithic dental prosthesis on multiple dental implants |

| US20150037757A1 (en) * | 2013-08-05 | 2015-02-05 | Norman Kwan | Method for attaching a dental prosthesis having multiple abutments |

| US10959813B1 (en) * | 2020-01-27 | 2021-03-30 | Global Implant Ltd. | Tissue level one-time abutment system and method |

-

2012

- 2012-07-09 GB GBGB1212125.7A patent/GB201212125D0/en not_active Ceased

-

2013

- 2013-06-28 KR KR1020157003379A patent/KR102278335B1/ko active IP Right Grant

- 2013-06-28 ES ES13732835T patent/ES2945328T3/es active Active

- 2013-06-28 CN CN201380036513.1A patent/CN104540470B/zh active Active

- 2013-06-28 EP EP13732835.7A patent/EP2869782B1/fr active Active

- 2013-06-28 CA CA2878188A patent/CA2878188C/fr active Active

- 2013-06-28 US US13/931,118 patent/US10441387B2/en active Active

- 2013-06-28 JP JP2015520842A patent/JP6259822B2/ja active Active

- 2013-06-28 WO PCT/EP2013/001901 patent/WO2014008987A1/fr active Application Filing

- 2013-06-28 BR BR112015000549-7A patent/BR112015000549B1/pt active IP Right Grant

-

2015

- 2015-01-06 ZA ZA2015/00037A patent/ZA201500037B/en unknown

-

2019

- 2019-10-10 US US16/598,315 patent/US20200138552A1/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US20200138552A1 (en) | 2020-05-07 |

| AU2013289610A1 (en) | 2015-01-29 |

| JP2015527114A (ja) | 2015-09-17 |

| CA2878188C (fr) | 2021-01-12 |

| BR112015000549A2 (pt) | 2017-06-27 |

| ZA201500037B (en) | 2016-03-30 |

| CA2878188A1 (fr) | 2014-01-16 |

| KR20150036467A (ko) | 2015-04-07 |

| CN104540470A (zh) | 2015-04-22 |

| CN104540470B (zh) | 2019-04-16 |

| JP6259822B2 (ja) | 2018-01-10 |

| EP2869782A1 (fr) | 2015-05-13 |

| GB201212125D0 (en) | 2012-08-22 |

| WO2014008987A1 (fr) | 2014-01-16 |

| US10441387B2 (en) | 2019-10-15 |

| KR102278335B1 (ko) | 2021-07-19 |

| BR112015000549B1 (pt) | 2021-07-13 |

| US20140011160A1 (en) | 2014-01-09 |

| ES2945328T3 (es) | 2023-06-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2869782B1 (fr) | Système d'ancrage | |

| JP5017285B2 (ja) | セラミック/金属製の歯科用アバットメント | |

| CA2273217C (fr) | Systeme d'implant dentaire de restauration anatomique de dents posterieures et anterieures | |

| KR101240116B1 (ko) | 덴탈 임플란트 | |

| KR100909912B1 (ko) | 입의 미관부에 사용하기 위한 임플란트 | |

| EP1849431A1 (fr) | Implant dentaire etroit et pieces associees | |

| US9883926B2 (en) | Conversion abutment for dental implants | |

| US20070031793A1 (en) | Provisional crown for dental implants | |

| US20070111163A1 (en) | Dental implant system | |

| US10806548B2 (en) | Methods and devices for countering gingival effects in dental restoration | |

| EP3793473B1 (fr) | Dispositif de façonnage de gencive, kit et système de cicatrisation dentaire | |

| US20070031792A1 (en) | Provisional crown for dental implants | |

| AU2013289610B2 (en) | Abutment system and dental methods | |

| KR101296740B1 (ko) | 넌-서브머지드 타입 임플란트용 지대주 | |

| CA2042992A1 (fr) | Mode de fabrication et d'implantation d'une prothese dentaire | |

| KR200493322Y1 (ko) | 치과용 임플란트 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20150209 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20190618 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20221110 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602013083635 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1560647 Country of ref document: AT Kind code of ref document: T Effective date: 20230515 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230515 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2945328 Country of ref document: ES Kind code of ref document: T3 Effective date: 20230630 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG9D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230821 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230719 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20230719 Year of fee payment: 11 Ref country code: CH Payment date: 20230705 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230819 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602013083635 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20230630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230628 |

|

| 26N | No opposition filed |

Effective date: 20240122 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20230419 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230630 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240515 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240509 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240502 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240529 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20240513 Year of fee payment: 12 Ref country code: FR Payment date: 20240509 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20240510 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 1560647 Country of ref document: AT Kind code of ref document: T Effective date: 20230419 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20240704 Year of fee payment: 12 Ref country code: ES Payment date: 20240705 Year of fee payment: 12 |