EP2829162B1 - Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable - Google Patents

Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable Download PDFInfo

- Publication number

- EP2829162B1 EP2829162B1 EP13714852.4A EP13714852A EP2829162B1 EP 2829162 B1 EP2829162 B1 EP 2829162B1 EP 13714852 A EP13714852 A EP 13714852A EP 2829162 B1 EP2829162 B1 EP 2829162B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- electrode

- plasma

- electrode tip

- tip

- screw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000000463 material Substances 0.000 claims description 31

- 238000001816 cooling Methods 0.000 claims description 6

- 239000011343 solid material Substances 0.000 claims description 2

- 239000002184 metal Substances 0.000 claims 1

- 238000007789 sealing Methods 0.000 description 7

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 5

- 229910052709 silver Inorganic materials 0.000 description 5

- 239000004332 silver Substances 0.000 description 5

- 239000003795 chemical substances by application Substances 0.000 description 4

- 239000010949 copper Substances 0.000 description 4

- 229910052735 hafnium Inorganic materials 0.000 description 4

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 description 4

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 3

- 229910001316 Ag alloy Inorganic materials 0.000 description 2

- 229910017944 Ag—Cu Inorganic materials 0.000 description 2

- 229910000881 Cu alloy Inorganic materials 0.000 description 2

- 229910017770 Cu—Ag Inorganic materials 0.000 description 2

- 229910001128 Sn alloy Inorganic materials 0.000 description 2

- 239000002826 coolant Substances 0.000 description 2

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 2

- 229910052726 zirconium Inorganic materials 0.000 description 2

- 229910000906 Bronze Inorganic materials 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 230000004308 accommodation Effects 0.000 description 1

- 239000010974 bronze Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/32—Plasma torches using an arc

- H05H1/34—Details, e.g. electrodes, nozzles

- H05H1/3436—Hollow cathodes with internal coolant flow

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/28—Cooling arrangements

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/32—Plasma torches using an arc

- H05H1/34—Details, e.g. electrodes, nozzles

- H05H1/3423—Connecting means, e.g. electrical connecting means or fluid connections

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05H—PLASMA TECHNIQUE; PRODUCTION OF ACCELERATED ELECTRICALLY-CHARGED PARTICLES OR OF NEUTRONS; PRODUCTION OR ACCELERATION OF NEUTRAL MOLECULAR OR ATOMIC BEAMS

- H05H1/00—Generating plasma; Handling plasma

- H05H1/24—Generating plasma

- H05H1/26—Plasma torches

- H05H1/32—Plasma torches using an arc

- H05H1/34—Details, e.g. electrodes, nozzles

- H05H1/3442—Cathodes with inserted tip

Definitions

- the invention relates to a plasma electrode for a plasma arc burner, comprising an electrode body which has at least one electrode core arranged on the electrode tip.

- Such plasma electrodes for use in plasma arc torches have become known in various embodiments.

- the JP 2007-180028 A or the EP 1 765 046 B1 or the DE000069937323T2 directed.

- the wear of the plasma electrode during operation is considerable.

- the electrode core inserted into the front side of the plasma electrode in the region of the electrode tip in a bore generates a plasma arc at temperatures in the range between 1,000 to 2,000 degrees Celsius and consists of an electrically conductive, highly emissive material, e.g. Hafnium or zirconium.

- the electrode tip is heavily stressed by the high firing temperatures.

- material erosion occurs on the electrode core which deposit as splashes of material on the electrode tip and its surroundings, which leads to undesirable wear and a limitation of the service life.

- the EP 1 633 172 A2 suggests the electrode core, which consists of a hafnium material, in an existing silver insert on the Hold electrode tip. This insert (see FIG. 7 ) is soldered into the front area of the electrode tip.

- the invention is therefore based on the object, a plasma electrode for a plasma arc burner of the type mentioned in such a way that a more easy and cost-effective replacement of the electrode is possible during wear.

- the invention is characterized by the technical teaching of claim 1.

- the invention is based on the assumption that the electrode consisting of a high-grade material (eg AG) has at least two parts and only the front, exchangeable tip part consists of a high-quality material (such as AG), whereas the rear electrode part consists of one less high quality material, such as Cu or a Cu alloy or a comparable material may exist.

- a high-grade material eg AG

- the front, exchangeable tip part consists of a high-quality material (such as AG)

- the rear electrode part consists of one less high quality material, such as Cu or a Cu alloy or a comparable material may exist.

- the division of the electrode according to the invention is particularly useful for electrodes from a total length of more than 10-12 mm.

- the division into two is such that the replaceable tip has a length of, for example, 6 mm, while the remaining, rear electrode part makes up the remaining length.

- a bipartition is especially with longer electrodes with a total length of e.g. 40 mm or more.

- the plasma electrode is formed at least in two parts and at least consists of the front electrode tip and a rear electrode part and that the electrode tip is replaceably held on the electrode part.

- the invention provides for a multi-part plasma electrode, wherein the simpler description is based in the following description of only two parts of this plasma electrode, although the plasma electrode can also consist of more than two parts.

- the description of a bipartite plasma electrode is therefore not intended to limit the scope of the invention.

- An essential feature of the invention is that in a two-part design of the plasma electrode is now possible to solve the front part of the rear part, because these two parts are preferably releasably connected to each other.

- the front electrode tip can be removed with the electrode core introduced there from the rear electrode portion of the plasma electrode, provided that wear on the electrode tip occurs.

- the detachable connection between the two parts of the plasma electrode is designed as a screw connection, as a plug-in connection or as a combined screw-type connector.

- the screw consists of two interlocking threads.

- At the electrode tip can be an internal thread be arranged, which can be screwed into an associated external thread in the region of the rear electrode portion of the plasma electrode.

- the electrode tip has an external thread which can be screwed onto an associated internal thread of the rear electrode part of the plasma electrode.

- a plug connection is used, such.

- a bayonet connector that can be solved and fixed by a rotary-plug movement.

- the detachable connection between the two parts of the plasma electrode consists of a sealed flange, wherein two oppositely disposed flanges on the two parts associated with each other and are liquid-tightly sealed from each other.

- a flange connection is secured by a union nut in connection with a thread on the opposite part.

- clamping connections are also provided.

- Such a clamp connection is z.

- the rear electrode portion of the plasma electrode is made of a low-cost copper material or a copper alloy, while the front portion of the electrode tip, which is subject to wear, consists of a silver material or a silver alloy.

- the electrode tip is made of high-quality silver or a silver alloy.

- silver as a highly conductive material has been given by way of example only. Of course, other highly conductive, readily processable materials can be used which have the properties of silver. In particular tin alloys come into consideration or copper-tin alloys (bronze).

- the abovementioned materials can be used in the same abovementioned material pairings as have been specified above using the example of the material Ag.

- the invention is not limited to hollow cylindrical plasma electrodes, in the interior of which a cooling tube is arranged, with which a cooling medium - preferably water - introduced into the interior of the plasma electrode, is diverted at the front end, in the vicinity of the electrode tip, and then out again the plasma electrode is led out.

- a cooling medium - preferably water - introduced into the interior of the plasma electrode is diverted at the front end, in the vicinity of the electrode tip, and then out again the plasma electrode is led out.

- the invention also claims uncooled hollow cylindrical or also consisting of solid material plasma electrodes, which are at least two parts and the front part subject to wear is easily detachably connected to the rear part.

- plasma electrode 1 is constructed in two parts and consists of the front, replaceable electrode tip 2 and a rear electrode part 3, which is centered with a radially outer mounting flange 7 on the inside of a fastening body (electrode holder), not shown, and otherwise with a thread 8 can be screwed into such a fastening body.

- the entire plasma electrode 1 can be inserted sealed in a fastening body, not shown.

- a cooling tube 6 is arranged centrally, which engages with its front end in a receiving space 5 in the region of the electrode tip 2.

- An electrode core 4 is inserted in a bore of the electrode tip 2 is made of a highly-emissive material, such. A hafnium or zirconium material.

- the cooling of the plasma electrode takes place in such a way that a coolant flow is introduced into the interior 10 of the cooling tube 6, which is deflected in the region of the receiving space 5 in the electrode tip 2 and is then recirculated via the radially outer inner bore 9.

- connection portion 11 of the detachable connection consists of a screw thread.

- a screw thread 12 is formed.

- opposing and rectified conical surfaces 13, 14 are arranged on associated flanges of the electrode tip 2 and the electrode member 3 and that further engages a preferably encircling annular flange 15 on the electrode member 3 in an associated annular groove 16 and there centered.

- FIG. 3 shows the composite structure of in FIG. 1 in the disassembled state shown plasma electrode, where it can be seen that the front, replaceable electrode tip 2 has a relatively short length 24 which is many times shorter than comparatively the non-replaceable electrode part 3 with a much greater length 25th

- the aspect ratios of these two lengths 24, 25 can range from 1: 1 to 1: 6.

- the electrode tip 2 is easily detachably mounted on the electrode-side electrode part 3 and therefore is easily replaceable when it is worn. It is kept short to keep material consumption low during replacement.

- FIGS. 5 to 8 show the kinematic reversal of a numeral 12 in the FIGS. 1 to 4 shown screw thread.

- the screw thread 12 from a on the inside of the electrode tip. 2 arranged internal thread, which is screwed into an associated, radially outwardly directed external thread on the electrode part 3.

- the threaded screw connection is sealed by a sealing ring 19 liquid-tight.

- FIGS. 7 and 8 show another embodiment of the screw, and the rest, that in the area of the electrode tip 2 also a key surface 20 may be provided for the attack of a suitable tool with which the electrode tip 2 can be unscrewed from the electrode part 3.

- an external thread is arranged on the rear side of the electrode tip 2, which cooperates with an internal thread in the interior of the electrode member 3 and the entire threaded connection is sealed liquid-tight by a sealing ring 19 which is inserted in an associated annular groove 23 on the vertical flange of the electrode tip 2 ,

- the external thread 21 on the electrode tip 2 thus cooperates with the internal thread 22 on the electrode part 3 as a screw thread 12.

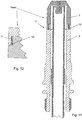

- FIGS. 9 to 12 show as a further embodiment, a plasma electrode in which the sealing ring 19 is integrally formed in the region of an outwardly open annular groove 23 at the foot of the vertical flange in the electrode part 3.

- the electrode tip 2 has an internal thread 22, which with the associated external thread 21 results in the sealed screw connection in the region of the connection part 11.

- FIGS. 11 and 12 show the in FIGS. 9 to 10 Threaded connection shown in the screwed state.

- FIG. 13 shows the state of the art according to the DE000069937323T2 and FIG. 2

- This document shows a screwed into a holder electrode 16 which is integrally formed and must be replaced when worn as an entire part.

- the electrode 16 is screwed with an upper screw thread 19 in a holder.

- the invention is now compared to this prior art is to form the known electrode 16 in two parts and form the front tip as easily replaceable electrode tip 2 and the rear part of the electrode 16 as an electrode part of the electrode body of the plasma electrode.

- FIG. 14 (Prior art according to the EP 1 765 046 B1 ) shows a replaceable, one-piece electrode 2 of considerable length, which corresponds in principle to the embodiment of the electrode according to the invention.

- the matching features are the upper thread and two annular grooves, in each of which an O-ring is inserted in order to screw the electrode sealed in an electrode holder can.

- the invention now provides that the in FIG. 14 shown electrode at the lowest point - is divided about the level of reference numeral 3 and there forms the replaceable electrode tip.

- the electrode tip thus formed only needs to be formed so long that the mounting surfaces to be arranged there and the electrode core can be arranged.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Plasma Technology (AREA)

- Arc Welding In General (AREA)

Claims (10)

- Electrode à plasma (1) pour une torche à arc de plasma composée d'un corps d'électrode qui se compose d'une pointe d'électrode avant (2) sur laquelle est disposé un noyau d'électrode (4), et de la partie d'électrode tubulaire qui fait suite à ladite pointe (2), ladite partie d'électrode comportant une bride de fixation (7) et un filetage (8) ou une douille d'emboîtement pour une fixation dans un porte-électrode,

caractérisée en ce que la pointe d'électrode est au moins en deux parties et se compose d'une pointe d'électrode avant (2) et d'une pointe d'électrode arrière (3), en ce que la pointe d'électrode avant (2) est fixée à la pointe d'électrode arrière (3) de manière à pouvoir être échangée, et en ce qu'une liaison amovible est disposée entre la pointe d'électrode avant (2) et la pointe d'électrode arrière (3) qui fait suite à celle-ci. - Electrode à plasma selon la revendication 1, caractérisée en ce que la liaison amovible entre la pointe avant (2) et la pointe arrière (3) de l'électrode à plasma (1) est conçue comme une liaison étanche par vissage ou par emboîtement ou par vissage et emboîtement (11).

- Electrode à plasma selon la revendication 2, caractérisée en ce que la liaison étanche par vissage ou par emboîtement ou par vissage et emboîtement (11) est conçue avec un centrage automatique.

- Electrode à plasma selon l'une des revendications 1 à 3, caractérisée en ce que le rapport de longueur (24, 25) entre la pointe d'électrode avant échangeable (2) et la pointe d'électrode arrière (3) est situé dans la plage entre 1:6 à 1:1.

- Electrode à plasma selon l'une des revendications 1 à 4, caractérisée en ce que le matériau de la pointe d'électrode avant (2) et de la pointe d'électrode arrière (3) est du même type.

- Electrode à plasma selon l'une des revendications 1 à 4, caractérisée en ce que le matériau de la pointe d'électrode avant (2) et de la pointe d'électrode arrière (3) est de types différents.

- Electrode à plasma selon l'une des revendications 1 à 6, caractérisée en ce que la liaison amovible entre la pointe avant (2) et la pointe arrière (3) de l'électrode à plasma (1) est conçue comme une liaison étanche par bride, avec un écrou-raccord pour fixer et bloquer la liaison par bride.

- Electrode à plasma selon l'une des revendications 1 à 7, caractérisée en ce que l'électrode à plasma (1) est conçue comme un corps métallique cylindrique creux dans l'espace intérieur (10) duquel est disposé un tube de refroidissement (6).

- Electrode à plasma selon l'une des revendications 1 à 7, caractérisée en ce qu'il est prévu sur la circonférence extérieure de la pointe d'électrode arrière (3) des saillies de vissage et/ou d'emboîtement pour la fixation de l'électrode à plasma (1) dans un corps de torche.

- Electrode à plasma selon l'une des revendications 1 à 9, caractérisée en ce que la pointe d'électrode avant (2), au moins, se compose d'un matériau plein.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13714852.4A EP2829162B1 (fr) | 2012-03-23 | 2013-03-22 | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12002077.1A EP2642832A1 (fr) | 2012-03-23 | 2012-03-23 | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable |

| PCT/EP2013/000876 WO2013139484A1 (fr) | 2012-03-23 | 2013-03-22 | Électrode à plasma pour torche à plasma à arc transféré à embout d'électrode interchangeable |

| EP13714852.4A EP2829162B1 (fr) | 2012-03-23 | 2013-03-22 | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2829162A1 EP2829162A1 (fr) | 2015-01-28 |

| EP2829162B1 true EP2829162B1 (fr) | 2017-05-17 |

Family

ID=48050654

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12002077.1A Withdrawn EP2642832A1 (fr) | 2012-03-23 | 2012-03-23 | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable |

| EP13714852.4A Not-in-force EP2829162B1 (fr) | 2012-03-23 | 2013-03-22 | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP12002077.1A Withdrawn EP2642832A1 (fr) | 2012-03-23 | 2012-03-23 | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US9736916B2 (fr) |

| EP (2) | EP2642832A1 (fr) |

| WO (1) | WO2013139484A1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109079294B (zh) * | 2018-10-31 | 2023-08-11 | 浙江巨化装备制造有限公司 | 全自动管板焊机枪头连续自动钨棒更换装置及更换方法 |

| WO2020206429A1 (fr) * | 2019-04-04 | 2020-10-08 | Hypertherm, Inc. | Consommables à longueur ajustable pour chalumeau à plasma refroidi par liquide |

| CZ202054A3 (cs) | 2020-02-05 | 2021-03-03 | B&Bartoni, spol. s r.o. | Sestava elektrody pro plazmový obloukový hořák se zlepšeným přenosem elektrického proudu |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5216221A (en) * | 1992-01-17 | 1993-06-01 | Esab Welding Products, Inc. | Plasma arc torch power disabling mechanism |

| US5440094A (en) * | 1994-04-07 | 1995-08-08 | Douglas G. Carroll | Plasma arc torch with removable anode ring |

| US6020572A (en) * | 1998-08-12 | 2000-02-01 | The Esab Group, Inc. | Electrode for plasma arc torch and method of making same |

| US6498316B1 (en) * | 1999-10-25 | 2002-12-24 | Thermal Dynamics Corporation | Plasma torch and method for underwater cutting |

| US7081597B2 (en) | 2004-09-03 | 2006-07-25 | The Esab Group, Inc. | Electrode and electrode holder with threaded connection |

| US8101882B2 (en) | 2005-09-07 | 2012-01-24 | Hypertherm, Inc. | Plasma torch electrode with improved insert configurations |

| US7256366B2 (en) | 2005-12-21 | 2007-08-14 | The Esab Group, Inc. | Plasma arc torch, and methods of assembling and disassembling a plasma arc torch |

| US9662747B2 (en) * | 2006-09-13 | 2017-05-30 | Hypertherm, Inc. | Composite consumables for a plasma arc torch |

| DE102008062731C5 (de) * | 2008-12-18 | 2012-06-14 | Kjellberg Finsterwalde Plasma Und Maschinen Gmbh | Elektrode für einen Plasmabrenner |

| DE102009016932B4 (de) * | 2009-04-08 | 2013-06-20 | Kjellberg Finsterwalde Plasma Und Maschinen Gmbh | Kühlrohre und Elektrodenaufnahme für einen Lichtbogenplasmabrenner sowie Anordnungen aus denselben und Lichtbogenplasmabrenner mit denselben |

| US8884179B2 (en) | 2010-07-16 | 2014-11-11 | Hypertherm, Inc. | Torch flow regulation using nozzle features |

| US9211603B2 (en) * | 2012-01-31 | 2015-12-15 | The Esab Group, Inc. | Plasma gouging torch and angled nozzle therefor |

-

2012

- 2012-03-23 EP EP12002077.1A patent/EP2642832A1/fr not_active Withdrawn

-

2013

- 2013-03-22 WO PCT/EP2013/000876 patent/WO2013139484A1/fr not_active Ceased

- 2013-03-22 EP EP13714852.4A patent/EP2829162B1/fr not_active Not-in-force

- 2013-03-22 US US14/361,903 patent/US9736916B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| US20140291303A1 (en) | 2014-10-02 |

| EP2829162A1 (fr) | 2015-01-28 |

| WO2013139484A1 (fr) | 2013-09-26 |

| EP2642832A1 (fr) | 2013-09-25 |

| US9736916B2 (en) | 2017-08-15 |

| WO2013139484A4 (fr) | 2013-11-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE60018968T2 (de) | Plasma-Lichtbogenbrenner, Plasmabrennerkathode und Plasmabrennerelektrode | |

| DE69630700T2 (de) | Schweisskontaktspitze | |

| DE2706559C2 (de) | Plasmaflammspritzpistole | |

| DE102008052458A1 (de) | Brenner und Kontaktspitze für Gasmetallbogenschweißen | |

| DE202013102979U1 (de) | Schweißbrenner für das Lichtbogen-Schutzgasschweißen und Kontaktrohr für einen solchen Schweißbrenner | |

| EP0372111B1 (fr) | Electrode pour un four de fusion du verre | |

| DE202009018173U1 (de) | Düsenschutzkappe und Düsenschutzkappenhalter sowie Lichtbogenplasmabrenner mit derselben und/oder demselben | |

| DE202008011356U1 (de) | Wolfram- Inertgas- Schweißbrenner | |

| EP2226899A1 (fr) | Dispositif de liaison de deux conducteurs électriques | |

| DE202015106360U1 (de) | Fräserkopfeinheit, Fräserschaft und Aufschraubfräser | |

| EP2855071B1 (fr) | Chalumeau pour le soudage au tungstène et au gaz inerte | |

| DE102016010341B4 (de) | Plasmabrenner und komponenten des plasmabrenners | |

| EP2829162B1 (fr) | Électrode à plasma pour une torche à plasma d'arc avec extrémité d'électrode échangeable | |

| EP2667689A1 (fr) | Électrode pour chalumeau de coupe au plasma ainsi que son utilisation | |

| DE69621360T2 (de) | Kohlenstoffelektrode | |

| DE102009059108A1 (de) | Elektrode mit Kühlrohr für eine Plasmaschneidvorrichtung | |

| EP2663167B1 (fr) | Tuyau de refroidissement pour une torche à plasma d'arc et écarteur | |

| EP1675144A1 (fr) | Disjoncteur à haute puissance avec conducteur pour les courants court-circuits résistant à des arcs électriques | |

| DE102014202435A1 (de) | Modular ausgebildeter Schweißelektrodenhalter | |

| DE10338774B4 (de) | Schweißbrennerelement, Bauteilkombination, Schweißbrenner und Schweißsystem | |

| EP1692922B1 (fr) | Dispositif de projection plasma | |

| DE10322116B3 (de) | Kontaktdüse für Flachdraht-Schweißen | |

| DE2642411C2 (de) | Kabelschuh für Elektrokabel | |

| DE1048651B (fr) | ||

| DE102013214551B4 (de) | Drahtdüse und Verfahren zum Laserfügen mit Zusatzdraht mit taktiler Drahtführung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20141023 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20160318 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20161206 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HOLLBERG, MANFRED |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HOLLBERG, MANFRED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 895523 Country of ref document: AT Kind code of ref document: T Effective date: 20170615 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502013007285 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20170517 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170817 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170817 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170917 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502013007285 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20180220 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180331 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180331 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 895523 Country of ref document: AT Kind code of ref document: T Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20130322 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170517 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170517 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230320 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502013007285 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241001 |