EP2440349B1 - Verfahren zur verarbeitung von stahlpulver - Google Patents

Verfahren zur verarbeitung von stahlpulver Download PDFInfo

- Publication number

- EP2440349B1 EP2440349B1 EP10722682.1A EP10722682A EP2440349B1 EP 2440349 B1 EP2440349 B1 EP 2440349B1 EP 10722682 A EP10722682 A EP 10722682A EP 2440349 B1 EP2440349 B1 EP 2440349B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel powder

- powder particles

- small steel

- balls

- deformed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/04—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/06—Making metallic powder or suspensions thereof using physical processes starting from liquid material

- B22F9/08—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying

- B22F9/10—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying using centrifugal force

Definitions

- the metal powder is fed to a jet mill and heated there in a chamber.

- the heated metal powder particles are subjected to a collision to provide smooth and reduced metal powder particles. These are fed to an output and collected.

- JP H03 130301 A describes a method for improving the surface quality of metal powder particles, in which the metal powder particles collide with each other, without plastic deformation of the metal powder particles occur.

- articles PC KING, SH ZAHIRI, M. JAHEDI "Focused ion beam micro-dissection of cold-sprayed particles", ACTA MATER, Vol. 56, 4 September 2008, pages 5617-5626 , and KIM K ET AL: "Thermal Softening Effect on the Deposition Efficiency and Microstructure of Hot Sprayed Metallic Powder", SCRIPTA MATERIALIA, ELSEVIER, AMSTERDAM, NL, Vol. 60, No.

- the object of the invention is to provide a method for processing steel powder consisting of a plurality of steel powder pellets, by means of which steel powder with non-spherical steel powder particles can be produced.

- the process of the invention is provided as a starting material steel powder, which consists of a plurality of steel powder pellets whose diameter is in the range of 100 microns to 500 microns.

- steel powder can be produced, for example, by the above-mentioned method.

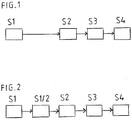

- a first step S1 heating of the steel powder pellets to a temperature at which the steel powder pellets are in the doughy state.

- This heating of the steel powder pellets can be carried out using an induction process, by application of radiant heat or in a hot inert gas stream.

- a collision of the steel powder pellets in the doughy state is brought about with a baffle body in order to obtain deformed steel powder particles.

- This baffle may be a baffle that is at right angles or at another angle to the Steel powder bead stream runs.

- This baffle plate may be formed propeller-shaped. Furthermore, can they are designed to be movable, for example, rotate or swiveled constantly.

- the steel powder particles deformed by collision with the baffle plate are collected in a collecting vessel according to a subsequent step S3.

- An advantageous embodiment is to transport the deformed steel powder particles by means of a conveyor belt in the collecting vessel, wherein the conveyor belt is disposed either between the baffle plate and the collecting vessel or wherein the conveyor belt itself serves as a baffle plate.

- An alternative embodiment is to collide the steel powder pellets in the doughy state against each other to obtain deformed steel powder particles having a non-spherical surface.

- step S4 After collecting the deformed steel powder particles in the collecting vessel, cooling of the deformed steel powder particles takes place in a step S4 until they are again in a solid state.

- the steel powder particles provided by step S2 in the collecting vessel in which they are collected in accordance with step S3 may be subjected to another processing.

- the resulting steel powder particles have, in contrast to the starting material on projections, edges and corners.

- steel powder which consists of a plurality of such deformed steel powder particles, for producing a drilling tool made of steel is used with internal, helically extending cooling channels, wherein the steel powder is kneaded with a binder, the steel powder kneaded with the binder is passed through a press tool to produce a strand having internal, rectilinear cooling passages, which the

- Pressing strand leaving each strand is cut to a desired length, the resulting blank is supported under support over its entire length of a rolling motion whose velocity varies linearly and steadily over the length of the body, so that the blank is twisted, and wherein the twisted

- the blank is sintered and then provided on its outer shell with spiral flutes.

- a first step S1 heating the steel powder pellets to a temperature at which the steel powder pellets are in the doughy state.

- a subsequent step S1 / 2 the steel powder pellets in the doughy state are subjected to an acceleration.

- This acceleration can be carried out by a magnetic field, by means of a spinning process or by means of a protective gas flow.

- the accelerated, in doughy state steel powder pellets are subjected to a collision with a baffle in a subsequent step S2, as well as in the case of FIG. 1 explained method to be deformed.

- the steel powder particles deformed by the collision are collected in a collecting vessel according to a subsequent step S3, where they cool according to a step S4 so that the steel powder particles finally are in a solid state.

- steel powder consisting of a plurality of steel powder pellets is processed, so that steel powder is provided, which consists of a plurality of steel powder particles, which is not spherical are but have projections, corners and edges.

- steel powder pellets located in the doughy state are accelerated before their collision process, steel powder pellets may shatter during the collision, so that a plurality of even smaller, deformed steel powder particles are formed from a steel powder pellet. This leads to a further improvement of the above-described and desired entanglement of the steel powder particles in the blank and thus to an even further dimensional stability of the blank.

Landscapes

- Powder Metallurgy (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102009024120A DE102009024120A1 (de) | 2009-06-06 | 2009-06-06 | Verfahren zur Verarbeitung von Metallpulver |

| PCT/EP2010/057383 WO2010139614A1 (de) | 2009-06-06 | 2010-05-28 | Verfahren zur verarbeitung von metallpulver |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2440349A1 EP2440349A1 (de) | 2012-04-18 |

| EP2440349B1 true EP2440349B1 (de) | 2019-07-03 |

Family

ID=42670556

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10722682.1A Active EP2440349B1 (de) | 2009-06-06 | 2010-05-28 | Verfahren zur verarbeitung von stahlpulver |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US9132481B2 (enExample) |

| EP (1) | EP2440349B1 (enExample) |

| JP (1) | JP5787883B2 (enExample) |

| DE (1) | DE102009024120A1 (enExample) |

| ES (1) | ES2742260T3 (enExample) |

| WO (1) | WO2010139614A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009024119A1 (de) * | 2009-06-06 | 2010-12-09 | Arno Friedrichs | Verfahren zur Verarbeitung von Metallpulver |

| US9555473B2 (en) * | 2011-10-08 | 2017-01-31 | The Boeing Company | System and method for increasing the bulk density of metal powder |

| JP6036597B2 (ja) * | 2013-08-02 | 2016-11-30 | トヨタ自動車株式会社 | 磁石用粉体の製造装置と製造方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03130301A (ja) * | 1989-07-28 | 1991-06-04 | Ube Ind Ltd | 金属粉末成形材の製造方法 |

| US20080118391A1 (en) * | 2006-10-30 | 2008-05-22 | Niotan, Inc. | Method and an Apparatus of Plasma Processing of Tantalum Particles |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2181123A (en) * | 1937-02-11 | 1939-11-28 | Glidden Co | Treatment of metallic powders |

| JPS61166905A (ja) * | 1985-01-16 | 1986-07-28 | Sumitomo Special Metals Co Ltd | 永久磁石用原料粉末の製造方法 |

| JPH01321096A (ja) * | 1988-06-24 | 1989-12-27 | Senju Metal Ind Co Ltd | 球形粉末はんだの変形方法 |

| DE69000179T2 (de) * | 1989-04-10 | 1993-01-07 | Gte Prod Corp | Verfahren zur herstellung von feinteilchen-pulvern durch zerstaeuben mit einer heissen scheibe. |

| US5039476A (en) * | 1989-07-28 | 1991-08-13 | Ube Industries, Ltd. | Method for production of powder metallurgy alloy |

| IL145498A (en) | 1999-03-19 | 2005-05-17 | Cabot Corp | Making niobium and other metal powders by milling |

| JP2004043883A (ja) * | 2002-07-11 | 2004-02-12 | Murata Mfg Co Ltd | 金属粉末の熱処理方法 |

| TWI381897B (zh) | 2004-12-22 | 2013-01-11 | Taiyo Nippon Sanso Corp | 金屬超微粉之製造方法 |

| JP2006351688A (ja) | 2005-06-14 | 2006-12-28 | Sumitomo Metal Mining Co Ltd | サマリウム−鉄−窒素系磁石微粉末の製造方法 |

| JP2007324270A (ja) * | 2006-05-31 | 2007-12-13 | Toyota Motor Corp | 磁性粉末の製造方法および圧粉コアの製造方法 |

| DE102009024119A1 (de) * | 2009-06-06 | 2010-12-09 | Arno Friedrichs | Verfahren zur Verarbeitung von Metallpulver |

-

2009

- 2009-06-06 DE DE102009024120A patent/DE102009024120A1/de not_active Ceased

-

2010

- 2010-05-28 US US13/265,652 patent/US9132481B2/en active Active

- 2010-05-28 JP JP2012513553A patent/JP5787883B2/ja active Active

- 2010-05-28 EP EP10722682.1A patent/EP2440349B1/de active Active

- 2010-05-28 WO PCT/EP2010/057383 patent/WO2010139614A1/de not_active Ceased

- 2010-05-28 ES ES10722682T patent/ES2742260T3/es active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03130301A (ja) * | 1989-07-28 | 1991-06-04 | Ube Ind Ltd | 金属粉末成形材の製造方法 |

| US20080118391A1 (en) * | 2006-10-30 | 2008-05-22 | Niotan, Inc. | Method and an Apparatus of Plasma Processing of Tantalum Particles |

Non-Patent Citations (2)

| Title |

|---|

| KIM K ET AL: "Thermal softening effect on the deposition efficiency and microstructure of warm sprayed metallic powder", SCRIPTA MATERIALIA, ELSEVIER, AMSTERDAM, NL, vol. 60, no. 8, 1 April 2009 (2009-04-01), pages 710 - 713, XP025953666, ISSN: 1359-6462, [retrieved on 20090113], DOI: 10.1016/J.SCRIPTAMAT.2008.12.050 * |

| P.C. KING, S.H. ZAHIRI, M. JAHEDI: "Focused ion beam micro-dissection of cold-sprayed particles", ACTA MATER, vol. 56, 4 September 2008 (2008-09-04), pages 5617 - 5626 * |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2010139614A1 (de) | 2010-12-09 |

| US9132481B2 (en) | 2015-09-15 |

| EP2440349A1 (de) | 2012-04-18 |

| JP2012529560A (ja) | 2012-11-22 |

| US20120060576A1 (en) | 2012-03-15 |

| DE102009024120A1 (de) | 2010-12-09 |

| JP5787883B2 (ja) | 2015-09-30 |

| ES2742260T3 (es) | 2020-02-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2794152B1 (de) | Verfahren zur fertigung eines kompakten bauteils sowie mit dem verfahren herstellbares bauteil | |

| DE602004013028T2 (de) | Verbessertes verfahren und verbesserte vorrichtung zum sintern von anorganischen materialien | |

| DE102010046468B4 (de) | Generatives Herstellverfahren und Pulver hierzu | |

| DE4023962A1 (de) | Feinkoernige titanschmiedstuecke und verfahren zu deren herstellung | |

| EP2890519A1 (de) | Verfahren zur herstellung eines verbundbauteils sowie ein verbundbauteil | |

| DE10131657B4 (de) | Verfahren zur direkten Herstellung von Werkzeugen durch Rapid Prototyping mit Freiform-Oberflächen und Werkzeug | |

| DE112009000504T5 (de) | Werkzeuge mit Arbeitsoberflächen aus verdichtetem Pulvermetall und Verfahren | |

| EP2440349B1 (de) | Verfahren zur verarbeitung von stahlpulver | |

| DE68914874T2 (de) | Herstellung von Fraktionen mit hohem Volumen an magnetisch ausgerichtetem Material vom RE-Fe-B-Typ durch Stauchung. | |

| EP3569311A1 (de) | Matrize mit metallgedruckten teilen zur extrusion von formkörpern | |

| EP3141335B1 (de) | Verfahren zum herstellen eines bauteils mit einem aus stahl bestehenden kernabschnitt | |

| DE10208868A1 (de) | Verfahren zur Herstellung eines Bauteils und/oder einer Schicht aus einer schwingungsdämpfenden Legierung oder intermetallischen Verbindung sowie Bauteil, das durch dieses Verfahren hergestellt wurde | |

| DE102018126420A1 (de) | Korngrenzendiffusionstechnik für seltenerdmagneten | |

| EP3569334B1 (de) | Verfahren zur herstellung eines bauteils | |

| EP2440350A1 (de) | Verfahren zur verarbeitung von metallpulver | |

| WO2024017425A1 (de) | Wälzlagerelement und verfahren zur herstellung eines wälzlagerelementes | |

| WO2023118298A1 (de) | Verfahren und vorrichtung zur erwärmung eines fahrzeugrads | |

| DE102011111011A1 (de) | Verstellschaufelelement und Verfahren zum Ausbilden, Reparieren und/oder Austauschen eines derartigen Verstellschaufelelements | |

| EP2877999B1 (de) | Verfahren zum herstellen eines anisotropen magneten | |

| EP2888064B1 (de) | Umformverfahren | |

| DE102011113854A1 (de) | Hartstoffpulver und Verfahren zur Herstellung von Hartstoffpulver | |

| CN109746359A (zh) | 一种锌合金小规格管材或棒材的热旋锻方法 | |

| DE102010035590B4 (de) | Verfahren und Vorrichtung zur Herstellung eines Strukturbauteils | |

| DE102015107475B3 (de) | Verfahren zum Fertigen eines Ringes, Wälzlager und Vorrichtung zum Fertigen eines Ringes | |

| DE102019134153A1 (de) | Sinterteil und Verfahren zu dessen Herstellung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20120109 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20150921 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20190211 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 1150361 Country of ref document: AT Kind code of ref document: T Effective date: 20190715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010016103 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KELLER AND PARTNER PATENTANWAELTE AG, CH |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20190703 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502010016103 Country of ref document: DE Representative=s name: ZIMMERMANN & PARTNER PATENTANWAELTE MBB, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502010016103 Country of ref document: DE Owner name: ARNO FRIEDRICHS HARTMETALL GMBH & CO. KG, DE Free format text: FORMER OWNER: FRIEDRICHS, ARNO, 95326 KULMBACH, DE |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: ARNO FRIEDRICHS HARTMETALL GMBH AND CO. KG, DE Free format text: FORMER OWNER: FRIEDRICHS, ARNO, DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: ARNO FRIEDRICHS HARTMETALL GMBH & CO.KG Effective date: 20191212 |

|

| REG | Reference to a national code |

Ref country code: LU Ref legal event code: PD Owner name: ARNO FRIEDRICHS HARTMETALL GMBH & CO. KG; DE Free format text: FORMER OWNER: FRIEDRICHS, ARNO Effective date: 20191203 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20200102 AND 20200108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191003 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191003 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191104 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2742260 Country of ref document: ES Kind code of ref document: T3 Effective date: 20200213 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191004 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20191103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 1150361 Country of ref document: AT Kind code of ref document: T Owner name: ARNO FRIEDRICHS HARTMETALL GMBH & CO. KG, DE Effective date: 20200312 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20200224 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010016103 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG2D | Information on lapse in contracting state deleted |

Ref country code: IS |

|

| 26N | No opposition filed |

Effective date: 20200603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: ARNO FRIEDRICHS HARTMETALL GMBH AND CO. KG, DE Free format text: FORMER OWNER: ARNO FRIEDRICHS HARTMETALL GMBH AND CO. KG, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190703 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230703 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250529 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250527 Year of fee payment: 16 Ref country code: ES Payment date: 20250602 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20250527 Year of fee payment: 16 Ref country code: IT Payment date: 20250521 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250526 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20250601 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20250505 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20250527 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20250527 Year of fee payment: 16 |