EP2239367B1 - Elektrisches Dampfbügeleisen mit einer Synchronisierungstemperaturanzeige - Google Patents

Elektrisches Dampfbügeleisen mit einer Synchronisierungstemperaturanzeige Download PDFInfo

- Publication number

- EP2239367B1 EP2239367B1 EP10157182A EP10157182A EP2239367B1 EP 2239367 B1 EP2239367 B1 EP 2239367B1 EP 10157182 A EP10157182 A EP 10157182A EP 10157182 A EP10157182 A EP 10157182A EP 2239367 B1 EP2239367 B1 EP 2239367B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- temperature

- soleplate

- electric iron

- ironing

- collar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F75/00—Hand irons

- D06F75/08—Hand irons internally heated by electricity

- D06F75/26—Temperature control or indicating arrangements

- D06F75/265—Temperature indicating arrangements; Control knobs

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F75/00—Hand irons

- D06F75/08—Hand irons internally heated by electricity

- D06F75/24—Arrangements of the heating means within the iron; Arrangements for distributing, conducting or storing the heat

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F75/00—Hand irons

- D06F75/08—Hand irons internally heated by electricity

- D06F75/26—Temperature control or indicating arrangements

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F75/00—Hand irons

- D06F75/38—Sole plates

Definitions

- the present patent application relates to an electric iron with a synchronizing temperature display.

- Conventional electric irons have rotatable temperature-setting dials for setting different temperatures for ironing clothing made of different materials. When an ironing temperature needs to be set either from low to high or from high to low during ironing, a user can rotate the dial from one position to another position.

- these conventional electric irons are not provided with any means for showing the user exactly how long it would take for the soleplate to reach the set temperature. The user does not have any clue what is the actual current temperature at the soleplate and whether it is ready to start ironing. Hence, the user may tend to start ironing when in fact the soleplate temperature may be still too high or too low. Ironing with inappropriate soleplate temperature can definitely cause damage to the clothing to be ironed.

- the patent application US 2006/081588A1 describes an interface for an iron has a graphic display indicating the current temperature selection, user controls for adjusting the current temperature selection, and a ready indicator adapted to indicate when the iron is at the currently selected temperature.

- an electric iron including the features of claim 1.

- the heating element includes a first section extending between a first edge of the soleplate and one side of the collar, and a second section extending between a second edge of the soleplate and an opposite side of the collar, and wherein a middle portion of each of the first and second sections of the heating element bends towards the collar.

- the collar is generally oval in shape.

- the electric iron further includes a circuit board connecting between the temperature display and the temperature sensor.

- the circuit board comprises a microcontroller unit for controlling the temperature at the soleplate and the synchronous display of the temperature on the temperature display.

- the electric iron further includes a control panel which includes a temperature setting button for setting a plurality of temperature ranges, and a plurality of temperature setting indicators for indicating the modes of the temperature setting.

- the plurality of temperature ranges includes a temperature range of about 90-120°C suitable for ironing silk, a temperature range of 120-150°C suitable for ironing polyester, a temperature range of about 150-200°C suitable for ironing cotton, and a temperature range of about 200-230°C suitable for ironing linen.

- the temperature sensor is a negative temperature coefficient temperature sensor.

- the temperature display is a LED display.

- FIG. 1 is a perspective view of an electric iron 1 with a synchronizing temperature display 2 provided on a handle 3.

- FIG. 2 is a cross sectional view of a soleplate 10 of the electric iron 1, a control panel 12 and a circuit board 14 according to an embodiment disclosed in the present patent application.

- the control panel 12 may be provided on the handle 3 or a body of the electric iron readily visible by a user during ironing.

- the soleplate 10 can be provided with a negative temperature coefficient (NTC) temperature sensor 16 or other suitable temperature sensors.

- the NTC temperature sensor 16 is disposed in a bore formed on an inner surface of the soleplate 10 at a center thereof.

- the NTC temperature sensor 16 can be electrically connected to the circuit board 14 by electrical wires 15, which is in turn electrically connected to the control panel 12.

- the control panel 12 may include a synchronizing temperature LED display 18 or any other suitable display, a power indicator 20, a temperature setting button 22, and a plurality of temperature setting indicators 24, 26, 28, 30.

- the synchronizing temperature LED display 18 is employed to indicate to the user the actual current temperature at the soleplate 10 during ironing.

- the temperature setting button 22 can be employed to set a desired temperature range at the soleplate 10. According to the illustrated embodiment shown in FIGS. 3 and 4 , there are four temperature setting indicators 24, 26, 28, 30 for indicating four temperature ranges respectively.

- the electric iron When power is supplied to the electric iron 1, the electric iron is in a stand-by mode. At this stand-by mode, the power button 20 is lit and the word “OFF" may be displayed on the LED display 18.

- a user can press the temperature setting button 22 in order to set a desired temperature range.

- the first temperature setting indicator 24 may start blinking and the temperature can be set at a range of 90-120°C suitable for ironing silk.

- the second temperature setting indicator 26 may start blinking and the temperature can be set at a range of 120-150°C suitable for ironing polyester.

- the third temperature setting indicator 28 may start blinking and the temperature can be set at a range of 150-200°C suitable for ironing cotton.

- the fourth temperature setting indicator 30 may start blinking and the temperature can be set at a range of 200-230°C suitable for ironing linen.

- the first temperature setting indicator 24 may start blinking again and the temperature can be set at a range of 90-120°C suitable for ironing silk, and so on.

- a microcontroller unit (MCU) on the circuit board 14 may start detecting the temperature at the NTC temperature sensor 16 on the soleplate 10. It is understood that the NTC temperature sensor 16 is located at a lower portion of the soleplate 10 such that the temperature of the NTC temperature sensor 16 can be the same as the temperature on the lower surface of the soleplate 10 on which the clothing to be ironed is contacted.

- MCU microcontroller unit

- the temperature setting indicator 24, 26, 28 or 30 corresponding to the set temperature range may start blinking slowly.

- the actual current temperature at the soleplate 10 can be displayed on the synchronizing temperature LED display 18. Electric circuit of a heating element 40 can be connected, and heat can be generated by the heating element 40 to heat up the soleplate 10.

- the temperature setting indicator 24, 26, 28 or 30 corresponding to the set temperature range may stop blinking and remains lit, and the actual current temperature at the soleplate 10 can be displayed on the synchronizing temperature LED display 18.

- the temperature setting indicator 24, 26, 28 or 30 corresponding to the set temperature range may start blinking quickly.

- the actual current temperature at the soleplate 10 can be displayed on the synchronizing temperature LED display 18. Electric circuit of the heating element 40 is disconnected and the generation of heat can be stopped.

- the temperature range is set at 120-150°C for ironing polyester. Since the actual current temperature at the soleplate 10 is 106°C, as indicated on the synchronizing temperature LED display 18, the temperature setting indicator 26 starts blinking slowly. This tells the user that the soleplate temperature is not hot enough for ironing polyester. Until the heating element heats the soleplate 10 up to a temperature of 120°C, then the temperature setting indicator 26 stops blinking and remains lit. This tells the user that the soleplate temperature is hot enough for ironing polyester and ironing can be commenced.

- FIG. 4 shows that the temperature range is set at 200-230°C for ironing linen, and the actual current temperature at the soleplate 10 is 208°C which is within the set temperature range hot enough for ironing.

- an electric iron with a synchronizing temperature display disclosed in the present application is that it can show the actual temperature of the soleplate at any time during an ironing process. This ensures that a user can iron clothing of different materials at the right temperature. For example, after setting a high temperature at a range of 150-200°C for ironing cotton, a user may want to lower the temperature of the soleplate to a range of 90-120°C for ironing silk. With the electric iron having a synchronizing temperature display, the user can set the temperature to a range of 90-120°C suitable for ironing silk and start ironing only after the actual soleplate temperature appearing on the synchronizing temperature LED display drops to 90-120°C.

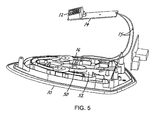

- the soleplate 10 may be provided with an integrally formed collar 50 extending upwardly from the inner surface 52 of the soleplate 10 and encompassing the temperature sensor 16.

- the collar 50 may be generally oval in shape.

- the heating element 40 is mounted on the soleplate 10. At least a portion of the heating element 40 is bent inwardly and disposed proximate to the collar 50. According to the illustrated embodiment, the heating element 40 includes a first section 40a extending between a first edge 10a of the soleplate 10 and one side 50a of the collar 50, and a second section 40b extending between a second edge 10b of the soleplate 10 and an opposite side 50b of the collar 50. Middle portions 40c, 40d of the first and second sections 40a, 40b of the heating element 40 respectively may bend towards the collar 50 into a generally neck-shaped portion.

- the heating element 40 and the collar 50 can prevent the temperature at the center of the soleplate 10 from dropping too fast causing a difference between the temperature at the soleplate 10 and the temperature displayed on the temperature LED display 18.

- the inwardly bending portions of the heating element 40 can heat up the center of the soleplate 10 where the NTC temperature sensor 16 is located so that the temperature at the center of the soleplate can be substantially equal to the temperature at the rest of the soleplate.

- the collar 50 can absorb more heat from the heating element 40 thereby preventing the temperature at the center of the soleplate 10 from dropping too fast causing a difference between the temperature at the soleplate 10 and the temperature displayed on the temperature LED display 18.

- the collar 50 is generally oval in shape, it is understood by one skilled in the art that the collar 50 can be in any other appropriate shape such as circle.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Irons (AREA)

Claims (6)

- Elektrisches Bügeleisen, umfassend:eine Sohlenplatte (10);ein Heizelement (40), das auf der Sohlenplatte (10) montiert ist;einen Temperatursensor zum Messen einer Temperatur der Sohlenplatte (10); undeine Temperaturanzeige (2), die mit dem Temperatursensor (16) verbunden ist, um synchron die Temperatur an der Sohlenplatte (10) anzuzeigen;dadurch gekennzeichnet, dassder Temperatursensor (16) in einem Loch angeordnet ist, das auf einer inneren Oberfläche der Sohlenplatte (10) an einem Zentrum davon gebildet ist,wobei die Sohlenplatte (10) einen Kragen (50) aufweist, der sich von einer inneren Oberfläche (52) der Sohlenplatte (10) aus nach oben erstreckt und den Temperatursensor (16) umgibt, undwobei das Heizelement (40) sich auf der Sohlenplatte (10) zwischen einem Rand der Sohlenplatte (10) und dem Kragen (50) erstreckt,wobei mindestens ein Teil des Heizelements (40) in der Nähe des Kragens (50) angeordnet ist.

- Elektrisches Bügeleisen gemäß Anspruch 1, wobei das Heizelement (40) einen ersten Abschnitt (40a), der sich zwischen einem ersten Rand (10a) der Sohlenplatte (10) und einer Seite (50a) des Kragens (50) erstreckt, und einen zweiten Abschnitt (40b) umfasst, der sich zwischen einem zweiten Rand (10b) der Sohlenplatte (10) and einer gegenüberliegenden Seite (50b) des Kragens (50) erstreckt, und wobei ein mittlerer Teil (40c, 40d) sowohl des ersten als auch des zweiten Abschnitts (40a, 40b) des Heizelements (40) sich in Richtung des Kragens (50) krümmt.

- Elektrisches Bügeleisen gemäß Anspruch 1, wobei der Kragen (50) eine allgemein ovale Form aufweist.

- Elektrisches Bügeleisen gemäß Anspruch 1, weiter umfassend ein Bedienfeld (12), das ein Temperatureinstellknopf (22) zum Einstellen mehrerer Temperaturbereiche und mehrere Temperatureinstellungsanzeiger (24) zum Anzeigen der Modi der Temperatureinstellung einschließt.

- Elektrisches Bügeleisen gemäß Anspruch 4, wobei die mehreren Temperaturbereiche

einen Temperaturbereich von ungefähr 90-120°C, der zum Bügeln von Seide geeignet ist,

einen Temperaturbereich von 120-150°C, der zum Bügeln von Polyester geeignet ist,

einen Temperaturbereich von ungefähr 150-200°C, der zum Bügeln von Baumwolle geeignet ist, und

einen Temperaturbereich von ungefähr 200-230°C einschließen, der zum Bügeln von Leinen geeignet ist. - Elektrisches Bügeleisen gemäß Anspruch 1, wobei der Temperatursensor (16) ein Temperatursensor mit negativem Temperaturkoeffizienten ist.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16786509P | 2009-04-08 | 2009-04-08 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2239367A1 EP2239367A1 (de) | 2010-10-13 |

| EP2239367B1 true EP2239367B1 (de) | 2012-02-15 |

Family

ID=42358056

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10157182A Not-in-force EP2239367B1 (de) | 2009-04-08 | 2010-03-22 | Elektrisches Dampfbügeleisen mit einer Synchronisierungstemperaturanzeige |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20100257761A1 (de) |

| EP (1) | EP2239367B1 (de) |

| JP (1) | JP3160112U (de) |

| CN (2) | CN101858032B (de) |

| AT (1) | ATE545728T1 (de) |

| HK (1) | HK1138992A2 (de) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100257761A1 (en) * | 2009-04-08 | 2010-10-14 | Lung Wai Choi | Electric iron with a synchronizing temperature display |

| ES2445163B1 (es) * | 2012-08-30 | 2014-12-10 | Bsh Electrodomésticos España, S.A. | Plancha, sistema de plancha y estación de planchado a vapor y procedimiento para planchar tejidos |

| CN103668920A (zh) * | 2013-11-28 | 2014-03-26 | 谢虹 | 一种迷你电熨斗 |

| EP3540114B1 (de) * | 2018-03-13 | 2021-06-09 | Electrolux Appliances Aktiebolag | Bügeleisen mit benutzerschnittstelle |

| IT201900002287A1 (it) * | 2019-02-18 | 2020-08-18 | De Longhi Appliances Srl | Ferro da stiro |

| CN110004692A (zh) * | 2019-05-23 | 2019-07-12 | 卓力电器集团有限公司 | 一种新型电熨斗 |

| WO2022055844A1 (en) * | 2020-09-08 | 2022-03-17 | Spectrum Brands, Inc. | Hybrid steamer iron assembly |

| US11707104B1 (en) | 2022-03-03 | 2023-07-25 | Cricut, Inc. | Heat press apparatuses, systems, and methods |

Family Cites Families (141)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USRE22048E (en) * | 1942-03-10 | Electric iron | ||

| US1046777A (en) * | 1909-05-01 | 1912-12-10 | Westinghouse Electric & Mfg Co | Electric heating apparatus. |

| US1039882A (en) * | 1912-04-30 | 1912-10-01 | Parker Clark Electric Company | Electrically-heated flat-iron. |

| US1398410A (en) * | 1920-06-21 | 1921-11-29 | Edwin L Wiegand | Embedding process |

| US1512209A (en) * | 1921-08-24 | 1924-10-21 | Gen Electric | Electric heater |

| US1742083A (en) * | 1925-03-21 | 1929-12-31 | Edison Electric Appliance Co | Electric heater |

| US1689809A (en) * | 1927-09-30 | 1928-10-30 | Westinghouse Electric & Mfg Co | Thermostatic device |

| US1908401A (en) * | 1929-06-17 | 1933-05-09 | Chicago Flexible Shaft Co | Thermostatically governed electric laundry iron |

| US1779960A (en) * | 1929-06-17 | 1930-10-28 | Chicago Flexible Shaft Co | Thermostatically-governed electric laundry iron |

| US1833594A (en) * | 1930-03-10 | 1931-11-24 | Solar Ind Inc | Thermostatic apparatus |

| US2004962A (en) * | 1931-11-27 | 1935-06-18 | Mcgraw Electric Co | Electric iron |

| US2041429A (en) * | 1932-10-31 | 1936-05-19 | Beardsley & Wolcott Mfg Compan | Electric sadiron |

| US2140852A (en) * | 1932-10-31 | 1938-12-20 | Stern Brown Inc | Sadiron |

| US1999107A (en) * | 1934-03-22 | 1935-04-23 | Proctor & Schwartz Electric Co | Flatiron |

| US2020538A (en) * | 1934-05-18 | 1935-11-12 | Coleman Lamp & Stove Co | Electric laundry iron |

| US2061419A (en) * | 1934-12-31 | 1936-11-17 | Edison General Elec Appliance | Temperature control device |

| US2078674A (en) * | 1935-01-02 | 1937-04-27 | Westinghouse Electric & Mfg Co | Baffled thermostat |

| US2111609A (en) * | 1935-04-10 | 1938-03-22 | Metals & Controls Corp | Thermostatically controlled heating device |

| US2115598A (en) * | 1935-08-06 | 1938-04-26 | Gen Electric | Temperature control device |

| US2277439A (en) * | 1935-08-30 | 1942-03-24 | Chicago Flexible Shaft Co | Sadiron |

| US2266708A (en) * | 1935-08-30 | 1941-12-16 | Chicago Flexible Shaft Co | Sadiron |

| US2124984A (en) * | 1936-03-28 | 1938-07-26 | Joseph Pavelks Sr | Electric iron |

| USRE21986E (en) * | 1937-05-17 | 1941-12-23 | Steam-generating flatiron | |

| US2183469A (en) * | 1939-03-20 | 1939-12-12 | Birtman Electric Co | Thermostat |

| US2277034A (en) * | 1939-03-30 | 1942-03-24 | Chicago Flexible Shaft Co | Sadiron |

| US2320013A (en) * | 1939-07-07 | 1943-05-25 | Mcgraw Electric Co | Electric iron |

| US2316907A (en) * | 1939-07-11 | 1943-04-20 | Wallace Stanley | Electric pressing iron |

| US2184270A (en) * | 1939-08-08 | 1939-12-26 | Gen Electric | Heating device |

| US2235891A (en) * | 1940-04-01 | 1941-03-25 | American Electrical Heater Co | Electric iron |

| US2281386A (en) * | 1940-04-02 | 1942-04-28 | Morris A Schwartz | Thermostatic control |

| US2338739A (en) * | 1940-08-02 | 1944-01-11 | Edward P Schreyer | Steam iron |

| US2311164A (en) * | 1941-02-24 | 1943-02-16 | Ernest F Pohl | Electric steaming iron |

| NL63487C (de) * | 1941-03-08 | 1900-01-01 | ||

| US2353425A (en) * | 1941-03-11 | 1944-07-11 | Westinghouse Electric & Mfg Co | Steam iron |

| US2368048A (en) * | 1941-05-02 | 1945-01-23 | Robert L Berenson | Electric steam iron |

| US2384644A (en) * | 1941-05-08 | 1945-09-11 | Edward P Schreyer | Pressing iron |

| US2345413A (en) * | 1941-05-20 | 1944-03-28 | Westinghouse Electric & Mfg Co | Steam iron |

| US2421538A (en) * | 1941-05-21 | 1947-06-03 | Westinghouse Electric Corp | Thermostatic switch |

| US2300230A (en) * | 1941-06-16 | 1942-10-27 | American Electrical Heater Co | Thermometer unit for electric irons |

| US2478507A (en) * | 1941-11-01 | 1949-08-09 | Mcgraw Electric Co | Electrically heated sadiron |

| US2439795A (en) * | 1942-01-09 | 1948-04-20 | Westinghouse Electric Corp | Thermostat |

| US2409420A (en) * | 1942-03-26 | 1946-10-15 | Westinghouse Electric Corp | Heating appliance |

| US2337078A (en) * | 1942-04-11 | 1943-12-21 | Westinghouse Electric & Mfg Co | Steam iron |

| US2389588A (en) * | 1942-10-29 | 1945-11-27 | Westinghouse Electric Corp | Heating apparatus |

| US2389587A (en) * | 1942-11-05 | 1945-11-27 | Westinghouse Electric Corp | Heating apparatus |

| US2422856A (en) * | 1944-05-18 | 1947-06-24 | William B Croney | Tilting electric flatiron |

| US2433556A (en) * | 1944-06-30 | 1947-12-30 | Philco Corp | Steam iron |

| US2496746A (en) * | 1944-11-04 | 1950-02-07 | Radiron Corp | Electric iron |

| US2476083A (en) * | 1945-01-18 | 1949-07-12 | Westinghouse Electric Corp | Thermostatic switch |

| US2585928A (en) * | 1945-04-02 | 1952-02-19 | Mcgraw Electric Co | Electric iron and method of making of same |

| US2527409A (en) * | 1946-05-31 | 1950-10-24 | Wilfred E Ellinwood | Tank for steam irons |

| US2500185A (en) * | 1946-11-22 | 1950-03-14 | Gen Electric | Steam iron steam generating means and water supply means therefor |

| US2537808A (en) * | 1946-12-11 | 1951-01-09 | Winsted Hardware Mfg Company | Electric-iron thermostat |

| US2547558A (en) * | 1947-09-22 | 1951-04-03 | Harry E Bremer | Steam generating electric iron |

| US2653480A (en) * | 1948-09-03 | 1953-09-29 | Presto Ind Inc | Temperature indicator for hand pressing irons |

| US2553274A (en) * | 1949-05-06 | 1951-05-15 | Ernest F Pohl | Electric heating unit for pressing irons |

| US2655745A (en) * | 1950-05-16 | 1953-10-20 | Casco Products Corp | Electric steam iron |

| US2694766A (en) * | 1950-09-25 | 1954-11-16 | Mcgraw Electric Co | Thermostat construction for sadirons |

| US2693651A (en) * | 1951-02-21 | 1954-11-09 | Kistner Merrill Miller | Folding steam iron |

| US2741044A (en) * | 1951-10-04 | 1956-04-10 | Nat Presto Ind | Sprinkling and steaming flat iron |

| US2668378A (en) * | 1952-06-27 | 1954-02-09 | Hoover Co | Electric iron |

| US2865119A (en) * | 1954-02-24 | 1958-12-23 | Mc Graw Edison Co | Steam iron with thermally-operated valve |

| US2810813A (en) * | 1954-10-27 | 1957-10-22 | Gen Electric | Thermostatically controlled flatiron |

| US2806106A (en) * | 1955-05-17 | 1957-09-10 | Stevens Mfg Co Inc | Constant calibration thermostat |

| US2833903A (en) * | 1956-02-16 | 1958-05-06 | Robert L Waddell | Fully automatic electric iron |

| US2903804A (en) * | 1956-10-23 | 1959-09-15 | Merrill M Kistner | Steam iron |

| US2976388A (en) * | 1957-05-27 | 1961-03-21 | Gen Electric | Thermostat control |

| US2887800A (en) * | 1957-05-27 | 1959-05-26 | Kistner Merrill Miller | Steam iron |

| US3098921A (en) * | 1957-07-10 | 1963-07-23 | Sunbeam Corp | Composite electrically heated devices |

| US2976627A (en) * | 1958-11-04 | 1961-03-28 | Steam Iron Corp | Steam iron |

| US2952086A (en) * | 1958-11-04 | 1960-09-13 | Steam Iron Corp | Steam iron |

| US3248813A (en) * | 1962-02-16 | 1966-05-03 | Carl F Quick | Steam iron |

| US3352998A (en) * | 1964-10-08 | 1967-11-14 | Matsushita Electric Industrial Co Ltd | Electric iron |

| US3403464A (en) * | 1967-02-20 | 1968-10-01 | Scovill Manufacturing Co | Electric iron with pushbutton valve control mechanism for converting from dry to steam operation and vice versa |

| US3412492A (en) * | 1967-08-10 | 1968-11-26 | Reimers Electra Steam Inc | Steam iron |

| US4017988A (en) * | 1976-04-07 | 1977-04-19 | General Electric Company | Self-cleaning steam iron |

| US4091551A (en) * | 1976-10-28 | 1978-05-30 | General Electric Company | Extra capacity steam iron |

| GB2064595A (en) * | 1979-11-30 | 1981-06-17 | Bimak Srl | Adjustable temperature electric iron |

| US4535556A (en) * | 1983-03-01 | 1985-08-20 | Alfredo Cavalli | Steam ironing apparatus with a separate water reservoir |

| US4523079A (en) * | 1983-09-20 | 1985-06-11 | Black & Decker Inc. | Electric iron having electronic control circuit with a power resistor mounted on the soleplate |

| US4686352B1 (en) * | 1984-04-27 | 1993-12-14 | Sunbeam Corporation | Electronic pressing iron |

| EP0187966B1 (de) * | 1984-12-18 | 1990-10-31 | Matsushita Electric Industrial Co., Ltd. | Heizgerät mit Wärmespeicheranordnung |

| US4688340A (en) * | 1985-01-16 | 1987-08-25 | Black & Decker Inc. | Travel steam and dry iron |

| DE3671055D1 (de) * | 1985-07-09 | 1990-06-13 | Aim Ind Australia | Selbsttaetige streichvorrichtung. |

| JPS6282919A (ja) * | 1985-10-04 | 1987-04-16 | 株式会社東芝 | 炊飯器 |

| US4745260A (en) * | 1986-01-22 | 1988-05-17 | Black & Decker Inc. | Automatic switching apparatus for an electric appliance |

| US4688339A (en) * | 1986-11-24 | 1987-08-25 | Tsai Hui Fang | No leak steam iron |

| US4748755A (en) * | 1986-12-29 | 1988-06-07 | Sunbeam Corporation | Housing assembly for electric steaming and pressing iron |

| FR2625641B1 (fr) * | 1987-12-30 | 1990-06-01 | Seb Sa | Procede pour realiser une plaque chauffante et article chauffant s'y rapportant |

| US4857706A (en) * | 1988-02-29 | 1989-08-15 | Diamond Paul J | Ironing accessory |

| US4910362A (en) * | 1988-03-14 | 1990-03-20 | Kinner Janet L | Electrical appliance with holder for securing an electrical cord |

| NL8900749A (nl) * | 1989-03-28 | 1990-10-16 | Philips Nv | Stoomstrijkijzer. |

| US5111028A (en) * | 1989-09-11 | 1992-05-05 | White Consolidated Industries, Inc. | Method and control arrangement for cooking appliances |

| US4939856A (en) * | 1989-09-25 | 1990-07-10 | Black & Decker Inc. | Adjustable steam flow control for an electric steam iron |

| US5028295A (en) * | 1989-10-10 | 1991-07-02 | Cracchiolo Jerome S | Carpet seaming iron with ultra thin guide strut and improved heat control |

| FR2654122B1 (fr) * | 1989-11-07 | 1993-07-30 | Moulinex Sa | Fer a repasser electrique. |

| GB2250755A (en) * | 1990-12-05 | 1992-06-17 | Superluck Electrics Corp | An ultrasonic iron |

| FR2679270A1 (fr) * | 1991-07-19 | 1993-01-22 | Philips Electronique Lab | Fer a repasser muni d'un detecteur de la nature des tissus. |

| DE4325453A1 (de) * | 1993-07-29 | 1995-02-02 | Philips Patentverwaltung | Elektrisches Bügeleisen |

| US5345703A (en) * | 1993-10-06 | 1994-09-13 | Black & Decker, Inc. | Steam iron seal with tangential flow for surge |

| DE4414221A1 (de) * | 1994-04-23 | 1995-10-26 | Braun Ag | Dampfbügeleisen |

| US5408769A (en) * | 1994-05-10 | 1995-04-25 | Black & Decker Inc. | Thermostat control for an electric iron |

| US5404662A (en) * | 1994-05-10 | 1995-04-11 | Black & Decker Inc. | Steam iron with a vertical steaming feature |

| US5595672A (en) * | 1994-05-19 | 1997-01-21 | Pentalpha Enterprises Ltd. | Automatic power interrupting apparatus for an electric appliance |

| DE69515986T2 (de) * | 1994-10-28 | 2000-11-02 | Koninklijke Philips Electronics N.V., Eindhoven | Verfahren zum dichten der dampfkammer eines bügeleisens |

| FR2728914A1 (fr) * | 1994-12-29 | 1996-07-05 | Philips Electronique Lab | Fer a repasser muni d'un detecteur thermique mesurant une temperature de tissu |

| CN1070559C (zh) * | 1995-01-23 | 2001-09-05 | 皇家菲利浦电子有限公司 | 用一种具有控制蒸汽发生量的织物温度传感器的蒸汽电熨斗 |

| DE19524333C1 (de) * | 1995-07-04 | 1996-08-14 | Rowenta Werke Gmbh | Dampfbügeleisen |

| US5615500A (en) * | 1995-11-03 | 1997-04-01 | Black & Decker Inc. | Iron with improved connection of soleplate and steam chamber cover |

| US5787615A (en) * | 1995-11-14 | 1998-08-04 | Sunbeam Products, Inc. | Spray and steam pump for a steam iron |

| US5628131A (en) * | 1995-12-18 | 1997-05-13 | Black & Decker Inc. | Steam surge system for an electric steam iron |

| US5747778A (en) * | 1996-01-05 | 1998-05-05 | Liu; Jung-Yang | Hot melting iron having a safety control circuit board |

| US5606810A (en) * | 1996-01-16 | 1997-03-04 | Black & Decker Inc. | Wire spacer for a shaft in an electrical appliance |

| US5623775A (en) * | 1996-01-16 | 1997-04-29 | Black & Decker Inc. | Electric steam iron with improved water tank and skirt assembly |

| US5704143A (en) * | 1996-08-19 | 1998-01-06 | Black & Decker Inc. | Dual surge iron with steam generating areas |

| US5718071A (en) * | 1997-01-10 | 1998-02-17 | Black & Decker Inc. | Steam iron with steam chamber ramp, puddle containment, and surge drying wall |

| US5901481A (en) * | 1997-08-15 | 1999-05-11 | Simmons; Michael E. | Ironing device for infant and children's clothing |

| DE19839730C1 (de) * | 1998-09-01 | 2000-03-30 | Gerd Reime | Schutzvorrichtung für Bügelgeräte |

| US5944943A (en) * | 1998-01-28 | 1999-08-31 | Orcon Corporation | Carpet seaming iron |

| DE19904815A1 (de) * | 1999-02-05 | 2000-08-10 | Braun Gmbh | Bügeleisen |

| US6172335B1 (en) * | 1999-08-27 | 2001-01-09 | Orcon Corporation | Carpet seaming iron with electronic temperature control |

| US6209239B1 (en) * | 1999-09-01 | 2001-04-03 | Hamilton Beach/Proctor-Silex, Inc. | Steam iron and method of manufacture of the steam chamber |

| US6243976B1 (en) * | 1999-09-01 | 2001-06-12 | Hamilton Beach/Proctor Silex, Inc. | Fill port assembly for a steam iron |

| US6568848B1 (en) * | 1999-09-20 | 2003-05-27 | Maverick Industries, Inc. | Wireless remote cooking thermometer system |

| FR2808162B1 (fr) * | 2000-04-21 | 2003-01-03 | Seb Sa | Element chauffant sur substrat aluminium pour appareil electromenager |

| US20020029498A1 (en) * | 2000-07-03 | 2002-03-14 | Howard Harrison | Rapid cool iron and related iron improvements |

| CN2427865Y (zh) * | 2000-07-06 | 2001-04-25 | 黄孝安 | 带显示屏的电熨斗 |

| US6683587B2 (en) * | 2001-07-31 | 2004-01-27 | Microchip Technology Incorporated | Switched mode digital logic method, system and apparatus for directly driving LCD glass |

| CN2530971Y (zh) * | 2001-12-31 | 2003-01-15 | 广东德豪润达电气股份有限公司 | 一种低温蒸汽电熨斗 |

| US20030136032A1 (en) * | 2002-01-17 | 2003-07-24 | Leung Albert Yat-Cheong | Self-cleaning steam iron |

| US6883257B2 (en) * | 2002-03-15 | 2005-04-26 | Kenneth J. Couch | Ironing board |

| US20050028408A1 (en) * | 2003-08-06 | 2005-02-10 | Tobias Andrew J. | Convertible iron/steamer |

| WO2005059233A1 (en) * | 2003-12-16 | 2005-06-30 | Koninklijke Philips Electronics N.V. | Steam iron having a lightweight soleplate and flat resistive heating tracks for heating the soleplate |

| US7096612B2 (en) * | 2004-01-30 | 2006-08-29 | Celaya, Emparanza Y Galdos, Internacional, S.A. | Domestic steam irons having a vaporization chamber and fitted with independent heat element |

| CN2719894Y (zh) * | 2004-03-24 | 2005-08-24 | 代允通 | 温度数显电熨斗 |

| US20060081588A1 (en) * | 2004-10-05 | 2006-04-20 | Bowser John O | Electric pressing iron with user interface |

| US20060076341A1 (en) * | 2004-10-08 | 2006-04-13 | Lozinski Gerald J | Pop-up auto-shutoff indicator for electric pressing irons |

| CN2858724Y (zh) * | 2005-10-08 | 2007-01-17 | 徐建忠 | 具有数字显示功能的蒸汽电熨斗 |

| FR2895421B1 (fr) * | 2005-12-22 | 2008-06-06 | Rowenta Werke Gmbh | Fer a repasser comprenant une vanne commandee par un element thermiquement deformable |

| US7395619B2 (en) * | 2006-01-27 | 2008-07-08 | Tunbow Electrical Limited | Steam iron |

| US20100257761A1 (en) * | 2009-04-08 | 2010-10-14 | Lung Wai Choi | Electric iron with a synchronizing temperature display |

-

2010

- 2010-03-19 US US12/727,237 patent/US20100257761A1/en not_active Abandoned

- 2010-03-22 AT AT10157182T patent/ATE545728T1/de active

- 2010-03-22 EP EP10157182A patent/EP2239367B1/de not_active Not-in-force

- 2010-03-26 HK HK10103166.0A patent/HK1138992A2/xx not_active IP Right Cessation

- 2010-03-30 CN CN201010157052.1A patent/CN101858032B/zh not_active Expired - Fee Related

- 2010-03-30 CN CN201020176753.5U patent/CN201634928U/zh not_active Expired - Lifetime

- 2010-04-02 JP JP2010002210U patent/JP3160112U/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| CN101858032B (zh) | 2013-03-27 |

| CN101858032A (zh) | 2010-10-13 |

| HK1138992A2 (zh) | 2010-09-03 |

| CN201634928U (zh) | 2010-11-17 |

| HK1150245A1 (en) | 2011-11-11 |

| JP3160112U (ja) | 2010-06-10 |

| ATE545728T1 (de) | 2012-03-15 |

| EP2239367A1 (de) | 2010-10-13 |

| US20100257761A1 (en) | 2010-10-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2239367B1 (de) | Elektrisches Dampfbügeleisen mit einer Synchronisierungstemperaturanzeige | |

| EP3202972B1 (de) | Wäschetrocknerbedienfeldvorrichtung und wäschetrockner | |

| CN205789718U (zh) | 一种温控器导电片组件结构 | |

| CN205919373U (zh) | 电磁炉 | |

| CN205789717U (zh) | 一种利用自身电阻控制温度的温控器 | |

| US20060043086A1 (en) | Domestic electric appliance | |

| CN206379304U (zh) | 可调节的温控器 | |

| CN207295119U (zh) | 局部熨烫型电子圆头锁眼机 | |

| HK1150245B (en) | Electric iron with a synchronizing temperature display | |

| CN204753211U (zh) | 电子控温熨斗 | |

| CN205828275U (zh) | 一种温控器的热传导结构 | |

| CN200994684Y (zh) | 安全型电饭煲 | |

| CN219862038U (zh) | 电熨斗 | |

| CN112438607B (zh) | 用于烹饪的控制方法、烹饪器具及计算机存储介质 | |

| CN209202856U (zh) | 一种控制装置可活动调整的烹饪器具 | |

| CN223682029U (zh) | 可拆卸组件式多区域智能独立温控加热服饰 | |

| CN218246803U (zh) | 电热水壶 | |

| CN219642134U (zh) | 一种自动调温系统及控制开关 | |

| CN215899447U (zh) | 瓶体加热套用加热膜 | |

| CN105352123B (zh) | 遥控器 | |

| CN214254931U (zh) | 集成式耦合器的安装结构 | |

| CN218279313U (zh) | 电热水壶 | |

| KR200350562Y1 (ko) | 전열식 매트의 히터선 배선구조 | |

| JP3777108B2 (ja) | 電気調理器 | |

| CN201358388Y (zh) | 数控恒温保温电热干衣器 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA ME RS |

|

| 17P | Request for examination filed |

Effective date: 20110331 |

|

| 17Q | First examination report despatched |

Effective date: 20110520 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: D06F 75/26 20060101AFI20110914BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 545728 Country of ref document: AT Kind code of ref document: T Effective date: 20120315 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602010000850 Country of ref document: DE Effective date: 20120412 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20120215 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20120215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120615 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120515 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120615 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120516 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 545728 Country of ref document: AT Kind code of ref document: T Effective date: 20120215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120331 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| 26N | No opposition filed |

Effective date: 20121116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602010000850 Country of ref document: DE Effective date: 20121116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120526 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120515 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120215 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120322 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100322 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140331 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20150319 Year of fee payment: 6 Ref country code: GB Payment date: 20150319 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150331 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602010000850 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160322 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20161130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160322 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161001 |