EP2201299B1 - Stützring für hitzeschildelemente eines flammenrohrs und eine brennkammeranordnung mit einem derartigen stützring - Google Patents

Stützring für hitzeschildelemente eines flammenrohrs und eine brennkammeranordnung mit einem derartigen stützring Download PDFInfo

- Publication number

- EP2201299B1 EP2201299B1 EP08842468A EP08842468A EP2201299B1 EP 2201299 B1 EP2201299 B1 EP 2201299B1 EP 08842468 A EP08842468 A EP 08842468A EP 08842468 A EP08842468 A EP 08842468A EP 2201299 B1 EP2201299 B1 EP 2201299B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- support ring

- flame tube

- groove

- combustion chamber

- groove wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000002485 combustion reaction Methods 0.000 title claims abstract description 23

- 238000002156 mixing Methods 0.000 claims description 30

- 238000005253 cladding Methods 0.000 claims 4

- 239000004575 stone Substances 0.000 description 26

- 238000001816 cooling Methods 0.000 description 16

- 239000007789 gas Substances 0.000 description 15

- 230000007704 transition Effects 0.000 description 3

- 238000005299 abrasion Methods 0.000 description 2

- 239000000919 ceramic Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000007689 inspection Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000002093 peripheral effect Effects 0.000 description 2

- 230000001052 transient effect Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000005552 hardfacing Methods 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/007—Continuous combustion chambers using liquid or gaseous fuel constructed mainly of ceramic components

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/42—Continuous combustion chambers using liquid or gaseous fuel characterised by the arrangement or form of the flame tubes or combustion chambers

- F23R3/60—Support structures; Attaching or mounting means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23M—CASINGS, LININGS, WALLS OR DOORS SPECIALLY ADAPTED FOR COMBUSTION CHAMBERS, e.g. FIREBRIDGES; DEVICES FOR DEFLECTING AIR, FLAMES OR COMBUSTION PRODUCTS IN COMBUSTION CHAMBERS; SAFETY ARRANGEMENTS SPECIALLY ADAPTED FOR COMBUSTION APPARATUS; DETAILS OF COMBUSTION CHAMBERS, NOT OTHERWISE PROVIDED FOR

- F23M2900/00—Special features of, or arrangements for combustion chambers

- F23M2900/05002—Means for accommodate thermal expansion of the wall liner

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/03041—Effusion cooled combustion chamber walls or domes

Definitions

- the present invention relates to a support ring for heat shield elements of a flame tube, in particular a flame tube of a gas turbine.

- the invention relates to a combustion chamber arrangement with a flame tube and a mixing housing, as it finds particular use in gas turbines.

- Support rings for heat shield elements may have a groove extending on its outer side, which serves as a cooling air passage.

- a section of a support ring according to the prior art is in FIG. 1 illustrated, wherein the support ring is received by the batt ring of a mixing housing.

- the figure shows a section of the support ring 1 and a section of a peg 3 of a mixing housing in a schematic cross-sectional view.

- the support ring has a reinforced portion 5, which in turn is provided with an inner groove 7 and an outer groove 9, both of which extend over the full circumference of the support ring.

- the outer groove 9 and the inner groove 7 are fluidly connected to each other via a number of radial through holes 11.

- the outer groove 9 forms a fresh air supply for cooling the support ring 1.

- the fresh air is then passed through the holes 11 into the combustion chamber interior.

- the reinforced area 5 also forms a flange-like projection projecting toward the interior of the combustion chamber, which forms a support for heat shield elements.

- the object of the present invention is to provide an advantageous support ring and an advantageous combustion chamber arrangement, which in particular make it possible to extend the maintenance intervals for the transition between the flame tube and the mixing housing.

- a flame tube in particular a gas turbine flame tube

- at least one groove is present. This has a relation to the radial direction of the support ring obliquely extending groove wall. Suitable angles between the surface normal of the oblique groove wall to the radial direction of the support ring are in particular in the range between 30 ° and 60 °.

- the oblique groove wall leads when grinding the Zinnenkranzes a mixing housing in the support ring that forms a wedge-shaped projection in the pinnacles. This has one of the oblique groove wall corresponding wedge surface. If, when switching off the gas turbine due to the different thermal expansion behavior of mixing housing and support ring in the axial direction of the support ring acting forces occur, the slope leads to acting in the radial direction of the support ring forces are generated which separate the pinnacles from the support ring. As a result, in particular the tearing off of pinnacles due to an excessive force in the axial direction of the support ring is avoided.

- passage openings may be located in the region of the groove which extend from the outside of the support ring to its inner side and serve as cooling air openings for cooling the support ring and for removing cooling air introduced through the groove.

- the groove wall opposite the oblique groove wall may have a non-planar geometry. In particular, it may form a curved surface in the axial direction of the support ring.

- a wear-resistant layer hard-facing, wear-resistant layer

- a combustion chamber arrangement according to the invention has a flame tube and a mixing housing. It can be used in particular in gas turbines.

- the flame tube has an output end with a support ring for heat shield elements, in particular for ceramic heat shield elements.

- the mixing housing has an edge with protruding pinnacles, wherein the pinnacles form a receiving portion for receiving the support ring.

- the Support ring designed as a support ring according to the invention.

- the armor of the pinnacles can be harder than the armor of the support ring.

- the armor can also be the same, or the armor of the support ring may be harder than the armor of the battlements.

- the armor of the merlons is harder than that of the support ring, since a mending and replacing the support ring in comparison to a repair or replacement of battlements represents less effort.

- a demolition of battlements with the same armor is more likely than damage to the support ring and has more critical consequences for the gas turbine.

- a combustion chamber arrangement according to the invention which has a support ring according to the invention for heat shield elements, also called a stone support ring, will be described below with reference to FIGS FIGS. 3 to 7 described.

- the present embodiment shows a combustion chamber arrangement in which the flame tube is arranged vertically, ie, the axial direction of the flame tube extends in the vertical direction.

- the radial directions of the flame tube represent horizontal directions. The hot gas flowing out of the flame tube in the vertical direction is deflected by the mixing housing in a horizontal flow direction.

- FIG. 3 shows the combustion chamber assembly, which has a flame tube 101 with a burner end 103, on which the burner (not shown) are arranged, and an outlet end 105, from which occur in the combustion chamber resulting hot gases occur, in a sectional view.

- the flame tube 101 is inserted with its outlet end 105 into a receptacle 109 of a mixing housing 107.

- the mixing housing passes the hot gases leaving the flame tube 101 to the turbine (not shown).

- the interior of the flame tube 101 is provided with ceramic heat shield elements, also called heat shield stones, to protect the combustion chamber wall from the corrosive hot gas.

- the heat shield stones 111 holding stone support ring 113 is arranged, of which a substantial part in the receptacle 109 of the mixing housing 107 is located.

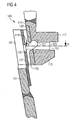

- the receiving portion 109 and the stone support ring 113 are in FIG. 4 partially enlarged.

- the stone support ring 113 has an outer side 115 and an inner side 117. Both in the outside 115, and in the inside 117 grooves 119, 121 are present, which extend over the entire circumference of the stone support ring 113.

- the outside of the stone support ring 113 is also provided with an abrasion-reducing armor 129.

- At regular intervals distributed around the circumference of the stone support ring 113 through holes 123 are present, which connect the groove 119 in the outer side 117 (hereinafter called outer groove 119) with the formed in the inner side 117 groove 121 (hereinafter referred to as inner groove 121) fluidly connect.

- the outer groove 119 serves as a cooling air passage, which allows the distribution of cooling air around the stone support ring 113 around.

- the cooling air can then pass from the outer groove 119 through the through holes 123 in the inner groove 121 and from there into the combustion chamber interior.

- the outer groove 117 and the inner groove 121 are disposed in a flange-like protrusion 122 protruding radially toward the combustion chamber interior.

- the upper surface 124 of the projection 122 forms a support surface for the lowermost row of the heat shield elements 111 (see FIG FIG. 3 ).

- the outer groove 119 of the stone support ring 113 has an inclined with respect to the radial direction of the stone support ring 113 groove wall 125.

- the surface normal of the oblique groove wall 125 includes with the radial direction of the support ring 113 an angle between 30 ° and 60 °. In the present embodiment, the angle is about 40 °.

- the oblique groove wall 125 opposite groove wall 127 has a non-planar geometry and is curved in the present embodiment in the axial direction of the support ring 113.

- a section through the stone support ring 113 along the line VV in FIG. 4 is in FIG. 5 shown. It can be seen in this that the through holes 123 do not extend in the radial direction of the support ring 113, but are inclined in the circumferential direction and enclose an angle of about 60 ° with the radial direction.

- the stone support ring 113 of the flame tube 101 is inserted into the receiving portion 109 of the mixing housing 107.

- This receiving portion 109 is formed by pinnacles 133, which are formed in the wall 131 of the mixing housing.

- the pinnacles 133 are in this case formed by a wall section of the mixing housing, which is penetrated by circumferentially distributed around the mixing housing recesses or recesses. These recesses or recesses extend from the edge of the peripheral wall, starting substantially in the axial direction of the flange into the peripheral wall.

- the receiving section 109 is given an increased flexibility with respect to the wall section of the mixing housing 107 which is not provided with the recesses or recesses, so that forces occurring between the mixing housing 107 and the flame tube 101 can be compensated to a certain extent.

- the inner sides 135 of the pinnacles 133 are planar and provided with an armor 137.

- the armor 137 of the merlons is harder than the armor 129 of the outside 115 of the stone support ring 113, so that occurring during operation abrasion caused by friction of the stone support ring 113 on the inside of the pinnacles 133, to a large extent on the stone support ring 113 concentrated.

- FIG. 6 shows a section of the stone support ring 113 and the receiving portion 109 when the combustion chamber assembly has reached a certain operating time.

- the Zinnenkranz of the mixing housing 107 grinds into the stone support ring 113 of the flame tube 101, if no previous findings and replacement or repair takes place. This condition is in FIG. 6 shown.

- the grinding creates a projection 139 in the pinnacles 133, which protrudes into the outer groove 119, that is, into the cooling air passage.

- this projection 139 has an oblique side 141 which is largely parallel to the oblique groove wall 125.

- the oblique groove wall 125 and the oblique side 141 created during grinding in the projections 139 of the pinnacles thus lead to a bevelled contact surface in relation to the radial direction and the axial direction of the two components, which uses or generates the forces generated by transient movement of the components with temperature changes ., converts the components independently of each other, ie, they are pushed apart, and the forces that occur do not cause any consequential damage, such as tearing of battlements, deformation, etc.

- a force diagram which transiently the force F caused by transient motion and the force exerted on the flame tube resultant force F and the resulting result.Fl the mixing housing force F result.Mi shows, in FIG. 7 shown.

- the curved side 127 of the outer groove 119 in the stone support ring 113 also causes even with considerable wear and an associated deep digging of the pinnacles 133 in the outer groove 119 of the stone support ring 113 always given a sufficiently large cooling air passage for the stone support ring is. An obstruction of thedeluftpasssage can be avoided.

- the groove wall 127 opposite the inclined groove wall 125 is curved

- the groove wall can be roof-shaped, that is to say with two planar wall sections which meet one another at an angle. In the simplest case, this can be realized by a rectangular in cross-section groove is introduced at an angle relative to the radial direction of the stone support ring 113 in the outside 115.

- the angle which the groove encloses with the radial direction is in this case preferably in the range between 30 ° and 60 °. In order to avoid blockage of the cooling air passage by a deeper incorporation of the battlements (abandoned by a longer operation), they can be introduced beyond the height of the possible incorporated batt in the support ring.

- the stone support ring is provided in the region of the groove (cooling air supply) with a slope (for example 40 °, but the slope is variable and functionally selected), which has a forced demolition of mixing housing and stone support ring result in cooling of the components.

- a slope for example 40 °, but the slope is variable and functionally selected

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Combustion Of Fluid Fuel (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Gas Burners (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL08842468T PL2201299T3 (pl) | 2007-10-26 | 2008-10-23 | Pierścień podporowy dla elementów osłony cieplnej płomienicy i układ komory spalania z tego rodzaju pierścieniem podporowym |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007051649 | 2007-10-26 | ||

| PCT/EP2008/064333 WO2009053417A2 (de) | 2007-10-26 | 2008-10-23 | Stützring für hitzeschildelemente eines flammenrohrs und eine brennkammeranordnung mit einem derartigen stützring |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2201299A2 EP2201299A2 (de) | 2010-06-30 |

| EP2201299B1 true EP2201299B1 (de) | 2011-05-11 |

Family

ID=40340467

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08842468A Active EP2201299B1 (de) | 2007-10-26 | 2008-10-23 | Stützring für hitzeschildelemente eines flammenrohrs und eine brennkammeranordnung mit einem derartigen stützring |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP2201299B1 (ru) |

| CN (1) | CN101855497B (ru) |

| AT (1) | ATE509236T1 (ru) |

| PL (1) | PL2201299T3 (ru) |

| RU (1) | RU2478881C2 (ru) |

| WO (1) | WO2009053417A2 (ru) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102012204103A1 (de) * | 2012-03-15 | 2013-09-19 | Siemens Aktiengesellschaft | Hitzeschildelement für einen Verdichterluftbypass um die Brennkammer |

| DE102017207392A1 (de) | 2017-05-03 | 2018-11-08 | Siemens Aktiengesellschaft | Silobrennkammer und Verfahren zum Umrüsten einer solchen |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8618859U1 (de) * | 1986-07-14 | 1988-01-28 | Siemens AG, 1000 Berlin und 8000 München | Hitzeschild |

| EP0539359B1 (de) * | 1990-07-17 | 1994-04-20 | Siemens Aktiengesellschaft | Rohrstück, insbesondere Flammrohr, mit gekühltem Stützrahmen für eine hitzefeste Auskleidung |

| US5749218A (en) * | 1993-12-17 | 1998-05-12 | General Electric Co. | Wear reduction kit for gas turbine combustors |

| GB2298267B (en) * | 1995-02-23 | 1999-01-13 | Rolls Royce Plc | An arrangement of heat resistant tiles for a gas turbine engine combustor |

| RU2212591C1 (ru) * | 2002-05-16 | 2003-09-20 | Открытое акционерное общество "Научно-производственное объединение "Сатурн" | Кольцевая камера сгорания газотурбинного двигателя |

| RU2300706C2 (ru) * | 2005-05-05 | 2007-06-10 | Открытое акционерное общество "Авиадвигатель" | Трубчато-кольцевая камера сгорания газотурбинного двигателя |

| EP2049840B1 (de) * | 2006-08-07 | 2018-04-11 | Ansaldo Energia IP UK Limited | Brennkammer einer verbrennungsanlage |

-

2008

- 2008-10-23 RU RU2010121163/06A patent/RU2478881C2/ru active

- 2008-10-23 EP EP08842468A patent/EP2201299B1/de active Active

- 2008-10-23 PL PL08842468T patent/PL2201299T3/pl unknown

- 2008-10-23 CN CN2008801132621A patent/CN101855497B/zh active Active

- 2008-10-23 AT AT08842468T patent/ATE509236T1/de active

- 2008-10-23 WO PCT/EP2008/064333 patent/WO2009053417A2/de active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| ATE509236T1 (de) | 2011-05-15 |

| EP2201299A2 (de) | 2010-06-30 |

| CN101855497A (zh) | 2010-10-06 |

| PL2201299T3 (pl) | 2011-10-31 |

| RU2010121163A (ru) | 2011-12-10 |

| WO2009053417A2 (de) | 2009-04-30 |

| RU2478881C2 (ru) | 2013-04-10 |

| CN101855497B (zh) | 2012-09-05 |

| WO2009053417A3 (de) | 2010-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102005060961B4 (de) | Gasturbine | |

| DE602004011859T2 (de) | Vorrichtung für die Regelung von Spalten in einer Gasturbine | |

| DE102011009409B4 (de) | Spinne für die Verwendung mit einem Kreiselbrecher sowie Kreiselbrecher mit einer Spinne | |

| DE102004023879B4 (de) | Axialdampfturbine | |

| DE102015100874A1 (de) | Dichtungseinrichtung zur Erbringung einer Abdichtung in einer Turbomaschine | |

| EP2196734A1 (de) | Brennstofflanze für einen Brenner | |

| DE102016205320A1 (de) | Turbinenschaufel mit Kühlstruktur | |

| DE102011105762A1 (de) | Kippsegmentlager | |

| DE102012100013A1 (de) | Axiale Haltevorrichtung für ein Turbinensystem | |

| WO2016071186A1 (de) | Brenneranordnung | |

| DE102006015327B9 (de) | Kolbenstangendichtring | |

| EP2201299B1 (de) | Stützring für hitzeschildelemente eines flammenrohrs und eine brennkammeranordnung mit einem derartigen stützring | |

| DE112016006522T5 (de) | Lagervorrichtung und Rotationsmaschine | |

| DE102014113510A1 (de) | Flüssigkeitsventil und dessen Spindel-Verpackungs-Konstruktion | |

| DE10303340A1 (de) | Kühleinrichtung | |

| DE102005033364A1 (de) | Axialdampfturbinenanordnung | |

| DE2158578A1 (de) | Stator-Schaufelkonstruktion | |

| DE102017207667A1 (de) | Verfahren zum Instandhalten einer Strömungsmaschine | |

| EP1656522A1 (de) | Brennkammer, insbesondere gasturbinenbrennkammer | |

| EP2024684B1 (de) | Gasturbine mit gepanzerten maschinenkomponenten | |

| EP3593048B1 (de) | Silobrennkammer und verfahren zum umrüsten einer solchen | |

| DE19943264A1 (de) | Maschine, insbesondere Zweitakt-Großdieselmotor | |

| EP3536913A1 (de) | Innenring für eine turbomaschine und entsprechendes herstellungsverfahren | |

| AT512609A1 (de) | Federelement | |

| EP2712704B1 (de) | Topfschleifscheibe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20100326 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: SUPPORT RING FOR HEAT SHIELD ELEMENTS ON A FLAME TUBE AND A COMBUSTION CHAMBER ARRANGEMENT WITH SAID SUPPORT RING |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008003528 Country of ref document: DE Effective date: 20110622 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110912 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110811 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E011564 Country of ref document: HU |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110812 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110822 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110911 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120214 |

|

| BERE | Be: lapsed |

Owner name: SIEMENS A.G. Effective date: 20111031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111123 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502008003528 Country of ref document: DE Effective date: 20120214 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120629 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111023 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20121023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110511 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 509236 Country of ref document: AT Kind code of ref document: T Effective date: 20131023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131023 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: HU Payment date: 20181215 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191024 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502008003528 Country of ref document: DE Owner name: SIEMENS ENERGY GLOBAL GMBH & CO. KG, DE Free format text: FORMER OWNER: SIEMENS AKTIENGESELLSCHAFT, 80333 MUENCHEN, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20211025 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20211015 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20221101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221101 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20231024 Year of fee payment: 16 Ref country code: DE Payment date: 20231027 Year of fee payment: 16 |