EP2016269B1 - Dispositif et procede pour actionner un dispositif de controle de la puissance d'un moteur a combustion interne - Google Patents

Dispositif et procede pour actionner un dispositif de controle de la puissance d'un moteur a combustion interne Download PDFInfo

- Publication number

- EP2016269B1 EP2016269B1 EP07785891.8A EP07785891A EP2016269B1 EP 2016269 B1 EP2016269 B1 EP 2016269B1 EP 07785891 A EP07785891 A EP 07785891A EP 2016269 B1 EP2016269 B1 EP 2016269B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- input

- power control

- control device

- clutch

- adjusting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000002485 combustion reaction Methods 0.000 title claims description 11

- 238000000034 method Methods 0.000 title description 5

- 230000005540 biological transmission Effects 0.000 claims description 29

- 230000008878 coupling Effects 0.000 description 9

- 238000010168 coupling process Methods 0.000 description 9

- 238000005859 coupling reaction Methods 0.000 description 9

- 230000001419 dependent effect Effects 0.000 description 4

- 230000006872 improvement Effects 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 230000009347 mechanical transmission Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D11/00—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated

- F02D11/06—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated characterised by non-mechanical control linkages, e.g. fluid control linkages or by control linkages with power drive or assistance

- F02D11/10—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated characterised by non-mechanical control linkages, e.g. fluid control linkages or by control linkages with power drive or assistance of the electric type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D11/00—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated

- F02D11/06—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated characterised by non-mechanical control linkages, e.g. fluid control linkages or by control linkages with power drive or assistance

- F02D11/10—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated characterised by non-mechanical control linkages, e.g. fluid control linkages or by control linkages with power drive or assistance of the electric type

- F02D2011/101—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated characterised by non-mechanical control linkages, e.g. fluid control linkages or by control linkages with power drive or assistance of the electric type characterised by the means for actuating the throttles

- F02D2011/103—Arrangements for, or adaptations to, non-automatic engine control initiation means, e.g. operator initiated characterised by non-mechanical control linkages, e.g. fluid control linkages or by control linkages with power drive or assistance of the electric type characterised by the means for actuating the throttles at least one throttle being alternatively mechanically linked to the pedal or moved by an electric actuator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D2200/00—Input parameters for engine control

- F02D2200/02—Input parameters for engine control the parameters being related to the engine

- F02D2200/04—Engine intake system parameters

- F02D2200/0404—Throttle position

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D2200/00—Input parameters for engine control

- F02D2200/60—Input parameters for engine control said parameters being related to the driver demands or status

- F02D2200/602—Pedal position

Definitions

- the invention relates to a device for actuating a power control device of an internal combustion engine comprising a driver-actuated input device for driver input of a power desired, a sensor device for detecting the position of the input device and generating a corresponding output signal and an adjusting device for adjusting the power control device taking into account the output signal of the sensor device, wherein the Power control device by means of the adjusting device by the signal of the input device can be actuated deviating and a method for actuating such a power control device.

- the DE 198 25 283 A1 describes a motor power control for motor vehicles with a power control element, which is decoupled from the power demand of the driver reproducing operation of the accelerator pedal in response to various operating parameters controllable by means of an electronic control unit.

- this engine power control is in the event of a fault, especially in case of failure of the connection between a sensor associated with the accelerator pedal and the control unit, limited in an emergency operation, the maximum engine power and still ensures a very good driving dynamics.

- the safety in the event of a fault is already substantially increased in the known engine output control, however, a further improvement in safety is possible.

- a throttle control apparatus in which a reduction gear having a semicircular ratchet wheel is provided coaxially with a motor shaft between an engine and a throttle valve.

- a device which comprises not only mechanical transmission means but also electromechanical transmission means with a switchable coupling element between the accelerator pedal and the throttle valve, wherein the coupling element is a double-acting coupling element.

- the accelerator pedal can be connected to the throttle valve via the mechanical or electromechanical transmission means.

- a device for controlling the application of vehicle engines, in which in addition to the foot-operated accelerator lever, an adjusting device is provided which is coupled to the control member for the application of the motor, such as a throttle or a control rod of an injection pump.

- the EP 0 427 410 shows a throttle valve actuator for connecting a throttle valve of a motor vehicle with the accelerator pedal either in a direct drive mode or in a controlled drive mode.

- the object of the invention is therefore to increase safety in an aforementioned device for actuating a power control device of an internal combustion engine and in particular to prevent inadvertently high engine power due to a driver not wanted by the driver control of the power control element.

- the invention is based on the idea that the adjusting device is connected to the power control device by means of a coupling having an input part and an output part, whose input part is assigned to the adjusting device and whose output part is assigned to the power control device. This makes it possible to decouple the actuating device from the power control device, so that the position of the actuating device is no longer relevant to the position of the power control device.

- a mechanical connection between the input device and power control device is effective.

- the desired power input by means of the input device on the driver side is preferred to the position of the actuating device based on sensor signals, thus increasing safety.

- the input part of the clutch can be decoupled from its output part.

- the position of the adjusting device for the power control device is ineffective.

- the clutch is a releasable, pawl clutch.

- the pawl clutch is an overrunning clutch - and overhohlkupplung - and includes an input and an output part, which direction of rotation dependent pawls are connected to each other.

- input and clutch output are connected in the reverse direction with each other, but the connection is releasable by means of an unlocking, so that a relative rotation between the input and an output part can also be enabled in the reverse direction.

- a contoured first transmission element assigned to the input device corresponds to a second transmission element having a counter contour and connected to a pawl.

- the first transmission element on a flat extension, which with a pin-shaped extension of the pawl corresponds.

- an operation of the power control device by means of the adjusting device in consideration of the output signal of the sensor device for detecting the position of the input device is possible in a normal operation, while in a deviation of the input by means of the input side driver input reduced power requirement of the set by means of the actuator position of the power control device at least a predetermined amount in the closing direction of the power control device, a positive connection between the first and second transmission element comes about and can be done deviating from the actuator actuation.

- the pawl can be brought into the unlocked position.

- the pawl by means of the first transmission element is releasable.

- the pawl is movably mounted in a part of the clutch and corresponds actuation direction dependent force-transmitting with the other part of the clutch.

- the pawl in the output part of the clutch is longitudinally displaceable, biased in the reverse direction by a spring, mounted and corresponds by means of an actuating direction-dependent effective toothing with a toothing of the input part of the clutch.

- the pawl is mounted in the input part of the clutch and corresponds with a toothing of the output part of the clutch

- the invention is further based on the idea that in a method for actuating a power control device of an internal combustion engine in the case of a deviation of the desired power input by means of the input device from the position of the power control device set by the adjusting device by at least a predetermined amount in the closing direction, the desired power for adjusting the power control device is inputted to the driver via the input device.

- the control device in the case of a preference for the power requirement entered by the driver on the input side, the control device is decoupled from the power control device and the power control device is actuated directly by means of the input device.

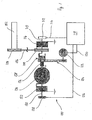

- FIG. 1 1 shows a device 100 for actuating a power control device 134 of an internal combustion engine (not shown here) with a clutch 138 arranged between an actuating device 122 and the power control device 134.

- the device 100 is for operating an internal combustion engine of a motorcycle and the power control device 134 is a throttle valve, however, in one embodiment, an internal combustion engine of a motor vehicle can be actuated and / or the power control device 134 is a Kraftstoffzumessventil or means for Hub Whynver selectedung an intake valve of an internal combustion engine be.

- the throttle valve is pivotable in the opening direction and to reduce the power in the closing direction.

- the throttle valve is rotatably connected to a throttle valve shaft 130, which is rotatable either by means of an here designed as an electric motor actuator 122 or manually by means of a here designed as a throttle grip input device 102.

- the driver inputs a power by means of the input device 102 by correspondingly rotating the throttle grip.

- a first pulley 104 is rotatably connected, which operates via a cable 106, a second pulley 108.

- the second pulley 108 is rotatably connected to a shaft 110, so that upon actuation of the throttle grip the shaft 110 is rotated.

- the rotation or the rotational position of the shaft 110 can be detected by means of a sensor 112, which is connected in a signal-conducting manner to a control device 118 by a line 114.

- the rotation or the rotational position of the throttle valve shaft 130 can be detected, which is connected to the control device 118 in a signal-conducting manner with a line 126.

- the control device 118 Based on the signals of the sensors 112, 128 and optionally further signals and / or stored information, the control device 118 outputs via a line 120 a driver's desired performance control signal to the actuator 122, which - in this case by means of a gear 124 with an input part of Clutch 138 is connected - with the throttle shaft 130 is in rotary drive connection.

- Both the shaft 110 and the throttle shaft 130 are acted upon by springs 116, 132 which are supported on the housing side in the throttle valve closing direction.

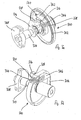

- FIG. 2 shows a detailed view of the clutch 138, which is designed as a releasable pawl clutch 200 in this embodiment.

- the pawl clutch 200 allows actuation of the power control device 134 either manually by means of the input device 102 or by means of the adjusting device 122.

- FIGS. 3a and 3b Detail views of the input part 302 and the unlocking of the unlockable locking clutch 300 and the output part 304 are in the FIGS. 3a and 3b shown.

- the pawl clutch 200, 333 comprises a pot-shaped input part 202, 302, which has a toothing 348 for connection to the toothing 344 of a pawl 206, 342 radially on the inside.

- a likewise cup-shaped output part 204, 304 is arranged, wherein the edge of the input part 202, 302 surrounds the edge of the output part 204, 304 and enclose input and output part of a disk-shaped space.

- the pawl 206, 342 is arranged, in this case, the output part 204, 304 a guide 346, in which the pawl 206, 342 is guided longitudinally displaceable.

- the guide 346 and the edge of the output part 204, 304 have an opening 220, 320 through which the pawl 206, 342 with its toothing 344 with the teeth 348 of the input part 202, 302 can correspond.

- the pawl 206, 342 is biased by a spring 340.

- the output part 204, 304 has a slot-shaped cutout 222, through which a pin-shaped extension 218, 318 of the pawl 206, 342 protrudes.

- the extension 218, 318 is designed with a spherical end.

- the extension 218, 318 corresponds to a flat extension 216, 316 of a disk-shaped transmission element 214, 314.

- the present arrangement forms a safety device, which in a deviation of the input by means of the input device 102 (throttle grip) driver input side reduced power desired from the set by means of the adjusting device 122 (electric motor) position of the power control device 134 (throttle) by at least a predetermined amount, a preferred consideration of means the input device 102 (throttle grip) ensures driver input side reduced power desired.

- the second pulley 108, 208 forms a first transmission element 214, 314, which has a flat extension 216, 316 and is arranged in the axial direction adjacent to the clutch 138, 200, 300, wherein the first transmission element 214, 314 and the clutch 138, 200 , 300 are each rotatable about at least approximately aligned axes relative to each other.

- the flat projection 216, 316 corresponds to the pin-shaped extension 218, 318 of the pawl 206, 342.

- the planar extension 216, 316 arrives at the pin-shaped extension 218, 318 to the plant or exerts a predetermined value exceeding pressure on this, wherein the first transmission element 214, 314 form-fit force-transmitting connected to the locking pawl 206, 342 second transmission element 220 and the pawl 206, 342 against the force of the spring 340 in Unlocking is moved.

- the teeth 344 of the pawl 206, 342 of the teeth 348 of the input part 202, 302 of the clutch 138, 200, 300 and the connection between input part 202, 302 and output part 204, 304 of the clutch 138, 200, 300 is released.

- the actuator 122 (electric motor) from the power control device 134 (throttle) is decoupled and the input device 102 (throttle grip) via the transmission elements 214, 314, 218, 318, 220, the pawl 206, 342 and the spring 340 with the Output part 204, 304 of the clutch 138, 200, 300 and thus with the power control device 134 (throttle) coupled.

- the power control device 134 is actuated in accordance with the setting device 122.

- the coupling input part 202, 302, the coupling output part 204, 304 with the second transmission element 342 and the first transmission element 214, 314 are arranged on a common shaft 310, wherein the pawl clutch 200, 300 with coupling input part 202, 302 and coupling output part 204, 304 with second transmission element 342 are rotatably mounted on the shaft 310 and the first transmission element 214, 314 with the shaft 310 is rotatably connected.

- the shaft 310 is kinematically coupled to the input device 102 (throttle grip), so that upon actuation of the input device 102, the shaft 310 and thus also the first transmission element 214, 314 are rotated.

- the adjusting device (electric motor) 122 which is coupled to the coupling input part 202, 302

- the clutch 200, 300 and thus also the second transmission element 342 is tracked according to the input by means of the input device 102 (throttle grip) driver input power requirement and only one small difference between the position of the input device 102 and the actuator 122 occurs, the flat projection 216, 316 of the first transmission element 214, 314 does not act on the pin-shaped extension 218, 318 of the second transmission element 342.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Control Of Throttle Valves Provided In The Intake System Or In The Exhaust System (AREA)

Claims (11)

- Installation (100) pour actionner une installation de commande de puissance (134) d'un moteur à combustion interne comprenant :- une installation d'entrée (102) actionnée par le conducteur pour entrer une demande de puissance par le conducteur,- une installation de capteurs (112) pour détecter la position de l'installation d'entrée (102) et générer un signal de sortie correspondant,- une installation de réglage (122) pour régler l'installation de commande de puissance (134) en tenant compte du signal de sortie de l'installation de capteur (112),installation dans laquelle l'installation de commande de puissance (134) est actionnée par l'installation de réglage (122) de manière différente du signal de l'installation d'entrée (102),

l'installation de réglage (122) est reliée à l'installation de commande de puissance (134) par un embrayage (138, 200, 300) ayant une partie entrée et une partie sortie (202, 204, 302, 304) dont la partie entrée (202, 302) est associée à l'installation de réglage (122) et dont la partie sortie (204, 304) est associée à l'installation de commande de puissance (134), caractérisée par

une liaison mécanique entre l'installation d'entrée (102) et l'installation de commande de puissance (134) agissant dans le sens de la fermeture de l'installation de commande de puissance (134) en cas d'écart de la demande de puissance réduite, introduite par l'installation d'entrée (102) côté conducteur par rapport à la position réglée par l'installation de réglage (122) de l'installation de commande de puissance (134). - Installation selon la revendication 1,

caractérisée par

un découplage de la partie entrée (202, 302), l'embrayage (138, 200, 300) par rapport à la partie de sortie (204, 304) agissant dans le sens de la fermeture de l'installation de commande de puissance (134) en cas d'écart entre la demande de puissance réduite introduite côté conducteur par l'installation d'entrée (102) par rapport à la position réglée par l'installation de réglage (122) de l'installation de commande de puissance (134), d'au moins une valeur prédéfinie. - Installation selon l'une des revendications 1-2,

caractérisée en ce que

l'embrayage (138, 200, 300) est un embrayage à crabot. - Installation selon l'une des revendications 1-3,

caractérisée par

un première élément de transmission (214, 314) associé à l'installation d'entrée (102) qui coopère de façon correspondante avec un second élément de transmission (218, 318) ayant un contour complémentaire, qui est relié à un verrou (206, 342) en liaison avec l'installation d'entrée (102) et l'installation de commande de puissance (134). - Installation selon l'une des revendications 1-4,

caractérisée en ce que

le premier élément de transmission (214, 314) a un prolongement en forme de surface (216, 316) qui coopère en correspondance avec un prolongement en forme de broche (318) du verrou (206, 342). - Installation selon l'une des revendications 1-5,

caractérisée en ce que

pour une liaison mécanique active entre l'installation d'entrée (102) et l'installation de commande de puissance (134), le verrou (206, 342) est mis en position déverrouillé. - Installation selon l'une des revendications 1-6,

caractérisée en ce que

le verrou (206, 342) entre la partie d'entrée (202, 302) et la partie de sortie (204, 304) de l'embrayage (138, 200, 300) agit en fonction du sens de l'actionnement et peut être libéré par le premier élément de transmission (214, 314). - Installation selon l'une des revendications 1-7,

caractérisée en ce que

le verrou (206, 342) est logé de manière mobile dans une partie (202, 302, 204, 304) de l'embrayage (138, 200, 300) et correspond dans le sens de la transmission de la force en fonction de la direction d'actionnement à l'autre partie (204, 304, 202, 302) de l'embrayage (138, 200, 300). - Installation selon l'une des revendications 1-8,

caractérisée en ce que

le verrou (206, 342) est coulissant longitudinalement dans la partie de sortie (204, 304) de l'embrayage (138, 200, 300), en étant précontraint par un ressort (340) dans le sens du verrouillage et coopère en correspondance par une denture (344) active indépendamment du sens de l'actionnement avec une denture (348) de la partie d'entrée (204, 304, 202,302) de l'embrayage (138, 200, 300). - Procédé d'actionnement d'une installation de commande de puissance (134) d'un moteur à combustion interne comprenant :- une installation d'entrée (102) actionnée par le conducteur pour entrer une demande de puissance côté conducteur,- une installation de capteurs (112) pour détecter la position de l'installation d'entrée (102) et générer un signal de sortie correspondant,- une installation de réglage (122) pour régler l'installation de commande de puissance (134) en tenant compte du signal de sortie de l'installation de capteur (112),caractérisé en ce qu'

l'installation de réglage (122) pouvant actionner l'installation de commande de puissance (134) différemment du signal de l'installation d'entrée (102),

en cas d'écart de la demande de puissance introduite côté conducteur par l'installation d'entrée (102) par rapport à la position réglée par l'installation de réglage (122) de l'installation de commande de puissance (134), d'au moins une valeur prédéterminée dans le sens de la fermeture, la demande de puissance d'entrée par l'installation d'entrée (102) du côté conducteur est prioritaire pour régler l'installation de commande de puissance (134),

en cas d'une priorité de la demande de puissance introduite par l'installation d'entrée (102) côté conducteur, l'installation de réglage (122) est découplée de l'installation de commande de puissance (134) et cette installation de commande de puissance (134) est actionnée directement par l'installation d'entrée (102). - Procédé selon la revendication 10,

caractérisé en ce qu'

en cas d'entrée côté conducteur d'une demande de puissance plus élevée par l'installation d'entrée (102) avec un gradient dépassant un gradient prédéfini, l'installation de commande de puissance (134) est actionnée par l'installation de réglage (122) par le signal de l'installation d'entrée (102) différemment avec un gradient limité.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200610036429 DE102006036429A1 (de) | 2006-08-04 | 2006-08-04 | Einrichtung und Verfahren zur Betätigung einer Leistungssteuerungseinrichtung einer Brennkraftmaschine |

| PCT/EP2007/005901 WO2008014863A1 (fr) | 2006-08-04 | 2007-07-04 | Dispositif et procédé pour actionner un dispositif de contrôle de la puissance d'un moteur à combustion INTERNE |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2016269A1 EP2016269A1 (fr) | 2009-01-21 |

| EP2016269B1 true EP2016269B1 (fr) | 2013-10-30 |

Family

ID=38541974

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07785891.8A Ceased EP2016269B1 (fr) | 2006-08-04 | 2007-07-04 | Dispositif et procede pour actionner un dispositif de controle de la puissance d'un moteur a combustion interne |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2016269B1 (fr) |

| DE (1) | DE102006036429A1 (fr) |

| WO (1) | WO2008014863A1 (fr) |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH453096A (de) | 1965-03-15 | 1968-05-31 | Senn Dipl Ing Dr Techn Eduard | Vorrichtung zur Änderung der Energiezufuhr bei Fahrzeugmotoren |

| JPH0196435A (ja) * | 1987-10-08 | 1989-04-14 | Mazda Motor Corp | 機関のスロットル弁制御装置 |

| DE3918852A1 (de) * | 1989-06-09 | 1990-12-13 | Pierburg Gmbh | Elektrisch ansteuerbare drosselklappenbetaetigungseinrichtung fuer brennkraftmaschinen |

| DE3918853A1 (de) * | 1989-06-09 | 1990-12-13 | Pierburg Gmbh | Elektrisch ansteuerbare drosselklappenbetaetigungseinrichtung fuer brennkraftmaschinen |

| DE4022344A1 (de) | 1989-08-22 | 1991-02-28 | Bosch Gmbh Robert | Einrichtung zum uebertragen einer stellposition eines bedienelements |

| DE3936875A1 (de) * | 1989-11-06 | 1991-05-08 | Hella Kg Hueck & Co | Drosselklappe fuer eine brennkraftmaschine |

| US5040508A (en) | 1989-11-09 | 1991-08-20 | Ford Motor Company | Throttle valve actuator |

| JPH055429A (ja) * | 1991-06-28 | 1993-01-14 | Hitachi Ltd | スロツトルアクチユエータ |

| JP2758535B2 (ja) | 1992-07-16 | 1998-05-28 | 株式会社日立製作所 | 電子スロットル制御装置 |

| DE4403604C2 (de) * | 1994-02-05 | 1998-02-19 | A B Elektronik Gmbh | Vorrichtung zur Steuerung der Verstellung einer die Leistung einer Brennkraftmaschine bestimmenden Drosselklappe |

| JPH07324636A (ja) | 1994-04-04 | 1995-12-12 | Nippondenso Co Ltd | スロットル弁制御装置 |

| DE19825283A1 (de) * | 1998-06-05 | 1999-12-09 | Bayerische Motoren Werke Ag | Motorleistungsregelung für Kraftfahrzeuge mit einem Leistungssteuerorgan |

| JP2004092550A (ja) * | 2002-09-02 | 2004-03-25 | Honda Motor Co Ltd | 車載内燃機関のスロットル制御装置 |

| DE10335700A1 (de) * | 2003-08-05 | 2005-02-24 | Bayerische Motoren Werke Ag | Einrichtung zur Betätigung einer Drosselklappe einer Brennkraftmaschine |

-

2006

- 2006-08-04 DE DE200610036429 patent/DE102006036429A1/de not_active Withdrawn

-

2007

- 2007-07-04 EP EP07785891.8A patent/EP2016269B1/fr not_active Ceased

- 2007-07-04 WO PCT/EP2007/005901 patent/WO2008014863A1/fr active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| DE102006036429A1 (de) | 2008-02-07 |

| WO2008014863A1 (fr) | 2008-02-07 |

| EP2016269A1 (fr) | 2009-01-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1759130B1 (fr) | Systeme de frein de stationnement | |

| EP1379752B1 (fr) | Dispositif pour l'actionnement automatique de la portiere d'un vehicule | |

| DE102017121007A1 (de) | Parksperre und Verfahren zur Betätigung dieser | |

| DE102006056042A1 (de) | System zur Verriegelung und Freigabe einer elektromechanischen Lenkung | |

| EP0341341A1 (fr) | Dispositif de réglage de charge | |

| EP2700545B1 (fr) | Procédé de fonctionnement d'un système de commande d'une moto | |

| DE4142809C2 (de) | Drosselklappen-Regelvorrichtung | |

| DE3730239A1 (de) | Elektrisch ansteuerbare stellvorrichtung zum verstellen der drosselklappe einer brenngemischdrosseleinrichtung von brennkraftmaschinen | |

| DE3641275A1 (de) | Einrichtung zur uebertragung der position eines durch einen fahrzeugfuehrer betaetigbaren steuerelements | |

| DE69523075T2 (de) | Motorisch angetriebenes system zum lenken eines fahrzeugs | |

| DE102018111184A1 (de) | Vorrichtung zum Betätigen einer Parksperre | |

| DE4222457C2 (de) | Gerät zum Steuern des Öffnungswinkels eines Drosselventils bei einem Motor mit innerer Verbrennung | |

| EP2016269B1 (fr) | Dispositif et procede pour actionner un dispositif de controle de la puissance d'un moteur a combustion interne | |

| EP1651850B1 (fr) | Dispositif d'actionnement d'un clapet d'etranglement d'un moteur a combustion interne | |

| DE4345557B4 (de) | Motorgetriebene Drosselklappenvorrichtung für einen Verbrennungsmotor | |

| DE102014226851B4 (de) | Betätigungsvorrichtung für eine Kupplung eines Kraftfahrzeugs sowie Kupplung mit einer entsprechenden Betätigungsvorrichtung | |

| EP1884642B1 (fr) | Dispositif et procédé destinés à l'actionnement d'un dispositif de commande de puissance d'un moteur à combustion interne | |

| EP2047086B1 (fr) | Dispositif et procédé pour actionner un dispositif de contrôle de la puissance d'un moteur à combustion interne | |

| EP0300153B1 (fr) | Dispositif de réglage de charge | |

| WO1992012885A1 (fr) | Direction assistee | |

| EP2047087B1 (fr) | Dispositif et procédé pour actionner un dispositif de contrôle de la puissance d'un moteur à combustion interne | |

| DE4345492B4 (de) | Elektronisch gesteuerte Drosselklappenvorrichtung | |

| DE19721239A1 (de) | Vorrichtung zur Betätigung der Drosselklappe eines Verbrennungsmotors | |

| DE102020005061A1 (de) | Lenksäule für ein Kraftfahrzeug | |

| EP0454971B1 (fr) | Positionneur de butée pour papillon des gaz |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20081010 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| DAX | Request for extension of the european patent (deleted) | ||

| RBV | Designated contracting states (corrected) |

Designated state(s): DE ES FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 20111202 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130531 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007012442 Country of ref document: DE Effective date: 20131224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131030 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: BAYERISCHE MOTOREN WERKE AKTIENGESELLSCHAFT |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007012442 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007012442 Country of ref document: DE Effective date: 20140731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20220729 Year of fee payment: 16 Ref country code: GB Payment date: 20220725 Year of fee payment: 16 Ref country code: DE Payment date: 20220621 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20220725 Year of fee payment: 16 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230503 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007012442 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240201 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230704 |