EP1990197B2 - Procédé d'ajustement automatisé de la compression d'un corps de rotation dans une machine d'impression - Google Patents

Procédé d'ajustement automatisé de la compression d'un corps de rotation dans une machine d'impression Download PDFInfo

- Publication number

- EP1990197B2 EP1990197B2 EP08103604.8A EP08103604A EP1990197B2 EP 1990197 B2 EP1990197 B2 EP 1990197B2 EP 08103604 A EP08103604 A EP 08103604A EP 1990197 B2 EP1990197 B2 EP 1990197B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotary body

- pressure

- pressure strip

- rotary

- image

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F33/00—Indicating, counting, warning, control or safety devices

- B41F33/0072—Devices for measuring the pressure between cylinders or bearer rings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F31/00—Inking arrangements or devices

- B41F31/30—Arrangements for tripping, lifting, adjusting, or removing inking rollers; Supports, bearings, or forks therefor

- B41F31/304—Arrangements for inking roller bearings, forks or supports

- B41F31/308—Swinging bearings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F33/00—Indicating, counting, warning, control or safety devices

- B41F33/0036—Devices for scanning or checking the printed matter for quality control

Definitions

- the present invention relates to a method for the automated adjustment of a rotary body pressure in a printing press, wherein a press strip image measurement is carried out on a printing substrate.

- each of the two rotating bodies forming a nip i. H. Rollers or cylinders, usually at least one has a rubber-elastic peripheral surface, the latter is flattened as a result of the pressing.

- This flattening is also referred to as a contact or press strip and has a width to be measured transversely to the roll rotation axis, the so-called press strip width.

- the width of the press strip can serve as a measure of the set pressure and can be measured in various ways.

- DE 10 2005 048 367 A1 describes a method for determining a nip width formed between two rotating bodies. The width of the nip is determined while a circumferential point passes through the nip.

- the press strip width generated in a nip between an inking roller and a printing form cylinder is measured using a press strip image which has been transferred to the printing sheet.

- the press strip image is measured by optoelectronic scanning.

- the measurement signals of the sensor used for optoelectronic scanning are transmitted to a control or regulating device which, based on this, generates control signals for actuating an actuator which adjusts the inking roller in such a way that the required pressure is present between it and the printing form cylinder.

- This object is achieved by a method with the features of claim 1. This process does justice to the complexity of modern roller inking units because it enables the interactions contained therein to be taken into account.

- the first actuating motor adjusts the second press strip in the main effect or primarily and the first press strip in a secondary effect or secondary.

- the second actuator can be used to set the first press strip in the main effect or primarily and the second press strip as a side effect or secondary.

- the two servomotors move the second rotation body and the third rotation body into a position relative to the first rotation body in which a common center point of the first rotation body and the second rotation body and a common center point of the second rotation body and the third rotation body Include non-right angle that is greater than 0 ° and less than 180 °.

- a forme cylinder is used as the first rotary body, an inking roller as the second rotary body and a rubbing roller as the third rotary body.

- the two images are measured on one and the same printed sheet.

- the two press strips are static press strips which are generated between them when the rotary body is stationary.

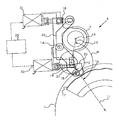

- Figure 1 shows a first rotary body 1, a second rotary body 2 and a third rotary body 3 as components of a printing press 4.

- the first rotary body 1 is a forme cylinder for lithographic offset printing.

- the second rotary body 2 is an inking roller with a rubber-elastic peripheral surface and is in contact with the first rotary body 1 during printing operation.

- the third rotating body 3 is a friction roller, which oscillates axially and is provided with a coaxial drive gear, and bears against the second rotating body 2.

- a common, first center point 11 of the first and second rotating bodies 1, 2 and a common, second center point 12 of the second and third rotating bodies 2, 3 enclose an angle ⁇ .

- the angle ⁇ lying between the center points 11, 12 is greater than 0 ° and less than 180 °, but not a right angle, but an obtuse angle.

- a first lever 21 is pivotally mounted about the axis of rotation or the center 13 of the third rotating body 3, to which a second lever 22 is fastened via a swivel joint 14.

- a third lever 23 is fastened to the first lever 21, in which a roller 16 is rotatably mounted, which is supported on a control cam 17.

- An electrical, first servomotor 31 for pivoting the second lever 22 about the swivel joint 14 is arranged on the second lever 22.

- the first servomotor 31 engages a first arm of the second lever 22 via a screw gear 18.

- the second rotary body 2 is supported in a second arm of the second lever 22.

- An electric, second servomotor 32 is fastened to the first lever 21 and engages the third lever 23 via a further screw gear 19 in order to pivot the latter together with the roller 16 stored therein about the swivel joint 15.

- the first lever 21 is pivoted about the center 13 of the third rotating body 3.

- the actuation of the second servomotor 32 serves to press the pressure in a common, first roll nip 41 (cf. Figure 2 ) of the first and second rotating bodies 1, 2 in order to meter the amount of fluid or ink transferred from the second rotating body 2 to the first rotating body 1.

- the actuation of the first servomotor 31 serves to press the pressure in a common, second nip 42 (cf. Figure 2 ) of the second and third rotating bodies 2, 3 in order to meter the amount of fluid or ink transferred from the third rotating body 3 to the second rotating body 2.

- the angle ⁇ is not a right angle, it is structurally inevitable that the actuation of the first actuator 31 not only effects the desired adjustment of a press strip width b in the second roller gap 42, but also has an undesirable side effect on the size of one Press strip width a affects in the first nip 41.

- Figure 2 shows the trigonometric conditions of the storage of the rotating body 1, 2 and 3 in a schematic representation. It can be seen from this that the size of the angle ⁇ deviating from 90 ° inevitably means that the adjustment of the roll provision made for the second roll gap 42 impairs the roll provision in the first roll gap 41.

- FIG. 3 shows a flow diagram of a method for automatic roller adjustment.

- the start takes place in method step 51.

- method step 51 contains the fact that the metering elements, eg. B. metering slide with zone screws, set so that all ink zones are open to the same extent and the same amount of ink is metered across the print width in all ink zones.

- the ink is fed from the ink fountain into the inking unit, with a dampening unit assigned to the inking unit being inactive during this ink inlet.

- the roller adjustment process is carried out immediately after a print job has been carried out, the washing, the uniform setting of the ink zone openings and the ink inlet can be omitted. In this case, only the dampening system is deactivated so that it no longer delivers dampening solution.

- the inking rollers including the second rotary body 2 and a dampening roller of the dampening unit are placed on the first rotary body 1 in order to transfer the printing ink from the inking unit onto the first rotary body 1 and transfer the offset printing form on it.

- This ink transfer takes place without transfer of the dampening solution to the offset printing form, so that the latter also accepts the printing ink in the non-printing, hydrophilic areas which would otherwise be kept free of color by the dampening solution. Therefore, in the case of the method variant in which the roller adjustment is carried out immediately after the printing job has been carried out, the offset printing form on the first rotary body 1 which was used for this printing job can be retained in the roller adjustment.

- an offset printing form specially provided for the roller adjustment is clamped onto the first rotary body 1.

- This special offset printing form has a homogeneous print image, so that deactivation of the dampening system is not necessary.

- the next step during a short run of the printing unit e.g. B. approx. 30 seconds, with no printing material being transported and printed, the printing ink distribution in the inking unit and on the first rotary body 1 is evened out.

- a static contact or press strip is placed in the first nip 41 (cf. Figure 2 ) and in a parallel process step 53 a static contact or press strip is generated in the second nip 42.

- the rotation of the first rotary body 1 and the applicator rollers adjacent to the latter, including the second rotary body 2, and the rotation of the third rotary body 3 are stopped in an angle of rotation position in which the plate leading edge of the offset printing form immediately after the last of the inking rollers seen in the direction of rotation of the first rotary body 1 stands.

- the standstill and the static pressure in the nips 41, 42 the printing ink is pressed out of these nips.

- the width of the press strips transferred to the printed sheets is determined. For this purpose, one is selected from the printed 5 to 10 printed sheets on which the two press strips are best recognizable.

- FIG 4 shows that this measuring device 24 is connected to an electronic control device 20, which in turn is connected to the servomotors 31, 32 (cf. Figure 1 ).

- the control device 20 calculates in a method step 56 the required correction values for the employment of the second on the first rotating body and the employment of the second on the third Rotational body.

- the control device 20 takes into account the already explained fact that the change in the placement of the second to the third rotating body entails a change in the placement of the second to the first rotating body.

- the influencing of one by the other employment can be influenced by the control device 20 on the basis of mathematical formulas stored therein, e.g. B.

- control device 20 controls the servomotors 31, 32 such that in a method step 57 the second servomotor 32 approaches the newly calculated target value for the employment of the second on the first rotating body and in a method step 58 that takes place simultaneously or in parallel first servomotor 31 starts the newly calculated target value of the employment of the second on the third rotating body.

- Executing method steps 57, 58 one after the other would be somewhat more time-consuming, but just as possible.

- the determination of the two target values made in method step 56 guarantees that, after their setting, the pressure or press strip width a, b in both roll nips 41, 42 is already correct and that no new measurement and readjustment is necessary.

- the roller adjustment is therefore already completed in a method step 59.

Landscapes

- Engineering & Computer Science (AREA)

- Quality & Reliability (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Rotary Presses (AREA)

Claims (6)

- Procédé pour l'ajustement automatisé d'une compression d'un corps de rotation dans une machine à imprimer (4), une mesure de l'image d'une bande de pression étant effectuée sur un support imprimé (25), pour lequel une image d'une première bande de pression qui est formée par un premier corps de rotation (1) ensemble avec un deuxième corps de rotation (2), et une image d'une deuxième bande de pression qui est formée par un deuxième corps de rotation (2) ensemble avec un troisième corps de rotation (3), sont mesurées et la compression du corps de rotation est ajustée automatiquement,

caractérisé en ce

qu'un dispositif électronique de commande (20) commande un premier servomoteur (31) et un deuxième servomoteur (32) en fonction de signaux de mesure d'un dispositif de mesure (24) pour la mesure des largeurs des images des deux bandes de pression pour régler les bandes de pression, pour lequel le dispositif de commande (20) pilote les servomoteurs (31, 32) de sorte que le deuxième servomoteur (32) atteigne une valeur cible nouvellement calculée pour le serrage du deuxième corps de rotation (2) contre le premier corps de rotation (1) et que le premier servomoteur (31) atteigne une valeur cible nouvellement calculée pour le serrage du deuxième corps de rotation (2) contre le troisième corps de rotation (3),

qu'une valeur cible définitive de la largeur de la première bande de pression et une valeur cible définitive de la largeur de la deuxième bande de pression sont réglées uniquement sur la base de la mesure de l'image de la première bande de pression et de l'image de la deuxième bande pression et d'aucune autre image des deux bandes de pression, et que la valeur cible définitive de la largeur de la première bande de pression et une valeur cible définitive de la largeur de la deuxième bande de pression sont réglées par un seul tour de du premier servomoteur (31) consécutif à la mesure des images et un seul tour du deuxième servomoteur (32) consécutif à la mesure des images. - Procédé selon la revendication 1,

caractérisé en ce

que le premier servomoteur (31) règle, en effet principal ou primaire, la deuxième bande de pression et, en effet annexe ou secondaire, la première bande de pression. - Procédé selon la revendication 1 ou 2,

caractérisé en ce

les deux servomoteurs (31, 32) amènent le deuxième corps de rotation (2) et le troisième corps de rotation (3) dans une position par rapport au deuxième corps de rotation (1), dans laquelle un point commun central (11) du premier corps de rotation (1) et du deuxième corps de rotation (2) et un point central commun (12) du deuxième corps de rotation (2) et du troisième corps de rotation (3) forment un angle non droit (α) supérieur à 0° et inférieur à 180°. - Procédé selon l'une des revendications 1 à 3,

caractérisé en ce

que le premier corps de rotation (1) est un cylindre de cliché, le corps de rotation (2) est un rouleau encreur et le troisième corps de rotation (3) un rouleau à friction. - Procédé selon l'une des revendications 1 à 4,

caractérisé en ce

que les deux images sont mesurées sur une seule et même feuille imprimée. - Procédé selon l'une des revendications 1 à 5,

caractérisé en ce

que les deux bandes de pression sont des bandes de pression statiques, qui sont générées entre les corps de rotation (1, 2, 3) au moment de leur immobilisation en rotation.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007022079A DE102007022079A1 (de) | 2007-05-11 | 2007-05-11 | Verfahren zum automatisierten Justieren einer Rotationskörperpressung in einer Druckmaschine |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1990197A2 EP1990197A2 (fr) | 2008-11-12 |

| EP1990197A3 EP1990197A3 (fr) | 2012-07-04 |

| EP1990197B1 EP1990197B1 (fr) | 2016-11-02 |

| EP1990197B2 true EP1990197B2 (fr) | 2020-04-29 |

Family

ID=39712377

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08103604.8A Not-in-force EP1990197B2 (fr) | 2007-05-11 | 2008-04-18 | Procédé d'ajustement automatisé de la compression d'un corps de rotation dans une machine d'impression |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20080276816A1 (fr) |

| EP (1) | EP1990197B2 (fr) |

| DE (1) | DE102007022079A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010000907B4 (de) * | 2010-01-14 | 2015-09-10 | Windmöller & Hölscher Kg | Verfahren und Vorrichtung zum Optimieren der Relativposition zumindest zweier Druckwerkszylinder |

| IT1403496B1 (it) * | 2010-12-27 | 2013-10-17 | Uteco Converting Spa | Sistema e procedimento di regolazione e controllo delle pressioni di cilindri di stampa in una macchina da stampa flessografica a tamburo centrale |

| WO2018029085A1 (fr) | 2016-08-09 | 2018-02-15 | Koenig & Bauer Ag | Procédé pour contrôler la largeur d'une bande de pression formée entre deux corps rotatifs d'un groupe d'impression |

| DE102016214713B4 (de) | 2016-08-09 | 2020-06-04 | Koenig & Bauer Ag | Verfahren zum Kontrollieren einer Streifenbreite eines Pressstreifens |

| DE102017201600B4 (de) | 2017-02-01 | 2019-04-25 | Koenig & Bauer Ag | Verfahren zum Kontrollieren mehrerer Pressstreifen hinsichtlich ihrer jeweiligen Streifenbreite |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10145957A1 (de) † | 2001-03-27 | 2002-10-17 | Windmoeller & Hoelscher | Vorrichtung und Verfahren zur Einstellung des Druckbildes in einer Flexodruckmaschine |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4211379C2 (de) * | 1992-04-04 | 1999-01-07 | Roland Man Druckmasch | Anilox-Offset-Druckeinheit mit einem Kurzfarbwerk |

| DE4232163C3 (de) * | 1992-09-25 | 2001-09-06 | Koenig & Bauer Ag | Vorrichtung zum Aufrechterhalten einer eingestellten Anpressung einer Farbauftragswalze an einem Formzylinder einer Rotationsdruckmaschine |

| US5448949A (en) * | 1993-08-24 | 1995-09-12 | Heidelberger Druckmaschinen Ag | Method and device for adjusting a contact pressure between ink-carrying cylinders of a printing machine |

| DE4427967B4 (de) | 1993-08-24 | 2004-09-30 | Heidelberger Druckmaschinen Ag | Verfahren zum Voreinstellen der Pressung zwischen farbführenden Zylindern einer Druckmaschine |

| JP4438155B2 (ja) * | 2000-01-31 | 2010-03-24 | 凸版印刷株式会社 | 印刷機のローラー調整方法とローラー調整装置、およびオフセット印刷機 |

| DE10211870B4 (de) * | 2001-03-29 | 2010-07-29 | Heidelberger Druckmaschinen Ag | Verfahren zur Justierung zweier aneinander anlegbarer Walzen eines Druckwerks |

| DE10302747A1 (de) * | 2003-01-24 | 2004-08-12 | Windmöller & Hölscher | Verfahren zur Korrektur von im Druckprozess auftretenden Schwankungen der auf das Druckbild übertragenen Farbmenge |

| US7225735B2 (en) * | 2004-05-03 | 2007-06-05 | Heidelberger Druckmaschinen Ag | Method for roller adjustment in a printing press |

| DE102005048367B4 (de) * | 2005-10-10 | 2010-08-05 | Wifag Maschinenfabrik Ag | Nip-Breitenmessung |

| WO2007086052A2 (fr) * | 2006-01-25 | 2007-08-02 | Advanced Vision Technology (Avt) Ltd. | Système et procédé de réglage de presse à imprimer |

-

2007

- 2007-05-11 DE DE102007022079A patent/DE102007022079A1/de not_active Withdrawn

-

2008

- 2008-04-18 EP EP08103604.8A patent/EP1990197B2/fr not_active Not-in-force

- 2008-05-12 US US12/119,040 patent/US20080276816A1/en not_active Abandoned

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10145957A1 (de) † | 2001-03-27 | 2002-10-17 | Windmoeller & Hoelscher | Vorrichtung und Verfahren zur Einstellung des Druckbildes in einer Flexodruckmaschine |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1990197A2 (fr) | 2008-11-12 |

| EP1990197B1 (fr) | 2016-11-02 |

| EP1990197A3 (fr) | 2012-07-04 |

| DE102007022079A1 (de) | 2008-11-13 |

| US20080276816A1 (en) | 2008-11-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1748892B1 (fr) | Procede pour reguler un transfert d'encre | |

| DE10013876B4 (de) | Verfahren zum Regeln der Farbgebung beim Drucken mit einer Druckmaschine | |

| EP2097261B1 (fr) | Presse rotative et procédé pour ajuster un de ses cylindres | |

| DE3435487C2 (fr) | ||

| DE102007008392B4 (de) | Integrierte Qualitätsregelung | |

| EP2759407B1 (fr) | Procédé de réglage et dispositif pour determiner la distance optimale entre au moins deux cylindres impliqués dans un procédé d'impression | |

| EP1820650B1 (fr) | Commande d'une presse à l'aide d'un modèle de torsion | |

| DE2845932A1 (de) | Kombiniertes feucht-farbwerk fuer offsetdruckwerke | |

| EP1990197B2 (fr) | Procédé d'ajustement automatisé de la compression d'un corps de rotation dans une machine d'impression | |

| EP2879878B1 (fr) | Procédé de réglage de la longueur d'impression d'une image d'impression dans une rotative polychrome | |

| DE4013003A1 (de) | Korrektur schraegliegender druckbilder | |

| DE10211870B4 (de) | Verfahren zur Justierung zweier aneinander anlegbarer Walzen eines Druckwerks | |

| EP2396174B1 (fr) | Procédé de réglage d'une couverture et procédé correspondant de mise en oeuvre dans une presse d'imprimerie comprenant plusieurs groupes d'impression | |

| DE60225396T2 (de) | Methode zum Voreinstellen der Farbe | |

| DE10261059A1 (de) | Verfahren und Vorrichtung zum Messen, Stellen und Regeln des Längs- und Seitenregisters sowie der Parallelität des Druckregisters in einer Mehrfarbendruckmaschine | |

| DE3204501C1 (de) | Vorrichtung zur Regelung der Farbzufuehrung in einer Rotationsdruckmaschine | |

| EP2762316B1 (fr) | Procédé de régulation d'un paramètre d'un dispositif d'encrage | |

| DE102006004307B4 (de) | Verfahren zum Messen und Einstellen der Bahnspannung zwischen Farbwerken einer Mehrfarbenmaschine | |

| DE102009001302A1 (de) | Verfahren zum Betreiben einer Druckmaschine | |

| DE102008006192B4 (de) | Verfahren zum Betreiben einer Druckmaschine | |

| DE102007034835A1 (de) | Verfahren zum Betreiben einer wellenlosen Druckmaschine und wellenlose Druckmaschine | |

| DE4300071C2 (de) | Verfahren zur Steuerung einer Farbführung in einem Druckwerk einer Druckmaschine | |

| DE102008061599A1 (de) | Verfahren zum Einstellen eines Feuchtwerks einer Druckmaschine | |

| DE102007063852B3 (de) | Integrierte Qualitätsregelung | |

| EP1839854A1 (fr) | Méthode et dispositif pour ajuster optimalement la position dans une machine d'impression rotative fléxographique |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHAFFRATH, DIETER Inventor name: LUCKHARDT, ULRICH Inventor name: DORENKAMP, FELIX Inventor name: HEILER, PETER Inventor name: MAYER, MARTIN |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B41F 31/30 20060101ALI20120522BHEP Ipc: B41F 33/00 20060101AFI20120522BHEP |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B41F 31/30 20060101ALI20120529BHEP Ipc: B41F 33/00 20060101AFI20120529BHEP |

|

| 17P | Request for examination filed |

Effective date: 20130104 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160316 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAC | Information related to communication of intention to grant a patent modified |

Free format text: ORIGINAL CODE: EPIDOSCIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160316 |

|

| GRAL | Information related to payment of fee for publishing/printing deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR3 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HEILER, PETER Inventor name: DORENKAMP, FELIX Inventor name: MAYER, MARTIN Inventor name: SCHAFFRATH, DIETER Inventor name: LUCKHARDT, ULRICH |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 841419 Country of ref document: AT Kind code of ref document: T Effective date: 20161115 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008014751 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502008014751 Country of ref document: DE Owner name: HEIDELBERGER DRUCKMASCHINEN AG, DE Free format text: FORMER OWNER: HEIDELBERGER DRUCKMASCHINEN AKTIENGESELLSCHAFT, 69115 HEIDELBERG, DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170203 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170202 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170302 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170302 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 502008014751 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170202 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: KOENIG & BAUER AG Effective date: 20170727 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20170418 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20171229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170418 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170418 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20170430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 841419 Country of ref document: AT Kind code of ref document: T Effective date: 20170418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: KOENIG & BAUER AG Effective date: 20170727 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: HEIDELBERGER DRUCKMASCHINEN AG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161102 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161102 |

|

| 27A | Patent maintained in amended form |

Effective date: 20200429 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502008014751 Country of ref document: DE |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230502 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230430 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502008014751 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20241105 |