EP1980335A1 - Anlage zur Trennung von feststoffabfallartigem Siedlungsabfall, im Besonderen zur Wiedergewinnung von langem, biegsamem Material - Google Patents

Anlage zur Trennung von feststoffabfallartigem Siedlungsabfall, im Besonderen zur Wiedergewinnung von langem, biegsamem Material Download PDFInfo

- Publication number

- EP1980335A1 EP1980335A1 EP20080154326 EP08154326A EP1980335A1 EP 1980335 A1 EP1980335 A1 EP 1980335A1 EP 20080154326 EP20080154326 EP 20080154326 EP 08154326 A EP08154326 A EP 08154326A EP 1980335 A1 EP1980335 A1 EP 1980335A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- long

- belt

- plant

- separation

- solid waste

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B13/00—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices

- B07B13/04—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices according to size

- B07B13/05—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices according to size using material mover cooperating with retainer, deflector or discharger

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B13/00—Grading or sorting solid materials by dry methods, not otherwise provided for; Sorting articles otherwise than by indirectly controlled devices

- B07B13/003—Separation of articles by differences in their geometrical form or by difference in their physical properties, e.g. elasticity, compressibility, hardness

Definitions

- the present invention relates to automatic plant for the sorting of solid waste similar to solid urban refuse, but not including special waste, and in particular for the separation and distribution of material, separating from the remainder any long, flexible material which can be recycled.

- the present invention relates to a device which enables the extraction from waste material (consisting mostly of packaging) originating from commercial, industrial or construction site sources of long, light, flexible and relatively thin material (film, sheeting, straps etc.) which usually obstructs the efficient sorting of various types of waste.

- the device according to the present invention comprises a drum rotating around its own axis fitted around its circumference with rods extending radially and suitably angled.

- the drum rotates so that the rods intersect the surface conveying the material at right angles.

- the rods sweep the material into a special container.

- the present invention relates to the field of plant and equipment for the sorting and recycling of waste and in particular waste which is similar to solid urban refuse and does not contain special or toxic wastes.

- Waste material must be sorted before it can be recycled and selection and sorting are therefore necessary parts of the recycling process.

- polyethylene tape, nylon sheeting or wires wrap around and hold small items of waste thereby preventing efficient sorting. In some cases these obstructions can even block the equipment.

- the sorting operatives are obliged to stop the equipment and recover this material by hand removing it from the conveyor belt. This is a laborious method of freeing the remaining material so that the sorting process cycle can continue.

- This patent combines a conveyor device carrying the heterogeneous material flow with a pickup device for picking up the material.

- the pickup device comprises a conveyor equipped with teeth which act on the heterogeneous flow of material; the teeth exert pressure on the material as they pickup the material.

- the object of the present invention is that of providing plant for the separation and subsequent recycling of long, flexible products, which eliminates or at least reduces the shortcomings described previously.

- the invention also provides a plant for the recovery, disposal and recycling of long, flexible products which given that it is simple and relatively inexpensive to manufacture could advantageously be used widely on a large scale.

- the channel is positioned to the side and it is for this reason that the selector device, in its preferred embodiment, comprises a drum rotating on its own axis, fitted around its circumference with rods extending radially and suitably angled.

- the drum rotates so that the rods intersect the flow of material to be sorted as it passes by.

- the rods are suitably spaced apart and are positioned at an angle in relation to the drum surface.

- the angle of the rods in relation to the drum surface is such that each rod passes gradually from a horizontal position where it touches the flow of material to a vertical position.

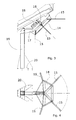

- the plant according to the present invention is shown in its entirety by the numeral 10 and substantially comprises one or more conveyor belts 11 and 12 positioned in sequence and designed to transport the product.

- At least one of the conveyor belts in this case the conveyor belt 12, carries the product to a raised area where the long product distribution device 13 according to the present invention is positioned.

- the distribution device 13 is fixed under the drive head of the conveyor belt 12 and comprises a drum 14 carrying a plurality of rods 15 which are positioned to intercept the long, flexible material.

- the drum 14 is fitted to a shaft 16, mounted on a bracket 17, which receives rotary power from a gear motor 18.

- the bracket 17 in turn is mounted on a column 19 which supports the sorting device at the top and which is fixed to the floor by means of a fixing plate 20.

- the drum 14 is mounted on an axis angled for example at approximately 45° and has rods 15 extending radially which are also angled at a specified angle in relation to the drum axis to form a layout which is substantially a truncated cone.

- the drum 14 carrying the rods 15 rotates in continuation driven by a shaft 16 powered by a gear motor 18.

- the machine is located directly underneath the conveyor belt drive head and where the material transported by the conveyor belt drops down into the area directly below where it can be collected by a first collection belt 21, while the long, flexible products selected by the device according to the present invention are collected on a second collection belt 22 running parallel to the first belt and in any case positioned outside the collection zone of the first belt.

- the collection belts 21 and 22 are positioned at right angles to the direction of travel of the conveyor belt 12.

- the angle of the drum 14 and also of the rods 15 as they pass from a horizontal to a vertical position means that the rods, when they are in their upper, horizontal position, can intercept the long, flexible material suspended from the belt head and then push it sideways holding it there until the following rod arrives in such a way that the material drops downwards onto a second conveyor belt 22.

- Separating efficiency and the size of the items extracted depends on the device speed in relation to the speed of the belt and the distance of the machine from the drive head of the belt.

- Figures 5 and 6 show a machine similar to that described previously with the only difference being that the drum 23, rather than being positioned underneath and on an axis with the feed belt 12, is positioned to the side on an axis which is at right angles to the conveyor.

- drum 23 selects all the long, rigid and flexible material first and then picks up the long, flexible material only from the belt 22 while the long, rigid material proceeds downstream.

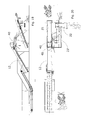

- Figures 7 and 8 show an embodiment where the selector 24 is not a drum type but a type with oscillating rods.

- the selector device 24 comprises a supporting framework 25 fitted with a pivot 26 on which an oscillating mobile slider 27 swivels.

- the selector device 24 is fixed with brackets 28 to the conveyor belt 12.

- the oscillating slider 27 is moved by an actuating cylinder (pneumatic or hydraulic) 29 fixed to the supporting framework 25.

- An end of the oscillating slider 27 is equipped with a sliding rod 30 which intercepts the long, flexible material.

- the sliding rod is moved backwards and forwards between a retracted position and an extended position by a second actuating cylinder 31 whose rod is connected to an attachment 32 enabling retraction and extension of the rod 30.

- the rod 30 on the slider 27 moves the long, flexible material transported by the conveyor belt 12 above to the side 12 so that it falls to the side of the normal dropping zone, in other words, onto the belt 22, while the short and rigid material drops onto the belt 21.

- Figures 11 and 12 show the previous device doubled where the two cylinders 31 operate to retract the rod but only at preset times thus enabling the long, flexible material to be conveyed to one side only.

- the mode of operation of the device and its related belt can be of two types, Solution A where the device and the belt operate in the continuous mode and Solution B where the device and the belt operate alternately.

- the belt travels forward by approximately 2 metres and then stops. At this point the device starts, completes its cycle and then stops. The belt then restarts.

- the separating efficiency and the size of the items extracted depend on the speed of the device in relation to the speed of the belt.

- the device must perform a complete cycle in at least the time it takes for the belt to travel 2 metres in Solution A, or, in Solution B the device must run be at twice the speed.

- Figures 13 to 16 show a solution where the device for selecting long, flexible material consists of a gripper 34.

- the machine on which the gripper 34 is mounted is positioned at a pre-set distance in front of the drive head of the conveyor 12 to which it is linked.

- the gripper 34 is on the belt axis while the machine structure and arm are in an offset position parallel to the belt axis.

- the machine comprises an arm 35 hinging on the pivot 36 of a support structure 37 and carrying, on its other end, a gripper 34 which substantially comprises two jaws hinged to each other which are opened and closed by means of actuating cylinders 34'.

- the arm 35 is rotated by an actuating cylinder 38 while the angle of the gripper is regulated by another actuating cylinder 39.

- the rest or start position of this device is with the arm 35 in the upper position and therefore, in this cycle step, with the cylinder 38 fully extended.

- the cylinder 39 extends thus retracting the gripper 34 so that it closes on the long, flexible material; while this is happening, the cylinder 38 is retracted until the arm 35 is at the end of its downward stroke.

- the gripper cylinders 34' open the gripper 34, the cylinder 39 shortens so that the gripper moves forwards; the gripper 34 activated by the gripper cylinders 34' closes thereby gripping the material which is hanging from the conveyor belt drive head.

- the work cycle continues as follows.

- the cylinder 39 extends thus retracting the gripper 34; the cylinder 38 extends thus raising the arm 35 to its upper position.

- the gripper 34 actuated by the cylinders 34' opens and deposits the long items in a special space or, better, on a special machine designed to recover the material.

- the mode of operation of the device and its related belt can be of various types.

- the preferred mode is the alternating operating mode where the machine and the belt operate alternately and where the gripper 34 travels forwards under the belt drive head and closes when the belt is stopped.

- the separating efficiency depends on the speed of the device in relation to the speed of the belt.

- Figures 17 and 18 show an embodiment where the selection device for long, flexible material comprises a chain 40 with rods 41 which move on a plane which is at a tangent to the material flow or which is at right angles to the flow of material, as shown in Figures 19 and 20 .

- the rods 41 located on the chain 40 push the long, light material into a container or onto a special conveyor belt 22 while the remaining product is deposited onto a conventional conveyor belt 21.

Landscapes

- Processing Of Solid Wastes (AREA)

- Investigation Of Foundation Soil And Reinforcement Of Foundation Soil By Compacting Or Drainage (AREA)

- Sorting Of Articles (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITVR20070053 ITVR20070053A1 (it) | 2007-04-11 | 2007-04-11 | Impianto per la separazione di rifiuti solidi assimilabili agli urbani in particolare per il recupero di materiali lunghi e flessibili |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1980335A1 true EP1980335A1 (de) | 2008-10-15 |

| EP1980335B1 EP1980335B1 (de) | 2015-07-29 |

Family

ID=39596440

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08154326.6A Not-in-force EP1980335B1 (de) | 2007-04-11 | 2008-04-10 | Anlage zur Trennung von feststoffabfallartigem Siedlungsabfall, im Besonderen zur Wiedergewinnung von langem, biegsamem Material |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1980335B1 (de) |

| IT (1) | ITVR20070053A1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105817419A (zh) * | 2016-05-19 | 2016-08-03 | 湖南尔瞻智能科技有限公司 | 全自动餐具分类整理一体机 |

| CN105921414A (zh) * | 2016-05-19 | 2016-09-07 | 湖南尔瞻智能科技有限公司 | 全自动筷子、勺子清洗包装一体机 |

| CN105921415A (zh) * | 2016-05-19 | 2016-09-07 | 湖南尔瞻智能科技有限公司 | 全自动筷子、勺子分类装置 |

| CN114505232A (zh) * | 2022-02-28 | 2022-05-17 | 杭州师范大学钱江学院 | 一种适用于机床车间的垃圾分类装置及方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3651938A (en) * | 1970-05-18 | 1972-03-28 | Lemay Machine Co | Automatic article segregation |

| DE7344199U (de) * | 1975-10-09 | Elke Technik Kerner F Kg | Sortiervorrichtung für Spritzgut | |

| EP0492259A1 (de) * | 1990-12-22 | 1992-07-01 | Lindemann Maschinenfabrik GmbH | Verfahren und Vorrichtung zum Aufbereiten von kleinstückigem Material |

| EP1105222A1 (de) | 1998-08-11 | 2001-06-13 | Gassner, Benno, sen. | Vorrichtung zur trennung von wertstoffgemischen |

| US20060180522A1 (en) * | 2004-12-28 | 2006-08-17 | Legtenberg Hermannus J M | Method and apparatus for sorting plastic and paper waste |

-

2007

- 2007-04-11 IT ITVR20070053 patent/ITVR20070053A1/it unknown

-

2008

- 2008-04-10 EP EP08154326.6A patent/EP1980335B1/de not_active Not-in-force

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7344199U (de) * | 1975-10-09 | Elke Technik Kerner F Kg | Sortiervorrichtung für Spritzgut | |

| US3651938A (en) * | 1970-05-18 | 1972-03-28 | Lemay Machine Co | Automatic article segregation |

| EP0492259A1 (de) * | 1990-12-22 | 1992-07-01 | Lindemann Maschinenfabrik GmbH | Verfahren und Vorrichtung zum Aufbereiten von kleinstückigem Material |

| EP1105222A1 (de) | 1998-08-11 | 2001-06-13 | Gassner, Benno, sen. | Vorrichtung zur trennung von wertstoffgemischen |

| US20060180522A1 (en) * | 2004-12-28 | 2006-08-17 | Legtenberg Hermannus J M | Method and apparatus for sorting plastic and paper waste |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105817419A (zh) * | 2016-05-19 | 2016-08-03 | 湖南尔瞻智能科技有限公司 | 全自动餐具分类整理一体机 |

| CN105921414A (zh) * | 2016-05-19 | 2016-09-07 | 湖南尔瞻智能科技有限公司 | 全自动筷子、勺子清洗包装一体机 |

| CN105921415A (zh) * | 2016-05-19 | 2016-09-07 | 湖南尔瞻智能科技有限公司 | 全自动筷子、勺子分类装置 |

| CN114505232A (zh) * | 2022-02-28 | 2022-05-17 | 杭州师范大学钱江学院 | 一种适用于机床车间的垃圾分类装置及方法 |

| CN114505232B (zh) * | 2022-02-28 | 2022-11-25 | 杭州师范大学钱江学院 | 一种适用于机床车间的垃圾分类装置及方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1980335B1 (de) | 2015-07-29 |

| ITVR20070053A1 (it) | 2008-10-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101326016B (zh) | 袋装垃圾处理装置 | |

| CN110683145B (zh) | 包装袋自动拆包系统及其拆袋分离机构 | |

| EP1980335B1 (de) | Anlage zur Trennung von feststoffabfallartigem Siedlungsabfall, im Besonderen zur Wiedergewinnung von langem, biegsamem Material | |

| IL98192A (en) | Method for removing liquid from a mixture of liquid and solid matter | |

| CN113600339A (zh) | 一种垃圾分类设备 | |

| US3663135A (en) | Automatic machine for cutting, cooling, drying and piling rubber sheets | |

| CN108910197B (zh) | 振动除残料式自动拆包卸料方法 | |

| EP0554207A2 (de) | Verfahren und Anordnung zum Sortieren von Artikeln | |

| CN117983352A (zh) | 一种园林绿化废弃物分选破碎装置 | |

| CN210192830U (zh) | 一种袋装物料投放装置 | |

| US4914994A (en) | Automated apparatus for debeading of scrap tires | |

| EP0443999B1 (de) | Vorrichtung zum Öffnen von Plastikbeuteln | |

| CN213107004U (zh) | 中药材干洗生产线 | |

| CN210474200U (zh) | 漂浮物垃圾破碎装置 | |

| CN110683146A (zh) | 包装袋自动拆包系统及其绳袋抽取分离机构 | |

| CN112293074A (zh) | 一种秸秆上料及切断设备 | |

| CN114408314B (zh) | 多工位拆包机 | |

| CN110525917A (zh) | 一种矿山智能除铁系统及除铁方法 | |

| CN106984546A (zh) | 一种样品全自动分类收集系统 | |

| JPH08239102A (ja) | 袋体回収装置 | |

| CN102836823A (zh) | 重力高效节能分选垃圾系统 | |

| CA2023501C (en) | Modified plastic bag opening apparatus | |

| CN107931300A (zh) | 一种生活垃圾卫生填埋场垃圾综合处理系统 | |

| CN106364918A (zh) | 一种带翻转的堆积装置 | |

| CN222780693U (zh) | 人机结合的麻袋烟包开包装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| 17P | Request for examination filed |

Effective date: 20090414 |

|

| 17Q | First examination report despatched |

Effective date: 20090514 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HOFMANN GROUP S.R.L. |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HOFMANN GROUP S.R.L. |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20150423 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: MENIA CADORE, VALENTINO |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20150518 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 738855 Country of ref document: AT Kind code of ref document: T Effective date: 20150815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008039214 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 738855 Country of ref document: AT Kind code of ref document: T Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151030 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151129 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151130 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602008039214 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 602008039214 Country of ref document: DE Representative=s name: HERNANDEZ, YORCK, DIPL.-ING., DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20160410 Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160410 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160410 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080410 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160430 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190621 Year of fee payment: 12 Ref country code: IT Payment date: 20190419 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190424 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602008039214 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200430 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201103 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200410 |