EP1978536B1 - Electromagnetic switching device - Google Patents

Electromagnetic switching device Download PDFInfo

- Publication number

- EP1978536B1 EP1978536B1 EP07006443A EP07006443A EP1978536B1 EP 1978536 B1 EP1978536 B1 EP 1978536B1 EP 07006443 A EP07006443 A EP 07006443A EP 07006443 A EP07006443 A EP 07006443A EP 1978536 B1 EP1978536 B1 EP 1978536B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- yoke

- bobbin

- switching device

- housing

- armature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000007858 starting material Substances 0.000 description 5

- 210000001331 nose Anatomy 0.000 description 3

- 239000004065 semiconductor Substances 0.000 description 3

- 239000000725 suspension Substances 0.000 description 2

- 238000004026 adhesive bonding Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/02—Bases; Casings; Covers

- H01H50/04—Mounting complete relay or separate parts of relay on a base or inside a case

- H01H50/041—Details concerning assembly of relays

- H01H50/045—Details particular to contactors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/16—Magnetic circuit arrangements

- H01H50/36—Stationary parts of magnetic circuit, e.g. yoke

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/02—Bases; Casings; Covers

- H01H50/04—Mounting complete relay or separate parts of relay on a base or inside a case

- H01H50/041—Details concerning assembly of relays

- H01H2050/046—Assembling parts of a relay by using snap mounting techniques

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/44—Magnetic coils or windings

- H01H2050/446—Details of the insulating support of the coil, e.g. spool, bobbin, former

Definitions

- Electromechanical switching devices are, for example, emergency stop switches, contactors or soft starters in automation technology, which are usually connected between a power source and a consumer such as electrical machines or drives.

- Such switching devices contain mechanical switching elements for power transmission or interruption, which are electrically actuated via an existing electromagnet in the switching device.

- a switching element is called bypass.

- the semiconductor switch is galvanically bridged by mechanically closing the bypass in order to reduce the (semiconductor) power loss in the soft starter during continuous operation of the motor.

- a mechanical switching element includes a magnetic coil which is fixedly fixed in the switching device and a solenoid driven by the magnetic coil yoke and armature, wherein the yoke is also fixedly disposed in the housing or relative to the magnetic coil and the armature is movable.

- the armature is connected to a contact carrier, which carries movable contacts, which are brought in case of closing of the switching element in turn with housing-fixed contacts in touch.

- the switching device also contains springs or spring plates, among other things. All components of the electromechanical switching device must be arranged with respect to their geometric arrangement to each other clearly over the life mechanically and electrically reliable.

- the yoke is fixed with respect to the magnetic coil or the armature and the housing.

- the yoke in known products, such as the 3RW40 soft starter size S6 (MLFB: 3RW4055) or contactor 3RT1023 size S0 from Siemens AG, the yoke, as well as the solenoid coil or the bobbin, on the housing of the switching device by a so-called yoke suspension attached.

- the yoke suspension includes, for example, the yoke comprehensive snap clips, which are locked with the upper housing part.

- FIG. 5 shows such a switching device 110 roughly schematically.

- a coil 100 is mounted on an upper housing part 102, for example, clipped on this.

- a yoke 104 is placed on the coil 100.

- the yoke 104 is also mounted on the upper housing part 102 yoke holder 112 by the yoke holder 112 are snapped to the upper housing part by means of snap connections 114. Coil 100 and yoke 104 are thus both held on the upper housing part.

- Coil 100, yoke 104 and insert 106 are clamped by a lower housing part 108, which is snapped onto the upper housing part 102, between both fixed or stationary.

- the remaining components of the switching device 110 are in FIG. 4 for the sake of clarity not shown.

- WO 95/12891 A is an electromechanical switching device with firmly arranged in a housing fixed contacts and a movable contact bridge for bridging the fixed contacts, with a, the contact bridge bearing movable contact carrier, and with an acting on the contact carrier electromagnet.

- a fixed bobbin is arranged in the housing, an armature coupled to the contact carrier, a yoke cooperating with the armature, and a fixing device acting on the yoke and bobbin for fixing the yoke to the bobbin.

- the GB 1 581 751 A describes an electromechanical switching device with a two-part housing and a magnet armature and yoke, wherein armature, yoke and bobbin are attached via two spring clip on the housing.

- Object of the present invention is to improve an electromechanical switching device with respect to the fixed fixation of the yoke in the switching device.

- an electromechanical switching device with firmly arranged in a housing fixed contacts and a movable contact bridge for bridging the fixed contacts.

- the contact bridge is supported by a movable contact carrier.

- the contact carrier is moved by an electromagnet acting on it.

- the electromagnet comprises a coil body fastened to the housing of the switching device, an armature coupled to the contact carrier and a yoke cooperating with the armature.

- the electromechanical switching device has a fixing device, which acts on the yoke and bobbins and serves to fix the yoke on the bobbin.

- the yoke is thus also fixed with respect to the housing and the bobbin in a fixed position, but attached via the fixing device directly to the bobbin, and not attached to the housing.

- the assembly of the yoke and bobbin unit in the housing is facilitated and requires only a single fastening operation.

- the fixing device has a bracket attachable to the bobbin for the yoke.

- a yoke holder which also during pre-assembly fixed the yoke to the bobbin by means of the holder.

- the presence of the Jochhalters or its correct installation can be controlled even before assembly of the switching device and thus easier.

- the fixing device may have a latching after fixing of the yoke latch.

- the yoke or the fixing device then only have to be snapped or latched onto the bobbin or vice versa.

- An additional step such as screwing, gluing, crimping or the like is eliminated.

- the fixing device may be integral with the bobbin running, the yoke in the fixed state engaging behind latching noses.

- the yoke can be attached to the bobbin in a particularly simple manner by moving it towards the bobbin, with the latching noses in this case outwards, i. be moved from its rest position. Only when the yoke is fully pushed on do the snap-in lugs snap back into their original position, thus reaching behind the yoke and fixing it.

- the fixing device may comprise a cage enclosing the yoke in the fixed state between it and the bobbin, which has for example cross-shaped pressure elements. Each pressure element then exerts pressure in each case on the yoke in the direction of the bobbin out, whereby this is pressed centrally over the on the bobbin.

- Such a cage can be latched onto the bobbin. Even so, the attachment of the cage is solved in a particularly simple manner and requires no further work step, such as the above screwing etc.

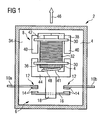

- FIG. 1 shows a highly simplified representation of a contactor 2 with a housing 4, which is cut to look into the interior of the contactor 2 can.

- a switching element 6 and an electromagnet 8 is arranged, which actuates the switching member 6.

- the switching element 6 comprises two, the wall of the housing 4 passing through fixed contacts 10a, b, which carry 12 each at their housing inner ends 12 contact buttons.

- the contact buttons 14 are each associated with further contact buttons 14, which are arranged on a movable contact 16.

- the movable contact 16 is mounted in a movable contact carrier 18.

- the electromagnet 8 comprises a bobbin 30, on which an electric coil 32 is wound. From the in FIG. 1 visible rear wall 34 of the housing 4 extends into the interior of the contactor 2 in, ie in FIG. 1 to the viewer, a part of the housing 4 in the form of a mounting tongue 36. On the mounting tongue 36 of the bobbin 30 is fixedly mounted, for example snapped, and thus fixed relative to the housing 4 fixed. In the bobbin 30 is with its central extension (in FIG. 1 not visible) introduced an E-shaped yoke 38, so that the two outer legs 40 of the yoke 38 laterally on the bobbin 30 over in the direction of the switching element 6 point.

- a yoke holder 42 includes the yoke 38 and fixes it on the bobbin 30 by the yoke holder 42 is fixedly attached to the bobbin 30, for example, snapped on this. The fixation comes close on the yoke 38 as short as possible, namely at the yoke 28 facing the end of the bobbin 30 at.

- the coil 32 is not energized and the armature 44 biased by a coil spring 48, which is supported on the armature 44 and on the mounting tongue 36, opposite to the arrow 46, ie in the opening direction of the contact buttons 14. He is therefore in his final position in OffenPosition.

- the contactor 2 is open, there is no electrical contact between the fixed contacts 10a, b.

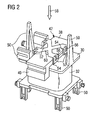

- FIG. 2 shows the bobbin 30 from FIG. 1 in a more detailed illustration together with the coil 32, the yoke 38 and the yoke holder 42.

- the yoke holder 42 is formed in the manner of a cage, at four points 52 on the bobbin 30 is attached.

- the fasteners are designed in the form of locking lugs 54, which are integrally formed on the bobbin and engage in corresponding openings 56 of the yoke holder 42 when it is pressed in the direction of arrow 58 during assembly on the bobbin 30 and the applied yoke 38.

- strained state of the yoke holder 42 via a pressure member 60 pressure in the direction of arrow 58 on the yoke 38 and presses it against the bobbin 30th

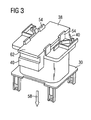

- FIG. 3 shows an alternative non-inventive embodiment of a bobbin 30, on which in turn latching noses 54 are formed. However, these do not serve as in FIG. 2 to mount a yoke holder 42, but act directly on the yoke 38 a. If the yoke 38 is applied during assembly in the direction of the arrow 58 on the bobbin 30, the locking lugs 54 deviate from the yoke 38 and rest only when this in the in FIG. 3 shown end position abuts the bobbin 30, behind the top 62 of the yoke holder 38 before to permanently attach this on the bobbin 30. In the FIG. 3 shown solution is opposite to in FIG. 2 shown solution suitable only for smaller holding down forces of the yoke 38 on the bobbin 30. For a separate yoke holder 42 in the embodiment according to. FIG. 3 unnecessary.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Electromagnets (AREA)

Description

Die Erfindung betrifft ein elektromechanisches Schaltgerät. Elektromechanische Schaltgeräte sind z.B. Not-Aus-Schalter, Schütze oder Sanftstarter in der Automatisierungstechnik, welche in der Regel zwischen einer Stromquelle und einem Verbraucher wie elektrischen Maschinen bzw. Antrieben geschaltet sind. Derartige Schaltgeräte enthalten mechanische Schaltglieder zur Stromübertragung bzw. -unterbrechung, welche über einen im Schaltgerät vorhandenen Elektromagneten elektrisch betätigt werden. Z.B. bei modernen Sanftstartern für Elektromotoren wird ein derartiges Schaltglied Bypass genannt. Im Falle eines vollständigen Durchschaltens eines Halbleiterschalters im Sanftstarter wird der Halbleiterschalter durch mechanisches Schließen des Bypasses galvanisch überbrückt, um die (Halbleiter-)Verlustleistung im Sanftstarter bei Dauerbetrieb des Motors reduzieren.

Ein mechanisches Schaltglied enthält eine Magnetspule, welche fest im Schaltgerät fixiert ist und einen von der Magnetspule angesteuerten magnetischen Kreis aus Joch und Anker, wobei das Joch ebenfalls im Gehäuse bzw. relativ zur Magnetspule fest angeordnet ist und der Anker beweglich ist. Der Anker ist mit einem Kontaktträger verbunden, welcher bewegliche Kontakte trägt, welche im Falle des Schließens des Schaltgliedes mit wiederum gehäusefesten Festkontakten in Berührung gebracht werden. Das Schaltgerät enthält auch unter anderem Federn bzw. Federteller. Alle Bauteile des Elektromechanischen Schaltgerätes müssen bezüglich ihrer geometrischen Anordnung zueinander eindeutig über die Lebensdauer mechanisch und elektrisch zuverlässig angeordnet werden. Im Besonderen ist hierbei das Joch ortsfest bezüglich der Magnetspule bzw. des Ankers und des Gehäuses zu befestigen.

Bei bekannten Produkten, wie z.B. dem Sanftstarter 3RW40 Baugröße S6 (MLFB:3RW4055) oder Schütz 3RT1023 Baugröße S0 der Firma Siemens AG wird das Joch, genau wie die Magnetspule bzw. der Spulenkörper, am Gehäuse des Schaltgeräts durch eine sogenannte Jochaufhängung befestigt. Die Jochaufhängung umfasst beispielsweise das Joch umfassende Schnappklammern, die mit dem Gehäuseoberteil verrastet werden.

A mechanical switching element includes a magnetic coil which is fixedly fixed in the switching device and a solenoid driven by the magnetic coil yoke and armature, wherein the yoke is also fixedly disposed in the housing or relative to the magnetic coil and the armature is movable. The armature is connected to a contact carrier, which carries movable contacts, which are brought in case of closing of the switching element in turn with housing-fixed contacts in touch. The switching device also contains springs or spring plates, among other things. All components of the electromechanical switching device must be arranged with respect to their geometric arrangement to each other clearly over the life mechanically and electrically reliable. In particular, in this case, the yoke is fixed with respect to the magnetic coil or the armature and the housing.

In known products, such as the 3RW40 soft starter size S6 (MLFB: 3RW4055) or contactor 3RT1023 size S0 from Siemens AG, the yoke, as well as the solenoid coil or the bobbin, on the housing of the switching device by a so-called yoke suspension attached. The yoke suspension includes, for example, the yoke comprehensive snap clips, which are locked with the upper housing part.

Es ist auch bekannt, das Joch auf den Spulenkörper aufzulegen und auf der dem Spulenkörper abgewandten Seite des Jochs ein Einlegeteil vorzusehen. Alle drei Komponenten werden dann zwischen einem Gehäuseunterteil und einem -oberteil fixiert, welche zusammengerastet sind. Das Gehäuseoberteil kann hierbei einstückig mit dem Spulenkörper ausgebildet sein. Eine derartige Anordnung ist als Schaltgerät 110 in

Die Nachteile der bekannten Lösungen sind, dass z.B. Schnapphaken für die Jochbefestigung durch Gehäuseteile im Gerät zur Verfügung stehen müssen, dass der Teileaufwand hoch ist, da für die Verschnappung separate Teile notwendig sind, dass die Jochhalterungen einen zusätzlichen Platzbedarf im Gerät beanspruchen und dass Montagefehler, z.B. das Vergessen eines Jochhalters bzw. einer Halteklammer auftreten können.The disadvantages of the known solutions are that, for example, snap hooks for yoke attachment by housing parts in the device must be available, that the parts cost is high, since the snapping separate parts are necessary that the yoke brackets require additional space in the device and that assembly errors, For example, forgetting a Jochhalters or a retaining clip can occur.

Aus der

Die

Aufgabe der vorliegenden Erfindung ist es, ein elektromechanisches Schaltgerät hinsichtlich der ortsfesten Fixierung des Jochs im Schaltgerät zu verbessern.Object of the present invention is to improve an electromechanical switching device with respect to the fixed fixation of the yoke in the switching device.

Die Aufgabe wird gelöst durch ein elektromechanisches Schaltgerät mit fest in einem Gehäuse angeordneten Festkontakten und einer beweglichen Kontaktbrücke zur Überbrückung der Festkontakte. Die Kontaktbrücke ist hierbei von einem beweglichen Kontaktträger getragen. Der Kontaktträger wird bewegt von einem auf ihn einwirkenden Elektromagneten. Der Elektromagnet umfasst einem am Gehäuse des Schaltgeräts befestigten Spulenkörper, einen mit dem Kontaktträger bewegungsgekoppelten Anker und ein mit dem Anker zusammenwirkendes Joch. Erfindungsgemäß weist das elektromechanische Schaltgerät eine Fixiervorrichtung auf, welche an Joch und Spulenkörpern angreift und zur Fixierung des Jochs am Spulenkörper dient.The object is achieved by an electromechanical switching device with firmly arranged in a housing fixed contacts and a movable contact bridge for bridging the fixed contacts. The contact bridge is supported by a movable contact carrier. The contact carrier is moved by an electromagnet acting on it. The electromagnet comprises a coil body fastened to the housing of the switching device, an armature coupled to the contact carrier and a yoke cooperating with the armature. According to the invention, the electromechanical switching device has a fixing device, which acts on the yoke and bobbins and serves to fix the yoke on the bobbin.

Das Joch ist also ebenfalls bezüglich des Gehäuses und des Spulenkörpers in einer festen Lage fixiert, jedoch über die Fixiervorrichtung direkt am Spulenkörper, und nicht am Gehäuse befestigt. Somit entsteht eine Einheit aus Magnetspule und Joch, welche als separate Funktionseinheit in einer Vormontage bereits zusammengefügt werden kann. Die Montage der Einheit aus Joch und Spulenkörper im Gehäuse ist dadurch erleichtert und benötigt nur einen einzigen Befestigungsvorgang.The yoke is thus also fixed with respect to the housing and the bobbin in a fixed position, but attached via the fixing device directly to the bobbin, and not attached to the housing. This results in a unit of magnetic coil and yoke, which can already be assembled as a separate functional unit in a pre-assembly. The assembly of the yoke and bobbin unit in the housing is facilitated and requires only a single fastening operation.

Die Fixiervorrichtung weist eine am Spulenkörper anbringbare Halterung für das Joch auf. Somit existiert ein separates Bauteil, ein Jochhalter, welcher ebenfalls bei Vormontage das Joch am Spulenkörper mittels der Halterung fixiert. Das Vorhandensein des Jochhalters bzw. dessen korrekte Montage kann jedoch bereits vor Zusammenbau des Schaltgerätes und damit einfacher kontrolliert werden.The fixing device has a bracket attachable to the bobbin for the yoke. Thus, there is a separate component, a yoke holder, which also during pre-assembly fixed the yoke to the bobbin by means of the holder. However, the presence of the Jochhalters or its correct installation can be controlled even before assembly of the switching device and thus easier.

Die Fixiervorrichtung kann eine nach Fixierung des Jochs einrastende Verrastung aufweisen. Das Joch bzw. die Fixiervorrichtung müssen dann lediglich auf den Spulenkörper oder umgekehrt aufgeschnappt bzw. eingerastet werden. Ein zusätzlicher Arbeitsschritt wie Verschrauben, Verkleben, Vercrimpen oder ähnliches entfällt.The fixing device may have a latching after fixing of the yoke latch. The yoke or the fixing device then only have to be snapped or latched onto the bobbin or vice versa. An additional step such as screwing, gluing, crimping or the like is eliminated.

Die Fixiervorrichtung kann einstückig mit dem Spulenkörper ausgeführte, das Joch im fixierten Zustand hintergreifende Rastnasen aufweisen. Das Joch kann so besonders einfach am Spulenkörper befestigt werden, indem es auf den Spulenkörper zubewegt wird und die Rastnasen hierbei nach außen, d.h. aus ihrer Rastposition bewegt werden. Erst bei vollständig aufgedrücktem Joch schnappen die Rastnasen in ihre ursprüngliche Lage zurück, hintergreifen damit das Joch und fixieren es.The fixing device may be integral with the bobbin running, the yoke in the fixed state engaging behind latching noses. The yoke can be attached to the bobbin in a particularly simple manner by moving it towards the bobbin, with the latching noses in this case outwards, i. be moved from its rest position. Only when the yoke is fully pushed on do the snap-in lugs snap back into their original position, thus reaching behind the yoke and fixing it.

Die Fixiervorrichtung kann einen das Joch im fixierten Zustand zwischen sich und dem Spulenkörper einschließenden Käfig umfassen, der beispielsweise kreuzförmig angeordnete Andruckelemente aufweist. Jedes Andruckelement übt dann jeweils für sich Druck auf das Joch in Richtung des Spulenkörpers hin aus, wodurch dieses zentral über den auf den Spulenkörper gedrückt wird.The fixing device may comprise a cage enclosing the yoke in the fixed state between it and the bobbin, which has for example cross-shaped pressure elements. Each pressure element then exerts pressure in each case on the yoke in the direction of the bobbin out, whereby this is pressed centrally over the on the bobbin.

Ein derartiger Käfig kann auf den Spulenkörper aufrastbar sein. Auch so ist das Befestigen des Käfigs in besonders einfacher Weise gelöst und erfordert keinen weiteren Arbeitsschritt, wie das oben genannte Anschrauben etc..Such a cage can be latched onto the bobbin. Even so, the attachment of the cage is solved in a particularly simple manner and requires no further work step, such as the above screwing etc.

Für eine weitere Beschreibung der Erfindung wird auf die Ausführungsbeispiele der Zeichnungen verwiesen. Es zeigen, jeweils in einer schematischen Prinzipskizze:

- FIG 1

- ein elektromechanisches Schaltgerät, dessen Gehäuse aufgeschnitten ist,

- FIG 2

- eine Magnetspule mit Joch und aufgeschnappten Fixierkäfig,

- FIG 3

- eine Magnetspule mit angeformter Fixiervorrichtung,

- FIG 4

- eine Jochbefestigung gemäß Stand der Technik durch Verpressung zwischen Gehäusehälften,

- FIG 5

- eine alternative Jochbefestigung gemäß Stand der Technik durch Befestigung an einem Gehäuseteil.

- FIG. 1

- an electromechanical switching device whose housing is cut open,

- FIG. 2

- a magnetic coil with yoke and snapped fixation cage,

- FIG. 3

- a magnetic coil with molded fixing device,

- FIG. 4

- a yoke mounting according to the prior art by compression between housing halves,

- FIG. 5

- an alternative yoke attachment according to the prior art by attachment to a housing part.

Der Elektromagnet 8 umfasst einen Spulenkörper 30, auf welchen eine elektrische Spule 32 aufgewickelt ist. Von der in

Über die Montagezunge 36 sind also Spulenkörper 30, Spule 32, Joch 38 und Jochhalter 42 ortsfest zum Gehäuse 4 fixiert. Auf der dem Joch 38 gegenüberliegenden Seite des Spulenkörpers 30 ist ein E-förmiger Anker 44 angebracht, um zusammen mit dem Spulenkörper 30 einen magnetischen Kreis des Elektromagneten 8 zu bilden. Der Anker 44 ragt mit seinem mittleren Schenkel 41 in das Innere der Spule 32. Der Anker 44 ist fest mit dem Kontaktträger 18 verbunden und damit mit diesem und dem Kontakt 16 bzw. den Kontaktknöpfen 14 bewegungsgekoppelt. Der Anker 44 ist in bzw. entgegen der Richtung des Pfeils 46 bewegbar. In

Durch Bestromen der Spule 32 wird in Joch 38 und Anker 44 ein Magnetkreis erzeugt, welcher den beweglichen Anker 44 relativ zum Gehäuse 4 in Richtung des Pfeils 46 bewegt und damit die Kontaktknöpfe 14 in gegenseitigen Kontakt bringt. Der elektrische Kontakt zwischen den Festkontakten 10a,b ist somit hergestellt.By energizing the

Außerdem ist zu erkennen, dass der Jochhalter 42 nach Art eines Käfigs ausgebildet ist, der an vier Stellen 52 am Spulenkörper 30 befestigt ist. Die Befestigungen sind in Form von Rastnasen 54 ausgeführt, welche am Spulenkörper angeformt sind und in entsprechende Öffnungen 56 des Jochhalters 42 eingreifen, wenn dieser in Richtung des Pfeils 58 bei der Montage auf den Spulenkörper 30 bzw. das aufgelegte Joch 38 aufgepresst wird. Im in

Claims (5)

- Electromechanical switching device (2) having fixed contacts (10a, b) securely arranged in a housing (4) and a moving contact bridge (16) for bridging the fixed contacts (10a, b), having a moving contact carrier (18) carrying the contact bridge (16), having a solenoid (8) acting on the contact carrier (18), said solenoid comprising a coil body (30), which is fixed to the housing (4), an armature (44), which is coupled to the contact carrier (18) so as to move with it, a yoke (38) acting together with the armature (44), and a fixing mechanism (42, 54), which engages with the yoke (38) and coil body (30) for fixing the yoke (38) to the coil body (30), characterized in that the fixing mechanism (42, 54) has a holder (42) for the yoke (38), which can be attached to the coil body (30).

- Switching device (2) according to Claim 1, in which the fixing mechanism (42, 54) has a latch (54, 56), which engages after fixing the yoke.

- Switching device (2) according to Claim 1 or 2, in which the fixing mechanism (42, 54) has latching lugs (54), which are designed in one piece with the coil body (30) and which engage behind the yoke (38) in the fixed state.

- Switching device (2) according to one of the preceding claims, in which the fixing mechanism (42, 54) comprises a cage (42), which encloses the yoke (38) in the fixed state between itself and the coil body (30).

- Switching device (2) according to Claim 4, in which the cage (42) can be clipped onto the coil body (30).

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07006443A EP1978536B1 (en) | 2007-03-28 | 2007-03-28 | Electromagnetic switching device |

| CN2007101954750A CN101276706B (en) | 2007-03-28 | 2007-11-30 | Electromechanical switching device |

| US12/000,495 US7737811B2 (en) | 2007-03-28 | 2007-12-13 | Electromechanical switching device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP07006443A EP1978536B1 (en) | 2007-03-28 | 2007-03-28 | Electromagnetic switching device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1978536A1 EP1978536A1 (en) | 2008-10-08 |

| EP1978536B1 true EP1978536B1 (en) | 2012-11-28 |

Family

ID=38187578

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07006443A Not-in-force EP1978536B1 (en) | 2007-03-28 | 2007-03-28 | Electromagnetic switching device |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US7737811B2 (en) |

| EP (1) | EP1978536B1 (en) |

| CN (1) | CN101276706B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8508321B2 (en) * | 2010-08-17 | 2013-08-13 | Song Chuan Precision Co., Ltd. | Relay with multiple coils |

| EP2437278B1 (en) * | 2010-09-30 | 2013-05-15 | Hager-Electro SAS | Assembly of a motor of a multipolar contactor |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1581751A (en) * | 1976-04-28 | 1980-12-17 | Bbc Brown Boveri & Cie | Electromagnetic contactors |

| WO1995012891A1 (en) * | 1993-11-04 | 1995-05-11 | Asea Brown Boveri Ab | Electromagnetically operated electric switching device |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL132206C (en) * | 1962-04-24 | |||

| US3215800A (en) * | 1962-07-02 | 1965-11-02 | Square D Co | Electromagnetic relay and contact carrier assembly therefor |

| DE7635899U1 (en) * | 1976-11-13 | 1977-03-03 | Brown, Boveri & Cie Ag, 6800 Mannheim | MOUNTING DEVICE FOR A MAGNETIC CORE WITH SHORT CIRCUIT RINGS AND A COIL |

| ATE169735T1 (en) * | 1993-10-22 | 1998-08-15 | Bf Patent Ag | APERTURE UNIT |

| DE19611997A1 (en) * | 1996-03-26 | 1997-10-02 | Siemens Ag | Electromagnetic relay |

| CN2416598Y (en) * | 2000-02-17 | 2001-01-24 | 正泰集团公司 | AC contactor |

| DE10013353C2 (en) * | 2000-03-17 | 2002-02-07 | Siemens Ag | Electromagnetic switching device, especially a contactor |

| DE10013314C2 (en) * | 2000-03-17 | 2002-01-17 | Siemens Ag | Electromagnetic switching device, especially a contactor |

| US6661321B1 (en) * | 2002-08-30 | 2003-12-09 | Tendex Electric Co., Ltd. | Electromagnetic switch |

| WO2005101441A1 (en) * | 2004-04-13 | 2005-10-27 | Siemens Aktiengesellschaft | Coil body for switchgear |

-

2007

- 2007-03-28 EP EP07006443A patent/EP1978536B1/en not_active Not-in-force

- 2007-11-30 CN CN2007101954750A patent/CN101276706B/en not_active Expired - Fee Related

- 2007-12-13 US US12/000,495 patent/US7737811B2/en active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1581751A (en) * | 1976-04-28 | 1980-12-17 | Bbc Brown Boveri & Cie | Electromagnetic contactors |

| WO1995012891A1 (en) * | 1993-11-04 | 1995-05-11 | Asea Brown Boveri Ab | Electromagnetically operated electric switching device |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1978536A1 (en) | 2008-10-08 |

| CN101276706B (en) | 2010-12-01 |

| US20080258851A1 (en) | 2008-10-23 |

| CN101276706A (en) | 2008-10-01 |

| US7737811B2 (en) | 2010-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE602005000652T2 (en) | Electromagnetic relay | |

| DE1267309B (en) | Electrical contactor in which the contact bridge and fixed contacts are designed as a structural unit | |

| EP2831900B1 (en) | Polarized electromagnetic relay and method for production thereof | |

| DE1256300B (en) | Contactor | |

| DE69604679T2 (en) | POLARIZED ELECTROMAGNETIC RELAY | |

| DE102008057555A1 (en) | Relay with flip-flop spring | |

| EP3443571B1 (en) | Electromagnetic actuating device which is monostable in the currentless state and use of such an actuating device | |

| WO1993001608A1 (en) | Electromagnetic relay | |

| EP1978536B1 (en) | Electromagnetic switching device | |

| DE112019002137T5 (en) | Electromechanical switch with moving contact and damper | |

| EP2645386A1 (en) | Relay with improved insulating properties | |

| EP1901326A1 (en) | Motor starter | |

| WO2017129488A1 (en) | Electromagnetic adjusting device and use of such an adjusting device | |

| EP0802552B1 (en) | Electrical switch with undervoltage release | |

| EP2737513A1 (en) | Electromagnetic relay | |

| EP3149758A1 (en) | Switching device with modular auxiliary switching unit | |

| DE1807319A1 (en) | relay | |

| DE102016011341A1 (en) | High-voltage contactor arrangement for a motor vehicle and method for transferring a high-voltage contactor arrangement between an open and a closed state | |

| DE102012106330B4 (en) | Spool core for electromagnetic drive and selbiger and method for its production | |

| DE3443556C2 (en) | Electrical switching device | |

| EP1085549A2 (en) | Bistable contactor | |

| DE202014010575U1 (en) | Power relay for a vehicle | |

| AT404522B (en) | ELECTROMAGNETICALLY CONTROLLED SWITCHING DEVICE WITH OPENING POLES | |

| DE202004013965U1 (en) | Solenoid type permanent magnet trigger mechanism for electronic overload relay has L-shaped tongue element for magnetic connection to electromagnetic system so rod element and attached components can move horizontally | |

| WO2011015409A1 (en) | Contact arrangement for an electromagnetic switching device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20070910 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17Q | First examination report despatched |

Effective date: 20090202 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 502007010937 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: H01H0050040000 Ipc: H01H0050360000 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01H 50/04 20060101ALI20120523BHEP Ipc: H01H 50/36 20060101AFI20120523BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 586546 Country of ref document: AT Kind code of ref document: T Effective date: 20121215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007010937 Country of ref document: DE Effective date: 20130117 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: SIEMENS AKTIENGESELLSCHAFT |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20121128 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130311 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130301 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 |

|

| BERE | Be: lapsed |

Owner name: SIEMENS A.G. Effective date: 20130331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26N | No opposition filed |

Effective date: 20130829 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130328 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007010937 Country of ref document: DE Effective date: 20130829 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130328 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130331 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130328 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 586546 Country of ref document: AT Kind code of ref document: T Effective date: 20130328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130328 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130328 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20070328 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20121128 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20220308 Year of fee payment: 16 Ref country code: IT Payment date: 20220322 Year of fee payment: 16 Ref country code: FR Payment date: 20220324 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20220518 Year of fee payment: 16 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230510 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502007010937 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230329 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230331 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231003 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230328 |