EP1910038B1 - Linearly driven and air-cooled boring and/or percussion hammer - Google Patents

Linearly driven and air-cooled boring and/or percussion hammer Download PDFInfo

- Publication number

- EP1910038B1 EP1910038B1 EP06762834A EP06762834A EP1910038B1 EP 1910038 B1 EP1910038 B1 EP 1910038B1 EP 06762834 A EP06762834 A EP 06762834A EP 06762834 A EP06762834 A EP 06762834A EP 1910038 B1 EP1910038 B1 EP 1910038B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- percussion

- hammer

- drive

- piston

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D17/00—Details of, or accessories for, portable power-driven percussive tools

- B25D17/20—Devices for cleaning or cooling tool or work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D11/00—Portable percussive tools with electromotor or other motor drive

- B25D11/06—Means for driving the impulse member

- B25D11/064—Means for driving the impulse member using an electromagnetic drive

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D2216/00—Details of portable percussive machines with superimposed rotation, the rotational movement of the output shaft of a motor being modified to generate axial impacts on the tool bit

- B25D2216/0007—Details of percussion or rotation modes

- B25D2216/0015—Tools having a percussion-only mode

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25D—PERCUSSIVE TOOLS

- B25D2217/00—Details of, or accessories for, portable power-driven percussive tools

- B25D2217/0011—Details of anvils, guide-sleeves or pistons

- B25D2217/0023—Pistons

Definitions

- the invention relates according to the preamble of claim 1 a drilling and / or percussion hammer with an electrodynamic linear drive.

- a drilling and / or percussion hammer with an electrodynamic linear drive is from the US-A-1 723 607 known.

- Drilling and / or impact hammers are usually driven by electric motors in which a rotor rotates a drive shaft.

- the rotor is usually coupled to a fan of a fan, which generates a cooling air flow. The rotational movement of the rotor is thus used in a simple manner for driving a radial or Axialltypicalerrades.

- An air spring impact mechanism is known in which a drive piston can be driven by an electrodynamic linear drive.

- the drive piston is coupled to a rotor of the linear drive, so that the linear reciprocating motion of the rotor is transmitted to the drive piston.

- the movement of the drive piston is transmitted via an air spring to a percussion piston, as is usual with air spring impact devices, which strikes against a tool end or an interposed anvil in a known manner.

- a percussion hammer which has a directly linear electrodynamically driven impact element.

- the impact element and a drive element form a functional unit and are rigidly or positively connected firmly.

- Chambers lying in front of and behind the impact or drive element are connected to themselves and to the ambient atmosphere via ducts.

- the hammer mechanism When the hammer mechanism is in operation, the volumes in front of and behind the impact element change in opposite directions. Due to the connection of both chambers, air is exchanged between the two chambers.

- the invention has for its object to provide a drilling and / or percussion hammer with an electrodynamic linear drive, in which a sufficient air cooling of the heat-generating components is ensured.

- An inventive hammer drill and / or percussion hammer (hereinafter referred to as hammer) has an air-conveying device with a linearly reciprocable pumping element for generating a cooling air flow.

- the pumping element is coupled to the drive element and / or the striking element of the percussion mechanism in such a way that the movement of the drive element and / or of the striking element can be transferred to the pumping element.

- the air conveying device has a pumping space and an air duct, wherein the pumping element can be moved back and forth in the pumping space and the pumping space can be brought into contact with the environment at least temporarily via the air duct.

- a type of air pump is formed, which functions similar to a bicycle pump (piston pump). Due to the coupling of the pump chamber with the environment via the air duct, there is the possibility that fresh cooling air can be supplied from the environment into the pump chamber or heated air can be released to the environment.

- the air channel has an intake passage for the inflow of. Air from the environment in the pump room. Accordingly, the air duct also has an outlet channel for the outflow of air from the pumping space into the environment. While in a variant not according to the invention the ambient air is conveyed back and forth in the air duct, when the air duct is divided into an intake duct and an exhaust duct a directional air flow can be achieved, which always flows only in one direction. Accordingly, cold air from the environment is supplied via the intake passage while the heated air is discharged to the environment via the exhaust passage.

- the drive element can, for. B. are formed by a drive piston in an air spring impact mechanism. It is reciprocated by the linear drive in a known manner. According to the invention, the pumping element is coupled to the drive element in an advantageous manner, so that it likewise has to reciprocate linearly. With the help of this oscillating linear movement, a cooling air flow can be generated, which is guided past the components to be cooled.

- the linearly driven air conveying device makes it possible to generate a cooling air flow without having to provide a rotary ventilator.

- the drive element is connected to a rotor of the linear drive.

- the drive element carries the rotor or is substantially completely formed by the rotor, so that the rotor simultaneously assumes the function of the drive element.

- the linear motor can be a switched reluctance motor (SR motor) and has several drive coils (stator) in the movement range of the rotor, which are switched according to the desired movement of the drive element.

- SR motor switched reluctance motor

- an electrodynamic drive z. B. is considered in the form of a single electromagnetic coil, which serves as a drive coil for the drive element.

- the return movement of the drive element can then z. B. via a coil spring o. ⁇ . respectively.

- Decisive is that the drive element is closely connected to the rotor.

- the coupling device has at least one between the drive element and the striking element effective stop.

- the stop ensures a positive transmission of the movement of the drive element to the striking element, which must then necessarily follow the movement of the drive element.

- the coupling device has an elastic element acting between the drive element and the striking element in at least one direction.

- the stop described above elastic, z. B. by a stopper held on the elastic element or an elastic coating.

- the elastic element may also be formed by a later explained air spring, when the percussion is realized as Luftfedertschwerk.

- the drive element, the rotor and the pumping element form a structural unit.

- these components can be integrally connected to each other, so that the movement of the rotor can be transferred lossless to the drive element and the pumping element.

- the drive element and the pumping element must then necessarily follow the movement of the rotor.

- the movement of the drive element via a mechanical, hydraulic or pneumatic coupling to the pumping element is transferable.

- a Bowden cable or a hydraulic line can run between the drive element and the pump element in order to transmit the movement of the drive element to the pump element with as little loss as possible.

- the pumping element can then also be arranged at a different location in the hammer.

- the pumping element is arranged in a region of the hammer which is decoupled from the impact mechanism in terms of vibration.

- the impact mechanism and the linear drive generate considerable vibrations due to the oscillating motion of the moving elements and the impact of the striking element.

- many approaches are known to reduce these vibrations z. B. to isolate from a handle of the hammer and to protect the operator from harmful vibrations. Accordingly, it is known in almost all hammers to decouple at least a portion vibrationally from the percussion.

- the arrangement of the pumping element in this vibration-decoupled region has the advantage that the pumping element and the remaining components of the air-conveying device are mechanically stressed less, so that a more reliable mode of operation can be achieved.

- the rotor is designed substantially cylindrical or hollow cylindrical. Alternatively, it may also have at least one axially extending plate-shaped or sword-like element. This plate-shaped element, the z. B. is formed as an extension on the drive element extends into the stator to achieve the desired drive effect.

- the air duct is arranged such that it runs along heat-generating components of the hammer, in particular along a part of a stator of the linear drive.

- the stator is traversed by an electric current and accordingly contributes significantly to the heat generation. This heat can be removed from the stator via the cooling air flowing through the air duct.

- a check valve is arranged in the intake duct and / or in the outlet duct, which permits an air flow only in one direction.

- a storage device which is in communicating connection with the outlet channel and serves for temporarily storing at least part of the air flowing out via the outlet channel.

- the storage device ensures a compensation of the air pressure fluctuations that inevitably arise due to the movement of the pumping element. Pressure peaks can be reduced by the fact that the storage device briefly absorbs air. If, on the other hand, no air is supplied by the pumping element, the storage device releases the air again and thus ensures a substantially uniform flow of cooling air.

- an elastic or spring-loaded element is provided in the storage device, which changes the size of a storage space as a function of the pressure of the air flow supplied by the pumping element.

- a cross section of the exhaust passage downstream of the storage device is smaller than a cross section of the exhaust passage upstream of the storage device. It is thus possible that the air flow conveyed by the pumping element can reach the storage device unhindered in order to fill the storage device with as little loss as possible. The actual cooling air flow is then discharged via the outlet channel of smaller cross-section, this outlet channel extending along the heat-generating components.

- a check valve can be arranged in the outlet channel between the pump chamber and the storage device.

- the pumping element is arranged in the direction of impact behind the drive element and the rotor.

- the pumping element can also be arranged next to the striking mechanism. It is desirable that the air pumping device must be arranged as space-saving as possible in the housing of the hammer in order not to increase the overall volume, especially the overall length.

- the striking mechanism is formed by an air spring impact mechanism.

- the drive element is designed as a drive piston and the impact element as a percussion piston, wherein the coupling device has a trained in a cavity between the drive piston and the percussion piston air spring.

- the air spring thus transmits in a known manner, the drive movement of the drive piston on the percussion piston.

- the coupling according to the invention of a linear drive with an air-conveying device can be applied to all types of striking mechanisms.

- the coupling according to the invention is suitable for percussion, which are designed as Heilfeder Farbwerke, and thus therefore known per se tube impactors (drive piston and percussion pistons with identical diameter), hollow piston impactors (drive piston with cavity in which the percussion piston moves) or drums with hollow percussion piston , in which the drive piston moves.

- the drive piston surrounds the percussion piston in the direction of impact before and behind the percussion piston such that the air spring is disposed behind the percussion piston and that before the percussion piston, a second air spring between the drive piston and the percussion piston can be formed ,

- this percussion type thus creates a double air spring, which on the one hand generates the movement of the percussion piston forward and on the other hand supports a return movement of the percussion piston.

- an effective for generating the air flow cross-sectional area of the pumping element is greater than acting on the air spring cross-sectional area of the drive piston.

- a significant heat output which must be dissipated.

- a correspondingly large cooling air flow is required.

- a correspondingly large cross-sectional area of the pumping element must be present.

- the pumping element can also be replaced by a plurality of individual pumping elements which, taken in themselves, are dimensioned smaller, but together achieve a sufficiently large effective cross-sectional area through their coupling with the rotor and thus their interaction together. Accordingly, the term “pumping element” refers only to the function, not to the specific embodiment.

- Fig. 1 to 8 show different embodiments of the hammer according to the invention in a greatly simplified sectional view.

- known per se components such.

- handles and electrical connections omitted, since they do not affect the invention.

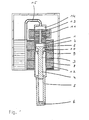

- Fig. 1 shows a first non-inventive embodiment with a driven by an electrodynamic linear actuator air spring impact mechanism.

- the air spring impact mechanism has as drive element a drive piston 1 which encloses a piston head 2 of a percussion piston 3 acting as a striking element.

- the percussion piston 3 extends with a shaft 4 in a percussion piston guide 5 and can strike in its foremost position against a tool end 6.

- an intermediate header can also be provided in a known manner.

- first air spring 7 acts between the drive piston 1 and the percussion piston 3, a cavity is formed, in which acts as a coupling device first air spring 7 acts.

- first air spring 7 acts in a forward movement of the drive piston 1, which is axially reciprocable in a percussion gear 8, a pressure builds up in the first air spring 7, which drives the percussion piston 3 to the front, so that it can finally strike against the tool end 6.

- a negative pressure which sucks the percussion piston 3.

- the return movement of the percussion piston 3 is also supported by the impact reaction at the tool end 6.

- a second air spring also serving as a coupling device is provided 9 formed, which comes into effect during the return movement of the drive piston 1. It also supports the return movement of the percussion piston 2.

- the oscillating, linear reciprocating movement of the drive piston 1 is effected by an electrodynamic linear drive.

- the drive piston 1 is coupled to a rotor 11 of the linear drive.

- the rotor 11 may be formed by a plurality of stacked electrical sheets and is reciprocated by alternating magnetic fields generated by a stator 12 of the linear drive.

- the operation of such a linear drive is known and z. B. in the DE 102 04 861 A1 described.

- the linear motor it may, for. B. may be a reluctance motor with external stator.

- the rotor 11 and the drive piston 1 form in the in Fig. 1 example shown a one-piece unit.

- a pumping element in the form of a pump piston 13 is formed, which is in a pumping chamber 14 back and forth. Since the pump piston 13 is integrally connected to the rotor 11 and the drive piston 1, the pump piston 13 must necessarily follow the movement of the rotor 11. As a result of the reciprocating movement, the pump piston 13 generates an overpressure or underpressure in the pumping chamber 14.

- the pumping chamber 14 communicates with the environment via an air channel 15.

- the air duct 15 is arranged to the hammer so that it is guided past at least a part of the heat-generating components (in this case in particular the stator 12), as in FIG Fig. 1 shown.

- the pump piston 13, the pumping chamber 14 and the air channel 15 form an air conveying device.

- the pumping element is shown cylindrically on the basis of the pumping piston 13.

- the pumping element can also take any other forms and z. B. be formed as a prismatic disc.

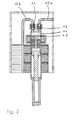

- Fig. 2 shows analogously to Fig. 1 a second embodiment of the invention. Identical components are identified by the same reference numerals. To avoid repetition, therefore, only the differences between the second and the first embodiment will be explained below.

- the air duct 15 is divided into an intake passage 15a and an exhaust passage 15b. Air from the environment can flow into the pumping chamber 14 via the intake duct 15a when the pump piston 13 moves downwards. In a return movement of the pump piston 13, the air is discharged from the pumping chamber 14 via the outlet channel 15b to the environment.

- an inlet check valve 16 is arranged in the intake passage 15a and an outlet check valve 17 is arranged in the outlet passage 15b.

- check valves 16, 17 are formed as spring-loaded balls.

- other types of check valves can be used.

- it will normally be sufficient to form the check valves by means of a rubber element attached on one side, which is lifted from a direction of a valve opening when it flows from one direction, while it is pressed in the reverse flow direction to the valve opening, and thereby closes.

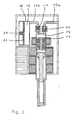

- Fig. 3 shows a third embodiment of the invention, which differs from the in Fig. 2 shown second embodiment differs in that in the region of the outlet channel 15b, a storage device 18 is provided.

- the memory device 18 is used to compensate for changes in air pressure, which inevitably arise in particular in the outlet channel 15b by the oscillating movement of the pump piston 13.

- the storage device 18 is able to eliminate pressure peaks by enlarging a storage space 19 against the action of a resilient element 20. As soon as the pumping pressure through the pump piston 13 decreases, the resilient element 20 causes a reduction of the storage space 19, so that an air flow through the downstream part of the outlet channel 15b is maintained.

- the elastic element 20 is designed as a helical spring which presses against a movable wall 21.

- this system can also z. B. be replaced by a rubber membrane.

- Fig. 4 shows a fourth embodiment of the invention in analogy to the second embodiment of Fig. 2 .

- the traveler is constituted by two sword-like plate projections 22 which are reciprocable in a correspondingly shaped stator 12.

- the pump piston 13 is connected via a piston rod 23 with the drive piston 1 in connection.

- the cross-sectional area of the pump piston 13 and the pumping chamber 14 can be increased, since these components are arranged behind the linear drive.

- Fig. 5 shows a fifth embodiment of the invention, in which the air conveying device is arranged axially to save space next to the air spring impact mechanism.

- the pump piston 13 and the pumping chamber 14 enclose for this purpose the air spring impact ring annular.

- two or more pumping pistons 13 may be provided, which are movable in respectively associated pumping chambers 14.

- the function of the pump piston 13 can thus be achieved by a plurality of individual pistons.

- the outlet channel 15b is also guided past the stator 12, in which the rotor 13 with plate extensions is movable.

- FIG. 6 A sixth embodiment of the invention is shown, Here, the air pumping device with the pump piston 13 and the pumping chamber 14 is provided separately from the drive piston 1 and the rotor 11.

- a hydraulic piston 24 is formed, which via a hydraulic line 25 hydraulic fluid to a hydraulic shaft 26 which is connected to the pump piston 13. Accordingly, the pump piston 13 follows substantially loss-free movement of the drive piston 1 and rotor 11. In a striking movement of the drive piston 1, the hydraulic piston 24 lowers, so that due to the negative pressure in the hydraulic line 25, the hydraulic shaft 26 is sucked up. As a result of the thus forced movement of the pump piston 13 upwards, air flows via the quite short intake passage 15a into the pumping chamber 14, which is expelled on a return movement of the drive piston 1 and a correspondingly transmitted movement to the pumping element 13 via the outlet channel 15. The return movement can be supported by an additional spring.

- the mechanical transmission of the movement of the drive piston 1 on the pump piston 13 can also be done by means of a movable, guided juxtaposition of balls in a pipe or hose connection.

- the pump piston 13 must then be forced by means of a spring in its starting position.

- the structural decoupling of the air conveying device from the linear drive and the air spring impact mechanism allows the air pumping device to be vibrationally decoupled in the hammer.

- Fig. 7 shows a schematic section through a seventh embodiment of the invention. Unlike the above based on the Fig. 1 to 6 described Beerfedertschwerken relates to the seventh embodiment according to Fig. 7 a striking mechanism in which the energy for the impact movement can not be transmitted by an air spring. Accordingly, this striking mechanism can not be called an air spring impact mechanism.

- the percussion mechanism is driven by an electrodynamic linear drive in a manner similar to the above-described air spring impact devices. It has a drive unit 30, which combines the functions of a drive element and a rotor of the linear drive with each other.

- the drive unit 30 is in Fig. 7 shown only schematically. So z. B. the structure of the rotor is not shown in detail. With respect to the runner, however, the above for the runner 11 (eg. Fig. 1 ) details.

- the drive unit 30 is similar to the manner described above in a tubular percussion gear housing 8 back and forth, wherein the movement is effected by the stator 12.

- the drive unit 30 is of sleeve-shaped construction and has in its interior a hollow region in which the percussion piston 3 forming a striking element can be moved back and forth. The percussion piston 3 then strikes in a known manner against the in Fig. 7 not shown tool.

- the coupling device has a driver 31 carried by the percussion piston 3, in particular by the piston head 2 of the percussion piston 3, which can be moved back and forth in recesses of the drive unit 30 in the working direction of the striking mechanism.

- the driver 31 may, for. B. are formed by a piston head 2 of the percussion piston 3 penetrating transverse pin, as in Fig. 7 shown.

- the recesses in the drive unit 30 are formed by two axially extending longitudinal grooves 32 which penetrate the wall of the hollow cylindrical drive unit 30.

- the coupling device is thus not formed by an air spring, but by the longitudinal grooves 32, the stops 33, 34 and the driver 31 in this embodiment.

- the structure described is merely illustrative. There are numerous other possibilities for the skilled artisan, as the movement of the drive unit 30 can be transferred to the percussion piston 3.

- the piston head 2 of the percussion piston 3 is positively coupled via a piston rod 35 with a pump piston 13.

- the pump piston 13 is reciprocable in a pumping chamber 14.

- the air from the environment can flow into the pumping chamber 14 in the manner described above, when the pump piston 13 moves down.

- the air is discharged from the pumping chamber 14 via the outlet channel 15b to the environment.

- Fig. 8 shows a section through a schematic representation of a striking mechanism according to an eighth embodiment of the invention, in which the striking mechanism as in the embodiment of Fig. 7 also not realized as Heilfedertschwerk. Unlike the in Fig. 7 embodiment shown, however, the pump piston 13 is positively coupled to the drive unit 30, as z. Tie Fig. 1 to 6 is shown. As a coupling device for transmitting the drive movement of the drive unit 30 to the percussion piston 3 but in Fig. 7 used solution shown.

- perforations 36 are provided in the drive unit 30.

- the openings 36 are in Fig. 8 only shown schematically. They should have the largest possible cross-sections, so that they can be flowed through unhindered by the air and form no noticeable air resistance.

- the drive unit 30 can be connected to the pump piston 13. If this is an arrangement similar to the Fig. 1 to 6 is selected, but in the eighth embodiment of the invention to make sure that actually no air spring is formed between the drive unit 30 and the percussion piston 3.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Percussive Tools And Related Accessories (AREA)

- Compressor (AREA)

Abstract

Description

Die Erfindung betrifft gemäß dem Oberbegriff von Patentanspruch 1 einen Bohr- und/oder Schlaghammer mit einem elektrodynamischen Linearantrieb. Ein solcher Bohr- und/oder Schlaghammer ist aus der

Bohr- und/oder Schlaghämmer (nachfolgend als Hämmer bezeichnet) werden üblicherweise durch Elektromotoren angetrieben, bei denen ein Rotor eine Antriebswelle dreht. Zur Kühlung des Motors und des im Hammer vorgesehenen Schlagwerks ist der Rotor meist mit einem Lüfterrad eines Gebläses gekoppelt, das einen Kühlluftstrom erzeugt. Die Drehbewegung des Rotors wird somit für den Antrieb eines Radial- oder Axiallüfterrades in einfacher Weise genutzt.Drilling and / or impact hammers (hereinafter referred to as hammers) are usually driven by electric motors in which a rotor rotates a drive shaft. For cooling the motor and hammer mechanism provided in the hammer, the rotor is usually coupled to a fan of a fan, which generates a cooling air flow. The rotational movement of the rotor is thus used in a simple manner for driving a radial or Axiallüfterrades.

Aus der

Bei einem derartigen Schlagwerk mit Linearantrieb sind prinzipbedingt keine rotierenden Bauteile vorgesehen. Dementsprechend kann auch kein rotierendes Gebläse in der einfachen Weise angekoppelt werden, wie dies bei einem Rotationsantrieb der Fall ist. Jedoch wird durch den Linearantrieb und das Luftfederschlagwerk beim Betrieb des Hammers Wärme erzeugt, die abgeführt werden muss.In such a striking mechanism with linear drive principle no rotating components are provided. Accordingly, no rotary blower can be coupled in the simple manner, as is the case with a rotary drive. However, heat is generated by the linear actuator and the air spring impactor during operation of the hammer, which must be dissipated.

In der

Der Erfindung liegt die Aufgabe zugrunde, einen Bohr- und/oder Schlaghammer mit einem elektrodynamischen Linearantrieb anzugeben, bei dem eine ausreichende Luftkühlung der wärmeerzeugenden Bauteile gewährleistet ist.The invention has for its object to provide a drilling and / or percussion hammer with an electrodynamic linear drive, in which a sufficient air cooling of the heat-generating components is ensured.

Erfindungsgemäß wird die Aufgabe durch einen Bohr- und/oder Schlaghammer nach Anspruch 1 gelöst. Vorteilhafte Ausgestaltungen der Erfindung sind in den abhängigen Ansprüchen angegeben.According to the invention the object is achieved by a drilling and / or percussion hammer according to

Ein erfindungsgemäßer Bohr- und/oder Schlaghammer (nachfolgend: Hammer) weist eine Luftförderungseinrichtung mit einem linear hin- und herbewegbaren Pumpelement zum Erzeugen einer Kühlluftströmung auf. Das Pumpelement ist mit dem Antriebselement und/oder dem Schlagelement des Schlagwerks derart gekoppelt, dass die Bewegung des Antriebselements und/oder des Schlagelements auf das Pumpelement übertragbar ist.An inventive hammer drill and / or percussion hammer (hereinafter referred to as hammer) has an air-conveying device with a linearly reciprocable pumping element for generating a cooling air flow. The pumping element is coupled to the drive element and / or the striking element of the percussion mechanism in such a way that the movement of the drive element and / or of the striking element can be transferred to the pumping element.

Bei dem erfindungsgemäßen Hammer weist die Luftförderungseinrichtung einen Pumpraum und einen Luftkanal auf, wobei das Pumpelement in dem Pumpraum hin- und herbeweglich ist und der Pumpraum wenigstens zeitweise über den Luftkanal mit der Umgebung in Verbindung bringbar ist. Durch die Bewegung des Pumpelements in dem Pumpraum wird eine Art Luftpumpe gebildet, die ähnlich einer Fahrradpumpe (Kolbenpumpe) funktioniert. Aufgrund der Kopplung des Pumpraums mit der Umgebung über den Luftkanal besteht die Möglichkeit, dass frische Kühlluft aus der Umgebung in den Pumpraum zugeführt bzw. erwärmte Luft an die Umgebung abgegeben werden kann.In the hammer according to the invention, the air conveying device has a pumping space and an air duct, wherein the pumping element can be moved back and forth in the pumping space and the pumping space can be brought into contact with the environment at least temporarily via the air duct. By the movement of the pumping element in the pumping space, a type of air pump is formed, which functions similar to a bicycle pump (piston pump). Due to the coupling of the pump chamber with the environment via the air duct, there is the possibility that fresh cooling air can be supplied from the environment into the pump chamber or heated air can be released to the environment.

Bei dem erfindungsgemäßen Hammer weist der Luftkanal einen Ansaugkanal zum Einströmen von. Luft aus der Umgebung in den Pumpraum auf. Entsprechend weist der Luftkanal auch einen Auslasskanal zum Ausströmen von Luft aus dem Pumpraum in die Umgebung auf. Während bei einer nicht erfindungsgemäßen Variante die Umgebungsluft in dem Luftkanal hin- und hergefördert wird, kann bei der Aufteilung des Luftkanals in einen Ansaugkanal und einen Auslasskanal eine gerichtete Luftströmung erreicht werden, die stets nur in eine Richtung strömt. Dementsprechend wird kalte Luft aus der Umgebung über den Ansaugkanal zugeführt, während die erwärmte Luft über den Auslasskanal an die Umgebung abgegeben wird.In the hammer according to the invention, the air channel has an intake passage for the inflow of. Air from the environment in the pump room. Accordingly, the air duct also has an outlet channel for the outflow of air from the pumping space into the environment. While in a variant not according to the invention the ambient air is conveyed back and forth in the air duct, when the air duct is divided into an intake duct and an exhaust duct a directional air flow can be achieved, which always flows only in one direction. Accordingly, cold air from the environment is supplied via the intake passage while the heated air is discharged to the environment via the exhaust passage.

Das Antriebselement kann z. B. bei einem Luftfederschlagwerk durch einen Antriebskolben gebildet werden. Es wird durch den Linearantrieb in bekannter Weise hin- und herbewegt. Erfindungsgemäß wird in vorteilhafter Weise das Pumpelement an das Antriebselement angekoppelt, so dass es sich ebenfalls linear hin- und herbewegen muss. Mit Hilfe dieser oszillierenden Linearbewegung kann ein Kühlluftstrom erzeugt werden, der an den zu kühlenden Komponenten vorbeigeführt wird. Die linear angetriebene Luftförderungseinrichtung ermöglicht das Erzeugen eines Kühlluftstroms, ohne dass ein Rotationslüfter vorgesehen sein muss.The drive element can, for. B. are formed by a drive piston in an air spring impact mechanism. It is reciprocated by the linear drive in a known manner. According to the invention, the pumping element is coupled to the drive element in an advantageous manner, so that it likewise has to reciprocate linearly. With the help of this oscillating linear movement, a cooling air flow can be generated, which is guided past the components to be cooled. The linearly driven air conveying device makes it possible to generate a cooling air flow without having to provide a rotary ventilator.

Bei einer vorteilhaften Ausführungsform der Erfindung ist das Antriebselement mit einem Läufer des Linearantriebs verbunden. Insbesondere ist es vorteilhaft, wenn das Antriebselement den Läufer trägt oder im Wesentlichen vollständig durch den Läufer gebildet wird, so dass der Läufer gleichzeitig die Funktion des Antriebselements übernimmt.In an advantageous embodiment of the invention, the drive element is connected to a rotor of the linear drive. In particular, it is advantageous if the drive element carries the rotor or is substantially completely formed by the rotor, so that the rotor simultaneously assumes the function of the drive element.

Der Linearmotor kann ein geschalteter Reluktanzmotor (SR-Motor) sein und weist im Bewegungsbereich des Läufers mehrere Antriebsspulen (Stator) auf die entsprechend der gewünschten Bewegung des Antriebselements geschaltet werden. Es sei darauf hingewiesen, dass als Linearmotor im Zusammenhang mit der Erfindung auch ein elektrodynamischer Antrieb z. B. in Form einer einzelnen elektromagnetischen Spule angesehen wird, die als Antriebsspule für das Antriebselement dient. Die Rückbewegung des Antriebselements kann dann z. B. über eine Schraubenfeder o. Ä. erfolgen. Maßgeblich ist es, dass das Antriebselement mit dem Läufer eng verbunden ist.The linear motor can be a switched reluctance motor (SR motor) and has several drive coils (stator) in the movement range of the rotor, which are switched according to the desired movement of the drive element. It should be noted that as a linear motor in connection with the invention, an electrodynamic drive z. B. is considered in the form of a single electromagnetic coil, which serves as a drive coil for the drive element. The return movement of the drive element can then z. B. via a coil spring o. Ä. respectively. Decisive is that the drive element is closely connected to the rotor.

Bei einer vorteilhaften Ausführungsform der Erfindung weist die Koppeleinrichtung wenigstens einen zwischen dem Antriebselement und dem Schlagelement wirksamen Anschlag auf. Der Anschlag gewährleistet eine formschlüssige Übertragung der Bewegung des Antriebselements auf das Schlagelement, welches dann zwingend der Bewegung des Antriebselements folgen muss.In an advantageous embodiment of the invention, the coupling device has at least one between the drive element and the striking element effective stop. The stop ensures a positive transmission of the movement of the drive element to the striking element, which must then necessarily follow the movement of the drive element.

Bei einer bevorzugten Ausführungsform weist die Koppeleinrichtung ein zwischen dem Antriebselement und dem Schlagelement in wenigstens eine Richtung wirksames elastisches Element auf. So ist es möglich, den oben beschriebenen Anschlag elastisch auszugestalten, z. B. durch ein an dem Anschlag gehaltenes elastisches Element oder eine elastische Beschichtung. Alternativ dazu kann das elastische Element auch durch eine später noch erläuterte Luftfeder gebildet werden, wenn das Schlagwerk als Luftfederschlagwerk realisiert wird.In a preferred embodiment, the coupling device has an elastic element acting between the drive element and the striking element in at least one direction. Thus, it is possible to design the stop described above elastic, z. B. by a stopper held on the elastic element or an elastic coating. Alternatively, the elastic element may also be formed by a later explained air spring, when the percussion is realized as Luftfederschlagwerk.

Bei einer besonders vorteilhaften Ausführungsform der Erfindung bilden das Antriebselement, der Läufer und das Pumpelement eine bauliche Einheit. Insbesondere können diese Bauelemente einstückig miteinander verbunden sein, so dass die Bewegung des Läufers verlustfrei auf das Antriebselement und das Pumpelement übertragen werden kann. Das Antriebselement und das Pumpelement müssen dann zwingend der Bewegung des Läufers folgen.In a particularly advantageous embodiment of the invention, the drive element, the rotor and the pumping element form a structural unit. In particular, these components can be integrally connected to each other, so that the movement of the rotor can be transferred lossless to the drive element and the pumping element. The drive element and the pumping element must then necessarily follow the movement of the rotor.

Bei einer Ausführungsform der Erfindung ist die Bewegung des Antriebselements über eine Mechanik-, Hydraulik- oder Pneumatikkopplung auf das Pumpelement übertragbar. Zum Beispiel kann zwischen dem Antriebselement und dem Pumpelement ein Bowdenzug oder eine Hydraulikleitung verlaufen, um die Bewegung des Antriebselements möglichst verlustfrei auf das Pumpelement zu übertragen. Bei dieser Variante ist es nicht erforderlich, dass das Antriebselement und der Läufer mit dem Pumpelement eine bauliche Einheit bilden. Vielmehr kann das Pumpelement dann auch an einem anderen Ort im Hammer angeordnet werden.In one embodiment of the invention, the movement of the drive element via a mechanical, hydraulic or pneumatic coupling to the pumping element is transferable. For example, a Bowden cable or a hydraulic line can run between the drive element and the pump element in order to transmit the movement of the drive element to the pump element with as little loss as possible. In this variant, it is not necessary that the drive element and the rotor form a structural unit with the pumping element. Rather, the pumping element can then also be arranged at a different location in the hammer.

Bei einer besonders vorteilhaften Weiterentwicklung ist das Pumpelement in einem Bereich des Hammers angeordnet, der schwingungsmäßig von dem Schlagwerk entkoppelt ist. Das Schlagwerk und der Linearantrieb erzeugen durch die oszillierende Bewegung der beweglichen Elemente und durch die Schlagwirkung des Schlagelements erhebliche Vibrationen. Aus dem Stand der Technik sind viele Lösungsansätze bekannt, um diese Vibrationen z. B. von einem Handgriff des Hammers zu isolieren und den Bediener vor schädlichen Schwingungen zu schützen. Dementsprechend ist es bei nahezu allen Hämmern bekannt, wenigstens einen Teilbereich schwingungsmäßig von dem Schlagwerk zu entkoppeln. Die Anordnung des Pumpelements in diesem schwingungsentkoppelten Bereich hat den Vorteil, dass das Pumpelement und die restlichen Bauelemente der Luftförderungseinrichtung mechanisch geringer beansprucht werden, so dass eine zuverlässigere Funktionsweise erreicht werden kann.In a particularly advantageous further development, the pumping element is arranged in a region of the hammer which is decoupled from the impact mechanism in terms of vibration. The impact mechanism and the linear drive generate considerable vibrations due to the oscillating motion of the moving elements and the impact of the striking element. From the prior art, many approaches are known to reduce these vibrations z. B. to isolate from a handle of the hammer and to protect the operator from harmful vibrations. Accordingly, it is known in almost all hammers to decouple at least a portion vibrationally from the percussion. The arrangement of the pumping element in this vibration-decoupled region has the advantage that the pumping element and the remaining components of the air-conveying device are mechanically stressed less, so that a more reliable mode of operation can be achieved.

Vorzugsweise ist der Läufer im Wesentlichen zylinderförmig oder hohlzylinderförmig gestaltet. Alternativ dazu kann er auch wenigstens ein sich in Axialrichtung erstreckendes plattenförmiges bzw. schwertähnliches Element aufweisen. Dieses plattenförmige Element, das z. B. als Fortsatz am Antriebselement ausgebildet ist, erstreckt sich in den Statorbereich, um die gewünschte Antriebswirkung zu erzielen.Preferably, the rotor is designed substantially cylindrical or hollow cylindrical. Alternatively, it may also have at least one axially extending plate-shaped or sword-like element. This plate-shaped element, the z. B. is formed as an extension on the drive element extends into the stator to achieve the desired drive effect.

Dementsprechend ist es besonders vorteilhaft, wenn der Luftkanal derart angeordnet ist, dass er entlang von wärmeerzeugenden Bauelementen des Hammers, insbesondere entlang einem Teil eines Stators des Linearantriebs verläuft. Der Stator wird von einem elektrischen Strom durchflossen und trägt dementsprechend wesentlich zur Wärmeerzeugung bei. Diese Wärme kann über die den Luftkanal durchströmende Kühlluft vom Stator abgeführt werden.Accordingly, it is particularly advantageous if the air duct is arranged such that it runs along heat-generating components of the hammer, in particular along a part of a stator of the linear drive. The stator is traversed by an electric current and accordingly contributes significantly to the heat generation. This heat can be removed from the stator via the cooling air flowing through the air duct.

Zur Unterstützung der gerichteten Luftströmung ist es besonders vorteilhaft, wenn in dem Ansaugkanal und/oder in dem Auslasskanal ein Rückschlagventil angeordnet ist, das eine Luftströmung nur in eine Richtung zulässt.To support the directed air flow, it is particularly advantageous if a check valve is arranged in the intake duct and / or in the outlet duct, which permits an air flow only in one direction.

Bei einer vorteilhaften Weiterentwicklung der Erfindung ist eine Speichereinrichtung vorgesehen, die mit dem Auslasskanal in kommunizierender Verbindung steht und zum Zwischenspeichern von wenigstens einem Teil der über den Auslasskanal ausströmenden Luft dient. Die Speichereinrichtung gewährleistet einen Ausgleich der Luftdruckschwankungen, die durch die Bewegung des Pumpelements zwangsläufig entstehen. Druckspitzen können dadurch abgebaut werden, dass die Speichereinrichtung kurzzeitig Luft aufnimmt. Wenn hingegen durch das Pumpelement keine Luft zugeführt wird, gibt die Speichereinrichtung die Luft wieder ab und sorgt so für einen im Wesentlichen gleichmäßigen Kühlluftstrom. Dafür ist es zweckmäßig, dass in der Speichereinrichtung ein elastisches bzw. federbelastetes Element vorgesehen ist, das die Größe eines Speicherraums in Abhängigkeit von dem Druck der von dem Pumpelement zugeführten Luftströmung verändert.In an advantageous further development of the invention, a storage device is provided, which is in communicating connection with the outlet channel and serves for temporarily storing at least part of the air flowing out via the outlet channel. The storage device ensures a compensation of the air pressure fluctuations that inevitably arise due to the movement of the pumping element. Pressure peaks can be reduced by the fact that the storage device briefly absorbs air. If, on the other hand, no air is supplied by the pumping element, the storage device releases the air again and thus ensures a substantially uniform flow of cooling air. For this purpose, it is expedient that an elastic or spring-loaded element is provided in the storage device, which changes the size of a storage space as a function of the pressure of the air flow supplied by the pumping element.

Vorzugsweise ist ein Querschnitt des Auslasskanals stromab von der Speichereinrichtung kleiner als ein Querschnitt des Auslasskanals stromauf von der Speichereinrichtung. Damit ist es möglich, dass die von dem Pumpelement geförderte Luftströmung ungehindert die Speichereinrichtung erreichen kann, um die Speichereinrichtung möglichst verlustfrei zu füllen. Der eigentliche Kühlluftstrom wird dann über den Auslasskanal mit kleinerem Querschnitt abgeführt, wobei sich dieser Auslasskanal entlang der wärmeerzeugenden Komponenten erstreckt.Preferably, a cross section of the exhaust passage downstream of the storage device is smaller than a cross section of the exhaust passage upstream of the storage device. It is thus possible that the air flow conveyed by the pumping element can reach the storage device unhindered in order to fill the storage device with as little loss as possible. The actual cooling air flow is then discharged via the outlet channel of smaller cross-section, this outlet channel extending along the heat-generating components.

Zur Unterstützung einer gerichteten Luftströmung kann in dem Auslasskanal zwischen dem Pumpraum und der Speichereinrichtung ein Rückschlagventil angeordnet sein.In order to support a directed air flow, a check valve can be arranged in the outlet channel between the pump chamber and the storage device.

Bei einer besonders vorteilhaften Ausführungsform der Erfindung ist das Pumpelement in Schlagrichtung gesehen hinter dem Antriebselement und dem Läufer angeordnet. Alternativ dazu kann das Pumpelement auch neben dem Schlagwerk angeordnet sein. Hierbei ist anzustreben, dass die Luftförderungseinrichtung möglichst platzsparend in dem Gehäuse des Hammers angeordnet sein muss, um das Bauvolumen, vor allem die Baulänge, nicht zu vergrößern.In a particularly advantageous embodiment of the invention, the pumping element is arranged in the direction of impact behind the drive element and the rotor. Alternatively, the pumping element can also be arranged next to the striking mechanism. It is desirable that the air pumping device must be arranged as space-saving as possible in the housing of the hammer in order not to increase the overall volume, especially the overall length.

Bei einer besonders bevorzugten Ausführungsform der Erfindung wird das Schlagwerk durch ein Luftfederschlagwerk gebildet. Dazu ist das Antriebselement als Antriebskolben und das Schlagelement als Schlagkolben ausgebildet, wobei die Koppeleinrichtung eine in einem Hohlraum zwischen dem Antriebskolben und dem Schlagkolben ausgebildete Luftfeder aufweist. Die Luftfeder überträgt somit in bekannter Weise die Antriebsbewegung des Antriebskolbens auf den Schlagkolben.In a particularly preferred embodiment of the invention, the striking mechanism is formed by an air spring impact mechanism. For this purpose, the drive element is designed as a drive piston and the impact element as a percussion piston, wherein the coupling device has a trained in a cavity between the drive piston and the percussion piston air spring. The air spring thus transmits in a known manner, the drive movement of the drive piston on the percussion piston.

Die erfindungsgemäße Kopplung eines Linearantriebs mit einer Luftförderungseinrichtung lässt sich auf alle Arten von Schlagwerken anwenden. Insbesondere eignet sich die erfindungsgemäße Kopplung für Schlagwerke, die als Luftfederschlagwerke ausgebildet sind, und somit also für an sich bekannte Rohrschlagwerke (Antriebskolben und Schlagkolben mit identischem Durchmesser), Hohlkolbenschlagwerke (Antriebskolben mit Höhlung, in der sich der Schlagkolben bewegt) oder Schlagwerke mit hohlem Schlagkolben, in dem sich der Antriebskolben bewegt.The coupling according to the invention of a linear drive with an air-conveying device can be applied to all types of striking mechanisms. In particular, the coupling according to the invention is suitable for percussion, which are designed as Luftfederschlagwerke, and thus therefore known per se tube impactors (drive piston and percussion pistons with identical diameter), hollow piston impactors (drive piston with cavity in which the percussion piston moves) or drums with hollow percussion piston , in which the drive piston moves.

Bei einer besonders vorteilhaften, einem Hohlkolbenschlagwerk ähnlichen Ausführungsform der Erfindung umschließt der Antriebskolben den Schlagkolben in Schlagrichtung gesehen vor und hinter dem Schlagkolben derart, dass die Luftfeder hinter dem Schlagkolben angeordnet ist und dass vor dem Schlagkolben eine zweite Luftfeder zwischen dem Antriebskolben und dem Schlagkolben ausbildbar ist. Bei diesem Schlagwerkstyp entsteht somit eine doppelte Luftfeder, die einerseits die Bewegung des Schlagkolbens nach vorne erzeugt und andererseits eine Rückbewegung des Schlagkolbens unterstützt.In a particularly advantageous, a hollow piston impact similar embodiment of the invention, the drive piston surrounds the percussion piston in the direction of impact before and behind the percussion piston such that the air spring is disposed behind the percussion piston and that before the percussion piston, a second air spring between the drive piston and the percussion piston can be formed , In this percussion type thus creates a double air spring, which on the one hand generates the movement of the percussion piston forward and on the other hand supports a return movement of the percussion piston.

Bei einer vorteilhaften Ausführungsform der Erfindung ist eine für das Erzeugen der Luftströmung wirksame Querschnittsfläche des Pumpelements größer als eine auf die Luftfeder wirkende Querschnittsfläche des Antriebskolben. Je nach Ausführung des Linearantriebs und des Luftfederschlagwerks kann unter Umständen eine erhebliche Wärmeleistung frei werden, die abgeführt werden muss. Für diesen Zweck ist ein entsprechend großer Kühlluftstrom erforderlich. Damit die Luftförderungseinrichtung diesen Kühlluftstrom erzeugen kann, muss eine entsprechend große Querschnittsfläche des Pumpelements vorhanden sein. Selbstverständlich kann das Pumpelement auch durch mehrere Einzel-Pumpelemente ersetzt werden, die für sich genommen zwar kleiner dimensioniert sind, jedoch durch ihre Kopplung mit dem Läufer und damit ihr Zusammenwirken gemeinsam eine ausreichend große wirksame Querschnittsfläche erreichen. Der Begriff des "Pumpelements" bezieht sich dementsprechend nur auf die Funktion, nicht auf die konkrete Ausgestaltung.In an advantageous embodiment of the invention, an effective for generating the air flow cross-sectional area of the pumping element is greater than acting on the air spring cross-sectional area of the drive piston. Depending on the design of the linear actuator and the air spring impact mechanism may be released under certain circumstances, a significant heat output, which must be dissipated. For this purpose, a correspondingly large cooling air flow is required. In order for the air conveying device to be able to generate this cooling air flow, a correspondingly large cross-sectional area of the pumping element must be present. Of course, the pumping element can also be replaced by a plurality of individual pumping elements which, taken in themselves, are dimensioned smaller, but together achieve a sufficiently large effective cross-sectional area through their coupling with the rotor and thus their interaction together. Accordingly, the term "pumping element" refers only to the function, not to the specific embodiment.

Diese und weitere Vorteile und Merkmale der Erfindung werden nachfolgend anhand von Beispielen unter Zuhilfenahme der begleitenden Figuren näher erläutert. Es zeigen:

- Fig. 1

- in schematischer Darstellung einen Schnitt durch einen nicht - erfin- dungsgemäßen Hammer in einer ersten Ausführungsform;

- Fig. 2

- in schematischer Darstellung eine zweite Ausführungsform der Erfindung;

- Fig. 3

- in schematischer Darstellung eine dritte Ausführungsform der Erfindung;

- Fig. 4

- in schematischer Darstellung eine vierte Ausführungsform der Erfindung;

- Fig. 5

- in schematischer Darstellung eine fünfte Ausführungsform der Erfindung;

- Fig. 6

- in schematischer Darstellung eine sechste Ausführungsform der Erfindung;

- Fig. 7

- in schematischer Darstellung eine siebte Ausführungsform der Erfindung; und

- Fig. 8

- einen Schnitt durch eine schematische Darstellung eines Schlagwerks gemäß einer achten Ausführungsform der Erfin- dung.

- Fig. 1

- a schematic representation of a section through a non - inventive hammer in a first embodiment;

- Fig. 2

- a schematic representation of a second embodiment of the invention;

- Fig. 3

- a schematic representation of a third embodiment of the invention;

- Fig. 4

- a schematic representation of a fourth embodiment of the invention;

- Fig. 5

- a schematic representation of a fifth embodiment of the invention;

- Fig. 6

- a schematic representation of a sixth embodiment of the invention;

- Fig. 7

- a schematic representation of a seventh embodiment of the invention; and

- Fig. 8

- a section through a schematic representation of a striking mechanism according to an eighth embodiment of the invention.

Das Luftfederschlagwerk weist als Antriebselement einen Antriebskolben 1 auf, der einen Kolbenkopf 2 eines als Schlagelement dienenden Schlagkolbens 3 umschließt. Der Schlagkolben 3 erstreckt sich mit einem Schaft 4 in eine Schlagkolbenführung 5 und kann in seiner vordersten Stellung gegen ein Werkzeugende 6 aufschlagen. Anstelle des Werzeugendes 6 kann auch in bekannter Weise ein Zwischendöpper vorgesehen sein.The air spring impact mechanism has as drive element a

Zwischen dem Antriebskolben 1 und dem Schlagkolben 3 ist ein Hohlraum ausgebildet, in dem eine als Koppeleinrichtung dienende erste Luftfeder 7 wirkt. Bei einer Vorwärtsbewegung des Antriebskolbens 1, der in einem Schlagwerksgehäuse 8 axial hin- und herbewegbar ist, baut sich in der ersten Luftfeder 7 ein Druck auf, der den Schlagkolben 3 nach vorne treibt, so dass er schließlich gegen das Werkzeugende 6 aufschlagen kann.Between the

Bei einer Rückbewegung des Antriebskolbens 1 entsteht in der ersten Luftfeder 7 ein Unterdruck, der den Schlagkolben 3 zurücksaugt. Die Rückbewegung des Schlagkolbens 3 wird auch durch die Stoß-Rückwirkung am Werkzeugende 6 unterstützt. Weiterhin ist - in Schlagrichtung gesehen - vor dem Kolbenkopf 2 eine ebenfalls als Koppeleinrichtung dienende zweite Luftfeder 9 ausgebildet, die bei der Rückbewegung des Antriebskolbens 1 zur Wirkung kommt. Sie unterstützt ebenfalls die Rückbewegung des Schlagkolbens 2.In a return movement of the

Zum Ausgleich von Luftverlusten in den Luftfedern 7, 9 sowie zur Unterstützung der Bewegung des Antriebskolbens 1 und des Schlagkolbens 3 sind verschiedene Luftöffnungen und -kanäle, wie z. B. mehrere Luftausgleichstaschen 10, vorgesehen. Deren Funktionsweise ist aus dem Stand der Technik bekannt, so dass sich an dieser Stelle eine eingehendere Beschreibung erübrigt.To compensate for air losses in the air springs 7, 9 and to support the movement of the

Die oszillierende, lineare Hin- und Herbewegung des Antriebskolbens 1 wird durch einen elektrodynamischen Linearantrieb bewirkt. Zu diesem Zweck ist der Antriebskolben 1 mit einem Läufer 11 des Linearantriebs gekoppelt. Der Läufer 11 kann durch mehrere übereinandergeschichtete Elektrobleche gebildet werden und wird durch wechselnde Magnetfelder, die durch einen Stator 12 des Linearantriebs erzeugt werden, hin- und herbewegt. Die Funktionsweise eines derartigen Linearantriebs ist an sich bekannt und z. B. in der

Der Läufer 11 und der Antriebskolben 1 bilden bei dem in

Direkt an dem Läufer 11 ist ein Pumpelement in Form eines Pumpkolbens 13 ausgebildet, der in einer Pumpkammer 14 hin- und herbeweglich ist. Da der Pumpkolben 13 mit dem Läufer 11 und dem Antriebskolben 1 einstückig verbunden ist, muss der Pumpkolben 13 zwangsläufig der Bewegung des Läufers 11 folgen. Durch die Hin- und Herbewegung erzeugt der Pumpkolben 13 in der Pumpkammer 14 einen Über- bzw. Unterdruck.Directly on the

Die Pumpkammer 14 steht über einen Luftkanal 15 mit der Umgebung in Verbindung. Der Luftkanal 15 ist derart zum Hammer angeordnet, dass er an wenigstens einem Teil der wärmeerzeugenden Komponenten (hier: insbesondere der Stator 12) vorbeigeführt wird, wie in

Wenn sich der Läufer 11 zusammen mit dem Antriebskolben 1 und dem Pumpkolben 13 nach unten bewegt, wird in der Pumpkammer 14 ein Unterdruck erzeugt, so dass Luft aus der Umgebung über den Luftkanal 15 bis in die Pumpkammer 14 einströmt. Bei einer Rückbewegung des Läufers 11 mit dem Antriebskolben 1 und dem Pumpkolben 13 wird die nun erwärmte Luft wieder aus der Pumpkammer 14 und dem Luftkanal 15 gedrückt. Beim nächsten Zyklus wird wieder frische Kühlluft angesaugt. Auf diese Weise kann eine wirksame Kühlung im Luftkanal 15 erreicht werden.When the

Das Pumpelement ist anhand des Pumpkolbens 13 zylindrisch dargestellt. Selbstverständlich kann das Pumpelement auch beliebige andere Formen annehmen und z. B. als prismatische Scheibe gebildet sein.The pumping element is shown cylindrically on the basis of the

Bei der zweiten Ausführungsform der Erfindung ist der Luftkanal 15 aufgeteilt in einen Ansaugkanal 15a und in einen Auslasskanal 15b. Über den Ansaugkanal 15a kann Luft aus der Umgebung in die Pumpkammer 14 einströmen, wenn sich der Pumpkolben 13 nach unten bewegt. Bei einer Rückbewegung des Pumpkolbens 13 wird die Luft aus der Pumpkammer 14 über den Auslasskanal 15b an die Umgebung ausgegeben.In the second embodiment of the invention, the

Zur Gewährleistung einer gerichteten Luftströmung ist in dem Ansaugkanal 15a ein Einlass-Rückschlagventil 16 und in dem Auslasskanal 15b ein Auslass-Rückschlagventil 17 angeordnet. Die in

Bei dem in

Jedoch ist bei der vierten Ausführungsform der Läufer durch zwei schwertähnliche Plattenfortsätze 22 gebildet, die in einem entsprechend ausgeformten Stator 12 hin- und herbeweglich sind.However, in the fourth embodiment, the traveler is constituted by two sword-

Der Pumpkolben 13 steht über eine Kolbenstange 23 mit dem Antriebskolben 1 in Verbindung.The

Bei dieser Bauart kann die Querschnittsfläche des Pumpkolbens 13 und der Pumpkammer 14 vergrößert werden, da diese Bauelemente hinter dem Linearantrieb angeordnet sind.In this design, the cross-sectional area of the

Der Pumpkolben 13 und die Pumpkammer 14 umschließen zu diesem Zweck das Luftfederschlagwerk ringförmig. Alternativ dazu können auch zwei oder mehr Pumpkolben 13 vorgesehen sein, die in jeweils zugeordneten Pumpkammern 14 beweglich sind. Die Funktion des Pumpkolbens 13 kann somit durch mehrere Einzelkolben erreicht werden.The

Bei der in

In

An der durch den Antriebskolben 1 und den Läufer 11 gebildeten Einheit ist ein Hydraulikkolben 24 ausgebildet, der über eine Hydraulikleitung 25 Hydraulikfluid zu einem Hydraulikschaft 26 fördert, der mit dem Pumpkolben 13 verbunden ist. Dementsprechend folgt der Pumpkolben 13 im Wesentlichen verlustfrei der Bewegung von Antriebskolben 1 und Läufer 11. Bei einer Schlagbewegung des Antriebskolbens 1 senkt sich der Hydraulikkolben 24 ab, so dass aufgrund des Unterdrucks in der Hydraulikleitung 25 der Hydraulikschaft 26 nach oben gesaugt wird. Infolge der damit erzwungenen Bewegung des Pumpkolbens 13 nach oben strömt Luft über den hier recht kurzen Ansaugkanal 15a in die Pumpkammer 14 ein, die bei einer Rückbewegung des Antriebskolbens 1 und einer entsprechend übertragenen Bewegung auf das Pumpelement 13 über den Auslasskanal 15 ausgestoßen wird. Die Rückbewegung kann durch eine zusätzliche Feder unterstützt werden.On the unit formed by the

Die mechanische Übertragung der Bewegung des Antriebskolbens 1 auf den Pumpkolben 13 kann auch mit Hilfe einer beweglichen, geführten Aneinanderreihung von Kugeln in einer Rohr- oder Schlauchverbindung erfolgen. Der Pumpkolben 13 muss dann mit Hilfe einer Feder in seine Ausgangsposition gezwungen werden.The mechanical transmission of the movement of the

Die bauliche Entkopplung der Luftförderungseinrichtung von dem Linearantrieb und dem Luftfederschlagwerk ermöglicht es bei der sechsten Ausführungsform, dass die Luftförderungseinrichtung schwingungsmäßig entkoppelt in dem Hammer angeordnet werden kann. Zum Beispiel ist es möglich, die Luftförderungseinrichtung an einer gegenüber dem Linearantrieb und dem Luftfederschlagwerk schwingungsmäßig entkoppelten Gehäusehaube 27 zu befestigen.The structural decoupling of the air conveying device from the linear drive and the air spring impact mechanism, in the sixth embodiment, it allows the air pumping device to be vibrationally decoupled in the hammer. For example, it is possible to fasten the air-conveying device to a

Das Schlagwerk wird in ähnlicher Weise wie die oben beschriebenen Luftfederschlagwerke durch einen elektrodynamischen Linearantrieb angetrieben. Es weist eine Antriebseinheit 30 auf, die die Funktionen eines Antriebselements und eines Läufers des Linearantriebs miteinander vereint. Die Antriebseinheit 30 ist in

Die Antriebseinheit 30 ist analog zu der oben beschriebenen Weise in einem rohrförmigen Schlagwerksgehäuse 8 hin- und herbewegbar, wobei die Bewegung durch den Stator 12 bewirkt wird.The

Die Antriebseinheit 30 ist hülsenförmig aufgebaut und weist in ihrem Inneren einen hohlen Bereich auf, in dem der ein Schlagelement bildende Schlagkolben 3 hin- und herbewegbar ist. Der Schlagkolben 3 schlägt dann in bekannter Weise gegen das in

Zur Übertragung der Bewegung der Antriebseinheit 30 auf den Schlagkolben 3 ist eine Koppeleinrichtung vorgesehen. Die Koppeleinrichtung weist einen von dem Schlagkolben 3, insbesondere von dem Kolbenkopf 2 des Schlagkolbens 3 getragenen Mitnehmer 31 auf, der in Ausnehmungen der Antriebseinheit 30 in Arbeitsrichtung des Schlagwerks hin- und herbewegbar ist. Der Mitnehmer 31 kann z. B. durch einen den Kolbenkopf 2 des Schlagkolbens 3 durchdringenden Querbolzen gebildet werden, wie in

Die Ausnehmungen in der Antriebseinheit 30 werden durch zwei sich axial erstreckende Längsnuten 32 gebildet, die die Wandung der hohlzylindrischen Antriebseinheit 30 durchdringen.The recesses in the

An den Stirnseiten der Längsnuten 32 werden untere Anschläge 33 und obere Anschläge 34 gebildet, die die Längsbewegung des Mitnehmers 31 in den Längsnuten 32 begrenzen.At the end faces of the

Bei einer Hin- und Herbewegung der Antriebseinheit 30 wird somit der Schlagkolben 3 über die jeweiligen Anschläge 33, 34 sowie den Mitnehmer 31 zwangsweise geführt. Bei einer Vorbewegung der Antriebseinheit 30 (in

Die Koppeleinrichtung wird bei dieser Ausführungsform somit nicht durch eine Luftfeder, sondern durch die Längsnuten 32, die Anschläge 33, 34 und den Mitnehmer 31 gebildet. Selbstverständlich dient der beschriebene Aufbau lediglich der Erläuterung. Es sind zahlreiche andere Möglichkeiten für den Fachmann erkennbar, wie die Bewegung der Antriebseinheit 30 auf den Schlagkolben 3 übertragen werden kann.The coupling device is thus not formed by an air spring, but by the

Der Kolbenkopf 2 des Schlagkolbens 3 ist über eine Kolbenstange 35 mit einem Pumpkolben 13 formschlüssig gekoppelt. Der Pumpkolben 13 ist in einer Pumpkammer 14 hin- und herbeweglich.The

Über den Ansaugkanal 15a kann die Luft aus der Umgebung in die Pumpkammer 14 in der oben beschriebenen Weise einströmen, wenn sich der Pumpkolben 13 nach unten bewegt. Bei einer Rückbewegung des Schlagkolbens 3 mit dem formschlüssig gekoppelten Pumpkolben 13 wird die Luft aus der Pumpkammer 14 über den Auslasskanal 15b an die Umgebung ausgegeben.Via the

Die weiteren Funktionen, insbesondere die Rührung des Kühlluftstroms und die Ausgestaltung der Luftförderungseinrichtung einschließlich eventueller Rückschlagventile können analog zu den oben beschriebenen Ausführungsformen realisiert werden.The other functions, in particular the stirring of the cooling air flow and the design of the air conveying device including any non-return valves can be realized analogously to the embodiments described above.

Damit sich oberhalb von dem Kolbenkopf 2 des Schlagkolbens 3 keine ungewollte Luftfeder ausbilden kann, sind Durchbrechungen 36 in der Antriebseinheit 30 vorgesehen. Die Durchbrechungen 36 sind in

Claims (20)

- Hammer drill and/or percussion hammer, having- an electrodynamic linear drive (11, 12);- a percussion mechanism which comprises a drive element (1; 30), which can be moved in a reciprocating manner by the linear drive (11, 12), a percussion element (3), which can be moved relative to the drive element (1; 30), and a coupling device (7; 31-34) which is effective between the drive element (1; 30) and the percussion element (3) and via which the movement of the drive element (1; 30) can be transmitted to the percussion element (3);

wherein- an air conveyance device is provided which comprises a pump element (13), which can be moved linearly in a reciprocating manner, to generate an air flow;- the pump element (13) is coupled to the drive element (1; 30) such that the movement of the drive element (1; 30) can be transmitted to the pump element (13);- the air conveyance device comprises a pump chamber (14) and an air channel (15);- the pump element (13) can be moved in a reciprocating manner in the pump chamber (14);- the pump chamber (14) can be connected to the surrounding area at least intermittently via the air channel (15);- the air channel (15) comprises an intake channel (15a) to allow the influx of air from the surrounding area into the pump chamber (14);characterised in that the air channel (15) comprises, in addition to the intake channel (15a), an outlet channel (15b) to allow air to flow out of the pump chamber (14) into the surrounding area. - Hammer drill and/or percussion hammer as claimed in claim 1, characterised in that the drive element (1) is connected to a rotor (11) of the linear drive.

- Hammer drill and/or percussion hammer as claimed in claim 1 or 2, characterised in that the drive element (1) supports the rotor (11) or is formed substantially completely by the rotor (11).

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 3, characterised in that the coupling device comprises at least one stop which is effective between the drive element (1) and the percussion element (3).

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 4, characterised in that the coupling device comprises an elastic element (7) which is effective between the drive element (1) and the percussion element (3) in at least one direction.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 5, characterised in that the drive element (1), the rotor (11) and the pump element (13) form a structural unit, in particular they are connected together in one piece.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 6, characterised in that the movement of the drive element (1) can be transmitted to the pump element (13) via a mechanical, hydraulic or pneumatic coupling.

- Hammer drill and/or percussion hammer as claimed in claim 7, characterised in that the pump element (13) is disposed in a region of the hammer drill and/or percussion hammer which in terms of oscillation is decoupled from the percussion mechanism.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 8, characterised in that the rotor (11) is substantially cylindrical or hollow-cylindrical.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 8, characterised in that the rotor (11) comprises at least one plate-shaped element (22) which extends in the axial direction.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 10, characterised in that the air channel (15) is disposed in such a manner that it extends along heat-generating structural elements of the hammer drill and/or percussion hammer, in particular along a portion of a stator (12) of the linear drive.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 11, characterised in that a non-return valve (16, 17) is disposed in the intake channel (15a) and/or in the outlet channel (15b).

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 12, characterised in that a storage device (18) is in communication with the outlet channel (15b) for the intermediate storage of at least a portion of the air flowing out via the outlet channel (15b).

- Hammer drill and/or percussion hammer as claimed in claim 13, characterised in that a cross-section of the outlet channel (15b) downstream of the storage device is smaller than a cross-section of the outlet channel (15b) upstream of the storage device (18).

- Hammer drill and/or percussion hammer as claimed in claim 13 or 14, characterised in that the storage device (18) can be filled during a backward movement of the drive element (1) and can be emptied during a percussion movement.

- Hammer drill and/or percussion hammer as claimed in any one of claims 13 to 15, characterised in that a non-return valve (17) is disposed in the outlet channel (15b) between the pump chamber (14) and the storage device (18).

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 16, characterised in that as seen in the percussion direction the pump element (13) is disposed behind the drive element (1) and the rotor (11) or next to the percussion mechanism.

- Hammer drill and/or percussion hammer as claimed in any one of claims 1 to 17,

characterised in that- the percussion mechanism is a pneumatic spring percussion mechanism;- the drive element is formed as a drive piston (1);- the percussion element is formed as a percussion piston (3); and in that- the coupling device comprises a pneumatic spring (7) which is formed in a hollow space between the drive piston (1) and the percussion piston (3). - Hammer drill and/or percussion hammer as claimed in claim 18, characterised in that a cross-sectional area of the pump element (13) which is effective for generating the air flow is greater than a cross-sectional of the drive piston (1) which acts upon the pneumatic spring (7).

- Hammer drill and/or percussion hammer as claimed in any one of claims 18 or 19, characterised in that as seen in the percussion direction the drive piston (1) surrounds the percussion piston (3) in front of and behind the percussion piston (3) such that the pneumatic spring (7) is disposed behind the percussion piston (3), and in that in front of the percussion piston (3) a second pneumatic spring (9) can be formed between the drive piston (1) and the percussion piston (3).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102005036560A DE102005036560A1 (en) | 2005-08-03 | 2005-08-03 | Drilling and / or percussion hammer with linear drive and air cooling |

| PCT/EP2006/007394 WO2007014688A1 (en) | 2005-08-03 | 2006-07-26 | Linearly driven and air-cooled boring and/or percussion hammer |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1910038A1 EP1910038A1 (en) | 2008-04-16 |

| EP1910038B1 true EP1910038B1 (en) | 2008-11-26 |

Family

ID=37101641

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06762834A Not-in-force EP1910038B1 (en) | 2005-08-03 | 2006-07-26 | Linearly driven and air-cooled boring and/or percussion hammer |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US20080314608A1 (en) |

| EP (1) | EP1910038B1 (en) |

| JP (1) | JP5130213B2 (en) |

| CN (1) | CN101277792B (en) |

| DE (2) | DE102005036560A1 (en) |

| ES (1) | ES2316084T3 (en) |

| WO (1) | WO2007014688A1 (en) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005030340B3 (en) * | 2005-06-29 | 2007-01-04 | Wacker Construction Equipment Ag | Impact mechanism with electrodynamic linear drive |

| DE102007000085A1 (en) * | 2007-02-13 | 2008-08-14 | Hilti Ag | Method for controlling a linear motor for driving a hammer mechanism |

| DE102007019030A1 (en) * | 2007-04-18 | 2008-10-23 | Brose Fahrzeugteile Gmbh & Co. Kommanditgesellschaft, Coburg | Door locking device e.g. hydraulic door locking device, for motor vehicle door, has release device to release tension of spring, when torque affecting output element is larger than or equal to actuating torque |

| DE102007030544A1 (en) * | 2007-06-30 | 2009-01-08 | Erwin Schmucker | Device for processing workpieces |

| DE102007000488A1 (en) * | 2007-09-12 | 2009-03-19 | Hilti Aktiengesellschaft | Hand tool with air spring impact mechanism, linear motor and control method |

| SE531860C2 (en) * | 2007-12-21 | 2009-08-25 | Atlas Copco Rock Drills Ab | Pulse generating device for inducing a shock wave in a tool and rock drilling rig including such device |

| DE102010004724A1 (en) * | 2010-01-15 | 2011-07-21 | Wacker Neuson SE, 80809 | Drilling and / or hammer with cooling of device components |

| WO2011133689A2 (en) | 2010-04-21 | 2011-10-27 | Michael Taylor | Grout removal tool |

| DE102011079819A1 (en) * | 2011-07-26 | 2013-01-31 | Hilti Aktiengesellschaft | Hand tool with storage facility |

| DE102012210097A1 (en) * | 2012-06-15 | 2013-12-19 | Hilti Aktiengesellschaft | control method |

| DE102012210101A1 (en) * | 2012-06-15 | 2013-12-19 | Hilti Aktiengesellschaft | control method |

| US8733610B2 (en) * | 2012-08-21 | 2014-05-27 | Tricord Solutions, Inc. | Fastener driving apparatus |

| DE102012220297A1 (en) * | 2012-11-08 | 2014-05-08 | Lincoln Gmbh | Lubrication assembly for lubrication system, has linearly movable piston which is connected with moving element, such that defined amount of lubricant conveyed by piston is induced more linearly in moving element |

| DE102013204970A1 (en) * | 2013-03-21 | 2014-10-09 | Robert Bosch Gmbh | Hand tool |

| CN103331734B (en) * | 2013-05-08 | 2016-04-06 | 成都恩承油气有限公司 | A kind of fluid pressure and inertia force double acting are led switching device shifter |

| CN103600108B (en) * | 2013-12-02 | 2015-11-04 | 宁波汉浦工具有限公司 | A kind of Handheld electric percussion drill |

| US10190604B2 (en) * | 2015-10-22 | 2019-01-29 | Caterpillar Inc. | Piston and magnetic bearing for hydraulic hammer |

| US10179424B2 (en) * | 2015-10-28 | 2019-01-15 | Caterpillar Inc. | Diagnostic system for measuring acceleration of a demolition hammer |

| WO2018104406A1 (en) * | 2016-12-06 | 2018-06-14 | Hilti Aktiengesellschaft | Electrodynamic drive |

| WO2021100703A1 (en) * | 2019-11-19 | 2021-05-27 | 京セラインダストリアルツールズ株式会社 | Electric tool |

| SE544592C2 (en) * | 2020-12-04 | 2022-09-20 | Construction Tools Pc Ab | Hammer device with an electrically operated piston drive arrangement |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1723607A (en) * | 1929-08-06 | Electric hammer and similar tool | ||

| BE351334A (en) * | ||||

| US1837197A (en) * | 1931-12-22 | Samuel berman | ||

| US852926A (en) * | 1905-12-21 | 1907-05-07 | American Inv S Company | Electric tool-driver. |

| US946267A (en) * | 1908-06-27 | 1910-01-11 | Virginia Electric Tool Mfg Company | Electrically-operated hammer. |

| US1797253A (en) * | 1927-07-09 | 1931-03-24 | Carl S Weyandt | Reciprocating motor |

| US1753910A (en) * | 1927-09-21 | 1930-04-08 | Nordiska Armaturfab Ab | Striking or hammering tool |

| US2254823A (en) * | 1940-06-10 | 1941-09-02 | Lloyd Parcells M | Electric hammer |

| US2588360A (en) * | 1950-06-09 | 1952-03-11 | Charles T Cole | Percussion tool |

| US2949909A (en) * | 1957-05-22 | 1960-08-23 | Macchioni Pietro Aurelio | Electromagnetic hammer |

| US3453463A (en) * | 1968-02-05 | 1969-07-01 | Gulf General Atomic Inc | Electrodynamic actuator |

| FR2085507A1 (en) * | 1970-04-28 | 1971-12-24 | Drye Lucien | |

| JPS6185382U (en) * | 1984-11-09 | 1986-06-05 | ||

| US5497555A (en) * | 1994-12-19 | 1996-03-12 | Averbukh; Moshe | Electromagnetic percussion device |

| DE19714288A1 (en) * | 1997-04-07 | 1998-10-08 | Hilti Ag | Drilling and / or chiseling device |

| FR2765904B1 (en) * | 1997-07-08 | 1999-10-08 | Jacques Demichelis | ELECTROMAGNETIC HAMMER WITH MOBILE FERROMAGNETIC MASS |

| DE10037418A1 (en) * | 2000-07-19 | 2002-02-07 | Hilti Ag | Electric hand tool device with electro-pneumatic hammer mechanism |

| DE10204861B4 (en) * | 2002-02-06 | 2004-01-29 | Wacker Construction Equipment Ag | Air spring hammer mechanism with electrodynamically driven drive piston |

-

2005

- 2005-08-03 DE DE102005036560A patent/DE102005036560A1/en not_active Withdrawn

-

2006

- 2006-07-23 US US11/997,635 patent/US20080314608A1/en not_active Abandoned

- 2006-07-26 JP JP2008524405A patent/JP5130213B2/en not_active Expired - Fee Related

- 2006-07-26 EP EP06762834A patent/EP1910038B1/en not_active Not-in-force

- 2006-07-26 ES ES06762834T patent/ES2316084T3/en active Active

- 2006-07-26 CN CN2006800277766A patent/CN101277792B/en not_active Expired - Fee Related

- 2006-07-26 WO PCT/EP2006/007394 patent/WO2007014688A1/en active Application Filing

- 2006-07-26 DE DE502006002214T patent/DE502006002214D1/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| DE502006002214D1 (en) | 2009-01-08 |

| DE102005036560A1 (en) | 2007-02-08 |

| EP1910038A1 (en) | 2008-04-16 |

| WO2007014688A1 (en) | 2007-02-08 |

| JP5130213B2 (en) | 2013-01-30 |

| US20080314608A1 (en) | 2008-12-25 |

| CN101277792A (en) | 2008-10-01 |

| JP2009502535A (en) | 2009-01-29 |

| ES2316084T3 (en) | 2009-04-01 |

| CN101277792B (en) | 2013-04-10 |

Similar Documents