EP1749651A2 - Vorrichtung zur Herstellung von Pellets - Google Patents

Vorrichtung zur Herstellung von Pellets Download PDFInfo

- Publication number

- EP1749651A2 EP1749651A2 EP06118449A EP06118449A EP1749651A2 EP 1749651 A2 EP1749651 A2 EP 1749651A2 EP 06118449 A EP06118449 A EP 06118449A EP 06118449 A EP06118449 A EP 06118449A EP 1749651 A2 EP1749651 A2 EP 1749651A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- extruder

- production machine

- pellet production

- presser wheels

- scrapers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/20—Roller-and-ring machines, i.e. with roller disposed within a ring and co-operating with the inner surface of the ring

- B30B11/201—Roller-and-ring machines, i.e. with roller disposed within a ring and co-operating with the inner surface of the ring for extruding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/20—Roller-and-ring machines, i.e. with roller disposed within a ring and co-operating with the inner surface of the ring

- B30B11/201—Roller-and-ring machines, i.e. with roller disposed within a ring and co-operating with the inner surface of the ring for extruding material

- B30B11/208—Roller constructions; Mounting of the rollers

Definitions

- the present invention relates to a pellet production machine in accordance with the introduction to the main claim.

- sawdust the waste material from wood machining

- pellets i.e. pressed to form small cylinders of a few centimetres in length

- other materials such as cereals, bran, manure and fodder are reduced to pellets.

- Pellet production machines currently present presser wheels which, with their lateral surface, press the material against a perforated wall from which the pellets leave by extrusion. These machines are divided into lateral extrusion machines in which the presser wheels, disposed with their axis horizontal, are positioned in the interior of a cylinder of perforated lateral surface rotating about a horizontal axis. The material to be reduced to pellets is fed into the rotating cylinder and is brought into contact with presser wheels by the cylinder movement, to be then extruded by the pressure of the presser wheels against the inner wall of the cylinder.

- the power required to operate the machine or to produce at a given power is strongly dependent on the type of material to be reduced to pellets: for example finer sawdust requires lower power than coarser sawdust.

- a machine of 12 kW power produces between 80 and 130 kg/h of pellets, hence a maximum of about 10 kg/h per kW of power.

- a machine with presser wheels of vertical axis which laterally extrudes the material presents the problem that the sawdust, or the material to be reduced to pellets, penetrates below the lower end of the presser wheels, causing them to seize rapidly.

- An object of the present invention is therefore to provide a pellet production machine by which the stated drawbacks are overcome, a particular object being to provide a particularly reliable machine, with presser wheels of vertical axis.

- Another object is to provide a machine which for the same power produces a greater quantity of pellets.

- a further object is to provide a machine of vertical axis and hence operationally more simple and more compact, as the material to be reduced to pellets is made to fall from above.

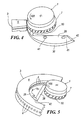

- the preferred embodiment of the machine comprises two presser wheels 1, 2 of substantially vertical axis disposed within a cylindrical extruder 3 of substantially vertical axis, the side wall of which comprises a plurality of radially directed holes 4 for extruding the pellets.

- the extruder 3 is in the form of a circular ring with an upper end 6.

- the lateral surface of each of the presser wheels 1 and 2 presents at the level of the radial holes 4 an annular thickening 7 and 8, which carries that lateral surface of the presser wheels 1 and 2 making contact with the inner wall 9 of the extruder 3.

- the presser wheels 1 and 2 are hollow and are closed upperly by a cap 22, 24.

- Each of the presser wheels 1 and 2 presents an axis 12 and 13 which penetrates into the base block 10.

- the base block 10 is of axissymmetric shape and is bounded upperly by a basal surface 11 in contact with the lower ends of the presser wheels 1 and 2.

- the base perimeter of the presser wheels 1 and 2 emerges from the basal surface 11 of the base bock 10.

- a base ring 15 which surrounds the base block 10 at a height slightly lower than that of the basal surface 11.

- the upper surface 17 of said base ring 15 defines, together with the basal surface 11 of the base block 10 and the inner wall of the extruder 3, a concavity into which the material to be reduced to pellets falls.

- the presser wheels 1 and 2 are rotatably constrained and are idle about their axes 12 and 13.

- the base block 10 is inserted into an outer structure 16 also mounted rotatable about its vertical axis, being supported by the bearing 18.

- a motor (not shown for simplicity) drives the base block 10 in the direction of the arrow 120.

- the presser wheels 1 and 2 rotate in the opposite direction to that in which the base block 10 rotates, as indicated by the arrows 100 and 110.

- the base block 10 presents a lateral disc 19 which extends below the base ring 15 and below the extruder 3, forming an upwardly facing groove in which a seal ring 20 with a downwardly facing groove is inserted to form a labyrinth preventing passage of the sawdust or other material, however fine, to be reduced to pellets.

- the machine comprises two scrapers 26 and 28 fixed to the basal surface 11 in an axially symmetric manner by screws 41, with their outer side 30, 32 extending beyond the basal surface 11, to lie adjacent to the inner wall 9 of the extruder 3.

- Their inner side presents a first inner portion 34, 36 which, by penetrating below the annular thickening 7 and 8 (represented in Figure 3 by a dashed line), grazes the lateral surface of the presser wheels 1 and 2, cooperating with it to remove the material to be reduced to pellets.

- Said first inner portion 34, 36 extends below the annular thickening 7 and 8, hence in proximity to that end of the presser wheels 1, 2 facing the basal surface 11.

- the inner side of the scrapers 26 and 27 presents an arcuate second inner portion 38, 40 and a rectilinear third inner portion 42, 44 forming an obtuse angle with the tangent to the inner wall 9 of the extruder 3.

- Said second inner portion 38, 40 is arcuate, with the concave inner part of the arc facing the direction of movement of the presser wheels 1 and 2 indicated by the arrows 100 and 110. Being idle about their axis, the presser wheels are dragged into movement by the material which becomes interposed between their lateral surface and the inner wall 9 of the extruder 3.

- Said scrapers 26 and 28 have a thickness equal to the height of the undercut formed by the annular thickenings 7 and 8, the material deposited on their upper surface lying substantially at the height of the radial holes 4.

- the first inner portion 34 and 36 is adjacent to the lateral surface of the presser wheels 1 and 2 and is hence rectilinear in its thickness.

- the second inner portion (38 and 40) and the third inner portion (42 and 44) of the two scrapers 26 and 28 are instead inclined along their thickness, to hence exert an upward lifting action on the material which they encounter during their movement.

- the upper surface of the two scrapers 26 and 28 is immediately below the annular thickening 7 and 8 and hence in proximity to the lower part of the radial holes 4 present in the extruder 3. This is particularly well visible in Figures 4 and 5.

- a cover 46 which terminates upperly in an aperture for feeding the material to be reduced to pellets, and presents on its sides an arcuate projection 47 extending along the outside of the extruder 3 to form a barrier positioned at a predetermined distance from the exit side of the radial holes 4.

- Figure 1 shows only the lowest part of the cover 46, to enable the upper part of the machine to be seen.

- the pellets just extruded by the radial holes 4 strike against the projection 47, to break and form cylinders of small height.

- the cover 46 rests on the upper end 6 of the extruder 3.

- the lateral surface of the annular thickenings 7 and 8 present gripping notches 50.

- the radial holes 4 are internally smoothed.

- the material to be reduced to pellets falls from above through the feed channel of the cover 46, to deposit on the basal surface 11, on the caps 22 and 24 of the presser wheels 1 and 2, on the upper surface of the scrapers 26 and 28, on the upper surface of the base ring 15 and on the upper end 6 of the extruder 3.

- a motor rotates the base block 10 in the direction of the arrow 120.

- the presser wheels 1 and 2 are dragged into movement in the direction indicated by the arrows 100 and 110.

- the material accumulated between the lateral surface of the annular thickenings 7 and 8 and the inner wall 9 of the extruder 3 is gradually pressed forcibly into the radial holes 4 of the extruder 3.

- the material which has fallen onto the upper end of the extruder 3 gradually falls into the extruder 3.

- the material accumulated on the upper surface 17 of the base ring 15 is lifted by the scrapers 26 and 28 and brought to the level of the radial holes 4, to be extruded.

- the material accumulated on the basal surface 11 and on the upper surface of the scrapers 26 and 28 tends to slide in proximity to the presser wheels 1 and 2, which cause it to leave the interior of the extruder 3 by extruding it through the radial holes 4.

- the material which falls onto the caps 22 and 24 of the presser wheels 1 and 2 tends to fall downwards and be finally extruded to form pellets.

- the material which tends to accumulate within the undercut formed by the annular thickening 7 and 8 of the presser wheels 1 and 2 is transferred by the movement of the presser wheels against the arcuate part of the second inner portion 38, 40 of the two scrapers 26 and 28. As it is inclined along its thickness, this portion lifts the material to prevent it blocking the operation of the presser wheels 1 and 2.

- On leaving the radial holes 4 the material to be reduced to pellets is compacted into cylindrical shape. These cylinders, being extruded radially, arrive against the arcuate projection 47 and then break, to form cylindrical pellets of small height.

- Two L-shaped elements or brushes can be disposed rigid with the base block 10, to remove the pellet forming material from the upper end 6 of the extruder 3 by making it fall towards the centre of the machine.

- An advantageous characteristic of the invention is that the radial holes 4 of the extruder 3 are internally smoothed to reduce friction during the extrusion operation.

- the two scrapers 26 and 28 can also be made in one piece, of such a shape as to be adjacent to both lateral surfaces of the presser wheels.

- the invention also includes a pellet production method, comprising the operation of pressing the material to be reduced to pellets against an extruder 3 by the pressure exerted by one or more presser wheels 1 and 2, and the operation of scraping away the material which deposits on the lateral surface of said presser wheels 1 and 2.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Glanulating (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI20051552 ITMI20051552A1 (it) | 2005-08-05 | 2005-08-05 | Macchina per la produzione di pellets |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1749651A2 true EP1749651A2 (de) | 2007-02-07 |

| EP1749651A3 EP1749651A3 (de) | 2010-07-14 |

Family

ID=37025052

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06118449A Withdrawn EP1749651A3 (de) | 2005-08-05 | 2006-08-04 | Vorrichtung zur Herstellung von Pellets |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1749651A3 (de) |

| IT (1) | ITMI20051552A1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102152490A (zh) * | 2010-12-17 | 2011-08-17 | 河南巨烽生物能源开发有限公司 | 生物质致密固体成型剪切式压块机 |

| CN110257123A (zh) * | 2019-07-04 | 2019-09-20 | 杭州万知科技有限公司 | 一种生物质燃料制备方法 |

| EP3369561B1 (de) | 2012-11-06 | 2020-04-15 | Franz Blieninger | Pelletpresse mit einer ablängvorrichtung für biogene faserhaltige pellets, sowie ein verfahren zur herstellung der pellets |

| CN115107252A (zh) * | 2022-06-30 | 2022-09-27 | 深圳市宏讯制造技术有限公司 | 挤压出料机构及挤压出料方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2870481A (en) | 1956-02-24 | 1959-01-27 | Bonnafoux Paul | Rotary pellet mill |

| US3017845A (en) | 1958-08-25 | 1962-01-23 | Mahoney Thomas P | Pellet mill |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2279632A (en) * | 1938-12-31 | 1942-04-14 | Edgar T Meakin | Apparatus for forming pellets |

| BE495322A (de) * | 1950-04-24 | |||

| DE952426C (de) * | 1953-12-16 | 1956-11-15 | Metallgesellschaft Ag | Ringwalzenpresse |

| SU404500A1 (ru) * | 1970-06-01 | 1973-10-22 | Устройство для гранулирования пастообразных | |

| NL186950C (nl) * | 1978-04-06 | 1991-04-16 | Ici Spa | Inrichting voor het continu uitpersen van vloeistofhoudend materiaal, in het bijzonder zaden of vruchten. |

-

2005

- 2005-08-05 IT ITMI20051552 patent/ITMI20051552A1/it unknown

-

2006

- 2006-08-04 EP EP06118449A patent/EP1749651A3/de not_active Withdrawn

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2870481A (en) | 1956-02-24 | 1959-01-27 | Bonnafoux Paul | Rotary pellet mill |

| US3017845A (en) | 1958-08-25 | 1962-01-23 | Mahoney Thomas P | Pellet mill |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102152490A (zh) * | 2010-12-17 | 2011-08-17 | 河南巨烽生物能源开发有限公司 | 生物质致密固体成型剪切式压块机 |

| EP3369561B1 (de) | 2012-11-06 | 2020-04-15 | Franz Blieninger | Pelletpresse mit einer ablängvorrichtung für biogene faserhaltige pellets, sowie ein verfahren zur herstellung der pellets |

| DE102013111828B4 (de) * | 2012-11-06 | 2025-10-02 | Franz Blieninger | Ablängvorrichtung für eine Pelletpresse, Pelletpresse mit einer solchenAblängvorrichtung für biogene faserhaltige Pellets, Verfahren zurHerstellung von biogenen faserhaltigen Pellets sowie Verwendung ei-ner Pelletpresse |

| CN110257123A (zh) * | 2019-07-04 | 2019-09-20 | 杭州万知科技有限公司 | 一种生物质燃料制备方法 |

| CN110257123B (zh) * | 2019-07-04 | 2020-07-03 | 杭州万知科技有限公司 | 一种生物质燃料制备方法 |

| CN115107252A (zh) * | 2022-06-30 | 2022-09-27 | 深圳市宏讯制造技术有限公司 | 挤压出料机构及挤压出料方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1749651A3 (de) | 2010-07-14 |

| ITMI20051552A1 (it) | 2007-02-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN211755833U (zh) | 一种水泥打散分级机 | |

| EP1749651A2 (de) | Vorrichtung zur Herstellung von Pellets | |

| CN112790396A (zh) | 一种核桃自动脱壳机及脱壳工艺 | |

| CN1257794C (zh) | 压缩机 | |

| CN115320162B (zh) | 一种石墨压球机 | |

| CN101249402B (zh) | 压辊式碾压制粒机 | |

| CN114225832B (zh) | 一种环保型生物质燃料颗粒成型装置 | |

| CN214439585U (zh) | 一种链锤式塑料粉碎机 | |

| CN115970582A (zh) | 一种立式环模生物质颗粒机 | |

| CN119176436B (zh) | 一种液态发酵生物饲料生产装置及方法 | |

| JP2000279839A (ja) | 破砕機の供給装置 | |

| RU194619U1 (ru) | Прессовой гранулятор | |

| CN220692058U (zh) | 电极膜压延机的给料装置 | |

| CN219985297U (zh) | 一种湿物料打散与定量给料装置 | |

| CN113526083A (zh) | 一种提升机 | |

| CN214854170U (zh) | 一种核桃磨皮机构及核桃自动脱壳机 | |

| CN212396673U (zh) | 弹性上箱体高效防滑动平模颗粒机 | |

| CN220386718U (zh) | 一种具有导料功能的雷蒙机研磨装置及雷蒙机 | |

| CN115070993A (zh) | 一种用于塑胶生产的原料预处理装置 | |

| CN223161422U (zh) | 一种污泥干化挤条机 | |

| CN118616172B (zh) | 一种便签纸生产用废料回收装置 | |

| PL79182B1 (en) | Apparatus for extruding flowable materials [gb1421453a] | |

| CN223818736U (en) | Graded grinding device based on optimized cement grain composition | |

| CN218354525U (zh) | 一种饲料生产用制粒装置 | |

| KR100340142B1 (ko) | 폐기물파쇄장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17P | Request for examination filed |

Effective date: 20110105 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20111118 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20120329 |