EP1577429B1 - Method and device for laying fibre tows of filaments - Google Patents

Method and device for laying fibre tows of filaments Download PDFInfo

- Publication number

- EP1577429B1 EP1577429B1 EP05004198A EP05004198A EP1577429B1 EP 1577429 B1 EP1577429 B1 EP 1577429B1 EP 05004198 A EP05004198 A EP 05004198A EP 05004198 A EP05004198 A EP 05004198A EP 1577429 B1 EP1577429 B1 EP 1577429B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- guide

- needles

- retainer

- hooks

- weft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B23/00—Flat warp knitting machines

- D04B23/10—Flat warp knitting machines for knitting through thread, fleece, or fabric layers, or around elongated core material

Definitions

- the invention relates to a method and apparatus for laying fiber slivers of filaments by means of irresistibly movable weft or Diagonalleger to fiber webs, which are stretched between two equipped with guide hooks and retaining pins transport in different directions and thus fed to a pre-consolidation station, wherein the endless, flat slivers individually spread, guided by means perpendicular to the predetermined laying direction aligned guide elements of the weft or diagonal laying transverse over both transport chains and wherein each of the slivers whose guide element traversing the series of guide hooks of the transport chain is formed, in each case a turn fold, which forms a lower run , an upper run and a vertex and is mounted in retaining elements.

- a method of the type mentioned was by the DE 101 49 161 C2 proposed.

- the group of slivers is guided diagonally across the transport chains with the aid of a weft or diagonal slitter.

- the guide elements for the slivers are aligned perpendicular to the direction of movement of the weft layer and arranged in a line next to each other parallel to the transport chains.

- the transport chains have two spaced rows of hooks. Adjacent to the scrim are the guide hooks. They have closely adjacent vertical needles with upwardly directed tip. Outside this row of guide hooks is another row of up and outward return needles. These are also arranged in high density.

- the guide elements on the weft or Diagonalleger are vertically immovable.

- a so-called. Wrinkle tensioner is introduced behind the guide element of the weft inserter, which guides the upper and lower strands of the turn fold separately at the vertex thereof until both strands are returned to the series of guide hooks after the offset of the upper step by means of the offset rake become.

- the fibers of the turning fold are tensioned and collected by a so-called loop tensioner and transferred to the row of retaining hooks in the form of a strand.

- the DE 100 21 341 A1 describes a similar device. Instead of the pusher bars, the gunner is assigned additional band fixations whose execution and mode of operation remain unclear. Obviously, these band fixations avoid skewing of the group of yarns during the offset behind the retention hooks. It is not possible with this arrangement to submit slivers of filaments. The pivoting of the guide elements carrying strips would always lead to strand formation. This makes it possible to produce no traffic-free scrim made of slivers.

- the weft guide of the weft or diagonal layer aligned parallel to the row of guide hooks has guide elements whose guide surfaces are aligned parallel to the row of guide hooks.

- the weft yarn guide performs no movement in the offset direction.

- the offset is due to a standard offset rake made in a known manner associated with the outwardly and upwardly directed return needles.

- the shooter with its guide elements is assigned subsequently activatable guide rakes which laterally fix the position of the slivers of the upper run of the turn fold and align them vertically in a plane parallel to the tips of the guide hooks.

- the function of the loop holder takes over here the folding clamp, which is pivotable about an axis. This passes his turning fold each a single retaining hook per sliver. This procedure is also unsatisfactory, since in particular when transferring the turning fold from the folding clamp on the individual retaining hooks, the turning fold is performed uncontrollably. The release of this fold by the folding clamp leads to Relaxing of fibers and slivers in the scrim.

- the object of the present invention is to propose a method and a device for laying endless fiber ribbons of filaments that control the distortions of the sliver in the turning fold with simple technical means such that both dreams are placed under defined conditions in the hooks of the transport chains can and the position and the tension of the inserted slivers between the transport chains are maintained.

- the first significant advantage of this solution is that the sliver sections of the yarn layer between the transport chains and the sliver sections in the area of the turn fold by the reliable fixation of the fibers of the slivers in guide hooks with narrow streets are separated from each other in terms of their voltage behavior. A temporary loosening of individual Fibers in the area of the turn fold do not automatically lead to a loosening of the fibers in the scrim.

- the second major advantage of the new method is that in particular the upper run of the turn fold, after the vertices are inserted into the retaining hooks directly through the weft or Diagonalleger, can be stretched and guided by means of the simple Einreicherers so that an erection of this upper Trumes is avoided before hanging in the guide hook. Possibly. Excess fiber lengths are kept near the apex area of the turn fold. At the same time, the unilaterally displaced during the offset band cross sections are distributed in the region of the guide elements by the action of the Einstreichers again over the entire guide area, so that the upper run of the turn fold completely spread and stretched the guide hook can be presented.

- the design of the method according to claim 3 leads to a higher security in that the excess fiber portions are kept in the region of the turn fold away from the region of the upper trousers, which is presented to the guide hook for hanging.

- the design of the guide hooks according to claim 4 allows the reliable separation between the tape sections in the scrim and the tape sections of the turn fold.

- a high degree of uniformity of the scrim is achieved in particular by tensioning and guiding the individual fiber slivers independently of each other in the yarn path in front of the guide elements and by matching the guide surfaces of these clamping and guide pins with the direction of the guide elements.

- the device defined in claim 6 for carrying out said method is simple and straightforward and brings in relation to known devices essential simplifications in terms of tools and the necessary precision of the control movements.

- the design of the double row of guide hooks and the series of retaining hooks according to claim 7 ensures particularly good clamping properties with simultaneous trouble-free insertion and removal of the slivers.

- the embodiment of the weft and Diagonalleger according to claim 8 is used in particular the modification of the method according to claim 5.

- the design of the gate according to claim 9 reduces the likelihood of random twisting of the belts in the yarn path between the spool and the weft or diagonal roller. Such distortions would lead to arbitrary irregularities in the clutch in the form of narrow lanes.

- the laying device as used in particular for multiaxial filament loom, consists of two laterally of the laying arrangement movable transport chains 1. These transport chains 1 move usually uniformly in the direction of a processing point, which is usually the effective point of a stitchbonding machine. For each thread layer of Geleges a separate laying arrangement is provided, the shot or Diagonalleger 2 in different directions on the Movement path of the two transport chains 1 to move back and forth. On a representation of this overall arrangement is omitted. It belongs to the well-known state of the art.

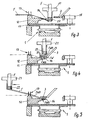

- the arrangement of the guide 13 and retaining elements 14 on the conveyor chain 1 is from the Fig. 1 seen.

- a support plate 11 which is each connected to a chain link, there is a two-part frame 12.

- guide hooks 13 are arranged in the form of a double row.

- the guide hooks 13 are relatively narrow and have narrow streets in the direction of the two rows of needles. It is advantageous to place about 15 to 25 needles per inch. Well proven has been the arrangement of 20 needles per inch.

- the shank cross section of the needles of the guide hooks is flattened vorteihafter way.

- the larger cross sections extend transversely to the direction of movement of the transport chains.

- the return needles 14 are attached.

- the return needles 14 are similarly densely arranged and designed as the needles of the guide hooks 13.

- these retaining hooks 14 are predominantly oriented horizontally. It would also be possible to use them inclined at an angle to the horizontal up or down. However, the horizontal orientation has proven to be particularly useful with regard to the preparation of the versions.

- a weft thread guide arranged on the weft or diagonal ruler 2 is provided.

- the weft yarn guide here consists of a guide rail 21, in which the guide elements 22 are arranged. At least these guide elements 22 are movable in three directions. Namely once across or diagonally to the transport chains for the laying motion, then in the longitudinal direction of the transport chains for the execution of an offset and finally in the vertical direction for the defined hooking in the guide hooks 13 and in the return needles fourteenth

- a former 3 is arranged horizontally movable from outside to inside.

- This inserter 3 is in the Figures 1 and 2 drawn with its Einreichkante 31 approximately in its foremost position.

- Fig. 2 The example of Fig. 2 the operation of the device in the individual phases by means of a guide element 22 / A to 22 / E will be described.

- the guide element 22 first traverses the row of guide hooks 13 of the transport chain 1. Behind this row of guide hooks 13, the guide elements 22 lower, so that the sliver F is fixed in a clamping manner in the row of guide hooks 13. If this process is completed, during the delay of the shotgun 2 already the offset V1 in the longitudinal direction of the transport chain 1.

- the guide elements 22 / A are still above the level of the return needles 14. If a part of the total offset - offset V1 - covered, the Guide bar 21 of the gun 2 lowered with their guide elements 22 down.

- the pusher edge 211 and 212 of the guide bar 21 moves the sliver F down. It is spliced by the tips of the return needles 14 and fixed in the lanes between the return needles 14 (position 22 / B). After the execution of a further offset V2 in this lowermost position, the guide rail 21 is raised with its guide elements 22 / C again. The sliver is spliced again and placed in the lanes between the return needles 14. The movement of the weft layer 2 in the direction of the other transport chain 1 begins in this phase, so that the sections of the vertex of the turning fold FW now finally fixed between the lanes of the return needles 14 become.

- the inserter 3 is moved ahead with its Einreichkante, preferably by means of a control piston, not shown, in the direction of the guide needle row 13. In this movement of the applicator 3, the same assists in wiping the corner fold FWS of the turn fold into the lanes of the retention hooks 14. At the same time, the landing edge 31 holds the fibers of the upper run FWO against the socket 12 of the return needles 14. This creates a pull on the outer fibers the fiber sliver FWO exerted, by means of which during the offset in the guide elements 22 unilaterally displaced sliver F is compensated again.

- Fig. 3 the position of the working elements is shown again. This illustrated position corresponds approximately to the position 22 / B of the guide element in the Fig. 2 , The first part of the offset V1 is completed and the guide elements 22 / B of the weft or diagonal layer 2 lower with the pusher edge 211 below the Row of retention pins 14. The liner 3 is still in the resting position.

- Position 22 / C of Fig. 2 is in Fig. 4 shown.

- the guide rail 21 of the weft or diagonal layer 2 has already been raised again with its guide element 22 / C and is in the first phase of its movement to the row of guide hooks 13.

- the former 3 has almost reached its end position. It clamps portions of the upper run of the turn fold FW to the socket 12 of the return needles 14 and aligns the sliver of the upper run FWO horizontally.

- the Fig. 5 shows a following position.

- the guide rail 21 of the weft or diagonal layer 2 has moved to a further lifting over the series of guide hooks 13 of the conveyor chain 1 and clamped by the holder 3 flat upper run of the turning fold FW so that the parts of the sliver F through the tips split the guide hook 13 and move the individual fiber strands in the streets between the guide hook 13 to the bottom of the same. There these bands are clamped. Possibly. Loose sections in the area of the turning fold FW do not shift into the area of the thread mesh between the transport chains 1.

- the sliver F is always stretched between the inserter 3 and the guide member 22 on the gun 2.

- This regularly existing tension is supported by a known clamping arrangement of guide pins 14 and dowel pins 13 above the guide elements on the weft 2.

- this guide and clamping arrangement is provided here individually for each sliver F.

- Such a guide and clamping arrangement is in Fig. 6 shown.

- the guide pins 24 and the clamping pin 23 are aligned parallel to the guide surface in the guide elements 22.

- the clamping pin 23 is in the horizontal direction elastically biased so that it can temporarily store excess sliver sections in the region of the turning fold FW while forming a small fold.

- This parallel alignment of the guide elements also applies to the feed roller 4, which is located at a distance above the range of motion of the weft or diagonal layer 2 between the two transport chains 1.

- This regularly difficult to access feed roller 4 is designed as a so-called.

- FIG Fig. 7 The scheme of feeding a sliver from the bobbin to the feed roller 4 is shown in FIG Fig. 7 shown.

- the guided on a horizontal axis in a gate coil 8 is slightly braked by means of brake 9. From the run-off point of the band is the same over a greater distance, which may be up to several meters, led to a broad, frangeless first guide roller 7 on which the sliver F depending on the respective expiration point on the spool 8 can shift laterally (see , Fig. 8 ).

- the upper run of this forming here loop of the band is then also performed over a long distance to a second guide roller or to a delivery 6. A strong lateral deflection of the sliver F is thus reliably prevented.

- the delivery mechanism 6 has three driven delivery rollers, which pulls the slivers F at a constant speed of the coils 8. Belonging to a delivery mechanism 6 coils 8 are offset in the gate against each other along their axes such that position their slivers without lateral guidance at a reasonable distance laterally on the delivery rollers.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Nonwoven Fabrics (AREA)

- Looms (AREA)

Description

Die Erfindung betrifft ein Verfahren und eine Vorrichtung zum Verlegen von Faserbändern aus Filamenten mittels changierend bewegbarer Schuss- oder Diagonalleger zu Fasergelegen, die zwischen zwei mit Führungshaken und Rückhaltenadeln ausgestatteten Transportmitteln in unterschiedlichen Legerichtungen gespannt und so einer Vorverfestigungsstation zugeführt werden, wobei die endlosen, flachen Faserbänder einzeln ausgebreitet, mittels senkrecht zur vorgegebenen Legerichtung ausgerichteten Führungselementen des Schuss- oder Diagonallegers quer über beide Transportketten ablegend geführt werden und wobei jedes der Faserbänder, dessen Führungselement die Reihe von Führungshaken der Transportkette ankommend überquert, zu je einer Wendefalte ausgeformt wird, die ein unteres Trum, ein oberes Trum und einen Scheitel aufweist und in Rückhalteelemente eingehangen wird.The invention relates to a method and apparatus for laying fiber slivers of filaments by means of irresistibly movable weft or Diagonalleger to fiber webs, which are stretched between two equipped with guide hooks and retaining pins transport in different directions and thus fed to a pre-consolidation station, wherein the endless, flat slivers individually spread, guided by means perpendicular to the predetermined laying direction aligned guide elements of the weft or diagonal laying transverse over both transport chains and wherein each of the slivers whose guide element traversing the series of guide hooks of the transport chain is formed, in each case a turn fold, which forms a lower run , an upper run and a vertex and is mounted in retaining elements.

Ein Verfahren der genannten Art wurde durch die

Die Führungselemente am Schuss- oder Diagonalleger sind vertikal unbeweglich. In der Wendephase wird hinter dem Führungselement des Schusslegers ein sog. Faltenspanner eingeführt, der die oberen und unteren Trume der Wendefalte am Scheitel derselben getrennt voneinander führt, bis beide Trume nach erfolgtem Versatz des oberen Trumes mittels von oben eingeschwenktem Versatzrechen der Reihe der Führungshaken wieder übergeben werden. Während der Ausführung des Versatzes werden die Fasern der Wendefalte durch einen sog. Schlingenspanner gespannt und gesammelt und der Reihe der Rückhaltehaken in Form eines Stranges übergeben.The guide elements on the weft or Diagonalleger are vertically immovable. In the turning phase, a so-called. Wrinkle tensioner is introduced behind the guide element of the weft inserter, which guides the upper and lower strands of the turn fold separately at the vertex thereof until both strands are returned to the series of guide hooks after the offset of the upper step by means of the offset rake become. During the execution of the offset, the fibers of the turning fold are tensioned and collected by a so-called loop tensioner and transferred to the row of retaining hooks in the form of a strand.

Diese Verfahrensweise erfordert wegen der großen Zahl der am Vorgang beteiligten Werkzeuge einen sehr hohen Steuerungsaufwand. Der angestrebte Effekt, nämlich zu einer wirklich gassenfreien Gestaltung der Fadengelege zu gelangen, wird nur mit Einschränkungen erreicht. Die Arbeitsgeschwindigke it bleibt begrenzt und ist unbefriedigend. Bei einer Veränderung der Breite der Faserbänder oder bei der Veränderung der Ausrichtung der Faserbandschar zwischen den Transportketten müssen stets die Arbeitselemente konstruktiv den neuen Bedingungen angepasst werden. Der Aufwand dafür ist hoch.This procedure requires a very high control effort because of the large number of tools involved in the process. The desired effect, namely to achieve a really gap-free design of the scrim, is achieved only with restrictions. The working speed remains limited and is unsatisfactory. In a change in the width of the slivers or in the change in the orientation of the sliver between the transport chains work elements must always be constructively adapted to the new conditions. The effort is high.

Mit der

Mit dieser Verfahrensweise und dieser Vorrichtung ist es jedoch nur möglich, Schussfadenscharen, deren Schussfäden seitlich nicht miteinander verbunden sind, zuverlässig in die Transportketten einzuhängen. Für Faserbänder aus z. B. Kohlenstoff- oder Glasfilamenten, bei denen die Filamente in einer vorgegebenen, definierten Lage - nämlich ein Band bildend - mittels adhäsiver Stoffe aneinander gehalten werden, ist diese Verfahrensweise nicht geeignet. Während des Versatzes richten sich die Querschnitte des Faserbandes unkontrolliert auf, so dass ein gleichmäßiges Einhängen, insbesondere des oberen Trumes, in die Reihe der Führungshaken nicht gewährleistet werden kann. Zudem wird während des Versatzes eines Faserbandes innerhalb eines Führungselementes am Schussleger das Band zu einem Strang umgeformt. Es gibt keine Möglichkeit, diesen Strang vor der Übergabe an die Führungshaken wieder auszubreiten. Im Randbereich des Geleges entstünden unregelmäßig breite Gassen, die als erhebliche Qualitätsmängel angesehen werden. Diese Verfahrensweise ist daher für das Verlegen von Faserbändern aus Filamenten nicht geeignet.However, with this procedure and this device, it is only possible to load weft thread groups whose weft threads are not laterally connected to each other reliably in the transport chains. For slivers from z. As carbon or glass filaments in which the filaments in a predetermined, defined position - namely forming a band - are held together by means of adhesive substances, this procedure is not suitable. During the offset, the cross sections of the sliver uncontrolled, so that a uniform hooking, especially the upper Trumes, can not be guaranteed in the series of guide hooks. In addition, during the displacement of a sliver within a guide element on the weft the band is formed into a strand. There is no way to spread this strand before handing it over to the guide hooks. In the margins of the jetty irregularly wide lanes, which are regarded as significant quality defects. This procedure is therefore not suitable for the laying of fiber ribbons of filaments.

Die

Durch die

Durch die Bewegung des Versatzrechens - unabhängig vom Schussleger - wird ein geführtes Band während des Versatzes innerhalb der Führungselemente im Schussleger zu einem Strang umgeformt. Dieser Strang wird abschließend in die Reihe der Führungshaken eingelegt und bildet die gefürchteten Gassen.Due to the movement of the offset rake - independently of the weft - a guided belt is deformed during the offset within the guide elements in the gun to a strand. This strand is finally inserted into the row of guide hooks and forms the dreaded lanes.

Durch die nicht veröffentlichte

Auch das brachte nicht den gewünschten Erfolg. Die Vorrichtung und deren Steuerung sind ähnlich aufwendig wie es in Bezug auf die

In einer weiteren Variante dieses genannten nicht vorveröffentlichten Dokumentes sind dem Schussleger mit seinen Führungselementen nachlaufend aktivierbare Führungsrechen zugeordnet, die die Lage der Faserbänder des oberen Trums der Wendefalte seitlich fixieren und vertikal in einer Ebene parallel zu den Spitzen der Führungshaken ausrichten. Die Funktion des Schlingenhalters übernimmt hier der Faltenspanner, der um eine Achse schwenkbar ist. Dieser übergibt seine Wendefalte jeweils einem einzelnen Rückhaltehaken pro Faserband. Diese Arbeitsweise ist ebenfalls unbefriedigend, da insbesondere bei der Übergabe der Wendefalte vom Faltenspanner auf die einzelnen Rückhaltehaken die Wendefalte unkontrolliert geführt wird. Das Freigeben dieser Falte durch den Faltenspanner führt zum Entspannen von Fasern und Faserbändern im Gelege.In a further variant of this document, which has not been previously published, the shooter with its guide elements is assigned subsequently activatable guide rakes which laterally fix the position of the slivers of the upper run of the turn fold and align them vertically in a plane parallel to the tips of the guide hooks. The function of the loop holder takes over here the folding clamp, which is pivotable about an axis. This passes his turning fold each a single retaining hook per sliver. This procedure is also unsatisfactory, since in particular when transferring the turning fold from the folding clamp on the individual retaining hooks, the turning fold is performed uncontrollably. The release of this fold by the folding clamp leads to Relaxing of fibers and slivers in the scrim.

Angesichts dieser scheinbar unlösbaren Schwierigkeiten beim Einhängen endloser Faserbänder aus Filamenten in die Haken der Transportketten hat man versucht, vorher abgelängte Faserbänder in gespannter Form über den beiden Transportketten auszurichten und in die Reihen der Führungshaken der Transportketten einzuhängen. Die freien Enden der Faserbandabschnitte verbrachte man - nach unten gerichtet - in eine weitere Klemme an der Transportkette, die an jeder Legeanordnung wieder geöffnet wurde, bevor neue Endabschnitte eingebracht werden. Auch diese Arbeitsweise zeigte sich als sehr schwierig beherrschbar. Die nicht unmittelbar mit den Klemmflächen der Klemmen in Verbindung kommenden Filamente der Faserbänder konnten nicht sicher gehalten und gespannt werden. Das Zusammenspiel der Klemmen mit unterschiedlicher Funktion ist unter industriemäßigen Bedingungen bei ausreichend hoher Geschwindigkeit nicht beherrschbar.In view of these seemingly unsolvable difficulties in hanging endless slivers of filaments into the hooks of the transport chains, attempts have been made to align previously cut slivers in a stretched form over the two transport chains and hook them into the rows of guide hooks of the transport chains. The free ends of the sliver sections were spent - directed downwards - in another clamp on the transport chain, which was reopened at each laying arrangement before new end sections are introduced. This way of working was also very difficult to control. The filaments of the slivers not directly connected to the clamping surfaces of the clamps could not be held securely and tightened. The interaction of the terminals with different functions is not manageable under industrial conditions at sufficiently high speed.

Die Aufgabe der vorliegenden Erfindung ist es, ein Verfahren und eine Vorrichtung für das Verlegen endloser Faserbänder aus Filamenten vorzuschlagen, die mit einfachen technischen Mitteln die Verwerfungen des Faserbandes in der Wendefalte derart kontrollieren, dass beide Trume unter definierten Bedingungen in die Haken der Transportketten eingelegt werden können und die Lage und die Spannung der eingelegten Faserbänder zwischen den Transportketten erhalten bleiben.The object of the present invention is to propose a method and a device for laying endless fiber ribbons of filaments that control the distortions of the sliver in the turning fold with simple technical means such that both dreams are placed under defined conditions in the hooks of the transport chains can and the position and the tension of the inserted slivers between the transport chains are maintained.

Diese Aufgabe wird durch das Verfahren nach Anspruch 1 auf überraschend einfache Weise gelöst.This object is achieved by the method according to

Der erste wesentliche Vorteil dieser Lösung besteht darin, dass die Faserbandabschnitte des Fadengeleges zwischen den Transportketten und die Faserbandabschnitte im Bereich der Wendefalte durch die zuverlässige Fixierung der Fasern der Faserbänder in Führungshaken mit engen Gassen hinsichtlich ihres Spannungsverhaltens voneinander getrennt werden. Ein zeitweiliges Lockern einzelner Fasern im Bereich der Wendefalte führt nicht automatisch zu einem Lockern der Fasern im Fadengelege.The first significant advantage of this solution is that the sliver sections of the yarn layer between the transport chains and the sliver sections in the area of the turn fold by the reliable fixation of the fibers of the slivers in guide hooks with narrow streets are separated from each other in terms of their voltage behavior. A temporary loosening of individual Fibers in the area of the turn fold do not automatically lead to a loosening of the fibers in the scrim.

Der zweite wesentliche Vorteil des neuen Verfahrens besteht darin, dass insbesondere das obere Trum der Wendefalte, nachdem die Scheitel in die Rückhaltehaken direkt durch den Schuss- oder Diagonalleger eingelegt wurden, mittels des einfachen Einstreichers so gespannt und geführt werden können, dass ein Aufrichten dieses oberen Trumes vor dem Einhängen in die Führungshaken vermieden wird. Evtl. überschüssige Faserlängen werden nahe dem Scheitelbereich der Wendefalte gehalten. Gleichzeitig werden die während des Versatzes einseitig verlagerten Bandquerschnitte im Bereich der Führungselemente durch die Wirkung des Einstreichers wieder über den ganzen Führungsbereich verteilt, so dass das obere Trum der Wendefalte vollständig ausgebreitet und gespannt den Führungshaken dargeboten werden kann.The second major advantage of the new method is that in particular the upper run of the turn fold, after the vertices are inserted into the retaining hooks directly through the weft or Diagonalleger, can be stretched and guided by means of the simple Einreicherers so that an erection of this upper Trumes is avoided before hanging in the guide hook. Possibly. Excess fiber lengths are kept near the apex area of the turn fold. At the same time, the unilaterally displaced during the offset band cross sections are distributed in the region of the guide elements by the action of the Einstreichers again over the entire guide area, so that the upper run of the turn fold completely spread and stretched the guide hook can be presented.

Die Zahl der für dieses Verfahren notwendigen Werkzeuge ist deutlich reduziert worden. Es sind weder einzeln steuerbare Faltenspanner noch Führungskämme oder Schlingenhalter erforderlich. Die nach diesem Verfahren hergestellten Gelege sind, soweit das erforderlich ist, auch gezielt und zuverlässig gassenfrei herstellbar.The number of tools required for this process has been significantly reduced. Neither individually controllable folding clamps nor guide combs or loop holders are required. The scratches produced by this process are, as far as that is required, also targeted and reliable off-gas produced.

Mit der Modifikation des Verfahrens nach Anspruch 2 wird erreicht, dass ein einziger Einstreicher für mehrere nebeneinander zugeführte Faserbänder mit einer ununterbrochenen Einstreichkante Verwendung finden kann. Die Ausbildung und Steuerung der Einstreicher vereinfacht sich erheblich.With the modification of the method according to claim 2 it is achieved that a single inserter can be used for a plurality of adjacent slivers fed with an uninterrupted Einreichkante. The training and control of the inserter simplifies considerably.

Die Gestaltung des Verfahrens nach Anspruch 3 führt zu einer höheren Sicherheit dahingehend, dass die überschüssigen Faserabschnitte im Bereich der Wendefalte von dem Bereich des oberen Trumes fern gehalten werden, der den Führungshaken zum Einhängen dargeboten wird.The design of the method according to

Die Gestaltung der Führungshaken nach Anspruch 4 ermöglicht die zuverlässige Trennung zwischen den Bandabschnitten im Gelege und den Bandabschnitten der Wendefalte. Eine hohe Gleichmäßigkeit der Gelege erreicht man insbesondere dadurch, dass man - im Fadenlauf vor den Führungselementen - die einzelnen Faserbänder unabhängig voneinander spannt und führt und dass die Führungsflächen dieser Spann- und Führungsstifte auf die Richtung der Führungselemente abgestimmt sind.The design of the guide hooks according to

Die in Anspruch 6 definierte Vorrichtung zur Ausführung des genannten Verfahrens ist einfach und überschaubar und bringt im Verhältnis zu bekannten Vorrichtungen wesentliche Vereinfachungen hinsichtlich der Werkzeuge und der notwendigen Präzision der Steuerbewegungen.The device defined in

Die Gestaltung der Doppelreihe der Führungshaken und der Reihe der Rückhaltehaken nach Anspruch 7 sichert besonders gute Klemmeigenschaften bei gleichzeitigem störungsfreiem Einlegen und Entfernen der Faserbänder.The design of the double row of guide hooks and the series of retaining hooks according to

Die Ausgestaltung der Schuss- und Diagonalleger nach Anspruch 8 dient insbesondere der Modifikation des Verfahrens nach Anspruch 5.The embodiment of the weft and Diagonalleger according to

Die Gestaltung des Gatters nach Anspruch 9 reduziert die Wahrscheinlichkeit, dass zufällig Verdrehungen der Bänder im Fadenlauf zwischen der Spule und dem Schuss- oder Diagonalleger entstehen. Solche Verdrehungen würden zu willkürlichen Unregelmäßigkeiten im Gelege in Form von in der Länge begrenzten Gassen führen.The design of the gate according to

Die Verwendung der Förder- oder Führungswalzen oder auch Spannrollen im Zulauf der Faserbänder nach Anspruch 10 verhindert das Wickeln einzelner Filamente auf diesen Walzen und unterstützt das ausgebreitete Führen der Faserbänder.The use of the conveying or guide rollers or tension rollers in the inlet of the slivers according to claim 10 prevents the winding of individual filaments on these rollers and supports the spreading guiding the slivers.

Die Erfindung soll nachstehend an einem Ausführungsbeispiel erläutert werden. In den dazugehörigen Zeichnungen zeigen:

- Fig. 1

- einen Querschnitt durch den Bereich einer Transportkette, in dem mittels Schussleger und Einstreicher eine Wendefalte ausgeformt wird,

- Fig. 2

- eine Draufsicht auf die in

Fig. 1 gezeigte Vorrichtung, wobei die Ausbildung der Wendefalte anhand mehrerer Positionen eines Führungselementes des Schuss- oder Diagonallegers aufgezeigt wird, - Fig. 3

- einen Querschnitt ähnlich der

Fig. 1 in einer Position, in der die Führungselemente des Schusslegers das untere Trum der Wendefalte in die Reihe der Rückhaltehaken einhängen, - Fig. 4

- eine Ansicht analog der

Fig. 3 in einer Position, in der der Einstreicher zwischen die Führungselem ente des Schusslegers und die Rückhaltehaken eingeführt wird, - Fig. 5

- einen Querschnitt nach

Fig. 3 , bei dem das zwischen dem Einstreicher und dem Führungselement des Schusslegers gespannte obere Trum der Wendefalte der Reihe der Führungshaken übergeben wird, - Fig. 6

- eine Darstellung der Bandführungs- und -spannelemente am Schussleger mit einer polygonartig gestalteten Führungswalze,

- Fig. 7

- eine schematische Darstellung des Bandverlaufes zwischen der Spule und den Zuführwalzen,

- Fig. 8

- eine teilweise Draufsicht auf

Fig. 7 , die den Faserbandverlauf zwischen dem Ablaufpunkt der Spule und der ersten Führungsrolle zeigt, und - Fig. 9

- eine polygonartig gestaltete Spannrolle des Bandspeichers.

- Fig. 1

- a cross section through the region of a transport chain, in which a turning fold is formed by means of weft and inserter,

- Fig. 2

- a top view of the in

Fig. 1 shown apparatus, wherein the formation of the turning fold is indicated by means of several positions of a guide element of the weft or diagonal layer, - Fig. 3

- a cross section similar to the

Fig. 1 in a position in which the guide elements of the shotgun hook the lower run of the turning fold in the row of retaining hooks, - Fig. 4

- a view analogous to

Fig. 3 in a position in which the inserter is inserted between the guide element of the weft inserter and the retention hooks, - Fig. 5

- a cross section after

Fig. 3 in which the upper run, stretched between the inserter and the guide element of the weft feeder, is handed over to the turn of the row of guide hooks, - Fig. 6

- a representation of the band guide and clamping elements on the weft with a polygonal-shaped guide roller,

- Fig. 7

- a schematic representation of the strip path between the spool and the feed rollers,

- Fig. 8

- a partial top view

Fig. 7 showing the sliver course between the discharge point of the spool and the first guide roller, and - Fig. 9

- a polygonal designed tension roller of the tape storage.

Die Legevorrichtung, wie sie insbesondere für multiaxiale Fadengelege verwendet wird, besteht aus zwei seitlich der Legeanordnung bewegbaren Transportketten 1. Diese Transportketten 1 bewegen sich i. d. R. gleichförmig in Richtung einer Verarbeitungsstelle, die meist die Wirkstelle einer Nähwirkmaschine ist. Für jede Fadenlage des Geleges ist eine separate Legeanordnung vorgesehen, deren Schuss- oder Diagonalleger 2 sich in unterschiedlichen Richtungen über der Bewegungsbahn der beiden Transportketten 1 hin und her bewegen. Auf eine Darstellung dieser Gesamtanordnung wird verzichtet. Sie gehört zum allgemein bekannten Stand der Technik.The laying device, as used in particular for multiaxial filament loom, consists of two laterally of the laying arrangement

Die Anordnung der Führungs- 13 und Rückhalteelemente 14 an der Transportkette 1 ist aus der

Der Schaftquerschnitt der Nadeln der Führungshaken ist vorteihafter Weise abgeflacht. Die größeren Querschnitte erstrecken sich quer zur Bewegungsrichtung der Transportketten 1.The shank cross section of the needles of the guide hooks is flattened vorteihafter way. The larger cross sections extend transversely to the direction of movement of the transport chains. 1

Im horizontalen Abschnitt der Fassung 12 sind die Rückhaltenadeln 14 befestigt. Die Rückhaltenadeln 14 sind ähnlich dicht angeordnet und gestaltet wie die Nadeln der Führungshaken 13. Diese Rückhaltehaken 14 sind jedoch überwiegend horizontal ausgerichtet. Es wäre auch möglich, dieselben in einem Winkel zur Horizontalen nach oben oder unten geneigt einzusetzen. Die horizontale Ausrichtung hat sich jedoch besonders im Hinblick auf die Herstellung der Fassungen als zweckmäßig erwiesen.In the horizontal portion of the

Im Bereich einer Legeanordnung ist ein auf dem Schuss- oder Diagonalleger 2 angeordneter Schussfadenführer vorgesehen. Der Schussfadenführer besteht hier aus einer Führungsleiste 21, in der die Führungselemente 22 angeordnet sind. Mindestens diese Führungselemente 22 sind in drei Richtungen beweglich. Nämlich einmal quer oder diagonal zu den Transportketten für die Legebewegung, dann in Längsrichtung zu den Transportketten für die Ausführung eines Versatzes und schließlich in vertikaler Richtung für das definierte Einhängen in die Führungshaken 13 und in die Rückhaltenadeln 14.In the area of a laying arrangement, a weft thread guide arranged on the weft or diagonal ruler 2 is provided. The weft yarn guide here consists of a

Zwischen der Ebene der Rückhaltenadeln 14 und einem teilweise wieder angehobenen Führungselement 22 ist ein Einstreicher 3 horizontal von außen nach innen bewegbar angeordnet. Dieser Einstreicher 3 ist in den

Am Beispiel der

Die Drückerkante 211 bzw. 212 der Führungsleiste 21 bewegt das Faserband F nach unten. Es wird durch die Spitzen der Rückhaltenadeln 14 aufgespleißt und in den Gassen zwischen den Rückhaltenadeln 14 fixiert (Position 22/B). Nach der Ausführung eines weiteren Versatzes V2 in dieser untersten Stellung wird die Führungsleiste 21 mit ihren Führungselementen 22/C wieder angehoben. Das Faserband wird erneut aufgespleißt und in die Gassen zwischen den Rückhaltenadeln 14 verbracht. Die Bewegung des Schusslegers 2 in Richtung der anderen Transportkette 1 beginnt in dieser Phase, so dass die Abschnitte des Scheitels der Wendefalte FW nun endgültig zwischen den Gassen der Rückhaltenadeln 14 fixiert werden.The

Sobald ein ausreichender vertikaler Raum zwischen den Rückhaltenadeln 14 und den Führungselementen 22 vorhanden ist, wird der Einstreicher 3 mit seiner Einstreichkante voran, vorzugsweise mit Hilfe eines nicht dargestellten Steuerkolbens in Richtung der Führungsnadelreihe 13 bewegt. Bei dieser Bewegung des Einstreichers 3 unterstützt derselbe das Einstreichen des Scheitelabschn ittes FWS der Wendefalte in die Gassen der Rückhaltehaken 14. Gleichzeitig hält die Einstreichkante 31 die Fasern des oberen Trums FWO an der Fassung 12 der Rückhaltenadeln 14. Dadurch wird ein Zug auf die äußeren Fasern des Faserbandes FWO ausgeübt, mit dessen Hilfe das während des Versatzes in den Führungselementen 22 einseitig verlagerte Faserband F wieder kompensiert wird.Once a sufficient vertical space between the return needles 14 and the

Dies ist in der Position des Führungselementes 22/D gut zu erkennen. Gleichzeitig sichert die Einstreichkante 31 in dieser Position, dass die Teile des Faserbandes zwischen dem Führungselement 22 und dieser Klemmkante gespannt bleiben und freie Faserteile sich außerhalb der Klemmlinie ansammeln. Das obere Trum FWO der Wendefalte FW wird dadurch ausgebreitet und gleichmäßig gespannt über die Reihe der Führungshaken 13 in Richtung der anderen Transportkette 1 bewegt. Dieser gespannte Abschnitt FWO des Faserbandes F ist exakt horizontal ausgerichtet und wird dadurch den Führungshaken 13 in einheitlicher Höhe vorgelegt. Eine besondere Hubbewegung der Führungselemente 22 ist für das Einlegen in die Reihe der Führungshaken 13 zunächst nicht vorgesehen. Die Notwendigkeit wird in Abhängigkeit von der Art der vorgelegten Faserbänder F von Fall zu Fall durch den Fachmann bestimmt.This can be clearly seen in the position of the

In

Die Position 22/C der

Die

Von besonderer Bedeutung ist, dass das Faserband F zwischen dem Einstreicher 3 und dem Führungselement 22 am Schussleger 2 immer gespannt ist. Diese regelmäßig vorhandene Spannung wird durch eine an sich bekannte Spannanordnung aus Führungsstiften 14 und Spannstiften 13 oberhalb der Führungselemente am Schussleger 2 unterstützt. Im Gegensatz zum bekannten Stand der Technik ist diese Führungs- und Spannanordnung hier jedoch für jedes Faserband F einzeln vorgesehen. Eine solcher Führungs- und Spannanordnung ist in

Diese parallele Ausrichtung der Führungselemente trifft auch für die Zuführwalze 4 zu, die sich im Abstand oberhalb des Bewegungsbereiches des Schuss- oder Diagonallegers 2 zwischen den beiden Transportketten 1 befindet. Diese regelmäßig nur schwer zugängige Zuführwalze 4 ist als sog. Polygonwalze oder als Walze mit Längsrippen, die entlang von Mantellinien ausgerichtet sind, ausgestaltet. Diese Ausführung soll dafür Sorge tragen, dass sich nicht einzelne aus dem Verband des Faserbandes F lösende Fasern um diese Zuführwalze 4 wickeln.This parallel alignment of the guide elements also applies to the

Das Schema der Zuführung eines Faserbandes von der Spule bis zur Zuführwalze 4 ist in

Das Lieferwerk 6 besitzt drei angetriebene Lieferwalzen, die die Faserbänder F mit gleichbleibender Geschwindigkeit von den Spulen 8 abzieht. Die zu einem Lieferwerk 6 gehörenden Spulen 8 sind in dem Gatter entlang ihrer Achsen gegeneinander derart versetzt, dass sich deren Faserbänder ohne seitliche Führung in einem angemessenen Abstand seitlich auf den Lieferwalzen positionieren.The

Die durch den Legevorgang erforderlichen unterschiedlichen Abzugsgeschwindigkeiten und die dadurch bedingten zeitweiligen Faserbandüberschüsse werden im Bereich des Bandspeichers 5 zwischengespeichert. Zur Sicherung der ausgebreiteten Lage des Faserbandes auch an der mit seitlichen Bünden versehenen Spannrolle 51 besitzt dieselbe eine polygone Lauffläche für das Faserband F. Diese wird hier durch einzelne ringförmig angeordnete Stifte gebildet (vgl.

Diese Anordnung und Gestaltung der Führungselemente im Bereich des Gatters hat sich bewährt. Die Zahl der Drehungen im Band, die zufällig entstehen können, hat sich damit deutlich verringert.This arrangement and design of the guide elements in the gate has proven itself. The number of spins in the band, which can happen by chance, has decreased significantly.

- 11

- Transportkettetransport chain

- 1111

- Trageplattesupport plate

- 1212

- Fassungversion

- 1313

- Führunghaken, DoppelreiheLeadership hook, double row

- 1414

- RückhaltehakenRetention hook

- 1515

- Stützrollesupporting role

- 22

- Schuss- oder DiagonallegerShot or diagonal eager

- 2121

- Führungsleisteguide rail

- 211, 212211, 212

- Drückerkantepresser edge

- 22 (A, B, C, D, E)22 (A, B, C, D, E)

- Führungselementguide element

- 2323

- Spannstiftdowel pin

- 2424

- Führungsstifteguide pins

- 33

- Einstreicheronce rich

- 3131

- EinstreichkanteCreaming edge

- 44

- Zuführwalzefeed

- 55

- Bandspeichertape storage

- 5151

- Spannrolleidler

- 66

- Lieferwerkdelivery mechanism

- 77

- Führungsrolleleadership

- 88th

- SpuleKitchen sink

- 99

- Bremsebrake

- A, B, C, D, EA, B, C, D, E

- Positionen eines Führungselementes in der WendephasePositions of a guide element in the turning phase

- FF

- Faserbandsliver

- FGFG

- FaserbandscharSliver crowd

- FWFW

- Wendefalteturning fold

- FWUFWU

- unteres Trumlower strand

- FWSFWS

- Scheitelvertex

- FWOFWO

- oberes Trumupper strand

- V1V1

- Versatz (vor dem Einhängen in die Rückhaltehaken)Offset (before hooking into the retaining hooks)

- V2V2

- Versatz (nach dem Einhängen in die Rückhaltehaken)Offset (after hanging in the retaining hooks)

Claims (10)

- Method for laying fibre bands made of filaments- by means of reciprocating weft layers or diagonal layers (2)- to form fibre-laid fabrics- - which are stentered in different laying directions between two transport chains (1) equipped with guide hooks (13) and retainer needles (14) and are thus fed to a prebonding station,wherein the continuous, planar fibre bands (F) are laid transversely over the two transport chains (1) in an individually spread out manner by means of guide members (22) of the weft layer or diagonal layer (2) orientated at right angles to the predetermined laying direction, wherein each of the fibre bands (F) of which the guide member crosses over the row of guide hooks (13) of the transport chain (1) in the incoming direction is formed into a turning fold (FW) which comprises a lower strand (FWU), an upper strand (FWO) and an apex, wherein the beginning of the lower strands (FWU) and the end of the upper strands (FWO) of the turning folds (FW) are fixed by clamping in gaps between the guide hooks (13), wherein the apexes of the turning folds (FW)- form an offset (V1, V2) for the fibre bands (F) in the turning phase of the weft layer or diagonal layer (2) and- are hooked up in loops and fixed in a spread out manner side by side in a row of retainer needles (14), which are arranged close together and directed substantially horizontally outwards, by lowering and raising the guide members (22), and

wherein the upper strands (FWO), forming between the retainer needles (14) and the guide members (22) of the weft layer or diagonal layer, of the turning folds of a group can be moved inwards from the outside directly above the retainer needles (14) transverse to the movement direction of the transport chains (1) by means of a stitch spreader (3) which is equipped with a spreading edge (31) orientated parallel to the movement direction of the transport chains (1), characterised in that

the fibre band portions of the apexes (FWS) are fixed in the gaps between the retainer needles (14) by the stitch spreaders (3),

in that the width of the fibre bands (F), which is reduced during the offsetting into the guide members (22), is increased again and

in that the cross-section of the upper strands of the turning folds is guided parallel to the plane of the retainer needles (14) and the portions of the fibre bands (F) are substantially held inserted between the spreading edge (31) and the guide members (22). - Method according to claim 1, characterised in that the spreader edge (31) of the stitch spreader (3) is guided closely above the row of retainer needles (14) in a positive manner from below and in a resilient manner from above.

- Method according to claim 2, characterised in that, during the movement of the guide members (22) from the outside over the row of guide hooks (14), the fibre bands (F) are braked on the transport chain (1) between the spreader edge (31) and a surface located at a distance in front of the row of guide hooks (13).

- Method according to claim 1, characterised in that the beginning of the lower strand (FWU) and the end of the upper strand (FWO) of the turning fold (FW) are fixed in the gaps between the needles of two rows of guide hooks (13) immediately adjacent to one another.

- Method according to claim 1, characterised in that each individual fibre band (F), independently of the other fibre bands of the group, is guided in the feed direction in front of the respective guide members (22) on the diagonal layer or weft layer (2) across the width of the fibre bands (F) under uniform tension and parallel to the respective guide member (22).

- Apparatus for laying fibre bands made of filaments to form fibre-laid fabrics, comprising a pair of endless, moveable transport chains (1) equipped with rows of guide hooks (13) and with retainer needles (14), also outwardly orientated and arranged lower than the holders (12) of the guide hooks (13), for guiding and fixing turning folds (FW),

one or more weft layers and/or diagonal layers (2) having guide members (22) which are orientated at right angles to the laying direction of the fibre bands (F) between the transport chains (1) and are used to guide continuous fibre bands,

one creel per weft layer or diagonal layer (2), said creel having tangentially unwinding bobbins (8) for supplying groups of fibre bands (F),

the transport chains (1) each being equipped with a double row of substantially vertical, needle-shaped guide hooks (13) and with a row of retainer needles (14), characterised in that,

the retainer needles (14) are orientated substantially horizontally and are located with their holders below the base portions of the guide hooks (13),

in that the rows of guide hooks (13) and the row of retainer needles (14) have a density of 15 to 30 needles per inch,

in that at least one stitch spreader (3) guided and controlled outside the transport chain (1) is assigned to each weft layer and/or diagonal layer (2) per transport chain (1),

in that each stitch spreader (3) is displaceably guided below the conventional movement region of the guide members (22) of the weft layer or diagonal layer (2) and transverse to the movement direction of the transport chains (1),

in that each stitch spreader (3) is equipped with a spreader edge (31) orientated parallel to the transport chains (1),- which is movable from outside over the retainer needles (14) into the region of the holders (12) thereof and- which extends over the region of the turning folds (FW) of the fibre bands (F) guided by a weft layer or diagonal layer (2). - Apparatus according to claim 6, characterised in that the needles of the double row of guide hooks (13) and/or the retainer needles (14) have a flattened cross-section, the cross-section being arranged such that the larger extension is transverse to the movement direction of the transport chains (1).

- Apparatus according to claim 6, characterised in that the weft layer or diagonal layer (2) has, for each of its guide members (22), separate guide pins (24) and/or dowel pins (23), the guide surfaces thereof being orientated parallel to the guide members (22).

- Apparatus according to claim 6, characterised in that the creel assigned to each bobbin (8) has at least one flangeless return roller (7) which is arranged at a distance of at least four bobbin widths after the previous unwinding point.

- Apparatus according to claim 6, characterised in that the conveyor or feed rollers (4) or the tension rollers (51) in the band store (5) have a polygonal cross-section in the inflow of the fibre bands (F).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004012305 | 2004-03-11 | ||

| DE102004012305A DE102004012305B3 (en) | 2004-03-11 | 2004-03-11 | Method and device for laying slivers of filaments |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1577429A1 EP1577429A1 (en) | 2005-09-21 |

| EP1577429B1 true EP1577429B1 (en) | 2011-02-16 |

Family

ID=34833116

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05004198A Not-in-force EP1577429B1 (en) | 2004-03-11 | 2005-02-25 | Method and device for laying fibre tows of filaments |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7120976B2 (en) |

| EP (1) | EP1577429B1 (en) |

| JP (1) | JP4108686B2 (en) |

| CN (1) | CN100480450C (en) |

| DE (2) | DE102004012305B3 (en) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8131395B2 (en) * | 2006-10-16 | 2012-03-06 | Ebert Composites Corporation | 90 degree ply placement system and method |

| DE202006018717U1 (en) * | 2006-12-12 | 2007-02-15 | Karl Mayer Malimo Textilmaschinenfabrik Gmbh | High productivity multiaxial machine, has thread laying device, thread store and thread reservoir with storage zone with length controlled in dependence on movement of laying device |

| DE102009022163B4 (en) * | 2009-05-20 | 2011-06-09 | Liba Maschinenfabrik Gmbh | Device for applying a unidirectional layer and multi-axial machine |

| DE102010006543A1 (en) * | 2010-02-01 | 2011-08-04 | Karl Mayer China LTD., Jiangsu | Device for putting weft thread bands, has carriage, which is movable into primary direction, and thread lever, which is moved in secondary direction opposite to carriage |

| DE102010006545A1 (en) * | 2010-02-01 | 2011-08-04 | Karl Mayer China LTD., Jiangsu | Device for producing mono- or multiaxial structure, comprises a solidification section and a laying area in which a transport belt is arranged respectively on both sides of the transport belt of a transport device |

| CN102285158A (en) * | 2011-06-14 | 2011-12-21 | 常州纽兰德复合材料有限公司 | Multiaxial non-woven mesh composite non woven and preparation method thereof |

| DE102011089657B4 (en) * | 2011-12-22 | 2014-01-02 | Liba-Maschinenfabrik Gesellschaft mit beschränkter Haftung | Device for applying a thread layer to parallel conveyor chains |

| TW201700384A (en) * | 2015-06-18 | 2017-01-01 | Chyau Ban Machinery Co Ltd | Separation device for separating a plurality of cross-folding fiber products comprising a separation base, first to third separation units and a fixing unit |

| CN111020859B (en) * | 2019-11-21 | 2021-04-20 | 福建宇邦纺织科技有限公司 | Weft feeding and laying device for preparing stitch-bonded fabric |

| CN114234760B (en) * | 2021-12-15 | 2024-03-19 | 苏州博众智能机器人有限公司 | Positioning structure |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE21341C (en) | Ta F. HARVEY in Dowlas, Grafschaft Glamorgan, England | Innovations in wind heating devices | ||

| DE12534C (en) | W. THAMM in Wien | Innovation in boiler tubes for steam boilers | ||

| DE42721C (en) | REINIGER, GEBBERT & SCHALL in Erlangen | Mouth gag with a device to hold an electric lamp and a mirror for examining the oral cavity | ||

| DE14140C (en) | A. becker in Dortmund | Attachment of wheel tires! Wheels of the railway wagons | ||

| DE7317C (en) | 1878-11-22 | 1879-09-24 | H. LÖWENBERG in Charlottenburg | Apparatus for plastic printing on smooth fabrics |

| DE49161C (en) | 1889-02-07 | 1889-10-23 | fr, BAUER in Oehringen, Württemberg | Knee lever mechanism for locking the lock on liquid manure drums |

| US3756043A (en) * | 1971-11-11 | 1973-09-04 | Wirkmaschinenbau Karl Marx Veb | Flat warp knitting machines |

| DE3017255C2 (en) * | 1980-05-06 | 1985-04-11 | Karl Mayer Textil-Maschinen-Fabrik Gmbh, 6053 Obertshausen | Weft thread magazine for warp knitting machines |

| DE3040393C2 (en) * | 1980-10-25 | 1985-05-02 | Karl Mayer Textil-Maschinen-Fabrik Gmbh, 6053 Obertshausen | Weft thread magazine with reverse weft for a warp knitting machine |

| DE3343048C2 (en) * | 1983-11-28 | 1987-05-14 | Liba Maschinenfabrik Gmbh, 8674 Naila | Method and device for laying cross weft threads for a warp knitting machine |

| US4877470A (en) * | 1986-10-23 | 1989-10-31 | J B Group, Inc. | Method for the production of bias fabrics |

| JPH01306664A (en) * | 1988-06-06 | 1989-12-11 | Polymer Processing Res Inst | Multi-axis non-woven fabric of yarn, its production and apparatus therefor |

| DE3932184C2 (en) * | 1989-09-27 | 1996-06-20 | Mayer Textilmaschf | Weft feed device for the weft magazine of a warp knitting machine |

| DE19742721C1 (en) * | 1997-09-26 | 1999-06-02 | Malimo Maschinenbau | Laying weft bands at warp knitter |

| DE10021341A1 (en) * | 2000-05-02 | 2001-11-15 | Fraunhofer Ges Forschung | Assembly to lay bands of weft yarns between edge hooks and in different orientations has a rotating yarn layer with yarn guide openings set at angular alignments to give an adjustable laying width |

| DE10149161C2 (en) * | 2001-10-04 | 2003-08-07 | Mayer Malimo Textilmaschf | Method and device for laying fiber sheets, in particular fiber tapes from fiber strands, to lay fiber |

| DE10207317C5 (en) * | 2002-02-21 | 2009-12-31 | Liba Maschinenfabrik Gmbh | Device for laying multiaxially oriented thread layers |

| DE10214140B4 (en) * | 2002-03-28 | 2008-03-20 | Liba Maschinenfabrik Gmbh | Holding device on the transport chains of a machine for presenting yarn layers, method for presenting and fixing filament shares to a scrim and Multiaxialmaschine for performing the method with a holding device |

| DE10312534B3 (en) * | 2003-03-20 | 2004-08-26 | Karl Mayer Malimo Textilmaschinenfabrik Gmbh | To lay bands of continuous filaments, to be passed to a warp knitter for the production of reinforcement fabrics for plastics/resin materials, takes them round folders to be laid at transport chain hooks |

-

2004

- 2004-03-11 DE DE102004012305A patent/DE102004012305B3/en not_active Expired - Fee Related

-

2005

- 2005-02-25 EP EP05004198A patent/EP1577429B1/en not_active Not-in-force

- 2005-02-25 DE DE502005010970T patent/DE502005010970D1/en active Active

- 2005-03-07 US US11/072,449 patent/US7120976B2/en not_active Expired - Fee Related

- 2005-03-11 JP JP2005069257A patent/JP4108686B2/en not_active Expired - Fee Related

- 2005-03-11 CN CNB2005100896157A patent/CN100480450C/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| DE502005010970D1 (en) | 2011-03-31 |

| CN1755000A (en) | 2006-04-05 |

| US7120976B2 (en) | 2006-10-17 |

| EP1577429A1 (en) | 2005-09-21 |

| DE102004012305B3 (en) | 2005-12-29 |

| JP2005256271A (en) | 2005-09-22 |

| CN100480450C (en) | 2009-04-22 |

| JP4108686B2 (en) | 2008-06-25 |

| US20050198792A1 (en) | 2005-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1577429B1 (en) | Method and device for laying fibre tows of filaments | |

| DE102007024124B3 (en) | Multi-axial machine for laying up composite fibres has first feed station for endless fibers and second feed station for pre-cut ribbon | |

| EP2028307B1 (en) | Method and device for placing a unidirectional thread layer on longitudinal conveyors, method for laying weft threads on warp knitting machines, and device to carry out said methods | |

| DE10214140B4 (en) | Holding device on the transport chains of a machine for presenting yarn layers, method for presenting and fixing filament shares to a scrim and Multiaxialmaschine for performing the method with a holding device | |

| EP2151517B1 (en) | Method for producing a unidirectional fibrous layer and device for spreading fibres | |

| DE2531734A1 (en) | THREAD GUIDE ON MESH-FORMING MACHINES WITH REVOLVING THREAD GUIDES | |

| DE3040393C2 (en) | Weft thread magazine with reverse weft for a warp knitting machine | |

| DE102009022163B4 (en) | Device for applying a unidirectional layer and multi-axial machine | |

| DD136861B1 (en) | DEVICE FOR FEEDING FAXES ON TEXTILE MACHINES | |

| DE10029492A1 (en) | Cone warping machine has a change creel where a number of bobbins are deployed for each yarn take-off point for a programmed warp yarn change according to pattern color requirements | |

| DE69701945T2 (en) | Device for the rapid introduction of thread into the channels of a warping machine working with a thread according to the thread system | |

| EP1512784B1 (en) | Method and apparatus for laying and fixing bands of rectilinear filaments | |

| DE10354348B4 (en) | Multi-needle sewing machine for combining sheets, e.g. mattress covers, includes feeder unit with conveying belts, especially for elastic materials | |

| DE19852281C2 (en) | Device for feeding a multilayer, multiaxial thread layer to the knitting point of a warp knitting machine | |

| DE4402510C2 (en) | Warp knitting machine with a weft magazine | |

| DE10207317C1 (en) | System to lay layers of multi-axial yarns/filaments, at the needle bar of a warp knitter, has longitudinal transport chains with needle beds fitted with two rows of needles to carry the yarns/filaments between them | |

| CH673042A5 (en) | ||

| DE19802994C1 (en) | Laying system for yarn bands, used in knitter | |

| DE10149161C2 (en) | Method and device for laying fiber sheets, in particular fiber tapes from fiber strands, to lay fiber | |

| DE4122358C2 (en) | ||

| DE4115059C2 (en) | Device for delimiting the thread balloons on a creel | |

| DE3003570C2 (en) | ||

| DE10258357B4 (en) | Method and laying arrangement for producing a web-shaped Multiaxialgeleges having multifilament threads | |

| DE19924430C2 (en) | Method and device for feeding and inserting sheets of thread into the hooks of transport chains | |

| EP3587646B1 (en) | Device and method for application of a band, strip or sheet-like unidirectional fibre layer with at least one bobbin creel carrying a plurality of coils |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20050906 |

|

| AKX | Designation fees paid |

Designated state(s): CH DE ES FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20100409 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502005010970 Country of ref document: DE Date of ref document: 20110331 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502005010970 Country of ref document: DE Effective date: 20110331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110527 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20111117 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502005010970 Country of ref document: DE Effective date: 20111117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110216 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20130315 Year of fee payment: 9 Ref country code: GB Payment date: 20130219 Year of fee payment: 9 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140225 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20141031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140225 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170217 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502005010970 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180901 |