EP1537334B1 - Pump, especially for a fuel injection device for an internal combustion engine - Google Patents

Pump, especially for a fuel injection device for an internal combustion engine Download PDFInfo

- Publication number

- EP1537334B1 EP1537334B1 EP03739364A EP03739364A EP1537334B1 EP 1537334 B1 EP1537334 B1 EP 1537334B1 EP 03739364 A EP03739364 A EP 03739364A EP 03739364 A EP03739364 A EP 03739364A EP 1537334 B1 EP1537334 B1 EP 1537334B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pump

- blind bore

- bore

- housing part

- valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000446 fuel Substances 0.000 title claims description 21

- 238000002485 combustion reaction Methods 0.000 title claims description 5

- 238000002347 injection Methods 0.000 title claims description 4

- 239000007924 injection Substances 0.000 title claims description 4

- 230000007704 transition Effects 0.000 claims description 4

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 239000002828 fuel tank Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M55/00—Fuel-injection apparatus characterised by their fuel conduits or their venting means; Arrangements of conduits between fuel tank and pump F02M37/00

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M55/00—Fuel-injection apparatus characterised by their fuel conduits or their venting means; Arrangements of conduits between fuel tank and pump F02M37/00

- F02M55/004—Joints; Sealings

- F02M55/005—Joints; Sealings for high pressure conduits, e.g. connected to pump outlet or to injector inlet

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M59/00—Pumps specially adapted for fuel-injection and not provided for in groups F02M39/00 -F02M57/00, e.g. rotary cylinder-block type of pumps

- F02M59/44—Details, components parts, or accessories not provided for in, or of interest apart from, the apparatus of groups F02M59/02 - F02M59/42; Pumps having transducers, e.g. to measure displacement of pump rack or piston

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B1/00—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders

- F04B1/04—Multi-cylinder machines or pumps characterised by number or arrangement of cylinders having cylinders in star- or fan-arrangement

- F04B1/0404—Details or component parts

- F04B1/0452—Distribution members, e.g. valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B53/00—Component parts, details or accessories not provided for in, or of interest apart from, groups F04B1/00 - F04B23/00 or F04B39/00 - F04B47/00

- F04B53/16—Casings; Cylinders; Cylinder liners or heads; Fluid connections

Definitions

- the invention relates to a pump, in particular for a fuel injection device for an internal combustion engine according to the preamble of claim 1.

- Such a pump is through the DE 198 48 035 A1 known.

- This pump has at least one pump element with a pump piston which is tightly guided in a cylinder bore of a housing part and delimits a pump working space in the cylinder bore with its end face.

- the pump piston is driven in a stroke.

- the pump working space has a connection with an inlet channel controlled by an inlet valve opening into the pump working space, and a connection with a drainage channel controlled by an outlet valve opening from the pump working space.

- the inlet valve has a valve member cooperating with a valve seat, which is acted upon by a valve spring to the valve seat.

- the opening into the pump working chamber part of the inlet channel is formed by an inserted into a bore of the housing part separate component, on which also the valve seat is formed.

- the bore of the housing part is closed with a screw plug. Due to the many items, the production and assembly of the known pump is complicated and expensive.

- the pump according to the invention with the features of claim 1 has the advantage that it is easy and inexpensive to manufacture and assemble, since the number of their parts is reduced.

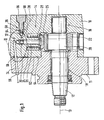

- FIG. 1 a pump in a longitudinal section

- FIG. 2 one in FIG. 1 With II designated section of the pump in an enlarged view.

- a pump is shown, which is provided in particular for a fuel injection device for an internal combustion engine, for example a motor vehicle.

- the pump thereby fuel under high pressure of up to 2000 bar promoted, for example, in a memory.

- the pump has a housing which has, for example, a housing part 10 and a flange part 11 connected thereto.

- a drive shaft 12 is arranged through which one or more arranged in the housing pump elements 14 are driven.

- a plurality of pump elements 14 are arranged distributed over the circumference of the drive shaft 12.

- the drive shaft 12 is connected via a bearing 16 in the housing part 10 and over a bearing 18 in the flange 11 is rotatably mounted about an axis 13 and is driven in a manner not shown by the internal combustion engine.

- the drive shaft 12 has an eccentric portion 20 on which a cam ring 22 is mounted.

- the pump element 14 has a pump piston 24 which is displaceably guided in an at least approximately radially to the drive shaft 12 extending cylinder bore 26 of the housing part 10.

- the pump piston 24 is supported with its piston foot 25 on the cam ring 22, wherein the piston 25 is held by a spring 28, which is supported on the one hand on the housing part 10 and the other hand on the piston 25 in contact with the cam ring 22.

- a pump working chamber 30 is limited in the cylinder bore 26 with its front side.

- the pump working space 30 can be connected to a fuel feed channel 34, in which low pressure prevails, by means of an inlet valve 32 which opens into the pump working chamber 30.

- the pump working chamber 30 can also be connected to the accumulator by means of an outlet valve 36 which opens toward the accumulator via a fuel outlet channel 38 extending in the housing part 10.

- the pump piston 24 When the pump piston 24 moves radially inward, it performs a suction stroke, wherein the inlet valve 32 is opened, so that fuel flows into the pump working chamber 30 via the fuel inlet passage 34, while the outlet valve 36 is closed.

- the pump piston 24 moves radially outward, it performs a delivery stroke, wherein the inlet valve 32 is closed and the fuel compressed by the pump piston 24 passes through the open outlet valve 36 under high pressure via the fuel drain passage 38 into the memory.

- a first blind bore 42 adjoins the pump work chamber 30, which is arranged in the end region of the cylinder bore 26 which is radially remote from the drive shaft 12, as part of the fuel feed channel 34.

- the first blind bore 42 has compared to the cylinder bore 26 has a smaller diameter and preferably extends at least approximately coaxial with the cylinder bore 26.

- the first blind bore 42 terminates within the housing part 10.

- the transition from the cylinder bore 26 to the first blind bore 42 is for example at least approximately conical and forms a valve seat 44 for the inlet valve 32.

- the inlet valve 32 has a valve member 46, which is formed for example as a ball, and which cooperates with the valve seat 44 for controlling the connection of the pump chamber 30 with the fuel supply passage 34.

- valve member 46 is acted upon by a prestressed valve spring 48, for example in the form of a helical compression spring, toward the valve seat 44.

- a support member may be arranged in the form of a spring plate.

- the valve spring 48 may be fixedly supported on the housing part 10 or as shown in the figure on the end face of the pump piston 24th

- first blind bore 42 opens as a further part of the fuel inlet channel 34 introduced in the housing part 10 second blind bore 50, which also ends in the housing part 10.

- the second blind bore 50 extends inclined to the first blind bore 42, preferably at least approximately perpendicular to the first blind bore 42 and at least approximately parallel to the rotational axis 13 of the drive shaft 12.

- the second blind bore 50 is introduced from a side facing the flange 11 side surface 52 of the housing part 10.

- the fuel inlet channel 34 is set starting from a side surface 54 the flange 11, wherein on the flange 11, a connection 56 may be provided for a supply line via which fuel is supplied from a fuel tank, for example by a feed pump.

- a sealing element 58 may be clamped.

- the mutually facing side surfaces 52 and 54 of the housing part 10 and the flange 11 extend for example at least approximately perpendicular to the axis of rotation 13 of the drive shaft 12 and may be flat.

- the housing part 10 and the flange 11 are connected to each other in a manner not shown, for example by means of several screws.

- the fuel channel 34 in the housing part 10 forming blind holes 42 and 50 can be introduced in a simple manner from the cylinder bore 26 forth or from the side surface 52 ago in the housing part 10.

- the housing part 10 has no openings for the fuel channel 34 on its outer side.

- For the inlet valve 32 only the valve member 46 and the valve spring 48 and optionally the support element arranged between them are required as additional components.

- a common housing part 10 is provided for a plurality of pump elements 14, in which a corresponding number of the cylinder bores 26 and the blind holes 42 and 50 are introduced.

- a separate housing part 10 is provided for each pump element 14, in each of which only a cylinder bore 26 and a blind bore 42,50 is introduced. The housing parts 10 of the pump elements 14 are then connected together in a suitable manner.

- a bore 60 which is at least approximately perpendicular to the longitudinal axis of the Cylinder bore 26 extends.

- the bore 60 is formed multi-stepped in diameter, with their opening into the pump working chamber 30 end portion has a small diameter.

- a central portion of the bore 60 joins away from the pump working space 30, wherein the transition between the end portion and the central portion may be approximately conical, for example, and forms a valve seat 62 for the outlet valve 36.

- a valve member 64 of the outlet valve 36 for example in the form of a ball, cooperates with the fuel outlet channel 38 for controlling the connection of the pump working chamber 30.

- a screw plug 66 is screwed. Between the plug screw 66 and the valve member 64 is a biased valve spring 68, for example in the form of a helical compression spring, clamped by the valve member 64 is acted upon the valve seat 62 out.

Description

Die Erfindung geht aus von einer Pumpe, insbesondere für eine Kraftstoff einspritzeinrichtung für eine Brennkraftmaschine nach der Gattung des Anspruchs 1.The invention relates to a pump, in particular for a fuel injection device for an internal combustion engine according to the preamble of claim 1.

Eine solche Pumpe ist durch die

Die erfindungsgemäße Pumpe mit den Merkmalen gemäß Anspruch 1 hat demgegenüber den Vorteil, daß diese einfach und kostengünstig herstellbar und montierbar ist, da die Anzahl von deren Einzelteilen reduziert ist.The pump according to the invention with the features of claim 1 has the advantage that it is easy and inexpensive to manufacture and assemble, since the number of their parts is reduced.

In den abhängigen Ansprüchen sind vorteilhafte Ausgestaltungen und Weiterbildungen der erfindungsgemäßen Pumpe angegeben.In the dependent claims advantageous refinements and developments of the pump according to the invention are given.

Ein Ausführungsbeispiel der Erfindung ist in der Zeichnung dargestellt und in der nachfolgenden Beschreibung näher erläutert. Es zeigen

In den

Im Gehäuseteil 12 schließt sich an den in dem der Antriebswelle 12 radial abgewandten Endbereich der Zylinderbohrung 26 angeordneten Pumpenarbeitsraum 30 als Teil des Kraftstoffzulaufkanals 34 eine erste Sackbohrung 42 an. Die erste Sackbohrung 42 weist gegenüber der Zylinderbohrung 26 einen kleineren Durchmesser auf und verläuft vorzugsweise zumindest annähernd koaxial zur Zylinderbohrung 26. Die erste Sackbohrung 42 endet innerhalb des Gehäuseteils 10. Der Übergang von der Zylinderbohrung 26 zur ersten Sackbohrung 42 ist beispielsweise zumindest annähernd konisch ausgebildet und bildet einen Ventilsitz 44 für das Einlassventil 32. Das Einlassventil 32 weist ein Ventilglied 46 auf, das beispielsweise als Kugel ausgebildet ist, und das mit dem Ventilsitz 44 zur Steuerung der Verbindung des Pumpenarbeitsraums 30 mit dem Kraftstoffzulaufkanal 34 zusammenwirkt. Das Ventilglied 46 wird durch eine vorgespannte Ventilfeder 48, beispielsweise in Form einer Schraubendruckfeder, zum Ventilsitz 44 hin beaufschlagt. Zwischen der Ventilfeder 48 und dem Ventilglied 46 kann ein Stützelement in Form eines Federtellers angeordnet sein. Die Ventilfeder 48 kann sich ortsfest am Gehäuseteil 10 abstützen oder wie in der Figur dargestellt an der Stirnseite des Pumpenkolbens 24.In the

In die erste Sackbohrung 42 mündet als weiterer Teil des Kraftstoffzulaufkanals 34 eine im Gehäuseteil 10 eingebrachte zweite Sackbohrung 50, die ebenfalls im Gehäuseteil 10 endet. Die zweite Sackbohrung 50 verläuft geneigt zur ersten Sackbohrung 42, vorzugsweise zumindest annähernd senkrecht zur ersten Sackbohrung 42 und zumindest annähernd parallel zur Drehachse 13 der Antriebswelle 12. Die zweite Sackbohrung 50 ist von einer dem Flanschteil 11 zugewandten Seitenfläche 52 des Gehäuseteils 10 aus eingebracht. Im Flanschteil 11 setzt sich der Kraftstoffzulaufkanal 34 ausgehend von einer Seitenfläche 54 des Flanschteils 11 fort, wobei am Flanschteil 11 ein Anschluss 56 für eine Zulaufleitung vorgesehen sein kann, über die beispielsweise durch eine Förderpumpe Kraftstoff aus einem Kraftstoffvorratsbehälter zugeführt wird. Am Übergang des Kraftstoffkanals 34 zwischen dem Flanschteil 11 und dem Gehäuseteil 10 kann ein Dichtelement 58 eingespannt sein. Die einander zugewandten Seitenflächen 52 und 54 des Gehäuseteils 10 und des Flanschteils 11 verlaufen beispielsweise zumindest annähernd senkrecht zur Drehachse 13 der Antriebswelle 12 und können eben ausgebildet sein. Das Gehäuseteil 10 und das Flanschteil 11 sind in nicht näher dargestellter Weise miteinander verbunden, beispielsweise mittels mehrerer Schrauben.In the first

Die den Kraftstoffkanal 34 im Gehäuseteil 10 bildenden Sackbohrungen 42 und 50 können auf einfache Weise von der Zylinderbohrung 26 her bzw. von der Seitenfläche 52 her in das Gehäuseteil 10 eingebracht werden. Das Gehäuseteil 10 weist dabei für den Kraftstoffkanal 34 an seiner Außenseite keine Öffnungen auf. Für das Einlassventil 32 sind als zusätzliche Bauteile lediglich das Ventilglied 46 und die Ventilfeder 48 sowie gegebenenfalls das zwischen diesen angeordnete Stützelement erforderlich. Es kann vorgesehen sein, dass für mehrere Pumpenelemente 14 ein gemeinsames Gehäuseteil 10 vorgesehen ist, in dem in entsprechender Anzahl die Zylinderbohrungen 26 sowie die Sackbohrungen 42 und 50 eingebracht sind. Alternativ kann auch vorgesehen sein, dass für jedes Pumpenelement 14 ein separates Gehäuseteil 10 vorgesehen ist, in dem jeweils nur eine Zylinderbohrung 26 sowie eine Sackbohrung 42,50 eingebracht ist. Die Gehäuseteile 10 der Pumpenelemente 14 sind dann in geeigneter Weise miteinander verbunden.The

Als Teil des Kraftstoffablaufkanals 38 mündet in den Pumpenarbeitsraum 30 in der Zylinderbohrung 26 eine Bohrung 60, die zumindest annähernd senkrecht zur Längsachse der Zylinderbohrung 26 verläuft. Die Bohrung 60 ist im Durchmesser mehrfach gestuft ausgebildet, wobei deren in den Pumpenarbeitsraum 30 mündender Endabschnitt einen kleinen Durchmessser aufweist. An den Endabschnitt schließt sich vom Pumpenarbeitsraum 30 weg ein mittlerer Abschnitt der Bohrung 60 an, wobei der Übergang zwischen dem Endabschnitt und dem mittleren Abschnitt beispielsweise etwa konisch ausgebildet sein kann und einen Ventilsitz 62 für das Auslassventil 36 bildet. Mit dem Ventilsitz 62 wirkt ein Ventilglied 64 des Auslassventils 36, beispielsweise in Form einer Kugel, zur Steuerung der Verbindung des Pumpenarbeitsraums 30 mit dem Kraftstoffablaufkanal 38 zusammen. In einen im Durchmesser gegenüber dem mittleren Abschnitt weiter vergrößerten und mit einem Innengewinde versehenen äußeren Abschnitt der Bohrung 60 ist eine Verschlußschraube 66 eingeschraubt. Zwischen der Verschlußschraube 66 und dem Ventilglied 64 ist eine vorgespannte Ventilfeder 68, beispielsweise in Form einer Schraubendruckfeder, eingespannt, durch die das Ventilglied 64 zum Ventilsitz 62 hin beaufschlagt ist.As part of the

Claims (7)

- Pump, in particular for a fuel injection device for an internal combustion engine, having at least one pump element (14) which has a pump piston (24) which is guided sealingly in a cylinder bore (26) of a housing part (10), delimits a pump working chamber (30) in the cylinder bore (26) and is driven in a reciprocating movement, the pump working chamber (30) having a connection to a feed channel (34), which connection is controlled by an inlet valve (32) which opens into the pump working chamber (30), and a connection to an outflow channel (38), which connection is controlled by an outlet valve (36) which opens out of the pump working chamber (30), the inlet valve (32) having a valve element (46) which interacts with a valve seat (44) and is loaded in a closing direction towards the valve seat (44) by a valve spring (48), characterized in that the feed channel (34) in the housing part (10) has a part which adjoins the pump working chamber (30) in the cylinder bore (26) in the form of a first blind bore (42) with a smaller diameter than the cylinder bore (26), in that the valve seat (44) is formed at the transition from the cylinder bore (26) to the first blind bore (42), and in that a second blind bore (50) opens into the first blind bore (42) as a further part of the feed channel (34).

- Pump according to Claim 1, characterized in that the first blind bore (42) extends at least approximately coaxially with respect to the cylinder bore (26).

- Pump according to Claim 1 or 2, characterized in that the second blind bore (50) extends in the housing part (10) in an inclined manner with respect to the first blind bore (42).

- Pump according to Claim 3, characterized in that the second blind bore (50) extends at least approximately perpendicularly with respect to the first blind bore (42).

- Pump according to one of Claims 1 to 4, characterized in that the second blind bore (50) starts from a side face (52) of the housing part (10), which side face (52) is adjoined by a further housing part (11).

- Pump according to one of the preceding claims, characterized in that a drive shaft (12) for driving the at least one pump element (14) is mounted rotatably in the housing part (10), in that the cylinder bore (26) and the first blind bore (42) extend at least approximately radially with respect to the rotational axis (13) of the drive shaft (12), and in that the second blind bore (50) extends at least approximately parallel to the rotational axis (13) of the drive shaft (12).

- Pump according to one of the preceding claims, characterized in that a separate housing part (10) is provided for in each case one pump element (14), in which separate housing part (10) the cylinder bore (26), the first blind bore (42), the valve seat (44) and the second blind bore (50) for the pump element (14) are made.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10239728A DE10239728A1 (en) | 2002-08-29 | 2002-08-29 | Pump, in particular for a fuel injection device for an internal combustion engine |

| DE10239728 | 2002-08-29 | ||

| PCT/DE2003/000383 WO2004022975A1 (en) | 2002-08-29 | 2003-02-11 | Pump, especially for a fuel injection device for an internal combustion engine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1537334A1 EP1537334A1 (en) | 2005-06-08 |

| EP1537334B1 true EP1537334B1 (en) | 2010-10-13 |

Family

ID=31502103

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03739364A Expired - Lifetime EP1537334B1 (en) | 2002-08-29 | 2003-02-11 | Pump, especially for a fuel injection device for an internal combustion engine |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US7210463B2 (en) |

| EP (1) | EP1537334B1 (en) |

| JP (1) | JP4309840B2 (en) |

| DE (2) | DE10239728A1 (en) |

| WO (1) | WO2004022975A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004028999A1 (en) * | 2004-06-16 | 2006-01-05 | Robert Bosch Gmbh | High-pressure pump for a fuel injection device of an internal combustion engine |

| EP1813844A1 (en) * | 2006-01-31 | 2007-08-01 | Centro Studi Componenti per Veicoli S.P.A. | High-pressure piston pump for delivering fuel to a common rail of an internal combustion engine |

| DE102008043217A1 (en) * | 2008-10-28 | 2010-04-29 | Robert Bosch Gmbh | High-pressure fuel pump for an internal combustion engine |

| US20130017107A1 (en) * | 2011-07-14 | 2013-01-17 | Neo Mechanics Limited | Diesel engine fuel injection pump which pistons are sealed with all metal seal rings |

| ITMI20132109A1 (en) * | 2013-12-17 | 2015-06-18 | Bosch Gmbh Robert | PUMP ASSEMBLY TO SUPPLY FUEL, PREFERABLY GASOIL, TO AN INTERNAL COMBUSTION ENGINE |

| US10012228B2 (en) * | 2014-04-17 | 2018-07-03 | Danfoss Power Solutions Gmbh & Co. Ohg | Variable fluid flow hydraulic pump |

| GB2555599A (en) * | 2016-11-02 | 2018-05-09 | Delphi Int Operations Luxembourg Sarl | Fuel pump |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1218675B (en) * | 1987-08-25 | 1990-04-19 | Weber Srl | RADIAL PUMP PUMP IN PARTICULAR PUMP FOR INJECTION OF FUEL IN DIESEL CYCLE ENGINES |

| IT239879Y1 (en) * | 1996-12-23 | 2001-03-13 | Elasis Sistema Ricerca Fiat | REFINEMENTS TO A PISTON PUMP, IN PARTICULAR TO A RADIAL APISTON PUMP FOR THE FUEL OF AN INTERNAL COMBUSTION ENGINE. |

| DE19801353A1 (en) * | 1998-01-16 | 1999-07-22 | Bosch Gmbh Robert | Radial piston pump providing HP fuel for fuel injection systems of internal combustion engines, especially with common rail injection system |

| DE19848035A1 (en) * | 1998-10-17 | 2000-04-20 | Bosch Gmbh Robert | Radial piston pump for high fuel pressure in IC engines with common-rail injection system has suction valve closure spring supported on pump piston and contained in long piston bore |

| JP4088738B2 (en) * | 1998-12-25 | 2008-05-21 | 株式会社デンソー | Fuel injection pump |

| IT1310755B1 (en) * | 1999-11-30 | 2002-02-22 | Elasis Sistema Ricerca Fiat | HIGH PRESSURE HYDRAULIC PUMP, IN PARTICULAR RUBBER PISTON PUMP FOR THE FUEL OF AN INTERNAL COMBUSTION ENGINE. |

| DE10117600C1 (en) | 2001-04-07 | 2002-08-22 | Bosch Gmbh Robert | High-pressure fuel pump for a fuel system of a direct-injection internal combustion engine, fuel system and internal combustion engine |

| US20040022654A1 (en) * | 2002-08-05 | 2004-02-05 | Takashi Ishida | Piston type small discharge pump |

-

2002

- 2002-08-29 DE DE10239728A patent/DE10239728A1/en not_active Withdrawn

-

2003

- 2003-02-11 EP EP03739364A patent/EP1537334B1/en not_active Expired - Lifetime

- 2003-02-11 WO PCT/DE2003/000383 patent/WO2004022975A1/en active Application Filing

- 2003-02-11 US US10/493,951 patent/US7210463B2/en not_active Expired - Lifetime

- 2003-02-11 JP JP2004533186A patent/JP4309840B2/en not_active Expired - Fee Related

- 2003-02-11 DE DE50313186T patent/DE50313186D1/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| US20050031478A1 (en) | 2005-02-10 |

| DE50313186D1 (en) | 2010-11-25 |

| EP1537334A1 (en) | 2005-06-08 |

| US7210463B2 (en) | 2007-05-01 |

| JP4309840B2 (en) | 2009-08-05 |

| JP2005537425A (en) | 2005-12-08 |

| DE10239728A1 (en) | 2004-03-11 |

| WO2004022975A1 (en) | 2004-03-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2207955B1 (en) | Fuel overflow valve for a fuel injection system, and fuel injection system having a fuel overflow valve | |

| EP1727983B1 (en) | High-pressure pump, in particular for a fuel-injection device in an internal combustion engine | |

| EP2032850B1 (en) | High pressure pump in particular for a fuel injection device on an internal combustion engine | |

| EP2798191B1 (en) | Fuel overflow valve for a fuel injection device, and fuel injection device comprising fuel overflow valve | |

| EP1552145B1 (en) | High pressure pump, especially for a fuel injection device in an internal combustion engine | |

| WO2008138800A1 (en) | Injector with piezo actuator | |

| DE102010031600A1 (en) | High pressure pump i.e. radial piston pump, for fuel injector of combustion engine in motor car, has plug comprising sealing collar located underneath screw thread, where filter element designed as wire is arranged in screw thread | |

| WO2005124153A1 (en) | High-pressure pump for a fuel injection device of an internal combustion engine | |

| EP1357283B1 (en) | Fuel injection system for internal combustion engine | |

| WO2013092968A2 (en) | Pump, in particular a high pressure fuel pump for a fuel injection device | |

| EP1537334B1 (en) | Pump, especially for a fuel injection device for an internal combustion engine | |

| EP1599668B1 (en) | Fuel injection device for an internal combustion engine | |

| EP2331821B1 (en) | High-pressure radial piston pump | |

| WO2004055368A1 (en) | High pressure pump for a fuel injection device for an internal combustion engine | |

| EP1530681B1 (en) | Fuel injection device for an internal combustion engine | |

| DE10139055A1 (en) | Method, computer program, control and / or regulating device and fuel system for an internal combustion engine | |

| EP1736662B1 (en) | Check valve, especially for a high pressure pump of a fuel injection device for an internal combustion engine | |

| WO2003018991A1 (en) | Fuel injection device for an internal combustion engine | |

| EP1759115B1 (en) | High pressure pump for a fuel injection device of an internal combustion engine | |

| EP3061967B1 (en) | Pump, in particular high-pressure fuel pump | |

| DE10355028A1 (en) | High pressure pump especially for vehicle has the piston rod and cam follower made in one piece and spring loaded to press onto the drive cam | |

| DE102022208452A1 (en) | Fuel overflow valve for a high-pressure fuel pump | |

| DE10139545A1 (en) | Fuel injection device for an internal combustion engine | |

| DE102009001465A1 (en) | Injection pump for supplying diesel to diesel engine of motor vehicle, has control chamber and control piston limited on side turned towards pump chamber, where pressure caused in control chamber supports spring effect | |

| WO2013037543A1 (en) | Pump, in particular a high-pressure fuel pump |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050329 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT SE SI SK TR |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): BG CH CY CZ DE FR GB LI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): DE FR GB |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REF | Corresponds to: |

Ref document number: 50313186 Country of ref document: DE Date of ref document: 20101125 Kind code of ref document: P |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20110714 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 50313186 Country of ref document: DE Effective date: 20110714 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20150223 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160211 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180426 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190221 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50313186 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190903 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200229 |