EP1536049A1 - Zahnstangeneinstellrad für Rundstrickmaschinen - Google Patents

Zahnstangeneinstellrad für Rundstrickmaschinen Download PDFInfo

- Publication number

- EP1536049A1 EP1536049A1 EP04001387A EP04001387A EP1536049A1 EP 1536049 A1 EP1536049 A1 EP 1536049A1 EP 04001387 A EP04001387 A EP 04001387A EP 04001387 A EP04001387 A EP 04001387A EP 1536049 A1 EP1536049 A1 EP 1536049A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- adjustment wheel

- gear rack

- sliding block

- adjustable sliding

- circular knitting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04B—KNITTING

- D04B15/00—Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind

- D04B15/32—Cam systems or assemblies for operating knitting instruments

- D04B15/327—Cam systems or assemblies for operating knitting instruments for stitch-length regulation

Definitions

- the present invention relates to a gear rack adjustment wheel for circular knitting machines to adjust an adjustable sliding block to a correct position for a smooth and precise knitting operation.

- a conventional cam fine-tuning apparatus includes a straddle dock 11, a sliding block 12 coupled on the straddle dock 11 that has a plurality of cams 16 fastened thereon, a fine-tuning assembly 13 located on the straddle dock 11 that has a screw thread, a retaining member 14 located respectively on an upper edge and a lower edge of the straddle dock 11, and a spring 15 located between the retaining member 14 at the lower edge of the straddle dock 11 and the sliding block 12.

- the fine-tuning assembly 13 has a first sloped surface 131 extending into a trough 121 of the sliding block 12 to be in contact with a second sloped surface 1211 formed on the trough 121.

- the fine-tuning assembly 13 presses the sliding block 12, with the first sloped surface 131 ramming the second sloped surface 1211 so that the sliding block 12 is pushed downwards along the first sliding surface 131.

- the spring 15, located between the retaining member 14 at the lower edge of the straddle dock 11 and the sliding block 12 is in a compressed state. After repeated use elastic fatigue or fatigue failure occurs, i.e. the elasticity weakens or disappears altogether. As a result, the sliding block 12 cannot return to its original position. Therefore, the circular knitting machine cannot operate properly and fails to knit correctly. Moreover, the service life of the spring 15 is limited and often requires replacement. Repairing a knitting machine is both costly and time consuming. Replacing parts not only increases overheads, while the machine is out of commission throughput is decreased.

- the present invention aims at providing an improved fine-tuning mechanism that can precisely adjust the sliding block to the correct position, thus enabling the circular knitting machine to achieve a smooth and precise knitting operation.

- the primary object of the invention is to solve the aforesaid disadvantages.

- the invention includes an adjustable sliding block which has a gear rack and an adjustment wheel containing a screw thread.

- the screw thread couples to the gear rack so that the adjustable sliding block can slide along the track of the adjustment wheel. Thereby the sliding block can be adjusted to the correct position to achieve a smooth and precise knitting operation.

- the gear rack adjustment wheel includes a holding deck located on a circular knitting machine, an adjustable sliding block slides along the bottom of the holding deck which has a gear rack formed on a lateral side, a sliding trough in the holding deck to communicate with the adjustable sliding block, an aperture formed on one side of the holding deck, and an adjustment mechanism which includes an adjustment wheel and an anchor pin for the adjustment wheel.

- the adjustment wheel is housed in the sliding trough which communicates with the adjustable sliding block so that the adjustment wheel can be in contact with the adjustable sliding block and adjust the adjustable sliding block.

- the adjustment wheel has a screw thread which may be coupled with the gear rack of the adjustable sliding block, a nut which has a scale to indicate the adjustment degree, and an annular ring spaced from the nut to form a gap to be wedged by the anchor pin to anchor the adjustment wheel at a desired position.

- the anchor pin is housed in the aperture in the holding deck.

- the relative position of the gear rack of the adjustable sliding block and screw track of the adjustment wheel may be altered, and the position of the adjustable sliding block may be adjusted.

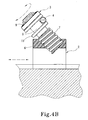

- the gear rack adjustment wheel for circular knitting machines includes a holding deck 1, an adjustable sliding block 2, slides in a sliding track 52 formed at the bottom of the holding deck 1 that has a gear rack 6 formed on a lateral side thereof, and an adjustment mechanism which includes an adjustment wheel 3 with a screw thread 7 formed thereon and an anchor pin 4 for the adjustment wheel.

- the holding deck 1 has a sliding trough 5 which reaches the adjustable sliding block 2 so that the adjustment wheel 3 can be in contact with the adjustable sliding block 2.

- the holding deck 1 further has an aperture 51 to receive an anchor pin 4 to anchor the adjustment wheel 3.

- the adjustment wheel 3 includes a screw thread 7 to couple with the gear rack 6, an annular ring 10 located on an extension of the screw thread 7, a nut 8 with a scale formed thereon, and a gap 9 formed between the nut 8 and the annular ring 10 to receive the anchor pin 4 which has one end exposed through the aperture 51 of the holding deck 1.

- FIG. 3 for the invention mounting on a circular knitting machine.

- the track of the screw thread 7 corresponds to the gear rack 6.

- Turning the adjustment wheel 3, allows the adjustable sliding block 2 to move on the sliding track 52.

- the scale on the adjustment wheel 3 and the other adjustment wheels 3 allows the other adjustable sliding blocks 2 to be moved to the same position. Therefore the operation of the circular knitting machine is more smooth and precise.

- the adjustment wheel 3 is housed in the sliding trough 5 of the holding deck 1 to couple with the gear rack 6 of the adjustable sliding block 2.

- the anchor pin 4 runs through the aperture 51 of the holding deck 1 to wedge in the gap 9 between the nut 8 and the annular ring 10 to anchor the adjustment wheel 3 to a selected location in the holding deck 1.

- the screw thread 7 also turns to drive the corresponding gear rack 6 so that the entire adjustable sliding block 2 can slide along the sliding track 52.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Braiding, Manufacturing Of Bobbin-Net Or Lace, And Manufacturing Of Nets By Knotting (AREA)

- Knitting Machines (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200310117005 | 2003-11-27 | ||

| CN 200310117005 CN1621593A (zh) | 2003-11-27 | 2003-11-27 | 圆编机齿排式调整轮 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP1536049A1 true EP1536049A1 (de) | 2005-06-01 |

Family

ID=34438487

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04001387A Withdrawn EP1536049A1 (de) | 2003-11-27 | 2004-01-22 | Zahnstangeneinstellrad für Rundstrickmaschinen |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1536049A1 (de) |

| CN (1) | CN1621593A (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2034065A1 (de) * | 2007-09-07 | 2009-03-11 | Pai Lung Machinery Mill Co. Ltd. | Vorrichtung zur Anpassung der Garnschleifendichte bei Rundstrickmaschinen |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104452088A (zh) * | 2014-12-19 | 2015-03-25 | 张家港润山针织机械有限公司 | 多功能码座 |

| CN113802259B (zh) * | 2021-07-15 | 2023-07-07 | 泉州精镁科技有限公司 | 一种用于圆形纬编机下圈三角的打表装置及打表方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE865503C (de) * | 1950-03-06 | 1953-02-02 | Aroldo Chiti | Vorrichtung zur Einstellung der Nadelsenker an Strickmaschinenschloessern |

| DE2425084A1 (de) * | 1974-05-24 | 1975-12-04 | Harry Apprich | Vorrichtung zum einstellen der steuernocken an strickmaschinen |

-

2003

- 2003-11-27 CN CN 200310117005 patent/CN1621593A/zh active Pending

-

2004

- 2004-01-22 EP EP04001387A patent/EP1536049A1/de not_active Withdrawn

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE865503C (de) * | 1950-03-06 | 1953-02-02 | Aroldo Chiti | Vorrichtung zur Einstellung der Nadelsenker an Strickmaschinenschloessern |

| DE2425084A1 (de) * | 1974-05-24 | 1975-12-04 | Harry Apprich | Vorrichtung zum einstellen der steuernocken an strickmaschinen |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2034065A1 (de) * | 2007-09-07 | 2009-03-11 | Pai Lung Machinery Mill Co. Ltd. | Vorrichtung zur Anpassung der Garnschleifendichte bei Rundstrickmaschinen |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1621593A (zh) | 2005-06-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6810695B1 (en) | Gear rack adjustment wheel for circular knitting machines | |

| US6962252B2 (en) | Curved belt support apparatus | |

| EP1123766B1 (de) | Werkzeuganlage | |

| EP1536049A1 (de) | Zahnstangeneinstellrad für Rundstrickmaschinen | |

| KR101412334B1 (ko) | 로터리 다이 커터의 칼날 장착대, 그 고정 방법 및 장치 | |

| CN112172328A (zh) | 一种移印机胶头自动更换机构 | |

| JP5109514B2 (ja) | 曲げ成形機の異常検知装置及びその異常検知装置を備えた曲げ成形機 | |

| EP1559820A1 (de) | Vorrichtung zur Schlosseinstellung in einer Rundstrickmaschine | |

| CN109249202B (zh) | 转向自适应定位装置 | |

| US6058987A (en) | Portable wood planing machine with mechanisms for locking and adjusting a carriage | |

| CN1283532C (zh) | 条形部件的传送带 | |

| KR101045779B1 (ko) | 캠 방식을 이용한 케이싱 가공 장치 | |

| JP2005240193A (ja) | 丸編み機のカム調整装置 | |

| KR101567149B1 (ko) | 턴브로치 장치 | |

| KR19990060201A (ko) | 힌지를 이용한 벤딩 장치 | |

| KR930008594B1 (ko) | 피이드 로울장치 | |

| US3755657A (en) | Scanning finger for electromechanical punch card scanner | |

| EP0516182A1 (de) | Vorrichtung zum Verstellen der Neigung von Greifern oder Fingern einer Transfereinrichtung | |

| CN1222410C (zh) | 用于印刷机的墨斗刮刀和具有这样的刮刀的墨斗 | |

| US20050126254A1 (en) | Press action simulator for aerial cam set up | |

| JPH10211521A (ja) | 板材折曲機の型幅調整装置 | |

| KR200418688Y1 (ko) | 터미널의 바렐성형장치 | |

| JPH09156849A (ja) | 乗かごガイドシュー装置の交換治具 | |

| US2686993A (en) | Generating apparatus | |

| EP3603973A1 (de) | Farbkastenvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050928 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 18W | Application withdrawn |

Effective date: 20060111 |