EP1524185A2 - Paquebot de navigation intérieure - Google Patents

Paquebot de navigation intérieure Download PDFInfo

- Publication number

- EP1524185A2 EP1524185A2 EP04024098A EP04024098A EP1524185A2 EP 1524185 A2 EP1524185 A2 EP 1524185A2 EP 04024098 A EP04024098 A EP 04024098A EP 04024098 A EP04024098 A EP 04024098A EP 1524185 A2 EP1524185 A2 EP 1524185A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- hull

- passenger

- ship

- hulls

- connection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B29/00—Accommodation for crew or passengers not otherwise provided for

- B63B29/02—Cabins or other living spaces; Construction or arrangement thereof

- B63B29/025—Modular or prefabricated cabins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B21/00—Tying-up; Shifting, towing, or pushing equipment; Anchoring

- B63B21/56—Towing or pushing equipment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B35/00—Vessels or similar floating structures specially adapted for specific purposes and not otherwise provided for

- B63B35/66—Tugs

- B63B35/665—Floating propeller units, i.e. a motor and propeller unit mounted in a floating box

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B35/00—Vessels or similar floating structures specially adapted for specific purposes and not otherwise provided for

- B63B35/66—Tugs

- B63B35/70—Tugs for pushing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H25/00—Steering; Slowing-down otherwise than by use of propulsive elements; Dynamic anchoring, i.e. positioning vessels by means of main or auxiliary propulsive elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B21/00—Tying-up; Shifting, towing, or pushing equipment; Anchoring

- B63B21/56—Towing or pushing equipment

- B63B2021/563—Pushing equipment

Definitions

- the invention relates to an inland passenger ship with an arrangement of passenger sleeping cabins for the accommodation of passengers.

- the object of the invention is therefore to show a way, as one for inland waterway trips provided passenger ship, which is an arrangement of passenger cabins has, with relatively little effort, but nevertheless high requirements becoming, can be made.

- each buoyant hull comprises a rear of this hull is provided with a motor drive unit for driving the ship and the passenger cabins are arranged on the front of the hull and that the two hulls shudder through a connection assembly, in particular also tensile strength connected to each other.

- the passenger-hull is free of the weight of the drive unit, so that on the front hull (Passenger-hull) acting longitudinal bending moment is drastically reduced.

- This allows a much simplified, less rigid and complex hull construction for the passenger-hull, and even at great length of the same. This reduces the costs.

- Even with the drive hull comes with the problem strong bending stress hardly or at least not to a significant extent be calculated because it is running much shorter than the passenger hull can.

- the rear hull will suitably be a fuel tank assembly for receiving fuel for the drive unit. Then it is also recommended to have at least one ballast water tank in the rear hull to dispose of ballast water, so that the weight loss by consumed Fuel through discharge of ballast water into the ballast water tank can be compensated.

- the ballast water tank in one direction considered transversely to the ship's longitudinal direction substantially adjacent to a fuel tank the fuel tank assembly is arranged, such as laterally beside or above or below.

- a level floating position of the front hull is encouraged by that a water tank assembly housed in the front hull when viewed in the ship's longitudinal direction at least approximately symmetrical with respect to a Displacement center of gravity of the front hull is arranged. If the Front hull at least one fresh water tank for receiving drinking water has, it is convenient, this fresh water tank at least approximately in the area of a center of gravity of the front hull, because so a changing level of water in the fresh water tank no Has an effect on the floating position of the front hull. As a further measure to achieve a level floating position of the front hull can the front hull at least one water tank, in particular ballast water tank, in a stern or / and bow end of this hull exhibit.

- the ship according to the invention is preferably not only the drive unit housed on the rear hull, but also at least one boiler for hot water production or / and at least one electric generator or / and at least one refrigeration compressor of an air conditioner.

- the accommodation all These components on the rear hull and the separate arrangement the passenger cabins on the front hull has as advantageous Effect that the noise pollution of passengers by such aggregates and the odor nuisance be kept low by the exhaust gases of the drive unit can. Also vibrations that are caused by single of these aggregates can be so kept away from the passenger hull, so that Overall, an increased travel comfort stops.

- connection of the two hulls in the ship's longitudinal direction or / and in horizontal ship's transverse direction by spring means or / and elastomeric agent has induced elasticity.

- connection the two hull serving mechanical connection components at least partially covered with a layer of a rubber elastic material be or consist of such a material.

- connection arrangement may be the two hulls connect with each other in an articulated way.

- the two hulls can be relative to each other about a substantially vertical vertical axis and / or in the significant horizontal longitudinal axis and / or a substantially horizontal Transverse axis pivotally connected to each other.

- Stellstoff can thereby a targeted adjustment of the two hulls relative to each other by at least allow a pivot axis in a desired relative pivoting position.

- connection arrangement may be the two Connecting hull swivel together.

- the draft of the front hull may be change more or less.

- one the hull, in particular the rear hull can thereby at least have a vertical guide shaft in which one of the power transmission between the two hulls participating connection component of the connection arrangement is guided vertically movable.

- connection component in the guide shaft

- wearing the connection component preferred a sliding body assembly which is in sliding engagement with walls or slideways of the Guide shaft stands.

- an adjustment arrangement by means of which the relevant parts of the slider assembly in the ship's longitudinal direction o-der / and in horizontal ship's transverse direction relative to the connection component are adjustable. By actuation of the adjusting arrangement, the Gleitoasaan ever be adjusted so that any unwanted movement between the game is switched off both hulls.

- connection arrangement may further comprise at least one of the power transmission between the two hulls not participating connecting fuse element comprise, when intact, a solution of the connection of the two hulls prevented and allowed in the destroyed state, a solution of the compound.

- a particularly cost-effective construction provides that the passenger cabins of pre-assembled containers are formed.

- the containers can at least partially be arranged in at least two levels one above the other.

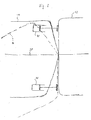

- the inland passenger ship shown in Figure 1 is off a total of two in the longitudinal direction of the ship successively arranged hulls 12, 14 assembled. Each of these hulls 12, 14 is made separately and forms a self-buoyant unit. In a connection area 16, the two hulls 12, 14 are connected together. In the embodiment 1, the rear hull 14 serves as a driving hull, while the front hull 12 is non-powered and from the rear hull Hull 14 is pushed. The connection between the two hulls 12, 14 is therefore an at least push-resistant.

- the front hull 12 is the one on which the passengers of the ship 10 are accommodated become. For this he is equipped with an arrangement of passenger cabins 18, in which the passengers can stay overnight. In the shown Embodiment, the passenger cabins 18 on two superposed planes distributed. It is understood that alternatively passenger cabins 18 only in a single Plane can be arranged or distributed on more than two levels. Preferably, all passenger cabins 18 of the ship 10 are on the front Hull 12 is arranged so that all passengers on the front hull 12 can spend the night. However, it is not in principle within the scope of the invention excluded, if necessary, a small part of the passenger cabins 18 also on to arrange the rear hull 14. What that needed to operate the ship 10 As far as ship's personnel are concerned, one or more cabins may be used for the Ship personnel on the front hull 12 or / and on the rear Hull 14 may be provided.

- the rear hull 14 forms the propulsion and control part of the ship 10. It is For this purpose with a dashed line in Figure 2 only indicated motor drive unit 20 equipped, which in a schematically indicated engine room 22nd is housed.

- the drive unit 20 drives at least one also at the rear Hull 14 mounted propulsion element 24 in the form of a propeller.

- the rear hull 14 is designed with a control station 26, from which a skipper can control the ride and operation of the ship 10. additionally are essentially all for the production of electricity and hot water Aggregates and any compressors of an air conditioner of the ship on the propulsion hull 14 housed.

- the arrangement of the passenger cabins 18 on the one hand and the drive unit 20 and the at least one propulsion element 24 on the other hand on separate hulls has the advantage that sound and vibration generated by the Drive unit 20 and the drive element 24 are caused in substantially to a lesser degree than conventional single-hull passenger ships Cabins 18 are transmitted. This allows any sound insulation measures and within the cabins 18 less expensive or possibly completely eliminated, which reduces the overall cost of producing the ship.

- FIGS. 1 and 2 clearly show that the passenger hull 12 is essential is longer than the drive hull 14.

- the passenger hull may 12 extend over much of the overall length of the ship 10.

- the passenger-hull 12th no special counterweights to compensate for the trim weight of the drive unit 20. It can therefore be over the entire length of the passenger hull 12 a high uniformity of the weight distribution can be achieved. This is beneficial to bending stresses of the passenger hull 12 by a horizontal transverse axis to keep low.

- Correspondingly lower requirements regarding Stability and flexural strength must then be considered in the design of the passenger hull 12 are met.

- the comparatively short length of the drive hull 14 leaves such bending stresses anyway only to a much lesser extent, namely even if the drive unit 14 comparatively far from the displacement center of gravity of the drive hull 14 is removed.

- Each of the hulls 12, 14 is designed to be essentially one has flat swimming position.

- Such a level swimming position can in particular be promoted by suitable arrangement of water tanks.

- the arrangement of fresh water tanks, the supply serve the passengers and the ship's staff with fresh water.

- the water level In such freshwater tanks will naturally during a cruise change if the water contained in the fresh water tanks gradually consumes becomes.

- This consumption of fresh water should advantageously no or have only insignificant influence on the trim position of the hull concerned.

- Two in Figure 2 schematically indicated fresh water tanks 28 on the passenger hull 12 are in the area of one for this purpose Displacement center of gravity 30 of the passenger hull 12 side by side arranged.

- a level floating position of the passenger hull 12 can also be favored be that at appropriate locations along the passenger hull 12 Ballastwassertanks arranged to serve with ballast purposes alone Ballast water can be filled.

- Ballast water tanks are in the Longitudinal ends of the passenger-hull 12 at 32 indicated schematically. you recognizes that two ballast water tanks 32 arranged side by side are. It goes without saying that at each longitudinal end of the passenger hull 12 only one ballast water tank 32 or more than two ballast water tanks 32 may be present. The same applies to the fresh water tanks 28.

- the Ballast water tank 32 in the passenger hull 12 may also serve to variable amount of drinking water in the fresh water tanks 28 to compensate, so that the hull 12 in question regardless of water consumption at a constant Draft can be kept. This can be for example with regard to the crossing of bridges by ship 10 will be significant.

- the trim weight of the Drive unit 20 by a suitable arrangement of one or more fuel tanks be compensated, in which fuel for the drive unit 20 is located.

- the drive unit 20 is the arranged in a rear area of the drive hull 14.

- the trim weight of the drive unit 20 is compensated by the fuel, which is divided into two located on the bow side fuel tanks 34 is located.

- the drive hull contains 14 two ballast water tanks 36, in which ballast water was added can be.

- the ballast water tank 36 of the consumed by Fuel resulting weight loss can be compensated. This way you can ensure that the drive hull 14 always on a level keel swims.

- the two fuel tanks 34 and the two Ballast water tanks 36 each only one such tank or more than two such tanks be provided.

- connection between the two hulls 12, 14 can be horizontal or rigid be agile.

- a hinge allows pivoting of the hull 12, 14 relative to each other about at least one axis.

- the joint connection be constructed so that the hulls 12, 14 by two or even around three mutually orthogonal axes can be pivoted relative to each other.

- the passenger ship 10 When the hulls 12, 14 relative to each other about a substantially vertical Vertical axis can be pivoted, the passenger ship 10 is enabled, to drive closer river curvatures. Conversely, such a flexibility allows of the ship 10 for a given river curvature a larger ship length than in known, einrümpfigen ships. This extra length of ship allows the Housing additional passenger cabins 18, reflecting the economy of the ship elevated.

- a pivotability of the two hulls 12, 14 relative to each other around a substantially horizontal longitudinal axis and / or about a substantially horizontal Transverse axis also allows a mutual dimming (longitudinal inclination) or a mutual Krlinden (bank) of the hulls 12, 14 in Sequence of wave movements of the water, on which the ship 10 drives. Conditional wave Demands on the ship 10 are kept so low.

- FIG. 1 With a solid line there is a position of the drive hull 14 in which it is substantially unwound to the passenger hull 12, i. aligned straight to this is.

- An exemplary pivoted position of the drive hull 14 is, however drawn with dashed lines. In this pivotal position is the drive hull 14 about a vertical vertical axis (a normal to the sheet plane Axis) pivoted relative to the passenger-hull 12.

- a vertical vertical axis a normal to the sheet plane Axis

- the Stellaktuatoren 40 are arranged approximately in the same horizontal plane and allow the drive hull 14 relative to the passenger hull 12th laterally swing out to a desired angle and in the set angular position to keep.

- the mechanical coupling of the Stellaktuatoren 40 with the two Hulls 12, 14 can be such that any mobility of the Hull 12, 14 relative to each other about a horizontal longitudinal axis and / or a horizontal transverse axis is not affected, i. mutual trim and trim Krcardterrorismen the hull 12, 14 are possible.

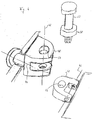

- FIG. 4 shows an exemplary structural design of a connecting joint, the relative movements of the hulls 12, 14 by three mutually orthogonal Axles allowed, specifically around a vertical vertical axis 42, a horizontal Longitudinal axis 44 and a horizontal transverse axis 46.

- This connecting joint comprises in the embodiment shown in Figure 4 a on one of the hull,

- the drive hull 14, about the horizontal longitudinal axis 44th rotatably mounted jaw 48, between the jaws one on the other Hull, such as the passenger hull 12 to the horizontal Transverse axis 46 pivotally mounted counterpart 50 is inserted.

- a safety bolt 52 allows mutual locking of the jaw piece 48 and the counterpart 50.

- the securing bolt 52 in openings 54, 56 of the jaw 48 and the counterpart 50 and inserted at its through the openings 54, 56th performed, free end secured by a securing member, such as a on this free end screwed nut 58.

- the bolt 52 ensures a thrust and tensile strength, but relatively movable around the vertical vertical axis 42 Connection of the two joint components 48, 50. It is understood that the in FIG 4 is merely exemplary. Various other joint structures are conceivable, the relative pivoting of the hull 12, 14 to allow one or more axes.

- At least the lowest container 64 are under the interposition of rubber buffers 66 on the main deck 62, so for a vibrational decoupling the container 64 from the hull of the passenger hull 12 to provide. Similar Rubber bumpers can also be placed between the containers of 64 superimposed levels be arranged, but are not shown in Figure 5.

- the frame structure 60 will be mounted on the main deck 62, before the containers 64 are lowered from above into the compartments 63. After this All containers 64 are discontinued, one or more plate parts 68 (in Figure 5 is only one schematically indicated) from above the frame structure 60 is placed and attached to this. The plate parts 68 can be used to form a Serve outer decks of the ship 10.

- Rubber-elastic materials or spring elements can also be advantageous in the Components of the connection between the two hulls 12, 14 for use come.

- the surfaces of the jaw piece 48, the counterpart 50 and the bolt 52 at least be partially covered with a rubber layer, so that the vibration transmission from the drive hull 14 to the passenger hull 12 further reduced becomes.

- Figure 6 shows an embodiment of a horizontally rigid connection between the hulls of a passenger ship according to the invention.

- the reference numerals in Figure 6 are each supplemented by a lower case, with the same or equivalent components as in the preceding figures, the same reference numerals are used.

- Under a horizontally rigid connection is the embodiment 6 shows a pivotable in a horizontal plane immovable connection of the two hulls 12a, 14a understood, but where in the vertical direction, a mobility of the hull relative to each other given is.

- the representation of Figure 6 is a top plan view, so that the vertical Direction perpendicular to the leaf level.

- each connection unit 70a includes a Coupling body 72, which may for example be designed as a hollow profile element.

- the coupling body 72a is in the ship's longitudinal direction, in the horizontal transverse direction of the ship and also firmly held on the passenger hull 12a in the vertical direction.

- he may, for example, in a not shown in Figure 6, according to Inserted in the top open receptacle, in which he by one or more safety bars or plates 74a against upward movement out of the receptacle is secured.

- the securing bracket 74a can, for example, by means of schematically indicated Screws 76a be fastened. By loosening the screws 76 a can the securing bracket 74 a removed and the coupling body 72 a from its associated Pickup be removed in the passenger hull 12a. On In this way, the connection of the two hulls 12a, 14a can be separated.

- the coupling body 72a projects into a vertical one Shaft 78a into it, in which the coupling body 72a is guided vertically movable.

- On the walls of the well 78a is an array of slideway members 80a provided with which held on the coupling body 72 sliding body or - shoes 82a are in sliding contact.

- the sliding shoes 82a are via spring elements 84a coupled to the coupling body 72a, so that in a horizontal direction Although a total of rigid, but a certain elasticity offering compound of Hull 12a, 14a results. This elasticity of the compound dampens vibrations, otherwise from the propulsion hull 14a to the passenger hull 12a would transfer.

- first adjusting unit 86a and a in horizontal transverse direction acting second adjustment unit 88a can be a whopping, play-free system of the sliding blocks 82a set on the Gleitbahn instituten 80a become.

- suitable adjustment of the adjusting units 86a, 88a a desired spring stiffness of the connection between the hulls 12a, 14a be effected.

- the adjustment unit 86a the distance between the two left-sided in this figure Sliders 82a and the clutch body 72a to adjust while it is the adjustment 88a allows the distance between the upper shoe in this figure 82a and the coupling body 72a to adjust.

- the adjusting units 86a, 88a may have two opposing jaws or plates, between which one or more adjustable adjusting elements are arranged, which determine the mutual distance of the jaws or plates.

- the adjusting elements can for example be adjusted in the direction of its axis cone or Be formed cone bodies.

- connection unit 70a further includes at least one connection fuse element 90a, which is installed so that only after its destruction one Separation of the connection is possible.

- the connection securing element 90a takes not at the power transmission between the hulls 12a, 14a part.

- it may be formed by a wire loop, which by not shown Holes in one of the screws 76a and the securing bracket 74a threaded through.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Ocean & Marine Engineering (AREA)

- Vehicle Step Arrangements And Article Storage (AREA)

- Vibration Prevention Devices (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04024098A EP1524185A3 (fr) | 2003-10-13 | 2004-10-08 | Paquebot de navigation intérieure |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03023204 | 2003-10-13 | ||

| EP03023204A EP1524184A1 (fr) | 2003-10-13 | 2003-10-13 | Paquebot de navigation intérieure |

| EP04024098A EP1524185A3 (fr) | 2003-10-13 | 2004-10-08 | Paquebot de navigation intérieure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1524185A2 true EP1524185A2 (fr) | 2005-04-20 |

| EP1524185A3 EP1524185A3 (fr) | 2005-06-22 |

Family

ID=34379370

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04024098A Ceased EP1524185A3 (fr) | 2003-10-13 | 2004-10-08 | Paquebot de navigation intérieure |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1524185A3 (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NO342733B1 (en) * | 2017-06-09 | 2018-08-06 | Kmg Tech | Connecting arrangement for attaching first and second vessel |

| CN110271647A (zh) * | 2019-08-01 | 2019-09-24 | 蚌埠市神舟机械有限公司 | 一种舟桥汽艇旁带装置 |

| CN116142382A (zh) * | 2023-02-28 | 2023-05-23 | 深海技术科学太湖实验室 | 非自航海洋浮式平台运输用动力浮箱装置及作业方法 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003047960A1 (fr) * | 2001-12-05 | 2003-06-12 | Kaefer Isoliertechnik Gmbh & Co Kg | Zone d'habitation conçue en particulier pour la zone offshore, bateau pourvu d'une telle zone d'habitation et procede de production d'une zone d'habitation |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3035537A (en) * | 1959-09-22 | 1962-05-22 | Smith Walter James | Steering connection between a barge and a pusher tug |

| FR2114187A5 (fr) * | 1970-11-19 | 1972-06-30 | Dulieu Raoul | |

| DD97817A3 (fr) * | 1971-08-04 | 1973-05-21 | ||

| NL7304543A (fr) * | 1972-04-15 | 1973-10-17 | ||

| US3964418A (en) * | 1974-03-06 | 1976-06-22 | Karnik Stanley D | Floating campground |

| ZA755386B (en) * | 1975-08-22 | 1977-04-27 | Rytac Ltd | A coupling device |

| US4066030A (en) * | 1976-03-01 | 1978-01-03 | Louis Milone | Mechanical coupling for marine vehicles |

| FI62984C (fi) * | 1980-10-24 | 1987-02-17 | Waertsilae Oy Ab | System foer hyttelement i fartyg. |

| FR2533193A1 (fr) * | 1982-09-21 | 1984-03-23 | Prestations Interna Exploit | Perfectionnement aux bateaux automobiles pour assurer le poussage et la gouverne de tout train de barges avec une economie optimale |

-

2004

- 2004-10-08 EP EP04024098A patent/EP1524185A3/fr not_active Ceased

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003047960A1 (fr) * | 2001-12-05 | 2003-06-12 | Kaefer Isoliertechnik Gmbh & Co Kg | Zone d'habitation conçue en particulier pour la zone offshore, bateau pourvu d'une telle zone d'habitation et procede de production d'une zone d'habitation |

Non-Patent Citations (2)

| Title |

|---|

| Geschmacksmuster DE-M9605102.7 |

| PLANUNGSGEMEINSCHAFT DEAS: "Baubeschreibung für ein Fluss-Kreuzfahrtschiff", PROJEKT 5630 - DESCRIPTION, vol. VERSION 1, November 1996 (1996-11-01), XP003019548 |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NO342733B1 (en) * | 2017-06-09 | 2018-08-06 | Kmg Tech | Connecting arrangement for attaching first and second vessel |

| NO20170942A1 (en) * | 2017-06-09 | 2018-08-06 | Kmg Tech | Connecting arrangement for attaching first and second vessel |

| CN110271647A (zh) * | 2019-08-01 | 2019-09-24 | 蚌埠市神舟机械有限公司 | 一种舟桥汽艇旁带装置 |

| CN116142382A (zh) * | 2023-02-28 | 2023-05-23 | 深海技术科学太湖实验室 | 非自航海洋浮式平台运输用动力浮箱装置及作业方法 |

| CN116142382B (zh) * | 2023-02-28 | 2024-01-26 | 深海技术科学太湖实验室 | 非自航海洋浮式平台运输用动力浮箱装置及作业方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1524185A3 (fr) | 2005-06-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69218622T2 (de) | Avanciertes seeboot für hohe geschwindigkeiten in oder über grobe see | |

| DE69802283T2 (de) | Schnelles einrumpfschiff mit heckstabilisatoren | |

| DE68909483T2 (de) | Amphibienfahrzeug. | |

| DE102014105883A1 (de) | Wasserfahrzeug | |

| DE2938319A1 (de) | Doppelrumpf-wasserfahrzeug | |

| EP2238015A2 (fr) | Vehicule marin a longueur de coque totale variable | |

| EP1021331B1 (fr) | Bateau multicoque de largeur variable | |

| DE69417575T2 (de) | Boot | |

| AT406143B (de) | Schiffskörper | |

| DE60318115T2 (de) | Flexible schiffe mit oberflächenanpassbaren rümpfen | |

| WO2020041908A1 (fr) | Moteur hors-bord partiellement immergé | |

| EP1524185A2 (fr) | Paquebot de navigation intérieure | |

| DE102010013608B4 (de) | Hausboot | |

| EP1524184A1 (fr) | Paquebot de navigation intérieure | |

| DE29908430U1 (de) | Schnelles seegehendes Schiff | |

| DE2805647A1 (de) | Schiffsrumpf | |

| DE102007021316B3 (de) | Flexibles Ballastgewicht für Segelschiffe | |

| DE10332087B3 (de) | Verfahren zur Herstellung eines Schwimmelements | |

| DE2833095A1 (de) | Schiffsrumpf | |

| DE102011017438A1 (de) | Verfahren und Vorrichtung für die Beseitigung von Schaukelbewegungen bei Schiffen und schwimmenden Arbeitsgeräten auf dem Wasser | |

| DE102012001866B4 (de) | Abstützsystem für Wasserfahrzeuge zum Abstellen auf einem Untergrund | |

| WO2004080792A1 (fr) | Dispositif de commande de proue pour un convoi pousse | |

| DE2363255A1 (de) | Wasserfahrzeug, insbesondere fuer sportliche zwecke | |

| DE10336547A1 (de) | SWATH-Boot | |

| DE2207980A1 (de) | Kraftgetriebenes mehrrumpfboot |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050929 |

|

| AKX | Designation fees paid |

Designated state(s): AT DE FR NL |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| 17Q | First examination report despatched |

Effective date: 20080328 |

|

| APBK | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNE |

|

| APBN | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2E |

|

| APBR | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3E |

|

| APAF | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNE |

|

| APBT | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9E |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN REFUSED |

|

| 18R | Application refused |

Effective date: 20141027 |