EP1516545B1 - Machine et procédé pour la fabrication simultanée de plusieurs tiges de cigarette - Google Patents

Machine et procédé pour la fabrication simultanée de plusieurs tiges de cigarette Download PDFInfo

- Publication number

- EP1516545B1 EP1516545B1 EP04090355A EP04090355A EP1516545B1 EP 1516545 B1 EP1516545 B1 EP 1516545B1 EP 04090355 A EP04090355 A EP 04090355A EP 04090355 A EP04090355 A EP 04090355A EP 1516545 B1 EP1516545 B1 EP 1516545B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- continuous

- tobacco

- double

- rod

- rods

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/14—Machines of the continuous-rod type

- A24C5/18—Forming the rod

- A24C5/1835—Multiple rod making devices

Definitions

- the invention relates to a device for producing two tobacco strands, which are guided parallel to each other to form a double strand, from at least one continuously supplied tobacco nonwoven, namely cigarette rod machine with a plurality of processing for a double strand processing elements, essentially comprising a strand conveyor for transporting the the tobacco fleece constructed tobacco strands on two suction belts, separating means for separating the excess tobacco from the tobacco strands, corresponding to each suction belt of the strand conveyor a format strip for forming the tobacco strands, means for feeding cigarette paper on each format tape, gluing means for gluing a respective protruding edge of the order the tobacco rod wrapped cigarette paper, measuring means for determining the weight and / or density of the individual tobacco strands of the double strand and release agent for separating cigar etten of the double strand.

- the invention relates to a method for the production of two tobacco strands, which are performed parallel to each other to form a double strand of at least one continuously supplied tobacco mat, comprising the steps of: transporting the tobacco strands constructed from the tobacco mat on two Saugbändem a strand conveyor in the direction of corresponding format strips Separating the excess tobacco from the tobacco strands prior to forming the tobacco strands, feeding cigarette paper onto the size bands, depositing the tobacco strands on the size bands on the cigarette paper, forming the tobacco strands, simultaneously wrapping the tobacco strands with the cigarette paper, gluing a respective protruding edge otherwise to the tobacco rod wrapped cigarette paper, final closure of the cigarette paper, measuring the weight and / or density of the tobacco strands, and separating cigarettes from the double strand.

- Such devices and methods are commonly used in the tobacco processing industry.

- Said devices are usually part of a production line comprising a distributor for the tobacco, the actual cigarette rod making machine, a transfer unit and a filter attachment machine.

- the cigarette rod machine is supplied from the distributor with a tobacco fleece, a kind of flat tobacco carpet.

- the known and generic cigarette rod making machines are designed for producing a single double strand from a total of two individual strands arranged in pairs, such that the two tobacco strands are produced parallel to each other as a pair with a set of processing elements for processing a double strand. This has the advantage that a more compact design is achieved compared to known cigarette rod making machines in which a plurality of individual and usually with an equal distance juxtaposed tobacco strands are produced.

- a device of the type mentioned in that the device for producing at least two formed from an even number of tobacco rods, formed in pairs double strands, wherein the distance between the two double strands is greater than the distance between the tobacco strands every double strand.

- a particularly compact device is realized in a surprisingly simple manner, which ensures an effective increase in performance.

- the pairwise arrangement of the tobacco strands each to a double strand allows for a particularly dense arrangement of the tobacco strands of a double strand, so that for the processing of two strands (a double strand) only one processing element is necessary.

- the inventive design also allows a dense arrangement of the tobacco strands of adjacent double strands, at the same time sufficient space for the required processing elements for the respective double strand is present.

- Another advantage is that it can be used essentially on known components of a cigarette double-strand machine. This makes it possible in particular to use in a space-saving manner already existing and known (standard) processing elements without further adaptation.

- two double strands are offset in height from each other and arranged side by side. This staggered arrangement ensures a particularly space-saving arrangement of the processing elements, which enables a powerful and very compact device.

- the two double strands are arranged one above the other, which also ensures a space-saving construction of the device.

- the double strands are driven separately from each other, such that the double strands formed from the tobacco strands independently can be produced.

- different cigarette brands can also be produced with different formats on a device.

- the object is achieved by a method with the steps mentioned above in that at least two paired double strands formed from an even number of tobacco rods are produced simultaneously, and the two double strands are guided at a distance from each other which is greater than that Distance between the tobacco strands of a double strand.

- the performance over known methods of the generic type is significantly increased, namely doubled.

- the two double strands are offset in height during processing and guided side by side, so that a particularly cost-effective and space-saving production is possible.

- the same advantages apply to the variant in which the two double strands are superimposed.

- duplexes By driving the duplexes separately in a further embodiment, independent operation or independent production of duplexes in a device is possible, so that e.g. Different formats can be produced simultaneously or with a time delay.

- the device is used for the parallel production of two double strands of tobacco, in which two tobacco strands are arranged in pairs next to each other.

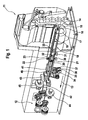

- a device 10 namely the cigarette rod machine with the respective upstream or downstream components shown.

- a manifold 11 On the input side of the device 10 is associated with a manifold 11, which is adapted to supply the device a plurality of streams of tobacco mat, preferably four streams, for further processing.

- an unspecified transfer device 12 Subordinated to the device is an unspecified transfer device 12, which transmits the produced on the device 10 - usually - double-length cigarettes to a downstream processing station, eg a (not shown) Filteransetzmaschine passes.

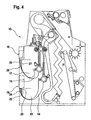

- Each strand conveyor 18, 19 has two suction belts 20, 21; 22, 23, wherein two suction belts 20, 21 and 22, 23 each serve to form a double strand 28, 29 consisting of two tobacco rods 24, 25 and 26, 27 respectively.

- the double strands 28, 29 are arranged side by side and parallel to each other.

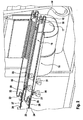

- the double strands 28, 29 are arranged in a vertical direction on different planes, so that they are formed offset in height to each other. In other words, the transport and processing levels of each double strand 28, 29 run at different heights.

- the double strands 28, 29 are arranged directly above one another. This means that e.g. the tobacco rod 24 of the double strand 28 is vertically below the tobacco rod 26 of the double strand 29 and the tobacco rod 25 of the double strand 28 is vertically below the tobacco rod 27 of the double strand 29.

- Each double strand 28, 29 are each assigned identical processing elements for producing the four strands 24 to 27, wherein the processing elements are designed such that they ensure the parallel processing of a double strand 28 and 29 respectively.

- the distance of the double strand 28 from the double strand 29 is at least as large as the distance between individual strands 24, 25 and 26, 27 of a double strand 28, 29, but preferably larger.

- the strand conveyors 18, 19 are formed in the embodiment shown as a circulating, endless belt conveyors such that the tobacco is preferably suspended in the transport direction 13 can be conveyed. Other types of transport, such as lying transport, are possible.

- the tobacco fleece is assigned to each suction belt 20 to 23 to form the respective tobacco rod 24 to 27 in a separate web. Below each suction belt 20 to 23 is a conventional release agent 30, 31, 32, 33 for trimming the tobacco strands 24 to 27, more precisely for separating the excess tobacco arranged.

- a format belt 34, 35, 36, 37 is arranged corresponding to each suction belt 20 to 23, the format belts 34, 35 for the continuation of the double strand 28 and the format strips 36, 37 serve to continue the double strand 29.

- Two format bands 34, 35 and 36, 37 each have a common drive. In the region of the overlap of the suction belts 20 to 23 on the one hand and the format belts 34 to 37 on the other hand, the transfer of the tobacco fleece from the suction belts 20 to 23 on the format tapes 34 to 37.

- the format bands 34 to 37 are arranged in a plane below the suction belts 20 to 23 and also designed as endless circulating belt conveyor.

- the format belts 34 to 37 each run through a (not shown) format for shaping the tobacco strands 24 to 27, namely in particular for the formation of cylindrical tobacco strands 24 to 27.

- In the area of the size bands 34 to 37 are further (not shown) means for feeding cigarette paper on the size bands 34 to 37 and Beleimungs Rhein 38 and 39, which are designed as nozzles, discs or the like for gluing the cigarette paper arranged. Behind the formats are then provided means 40, 41 for heating or drying the glue seams.

- each double strand 28, 29 is assigned a measuring means 42, 43 for weight and / or density determination of the tobacco strands 24 to 27.

- the measuring means 42, 43 are arranged parallel to each other in the embodiment shown, but may also be offset from one another. Behind the measuring means 42, 43 separating means 44 and 45 are arranged before the tobacco strands 24 to 27 of the transfer device 12 are transferred.

- the separating means 44, 45 are each designed to separate double-length cigarettes of a double strand 28, 29.

- more than two double-strand pairs can be arranged side by side and / or vertically offset from one another or else one above the other.

- the device 10 is designed for producing an even number of tobacco strands, wherein the tobacco strands are arranged and guided in pairs.

- the corresponding components, namely the upstream distributor and the downstream transfer device are then designed accordingly.

- all processing elements or functional elements or functions are redundant, namely for each double strand 28, 29, wherein the processing elements, each of which is designed for processing a double strand 28, 29, corresponding to the superimposed double strands 28, 29 are also arranged one above the other.

- the operation of the device 10, which consists in the embodiments shown quasi two sub-devices, namely for each double strand 28, 29 a sub-device, in a common housing, variable.

- the double strands 28, 29 or the respective sub-devices can be driven separately. This can e.g. by assignment of individual drives for each double strand 28, 29 done.

- at least two double strands 28, 29 formed from the tobacco strands 24 to 27 can be produced independently of one another.

- different formats e.g. different tobacco rod lengths and / or tobacco rod diameter, can be produced.

- all double strands 28, 29 or sub-devices are also jointly drivable, e.g. through a superordinate total drive.

- the process for producing two double strands proceeds in principle as follows: Tobacco is fed from the distributor 11 in four streams to the device 10.

- the tobacco is designed as a fleece. Via the fluidized beds 14 to 17, each strand conveyor 18, 19 or each suction belt 20 to 23 of the strand conveyors 18, 19 is fed a uniform part of the fleece, wherein the fleece within the fluidized beds 14 to 17 by a circulating air flow to the underside of the suction belts 20 until 23 is pressed or sucked.

- a circulating air flow to the underside of the suction belts 20 until 23 is pressed or sucked.

- the circumferentially driven suction belts 20 to 23 then transport the tobacco fleece or the tobacco strands 24 to 27 suspended therefrom for further processing, the hanging tobacco strands 24 to 27 being freed of excess tobacco by the separating means 30 to 33.

- the trimmed tobacco strands 24 to 27 are then placed on each placed on the format tape 34 to 37 cigarette paper.

- In this area are the format bands 34 to 37 with the cigarette paper positioned thereon and the suction belts 20 to 23 in synchronism.

- the cigarette paper is withdrawn from a reel, passed through a printing unit and then placed on the respective format tape 34 to 37.

- the format belts 34 to 37 transport each tobacco rod 24 to 27 and the cigarette paper by the format in which the cigarette paper is wound around the strand 24 to 27.

Landscapes

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

Claims (15)

- Dispositif de fabrication de deux boudins de tabac (24, 25) guidés en parallèle l'un à côté de l'autre pour former un double boudin (28), à partir d'au moins une nappe de tabac amenée en continu, à savoir une machine à confectionner des boudins de cigarettes comportant une pluralité d'éléments de traitement conçus pour le traitement d'un double boudin (28), comprenant essentiellement un transporteur de boudin (18) pour le transport sur deux bandes aspirantes (20, 21), des boudins de tabac (24, 25), formés à partir de la nappe de tabac, des moyens de séparation (30, 31) pour séparer l'excédent de tabac des boudins de tabac (24, 25), en correspondance avec chaque bande aspirante (20, 21) du transporteur de boudin (18), une bande de mise au format (34, 35) avec un format pour former les boudins de tabac (24, 25), des moyens d'apport de papier à cigarette sur chaque bande de mise au format (34, 35), des dispositifs d'encollage (38) pour l'encollage d'un bord, se trouvant à l'opposé du papier à cigarette alors enroulé autour du boudin de tabac (24, 25), des moyens de mesure (42) pour déterminer le poids et/ou la densité des boudins de tabac (24, 25) individuels du double boudin (28) ainsi que des moyens de séparation (44) pour séparer les cigarettes du double boudin (28),

caractérisé en ce que le dispositif (10) est réalisé pour la fabrication d'au moins deux doubles boudins (28, 29) formés à partir d'un nombre pair de boudins de tabac (24, 25 ; 26, 27) et disposés par paire, la distance entre les deux doubles boudins (28, 29) étant supérieure à la distance entre les boudins de tabac (24, 25 ; 26, 27) de chaque double boudin (28, 29). - Dispositif selon la revendication 1, caractérisé en ce que deux doubles boudins (28, 29) sont disposés en parallèle l'un par rapport à l'autre.

- Dispositif selon la revendication 1 ou 2, caractérisé en ce que les deux doubles boudins (28, 29) sont disposés en étant décalés en hauteur l'un par rapport à l'autre et à côté l'un de l'autre.

- Dispositif selon la revendication 1 ou 2, caractérisé en ce que les deux doubles boudins (28, 29) sont disposés l'un au-dessus de l'autre.

- Dispositif selon la revendication 4, caractérisé en ce que le boudin de tabac (24) du double boudin (28) est disposé verticalement au-dessous du boudin de tabac (26) du double boudin (29) et en ce que le boudin de tabac (25) du double boudin (28) est disposé verticalement au-dessous du boudin de tabac (27) du double boudin (29).

- Dispositif selon l'une des revendications 1 à 3, caractérisé en ce que tous les éléments de traitement sont présents de façon redondante, les éléments de traitement qui sont respectivement prévus pour le traitement d'un double boudin (28, 29), étant également disposés en étant décalés en hauteur l'un par rapport à l'autre et à côté l'un de l'autre.

- Dispositif selon l'une des revendications 1, 2, 4 et 5, caractérisé en ce que tous les éléments de traitement sont présents de façon redondante, les éléments de traitement qui sont respectivement prévus pour le traitement d'un double boudin (28, 29), étant également disposés l'un au-dessus de l'autre.

- Dispositif selon l'une des revendications 1 à 7, caractérisé en ce que les doubles boudins (28, 29) peuvent être entraînés séparément l'un de l'autre de telle sorte que les doubles boudins (28, 29) formés à partir des boudins de tabac (24, 25 ; 26, 27) peuvent être fabriqués indépendamment l'un de l'autre.

- Procédé de fabrication de deux boudins de tabac (24, 25) sur un dispositif, qui sont guidés en parallèle l'un à côté de l'autre pour former un double boudin (28), à partir d'au moins une nappe de tabac amenée en continu, comprenant les étapes de:- transport des boudins de tabac (24, 25), constitués à partir de l'intissé de tabac, sur deux bandes aspirantes (20, 21), d'un transporteur de boudin (18) en direction des bandes de mise au format (34, 35) correspondantes,- séparation de l'excédent de tabac d'avec les boudins de tabac (24, 25) avant la mise au format des boudins de tabac (24, 25),- apport de papier à cigarette sur les bandes de mise au format (34, 35),- dépôt des boudins de tabac (24, 25) sur les bandes de mise au format (34, 35) ou sur le papier à cigarette,- mise en forme des boudins de tabac (24, 25),- enroulement simultané des boudins de tabac (24, 25) dans le papier à cigarette,- encollage d'un bord, se trouvant à l'opposé du papier à cigarette alors enroulé autour du boudin de tabac (24, 25),- fermeture définitive du papier à cigarette,- mesure du poids et/ou de la densité des boudins de tabac (24, 25) et- séparation des cigarettes d'avec le double boudin (28),caractérisé en ce qu'au moins deux doubles boudins (28, 29) formés à partir d'un nombre pair de boudins de tabac (24, 25 ; 26, 27) et disposés par paire sont fabriqués en même temps sur le dispositif et en ce que les deux doubles boudins (28, 29) sont guidés l'un par rapport à l'autre à une distance qui est supérieure à la distance entre les boudins de tabac (24, 25 ; 26, 27) d'un double boudin (28, 29).

- Procédé selon la revendication 9, caractérisé en ce que deux doubles boudins (28, 29) sont guidés en parallèle l'un par rapport à l'autre.

- Procédé selon la revendication 9 ou 10, caractérisé en ce que, pendant le traitement, les deux doubles boudins (28, 29) sont décalés en hauteur l'un par rapport à l'autre et sont guidés en parallèle à côté l'un de l'autre.

- Procédé selon la revendication 9 ou 10, caractérisé en ce que les deux doubles boudins (28, 29) sont guidés l'un au-dessus de l'autre.

- Procédé selon la revendication 12, caractérisé en ce que le boudin de tabac (24) du double boudin (28) est guidé verticalement au-dessous du boudin de tabac (26) du double boudin (29) et en ce que le boudin de tabac (25) du double boudin (28) est guidé verticalement au-dessous du boudin de tabac (27) du double boudin (29).

- Procédé selon l'une des revendications 9 à 13, caractérisé en ce que chaque double boudin (28, 29) est traité par un jeu séparé d'éléments de traitement prévus pour le traitement d'un double boudin (28, 29).

- Procédé selon l'une des revendications 9 à 14, caractérisé en ce que les doubles boudins (28, 29) sont entraînés séparément.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04090355A EP1516545B1 (fr) | 2003-09-16 | 2004-09-16 | Machine et procédé pour la fabrication simultanée de plusieurs tiges de cigarette |

| PL04090355T PL1516545T3 (pl) | 2003-09-16 | 2004-09-16 | Urządzenie i sposób jednoczesnego wytwarzania kilku pasm papierosów |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03090297 | 2003-09-16 | ||

| EP03090297 | 2003-09-16 | ||

| EP04090024 | 2004-01-24 | ||

| EP04090024 | 2004-01-24 | ||

| EP04090355A EP1516545B1 (fr) | 2003-09-16 | 2004-09-16 | Machine et procédé pour la fabrication simultanée de plusieurs tiges de cigarette |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1516545A1 EP1516545A1 (fr) | 2005-03-23 |

| EP1516545A8 EP1516545A8 (fr) | 2005-06-15 |

| EP1516545B1 true EP1516545B1 (fr) | 2008-07-16 |

Family

ID=34198555

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04090355A Not-in-force EP1516545B1 (fr) | 2003-09-16 | 2004-09-16 | Machine et procédé pour la fabrication simultanée de plusieurs tiges de cigarette |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1516545B1 (fr) |

| PL (1) | PL1516545T3 (fr) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005024645A1 (de) * | 2005-05-25 | 2006-11-30 | Hauni Maschinenbau Ag | Vorrichtung zur Aufbereitung und/oder Herstellung von stabförmigen Gegenständen der tabakverarbeitenden Industrie |

| DE102006009148B9 (de) * | 2006-02-24 | 2010-12-02 | Hauni Maschinenbau Ag | Strömungskörper einer Zigarettenstrangmaschine |

| DE102006031216A1 (de) * | 2006-06-30 | 2008-01-03 | Hauni Maschinenbau Ag | Strömungskörper in einer Strangmaschine der Tabak verarbeitenden Industrie |

| DE102009022757A1 (de) * | 2009-05-26 | 2010-12-02 | Hauni Maschinenbau Ag | Strangmaschine der Tabak verarbeitenden Industrie |

| DE102012102338A1 (de) | 2012-03-20 | 2013-09-26 | Hauni Maschinenbau Ag | Messanordnung zum Messen von in Strangmaschinen der Tabak verarbeitenden Industrie hergestellten und geförderten Strängen |

| DE102012102340A1 (de) | 2012-03-20 | 2013-09-26 | Hauni Maschinenbau Ag | Messanordnung, ausgebildet und eingerichtet zum Messen von in Strangeinheiten der Tabak verarbeitenden Industrie hergestellten Strängen und/oder Strangabschnitten sowie Strangeinheit mit einer solchen Messanordnung |

| DE102012105121A1 (de) | 2012-06-13 | 2013-12-19 | Hauni Maschinenbau Ag | Messmodul und Messanordnung zum Messen von in Strangmaschinen der Tabak verarbeitenden Industrie hergestellten Strängen und/oder Strangabschnitten sowie Strangmaschine mit solchen Messmodulen bzw. einer solchen Messanordnung |

| EP2641489B1 (fr) | 2012-03-20 | 2018-09-26 | Hauni Maschinenbau GmbH | Dispositif de mesure, conçu pour et destiné à la mesure de tiges et/ou de sections de tige fabriquées dans des unités de fabrication de tiges de l'industrie de traitement du tabac ainsi qu'unité de fabrication de tiges dotée d'un tel dispositif de mesure |

| DE102012208450B4 (de) * | 2012-05-21 | 2015-03-26 | Hauni Maschinenbau Ag | Strangformungsvorrichtung und Strangmaschine der Tabak verarbeitenden Industrie |

| DE102012104613A1 (de) * | 2012-05-29 | 2013-12-05 | Hauni Maschinenbau Ag | Anordnung und Verfahren zum Herstellen von Artikelsträngen aus umhülltem Fasermaterial der Tabak verarbeitenden Industrie |

| DE102013222918B3 (de) * | 2013-11-11 | 2015-02-12 | Hauni Maschinenbau Ag | Anordnung und Verfahren zur Herstellung von mit Filtern versehenen stabförmigen Rauchartikeln |

| DE102014107747A1 (de) | 2014-06-03 | 2015-12-03 | Hauni Maschinenbau Ag | Messmodul, Messanordnung und Strangmaschine in der Tabak verarbeitenden Industrie |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4336812A (en) * | 1979-05-22 | 1982-06-29 | G.D. Societa Per Azioni | Machine for simultaneously producing two continuous cigarette rods |

| US4848369A (en) * | 1987-03-28 | 1989-07-18 | Korber Ag | Method of and machine for simultaneously making two or more rods from fibrous material |

| US4858626A (en) * | 1986-12-17 | 1989-08-22 | G.D. Societa' Per Azioni | Method of optimizing the standard weight variation of cigarettes on a dual-rod cigarette manufacturing machine |

| US4889138A (en) * | 1986-06-11 | 1989-12-26 | Korber Ag | Method of and apparatus for simultaneously making plural tobacco streams |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB216868A (en) * | 1923-05-30 | 1925-06-18 | Tescawi Zigaretten Vertriebsge | Multiple continuous rod cigarette machine |

| DE3739874C2 (de) * | 1987-11-25 | 1996-09-05 | Hauni Werke Koerber & Co Kg | Verfahren und Vorrichtung zur Herstellung von Fasersträngen der tabakverarbeitenden Industrie |

| DE3742251A1 (de) * | 1987-12-12 | 1989-06-22 | Hauni Werke Koerber & Co Kg | Strangmaschine zum herstellen eines doppelstrangs der tabakverarbeitenden industrie |

| IT1279993B1 (it) * | 1995-07-27 | 1997-12-23 | Gd Spa | Metodo e macchina per la realizzazione contemporanea di piu' bachi di sigaretta |

| EP1364588B1 (fr) * | 2002-05-21 | 2006-07-12 | Hauni Maschinenbau AG | Dispositif et procédé pour la formation d'au moins deux tiges de tabac dans une machine de fabrication de tige de tabac |

-

2004

- 2004-09-16 PL PL04090355T patent/PL1516545T3/pl unknown

- 2004-09-16 EP EP04090355A patent/EP1516545B1/fr not_active Not-in-force

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4336812A (en) * | 1979-05-22 | 1982-06-29 | G.D. Societa Per Azioni | Machine for simultaneously producing two continuous cigarette rods |

| US4889138A (en) * | 1986-06-11 | 1989-12-26 | Korber Ag | Method of and apparatus for simultaneously making plural tobacco streams |

| US4858626A (en) * | 1986-12-17 | 1989-08-22 | G.D. Societa' Per Azioni | Method of optimizing the standard weight variation of cigarettes on a dual-rod cigarette manufacturing machine |

| US4848369A (en) * | 1987-03-28 | 1989-07-18 | Korber Ag | Method of and machine for simultaneously making two or more rods from fibrous material |

Also Published As

| Publication number | Publication date |

|---|---|

| PL1516545T3 (pl) | 2008-11-28 |

| EP1516545A8 (fr) | 2005-06-15 |

| EP1516545A1 (fr) | 2005-03-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2630614A1 (de) | Verfahren und vorrichtung zur herstellung strangartiger gegenstaende in der tabakindustrie | |

| EP1516545B1 (fr) | Machine et procédé pour la fabrication simultanée de plusieurs tiges de cigarette | |

| EP2363029A1 (fr) | Tambour de transport de l'industrie de traitement du tabac | |

| EP1625799A1 (fr) | Arrangement pour la production d'au moins une tige de filtre | |

| EP2659792B1 (fr) | Procédé et dispositif de rassemblement de groupes de segments de filtre | |

| DE60009015T2 (de) | Verfahren und Einrichtung zur Herstellung von Filterzigaretten | |

| EP1638419B1 (fr) | Machine d'assemblage de filtres a courroie double, et procede de production de cigarettes a bout filtre | |

| DE2421848A1 (de) | Verfahren und vorrichtung zur herstellung von tabakrauch-filtern | |

| EP1568288A1 (fr) | Procédé et appareil pour enlever des corps étrangers du tabac | |

| WO2011014968A1 (fr) | Unité de pliage et procédé pour plier un flux imbriqué de produits | |

| DE4103017C2 (de) | Verfahren und Vorrichtung zur Herstellung von Filterzigaretten | |

| DE10153655A1 (de) | Vorrichtung zum Umhüllen von Gruppen von Filtersegmenten mit einem Umhüllungsmaterial zur Herstellung von Multisegmentfiltern der tabakverarbeitenden Industrie und Multisegmentfilterherstelleinrichtung | |

| EP1516547B1 (fr) | Dispositif et procédé pour transférer articles en forme de tige | |

| EP1779739B1 (fr) | Dispositif d'alimentation de filtres | |

| DE3509711A1 (de) | Vorrichtung zur zufuhr von zigaretten zur umhuellungsstrecke einer verpackungsmaschine | |

| EP3262959B1 (fr) | Positionnement de produits en forme de tiges de l'industrie de traitement du tabac dans une machine d'insertion | |

| DE2614350B2 (de) | Vorrichtung zum Fördern von zylindrischen stabförmigen Gegenständen in der Tabakindustrie | |

| DE2811176A1 (de) | Verfahren und vorrichtung zum herstellen eines aus unterschiedlichen filterkomponenten zusammengesetzten rezessfilterstranges | |

| DE3617252A1 (de) | Verfahren und vorrichtung zum herstellen eines faserstranges der tabakverarbeitenden industrie | |

| EP1629735B1 (fr) | Dispositif d'alimentation de filtres | |

| DE2540650A1 (de) | Vorrichtung zum ueberfuehren queraxial zugefuehrter filterstopfen in laengsaxialer richtung auf einen huellmaterialstreifen | |

| EP1516546B1 (fr) | Dispositif et procédé pour transférer articles en forme de tige | |

| CH630786A5 (en) | Cigarette filter and use thereof, method for its production and machine for carrying out the method | |

| DE102015001606B3 (de) | Verfahren und Vorrichtung zum Herstellen von Folienzigaretten, Folienzigarillos oder dergl., insbesondere mit einem Filtersegment im Querverfahren | |

| DE102010019661A1 (de) | Vorrichtung und Verfahren zum Befüllen von Schragen mit stabförmigen Artikeln sowie Herstellmaschine für stabförmige Artikel mit einer solchen Vorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HAUNI MASCHINENBAU AG |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| 17P | Request for examination filed |

Effective date: 20050922 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20060324 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004007594 Country of ref document: DE Date of ref document: 20080828 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081027 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081216 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081016 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| BERE | Be: lapsed |

Owner name: HAUNI MASCHINENBAU A.G. Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| 26N | No opposition filed |

Effective date: 20090417 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20090529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080916 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080916 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090117 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081017 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110922 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20110927 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20130401 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130401 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20130821 Year of fee payment: 10 Ref country code: GB Payment date: 20130925 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20130920 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20130930 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004007594 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140916 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004007594 Country of ref document: DE Effective date: 20150401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150401 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140916 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: LAPE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140916 |