EP1514603B1 - Dispositif de traitement de matière - Google Patents

Dispositif de traitement de matière Download PDFInfo

- Publication number

- EP1514603B1 EP1514603B1 EP04021326A EP04021326A EP1514603B1 EP 1514603 B1 EP1514603 B1 EP 1514603B1 EP 04021326 A EP04021326 A EP 04021326A EP 04021326 A EP04021326 A EP 04021326A EP 1514603 B1 EP1514603 B1 EP 1514603B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- crushing

- coarse

- recesses

- comminution

- chisels

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000463 material Substances 0.000 title claims description 76

- 230000002093 peripheral effect Effects 0.000 claims abstract description 3

- 238000000227 grinding Methods 0.000 claims description 11

- 229910052500 inorganic mineral Inorganic materials 0.000 claims description 5

- 239000011707 mineral Substances 0.000 claims description 5

- 238000003801 milling Methods 0.000 claims description 4

- 238000010009 beating Methods 0.000 claims 1

- 239000004575 stone Substances 0.000 description 18

- 238000000034 method Methods 0.000 description 16

- 239000011435 rock Substances 0.000 description 11

- 239000004927 clay Substances 0.000 description 10

- 235000013312 flour Nutrition 0.000 description 9

- 235000013339 cereals Nutrition 0.000 description 8

- 239000000203 mixture Substances 0.000 description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 8

- 238000010276 construction Methods 0.000 description 7

- 238000009412 basement excavation Methods 0.000 description 6

- 239000004568 cement Substances 0.000 description 5

- 230000000694 effects Effects 0.000 description 5

- 239000002689 soil Substances 0.000 description 5

- 235000008733 Citrus aurantifolia Nutrition 0.000 description 4

- 235000011941 Tilia x europaea Nutrition 0.000 description 4

- 239000000654 additive Substances 0.000 description 4

- 239000011449 brick Substances 0.000 description 4

- 239000004567 concrete Substances 0.000 description 4

- 239000000470 constituent Substances 0.000 description 4

- 239000000356 contaminant Substances 0.000 description 4

- 239000004571 lime Substances 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 239000002699 waste material Substances 0.000 description 4

- 239000004615 ingredient Substances 0.000 description 3

- 238000009434 installation Methods 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 239000000725 suspension Substances 0.000 description 3

- 239000002023 wood Substances 0.000 description 3

- 235000019738 Limestone Nutrition 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- -1 coarse gravel Substances 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 238000005342 ion exchange Methods 0.000 description 2

- 239000006028 limestone Substances 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000010813 municipal solid waste Substances 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000010802 sludge Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 150000008064 anhydrides Chemical class 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 239000002956 ash Substances 0.000 description 1

- 239000010426 asphalt Substances 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 235000012216 bentonite Nutrition 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 210000000481 breast Anatomy 0.000 description 1

- 230000004087 circulation Effects 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 239000010438 granite Substances 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 238000005469 granulation Methods 0.000 description 1

- 230000003179 granulation Effects 0.000 description 1

- 230000036571 hydration Effects 0.000 description 1

- 238000006703 hydration reaction Methods 0.000 description 1

- 230000007774 longterm Effects 0.000 description 1

- 235000012054 meals Nutrition 0.000 description 1

- 239000013081 microcrystal Substances 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000004886 process control Methods 0.000 description 1

- 239000010453 quartz Substances 0.000 description 1

- 238000001953 recrystallisation Methods 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 238000005728 strengthening Methods 0.000 description 1

- 238000001238 wet grinding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/28—Details

- B02C4/30—Shape or construction of rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C13/00—Disintegrating by mills having rotary beater elements ; Hammer mills

- B02C13/20—Disintegrating by mills having rotary beater elements ; Hammer mills with two or more co-operating rotors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/14—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives within horizontal containers

- B02C18/142—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives within horizontal containers with two or more inter-engaging rotatable cutter assemblies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C18/00—Disintegrating by knives or other cutting or tearing members which chop material into fragments

- B02C18/06—Disintegrating by knives or other cutting or tearing members which chop material into fragments with rotating knives

- B02C18/16—Details

- B02C18/18—Knives; Mountings thereof

- B02C18/182—Disc-shaped knives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C21/00—Disintegrating plant with or without drying of the material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C23/00—Auxiliary methods or auxiliary devices or accessories specially adapted for crushing or disintegrating not provided for in preceding groups or not specially adapted to apparatus covered by a single preceding group

- B02C23/02—Feeding devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/02—Crushing or disintegrating by roller mills with two or more rollers

- B02C4/08—Crushing or disintegrating by roller mills with two or more rollers with co-operating corrugated or toothed crushing-rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C4/00—Crushing or disintegrating by roller mills

- B02C4/10—Crushing or disintegrating by roller mills with a roller co-operating with a stationary member

Definitions

- the invention relates to a device for the treatment of excavated earth, sludges, garbage or other material that may contain contaminants.

- the shredding device is suitable for example for mineral materials, such as excavated soil, coarse gravel, stones or other material. It is a fine comminution possible, with particle sizes of 10 mm to 60 mm can be achieved.

- a device for processing mineral material, in particular excavated soil known, which may also contain brittle, coarse-grained ingredients.

- For comminution serves a splitting mechanism with two counter-rotating shafts, which sit on sharpened chisels. These serve to burst the coarse ingredients to cause comminution. This can be done in the presence of cohesive material, ie clay or clay-containing material.

- the coarse components are comminuted to a particle size of about 60 mm.

- the flour and fine grain content is low.

- the material thus produced is in principle suitable for re-installation as a result of the comminution of the coarse components. For example, for filling excavated soil pits, such as pits or trenches. However, it is necessary to add to the material to be treated an additive, such as cement, ash, stone meal, granules, fibers, wood chips, wood flour, suspensions, such as lime suspensions, bentonites or dense suspensions.

- an additive such as cement, ash, stone meal, granules, fibers, wood chips, wood flour, suspensions, such as lime suspensions, bentonites or dense suspensions.

- the material to be processed of indefinite shape for example, in the presence of lumpy coarse material subjected to a crushing process in which the lumpy coarse material is at least partially crushed and mixed with the material.

- the comminution is preferably set so that the lumpy coarse material bindable components releases.

- the process is driven in such a way that the bondable constituents which are generally fine constituents produced act as an aggregate, so that the treatment can take place without the addition of additional additives, such as cement, lime, fibers, chips and the like.

- additional additives such as cement, lime, fibers, chips and the like.

- This fine fraction is mixed during the crushing process in the loamy-clay component and then acts as an aggregate.

- the grinding of the lumpy coarse material can also be done separately.

- an aggregate having binding ability e.g., cement, lime, dusts, seeds, nuts / nutshells.

- the ground coarse constituents above all have water-binding capacity and thus increase the stability and load-bearing capacity of the treated material, when e.g. is used for filling excavated ditches without provoking an unhealthy after hardening of the material.

- the carrying capacity of the material to be treated is merely brought about by the addition of cement, the material cures so strongly that a later re-opening of the trench becomes difficult.

- the invention makes it possible in many cases to reduce the need for additional additives below 0.5 wt.%. Often, additional aggregate is completely unnecessary. With water contents of up to 30% and stone content of approx. 50%, it is usually possible to completely dispense with additional binder.

- the rock flour produced during the comminution process acts like an aggregate.

- the rock flour may show different binding properties depending on the chemical nature. For example, it may be water absorbent. In addition, it can have a strengthening effect through ion exchange processes. It may further show a pozzolanic binding effect. It can also act as a binding agent by absorbing water, for example when it contains anhydride components. In addition, it can form hydrate bonds that can come about through microcrystal growth. This is particularly the case when used as coarse material concrete or other construction waste be used. As a rule, such construction waste still contains unbound components and thus a residual binding capacity. In addition, recrystallization operations may result in re-setting after fine milling.

- the material can also be adjusted to be dry enough to be sieved. It turns out that still existing stones can be screened out without significant adhesion of clay or the like.

- disks with chisels are provided on at least one shaft, wherein these disks are asymmetrical.

- a receiving space for coarse components is formed, wherein a disk, when carrying two chisels, has a small and a large receiving space. This ensures that on the one hand very large, coarse chunks can be crushed, while on the other hand prevents larger amounts of average grain between unobstructed slices fall through each other.

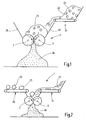

- FIG. 1 a crusher 1 is illustrated which serves as a crushing, milling and trash removing device. It has, for example, two counter-rotating shafts 2, 3 with crushing tools seated thereon.

- the crushing tools for example, according to DE 101 11 305 A1 or according to DE 202 14 956 U1 be educated. Notwithstanding these documents, however, the crushing tools are adjusted so that not only a grain size of about 60 mm grain size but at least a portion of the coarse components is much more crushed. This can be achieved in different ways.

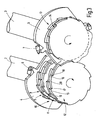

- FIG. 3 directed. This illustrates the waves 2, 3 in perspective view. They carry axially offset from each other discs 4, 5, which are provided at their periphery with recesses. In these recesses breakers 6, 7 can sit.

- the recesses may be formed with each other the same or different.

- the refracting bits 6, 7 preferably have conical tips which move towards one another above a plane defined by the two shafts 2, 3. The corresponding opposite directions of rotation of the shafts 2, 3 are in FIG. 3 indicated by arrows. Stones picked up between the tips of the breaker chisels 6, 7 are burst open by the notch effect of the slow-running shafts (eg approximately 10 to 60 revolutions / minute). Any existing contaminants (wood, steel, car tires) are either processed or rejected.

- the waves 2, 3 are densely occupied with toothed discs 8 to 14, which are formed equal to each other. It is also possible to use different toothed discs.

- the teeth 15, 16 have approximately radially oriented in the direction of rotation facing breast surfaces 17, 18 and against the circumferential direction sloping back surfaces 19, 20 on.

- the toothed disks 8 to 14 are each arranged on a gap, ie adjacent toothed pulleys arranged on the shaft 2 each enclose a gap into which the toothed disks of the shaft 3, which are likewise arranged with gaps relative to one another, engage.

- the number of toothed disks 8 to 14 is preferably greater than that of the chisel carrier disks (disks 4, 5).

- Each toothed disc is associated with a substantially cylindrical pressure surface on the respective opposite shaft, which with the tooth back 18, 19 of the respectively opposing toothed disc serves a pressure nip for grinding the coarse material.

- the comminution device 1 also has a drive device for the two shafts 2, 3.

- the drive device can be formed by two hydraulic motors, of which each shaft 2, 3 is assigned to one each. Both hydraulic motors can be driven by a common diesel engine.

- a conveyor 21 is also arranged, which is a in FIG. 1 schematically promotes illustrated material mixture 22 to the crusher 1.

- the conveyor 21 may be formed by a chute in the simplest case. It can also be designed as a belt conveyor.

- the material mixture 22 is, for example Excavated soil with loamy composition. It contains coarse material in the form of bricks 23, 24. These may naturally have been contained in the material mixture 22 or added randomly.

- the bricks 23, 24 may be bricks, concrete blocks, natural stones (limestone, sandstone, granite, basalt, gneiss, tuff, porphyry or the like). It is also possible a mixture of different stones, demolition materials, road surface, gravel, gravel, sand or the like.

- the material mixture 22 is conveyed by the conveyor 21 to the comminution device 1. It can be collected here in a hopper 25 above the crusher 1.

- the comminution tools carried by the shafts 2, 3 detect the loamy-cohesive material and convey it downwards.

- the stones 23, 24 of the refracting bits 6, 7 ( FIG. 3 ) split and broken.

- the fragments are further comminuted by the toothed discs 8 to 14, wherein the process control is selected so that a high proportion of fines is formed.

- the crushing leads at least partially to the fine-fine grinding of the stones.

- the resulting rock flour (quartz, lime or the like) is immediately mixed with the loamy-clay material of the material mixture 22.

- the comminution device 1 according to FIG. 2 is particularly suitable for the treatment of material 27 with loamy clay basic structure without its own coarse components. These can be conveyed with a further conveyor 28 to the grinder, which form the two shafts 2, 3 with their discs 4, 5 and pulleys 8 to 14. It can be done here a metered feed of material 27 and stones 22, 23.

- the stones 22, 23 are especially construction waste, ie concrete chunks, brick debris, other demolition material and natural stones.

- the crushing of the stones 22, 23 takes place in the presence of the material 27, which in turn generates rock flour, which is largely homogeneously mixed with the material 27.

- the resulting material 26 is suitable for installation on the construction site.

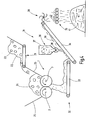

- FIG. 4 illustrated plant is the crushing device 1, as they are already off FIG. 1 shows and has been described in connection with this, supplemented by an aftertreatment device 31.

- a belt conveyor 32 with two conveyor belts 33, 34 which supply the homogenized material discharged from the shredding device as a material stream to a roller classifier 35.

- a metering device 36 is arranged, with which the material lying on the conveyor belts 33, 34 material 26 additive, such as cement, can be supplied.

- the metering device 36 includes, for example, a storage vessel 37 and a rotary valve 38 at the output thereof.

- a conveying wheel or a post-shredding device 39 can be arranged, which detects the material delivered by the conveyor belt 34 with radially arranged straight or curved tines and feeds it to the roller classifier 35.

- This has a group of equal or counter-rotating round or oval body, between which the fines of the discontinued material is passed down.

- a material accumulation 41 below the roll classifier 35 in FIG. 4 arranged a material accumulation 41.

- the coarse fraction such as individual unmilled stones 42, is delivered from the roll classifier 35 on one side. This coarse component can be fed to further processing.

- the metering device 36 is preferably set so that it emits only small amounts of substance, which accounts for less than 0.5 wt.% Of transported by the conveyor belts 33, 34 amount of substance. It can also be provided a control device which determines the dosage as a function of the residual moisture of the material 26. A corresponding moisture measuring device can be provided, but is in FIG. 4 not further illustrated. In the processing of sludge can also be driven with higher dosing.

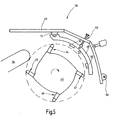

- FIG. 4 only schematically indicated mixing device 39 with Nachzerkleintationsfunktion is in FIG. 5 illustrated in more detail.

- a rotor 43 with preferably horizontally arranged axis of rotation, which is driven by a hydraulic motor or other drive source ago.

- the rotor preferably extends over the entire width of the in FIG. 4 It is at its periphery with Maschinenenbergen, eg chisels 44, 45, 46, 47 occupied, which are employed obliquely against the direction of rotation.

- pointed bits are used with a rounded tip.

- the bits 44 to 47 are rigidly mounted.

- the rotational speed of the rotor 43 is in the range of 200 to 1,000 revolutions / min for most applications. established. A speed of 400 revolutions is preferred.

- the rotor 43 is associated with a hood 48, which is arranged above the rotor 43 on the conveyor belt 34 opposite side.

- the hood preferably covers about a quarter of the circumference of the rotor 43. It is mounted on a cover 49, which is arranged above the rotor 43 about a pivot axis 50 pivotally.

- a hydraulic cylinder opens and closes the cover 49.

- the rotor is for example firmly connected to the conveyor belt 34 or to a scaffold, which also carries the rotor 43 and the conveyor belt 34.

- the hood 48 is pivotally mounted on the carrier 49 via a corresponding bearing device 51.

- the pivot axis is arranged above the rotor 43.

- the pivoting position is by an adjustment mechanism 52, for example set in the form of a simple adjusting screw or in the form of fluid cylinders (hydraulics, pneumatics).

- the hood 48 is curved approximately parallel to the circle defined by the chisels 44, 45, 46, 47 flight circle. It thus limits with the rotor 43 a gap-shaped comminuting space 53. If necessary, one, two or more blow bars 54, 55 may be held on the hood 48, which extend over the entire axial length of the rotor 43 and in the direction of the rotor 43 protrude.

- the mixing device 39 effects further mixing and comminution of the material conveyed by the conveyor belt 34.

- the grain size can be adjusted as desired with the adjustment mechanism 52. It is thus given a largely homogeneous material on the Rollenklassierer 35.

- a grinding operation is carried out in which the crushing, grinding and Störstoffbeeitungs adopted both of the relevant Excavation and in addition of lumpy coarse material is passed through.

- the crushing of the coarse material by suitable breakage and / or crushing rock powder is used as a kind of locally generated aggregate for excavation. This aggregate is suitable both to regulate the moisture of the excavation or sludge and to stabilize and solidify it.

- the material is puncture proof. Also a granulation is possible.

- the degree of drying and solidification can be adjusted by the degree of grinding, for example by the coarse constituents are ground more or less depending on the degree of moisture or desired Nachverfestist.

- coarse components such as asphalt, construction waste, concrete chunks or natural stones may be added in addition to the excavation to produce the desired amounts of rock flour during the crushing process.

- the shredder grinding and disposal facility shreds shredded contaminants and prevents the passage of non-shredded contaminants. These are rejected. For example, large steel parts are not detected or they lead to blocking and reversing of the machine. Overload or single or multiple reversing can lead to shutdown.

- FIGS. 6 and 7 illustrate the discs 4, 5 separately. They are preferably formed asymmetrically. As FIG. 6 illustrated, the disc 4, two diametrically opposite seats 61, 62 for chisel, as seen from FIG. 3 or for the seat 62 off FIG. 7 emerge.

- the two chisels 6, 7 define a circle 63, ie their tips run on the common diameter D2.

- the chisels 6, 7 are housed in recesses of the disk body 60, wherein the recesses in the region of the seats 61, 62 are identical. In front of the chisels 6, 7, however, distinctive recesses 64, 65 are formed.

- the recess 64 of the bit 6 extends, for example, only over a range of, for example, 60 °

- the recess 65 extends over a peripheral region of significantly more than 90 °. This allows different sized coarse components of the chisels 6, 7 are detected. While too large stones or other coarse components of the recess 64 leading hurrying area 66 of the disk body 60 are rejected, such chunks can get into the recess 65 and are detected by the chisel 7.

- the area 66 which extends up to the diameter D2 and which largely fills the space between the chisels 6, 7 prevents between the disks 4, 5 of the two shafts 2, 3 (see FIG FIG. 3 ) create too large spaces, could fall through the middle grain.

- FIGS. 6, 7 presented discs 4, 5 thus allow on the one hand the efficient crushing of particularly coarse material, while on the other hand ensure that a high proportion of fine grain is formed and the crushed material contains very little middle grain.

- the chisels 6, 7 can be the same or different as illustrated.

- the chisel 7 adjacent to the larger recess 65 may be configured for coarse shredding and the other chisel 6 for smaller size.

- liquid such as e.g. Water or an aqueous solution to which material is added.

- the addition of water can be done, for example, to effect or assist the setting of the added or generated fines.

- the removal of liquid by adding powdered dry material or moistening the material by adding water, depending on the initial moisture content of the material.

- the shredding device has a shaft with a plurality of disks, at least some of which are provided with separate shredding tools in the form of crushers. These are on the discs, for example rigidly attached.

- the breaker bits are oriented approximately in the circumferential direction and sit in corresponding recesses of the disc to which they are attached.

- the recesses have different dimensions. If one disc carries two chisels, one recess is slightly smaller while the other one is slightly larger. The larger recess allows the shredding of coarse material.

- the fact that the larger recess is associated with only one of the bits prevents gaps between adjacent shafts, in particular a twin-shaft shredder, from passing through which too much uncomminuted material can fall.

- the two-shaft shredder equipped with respective discs allows the production of small-sized material directly from coarse rock in a single crushing stage.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Crushing And Pulverization Processes (AREA)

- Mixers Of The Rotary Stirring Type (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Crushing And Grinding (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

- Disintegrating Or Milling (AREA)

- Processing Of Solid Wastes (AREA)

Claims (8)

- Dispositif comportant un système de concassage (1) présentant au moins un arbre qui porte des disques (4, 5) équipés d'outils de concassage avec sur chaque disque un évidement disposé en amont de chaque tranchant de fracturation par rapport au sens de rotation, au moins deux évidements différents étant présents, ce dispositif étant caractérisé en ce que les évidements (64, 65) ont des longueurs différentes en direction périphérique.

- Dispositif selon la revendication 1, qui comporte un dispositif d'avancement (21) pour assurer une amenée contrôlée du matériau minéral au système de concassage (1).

- Dispositif selon la revendication 1, qui comporte un dispositif d'avancement (21) pour assurer une amenée contrôlée de matériau grossier au système de concassage (1).

- Dispositif selon la revendication 1, caractérisé en ce qu'en aval du système de concassage (1) est disposé un autre système de concassage (39) sous la forme d'un dispositif de fraisage.

- Dispositif selon la revendication 4, caractérisé en ce que l'autre système de concassage (39) est un dispositif de fraisage équipé de batteurs réglables.

- Dispositif selon la revendication 5, caractérisé en ce que le l'autre système de concassage (39) fonctionne en broyeur.

- Dispositif selon la revendication 1, caractérisé en ce que le système de concassage (1, 39) est à plusieurs étages.

- Dispositif selon la revendication 1, caractérisé en ce que les évidements (64) présentent des profondeurs différentes.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20314136U DE20314136U1 (de) | 2003-05-14 | 2003-09-10 | Vorrichtung zur Materialaufbereitung |

| DE20314136U | 2003-09-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1514603A2 EP1514603A2 (fr) | 2005-03-16 |

| EP1514603A3 EP1514603A3 (fr) | 2005-07-27 |

| EP1514603B1 true EP1514603B1 (fr) | 2009-04-01 |

Family

ID=34129833

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04021326A Expired - Lifetime EP1514603B1 (fr) | 2003-09-10 | 2004-09-08 | Dispositif de traitement de matière |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1514603B1 (fr) |

| AT (1) | ATE427161T1 (fr) |

| DE (1) | DE502004009261D1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DK1951450T3 (en) | 2005-11-16 | 2017-06-19 | Tagpap Recycling Aps | Process and apparatus for recycling bitumen-containing products |

| DE102016108105A1 (de) * | 2016-05-02 | 2017-11-02 | Hydro Aluminium Rolled Products Gmbh | Zerkleinerungsanlage und Zerkleinerungsverfahren zur Zerkleinerung von Aluminiumschrott |

| CN111632701A (zh) * | 2020-05-18 | 2020-09-08 | 高梅真 | 一种建筑工程用废料处理设备 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT393236B (de) * | 1986-07-29 | 1991-09-10 | Liezen Maschf | Vorrichtung zum zerkleinern von stueckigem material |

| DE4418627A1 (de) * | 1993-05-27 | 1994-12-01 | Hitachi Ltd | Verfahren und Vorrichtung zur Rückgewinnung von Treibgas aus geschäumten Materialien |

| US6402070B1 (en) * | 1999-02-25 | 2002-06-11 | Kyocera Corporation | Bone-mill |

| DE10235241A1 (de) * | 2002-03-14 | 2003-11-13 | Franz Gail | Mahlverfahren und Mühle zum Herstellen von Tierfutter aus Körnerfrüchten |

| DE20214956U1 (de) * | 2002-09-27 | 2002-11-28 | Schenk, Jürgen, 70188 Stuttgart | Zerkleinerungseinrichtung |

| US20070272776A1 (en) * | 2003-05-14 | 2007-11-29 | Jurgen Schenk | Method and Apparatus for Processing Excavated Earth |

| DE20314136U1 (de) * | 2003-05-14 | 2003-12-04 | Schenk, Jürgen | Vorrichtung zur Materialaufbereitung |

-

2004

- 2004-09-08 AT AT04021326T patent/ATE427161T1/de active

- 2004-09-08 DE DE502004009261T patent/DE502004009261D1/de not_active Expired - Lifetime

- 2004-09-08 EP EP04021326A patent/EP1514603B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1514603A2 (fr) | 2005-03-16 |

| DE502004009261D1 (de) | 2009-05-14 |

| EP1514603A3 (fr) | 2005-07-27 |

| ATE427161T1 (de) | 2009-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7581689B2 (en) | Device for processing excavated material | |

| DE102005011964B4 (de) | Universalgerät mit Anbauklassierer | |

| DE10202536A1 (de) | Fräseinrichtung für Boden, Fels, Aushub oder anderes Material | |

| EP1337339A1 (fr) | Dispositif et procede pour travaux d'excavation | |

| WO2004101156A1 (fr) | Procede et dispositif de traitement de deblais | |

| DE3240126C2 (de) | Vorrichtung zur Hartzerkleinerung von grobstückigen, verfestigten Gesteinsgemischen | |

| EP2482987B1 (fr) | Procédé et dispositif de fragmentation de matière minérale | |

| DE10111300B4 (de) | Aufbereitungsvorrichtung insbesondere für Aushub | |

| EP1514603B1 (fr) | Dispositif de traitement de matière | |

| EP2981360A1 (fr) | Dispositif et procédé servant à broyer des matières minérales avec un système à ressort | |

| EP3204162A1 (fr) | Dispositif de concassage de minerai comportant un dispositif ressort hydraulique et procédé correspondant | |

| DE4324234A1 (de) | Fräsbrecher | |

| DE10111305B4 (de) | Vorrichtung und Verfahren zum Aufbereiten von Material, insbesondere mineralischem Material wie Bodenaushub | |

| DE10337590A1 (de) | Verfahren und Vorrichtung zum Aufbereiten von Aushub | |

| DE19612074A1 (de) | Mobile Vorrichtung zur Verbesserung von Bodenmaterial | |

| DE20314136U1 (de) | Vorrichtung zur Materialaufbereitung | |

| DE20214956U1 (de) | Zerkleinerungseinrichtung | |

| JP3778689B2 (ja) | 埋立廃棄物の処分方法 | |

| DE3816872C2 (fr) | ||

| DE20108464U1 (de) | Aufbereitungsvorrichtung, insbesondere für Aushub | |

| WO2024201509A1 (fr) | Dispositif de préparation d'une composition de mélange d'argile pour la fabrication d'une brique d'argile et procédé associé | |

| DE2633505A1 (de) | Einrichtung zum zerkleinern von unsortierten abfaellen, wie haus-, kommunal, industrie- und aehnlichem muell | |

| DE20112111U1 (de) | Mobile Vorrichtung zum Sieben, Separieren, Brechen, Zerkleinern und/oder Mischen | |

| DE102004038959A1 (de) | Verfahren und Vorrichtung zur Aufbereitung von Erdstoffen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7B 02C 4/30 B Ipc: 7B 02C 23/02 B Ipc: 7B 02C 18/18 B Ipc: 7B 02C 4/08 A Ipc: 7B 02C 21/00 B Ipc: 7B 02C 4/10 B Ipc: 7B 02C 18/14 B Ipc: 7B 02C 13/20 B |

|

| 17P | Request for examination filed |

Effective date: 20060111 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20061128 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: KIRKER & CIE S.A. |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004009261 Country of ref document: DE Date of ref document: 20090514 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090902 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090712 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090701 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090922 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 |

|

| 26N | No opposition filed |

Effective date: 20100105 |

|

| BERE | Be: lapsed |

Owner name: SCHENK, JURGEN Effective date: 20090930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090930 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20090922 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090908 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100908 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20110531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090401 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20091001 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110923 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20110914 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20120930 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 427161 Country of ref document: AT Kind code of ref document: T Effective date: 20120908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120908 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004009261 Country of ref document: DE Effective date: 20140401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140401 |