EP1262609A1 - Eléments de revêtement de sol à joint d'étanchéité - Google Patents

Eléments de revêtement de sol à joint d'étanchéité Download PDFInfo

- Publication number

- EP1262609A1 EP1262609A1 EP20020291309 EP02291309A EP1262609A1 EP 1262609 A1 EP1262609 A1 EP 1262609A1 EP 20020291309 EP20020291309 EP 20020291309 EP 02291309 A EP02291309 A EP 02291309A EP 1262609 A1 EP1262609 A1 EP 1262609A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- seal

- elements

- layer

- joint

- interlocking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/02—Flooring or floor layers composed of a number of similar elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F15/00—Flooring

- E04F15/02—Flooring or floor layers composed of a number of similar elements

- E04F15/04—Flooring or floor layers composed of a number of similar elements only of wood or with a top layer of wood, e.g. with wooden or metal connecting members

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F2201/00—Joining sheets or plates or panels

- E04F2201/01—Joining sheets, plates or panels with edges in abutting relationship

- E04F2201/0107—Joining sheets, plates or panels with edges in abutting relationship by moving the sheets, plates or panels substantially in their own plane, perpendicular to the abutting edges

- E04F2201/0115—Joining sheets, plates or panels with edges in abutting relationship by moving the sheets, plates or panels substantially in their own plane, perpendicular to the abutting edges with snap action of the edge connectors

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F2201/00—Joining sheets or plates or panels

- E04F2201/07—Joining sheets or plates or panels with connections using a special adhesive material

Definitions

- the invention relates to a floor covering element, multilayer, laid floating, that is to say not secured to the slab or the structure to be clad with the building that we want to equip.

- the invention relates to the field of floating poses in which typically a underlay (felt, carpet, ...) or a foam sheet is interposed between the covering and the floor.

- the covering is fixed (typically glued) on the ground on a slab (often a patched slab covered with a fluid coating forming a bonding bed).

- an object of the invention is to improve the resistance to the humidity of the coating and more generally, the resistance over time of the element once installed, the risk being that substances will flow or pile up between two joined elements, risking damage.

- an important characteristic of the invention provides the seal has an adhesive front face to stick against the side in look of the other element, in the mutually locked position of the first and second elements.

- Another object of the invention is to ensure positioning also perfect as possible of the two adjacent elements, while promoting the holding and joint control.

- the element provided with the seal has a length with, along this length, a joint made up of a succession of joint sections with a interruption between two successive sections.

- another characteristic of the invention advises that the joint can be presented as a flange having a naturally erect wing along the edge of the element to which it is attached.

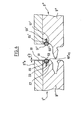

- Two such elements, 1, 3, typically called boards or slats, are linked together during installation, by interlocking means materialized here by a male element 15 for element 3 and one per element complementary female 17, for element 1.

- the two means 15, 17, are located on at least one of the sides, such as 19a and 19'a of the elements concerned, at the location of at least one of their edge (vertical).

- system clip acting by interlocking and elastic wedging.

- Either of these interlocking means 15, 17 is (are) topped by at least one seal such as 21.

- the seal 21 is a seal for liquids which is housed at the level of the second layer 9.

- This seal seals when it is pressed against the side in look of the adjacent element, i.e. when the two elements 1, 3, are interlocked, and therefore blocked by fitting 15 into 17, the joint then being in a projecting position, between the elements.

- the joint used is a malleable polyolefin adhesive (can be crushed more or less elastic at room temperature) and having a power sticky higher than a temperature close to its temperature of softening (melting) only at room temperature. At this temperature, ambient, it can stick repeatedly.

- the seal is placed hot on the slice of the slat to which it must adhere. It is therefore placed just above of the interlocking zone 41, at the location of the support layer 9 underlying the wear layer 5. Its temperature at the outlet of the removal is between 160 ° C and 220 ° C (to within 10 ° C).

- the cord (full) deposited by this nozzle progresses between 15 m / min and 25 m / min (to within 20%) and deposit between 0.1 g and 1.5 g / mL (linear meter). Once glued to this slice, let the cord cool.

- the interlocking created by the cooperation (snap-in) of male and female elements 15, 17, causes adhesion of the seal to the edge of the adjacent slat which comes to press against it.

- the pressure exerted during of this contact is between approximately 1.5 kg / cm and 7 kg / cm (typically, approximately 2 to 4 kg / cm for a layer of HDF and approximately 4 to 6 kg / cm for a layer 9 of softwood batten).

- hot melt polyolefin based glue hot melt polyolefin glue

- pressure sensitive hot melt polyolefin based glue thermoplastic, in particular of polypropylene, for its reliability and ease of installation advantages artwork.

- the bead forming the joint can be continuous or discontinuous, depending on the degree of tightness desired.

- the wall can be plane.

- a protrusion 25 has been arranged in projection on the edge 19'a, at the level of the second layer 9, opposite said joint, now marked 21 '.

- this hard, rigid outgrowth (typically based of wood if it was formed from material with layer 9) has been made towards the lower part of the seal when it is in position (or in a state) no active as in FIG. 2, the protuberance 25 having even been here conformed and arranged to block any possible downward movement of the seal when is overwritten in the active position as in Figure 3.

- the projection 25 shown in view enlarged in FIG. 4 presents an upper face 25a overall oblique to line 100 embodying the general plane in which extend the elements (see Figure 7), but also present, at the place of its free apex 25b a projection which defines an obstacle preventing any exit from the joint downwards, the apex then being located at the end lower joint when the two elements 1, 3, are fitted as on the figure 3.

- the (each) seal such as 21 ' is preferably housed in a cavity 27 formed, in FIG. 2, in hollow relative to the general vertical plane of the section 19a.

- the seal 21 ' of Figure 2 is a hollow joint (which can typically appear as a tubular tube) mechanically forcibly engaged in an orifice 29 formed in the bottom of the cavity 27. Notches 31 effectively retain the seal which, in this non-active position, protrudes clearly outside the cavity, the empty interior space 33a of its bead portion 33 allowing it to be effectively crushed and deformed when interlocking the elements.

- the seal 21 'further has an upright upper wing 35 which extends to the level of the upper layer 5 against which it is supported, favoring an effective positioning of the joint in its active state.

- At least the front face 37 of the rod portion of the seal is adhesive so that the seal sticks against the area opposite the edge 19'a.

- a gap 39 remains above the zone 19a 1 , this gap extending, with a reduced width (see d 2 with respect to d 1 in FIG. 3) over the entire height of the first layer 5 of each of the elements.

- the seal 21, then in the crushed active position extends essentially above the level of the apex 25b, a marginal part of the seal extending below, but only up to the place of the upper limit of the support area 19a 1 , thus avoiding any interference between the sealing area of the gap 39 and the interlocking area 41 bordered above and below by the contact areas 19a 1 and 19a 2 .

- wing 35 which provides a stabilization of the joint during its deformation and increases the tightness at the place of the upper layer 5.

- This wing 35 extends (at least essentially) to the look of this upper layer 5, while the tubular bead 33 extends at the location of the gap 39, at the second layer 9, this both in the active and inactive state of the seal.

- Figure 6 shows that the (each) joint element may overflow from this cavity, in the non-active state of said seal.

- each joint part is curved outwards and overflows from the corresponding cavity, 55, 55 'respectively.

- Each part of the joint is linked to the location of its zone back (for example, by adhesion) to an insert (respectively 57, 57 ') anchored in the thickness of the second layer 9 "of each element 1", 3 ", of covering ready to be assembled.

- the anchoring can be carried out by a notched end, respectively 59, 59 ', forcibly engaged.

- the two cavities and the two joint parts face each other and are located on the same level.

- the control of the upward deformation of the joint is less precise.

- the design of the contact zone 19 "a 1 is adapted to prevent the seals from descending clearly in the direction of the interlocking zone 41".

- the gap 61 with a depth of 2 (relative to the slightly protruding end of the wall 19 "a 1 ) reserved above the joint 51 up to the upper surface 5" a allows the two elements to seal 51, 51 ', to naturally take their active compressed position above said zone 19 "to 1 .

- the projecting front part 53, 53 ′ of said seals will be coated with a protective film (not shown to avoid overload the figure).

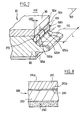

- the perspective therefore makes it possible to show the plane (in general typically horizontal) 100 in which each covering element, such as that partially shown in this figure and identified 20.

- the figure shows the male locking element 115 formed of material, projecting, at the level of the second layer 90. Above the bead interlocking 115 extends the area 119 of contact between the elements of coating, preventing the seal 125 still located above from reaching the area of the bead 115, in the compressed active state of the joint, when the bead 115 is locked.

- the seal 125 is interrupted (in its non-active state) before having reached the level of the first upper layer 50 of the element 20.

- the front face 50a of this layer 5 thus that the part of the front face 90a of the second layer 90 which extends it in the same vertical are offset in depth by a distance d 20 relative to the vertical plane in which the wall 119 extends, so as to reserve a gap 610 for deploying the seal 125 when the element 20 is locked to its adjacent complementary element, as shown in FIG. 3.

- FIG. 7 An additional interest of figure 7 is to show that the joint 125 extends horizontally, parallel to the general plane 100, to the like a housed band (in this case entirely in its inactive state) in the cavity 270 hollowed out on the front surface of the second layer 90.

- the joint 125 has a length horizontally, materialized here by the frame L and, along this length, looks like a succession of joint sections, such as 125a, 125b, with an interruption, such as 150a, 150b, between two adjacent sections.

- each joint can be a sticky putty ("adhesive, hot melt putty ").

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Floor Finish (AREA)

- Laminated Bodies (AREA)

- Building Environments (AREA)

- Road Signs Or Road Markings (AREA)

- Carpets (AREA)

- Details Of Aerials (AREA)

Abstract

Description

- d'un "vrai parquet" dont la couche de surface est (essentiellement) en bois et se présente sous la forme d'une ou plusieurs lame(s) (également appelées planches, frises, lattes, ...),

- ou d'un "similiparquet" (appelé également "faux parquet" ou "laminé", c'est-à-dire un revêtement ayant l'aspect d'un parquet mais contenant beaucoup moins de bois qu'un "vrai parquet"), tant le parquet que le similiparquet étant à poser flottant.

- les poses flottantes,

- les poses collées.

- une première couche rigide dure, présentant une face supérieure visible,

- et au moins une deuxième couche sous-jacente mécaniquement résistante, rigide, de support de la première couche, cette deuxième couche sous-jacente comprenant des moyens d'interverrouillage adaptés pour coopérer mécaniquement avec des moyens complémentaires d'interverrouillage dont est pourvu un deuxième élément adapté pour coopérer avec le premier et qui comprend les mêmes dites première et seconde couches, la deuxième couche du premier ou du deuxième élément comprenant en outre un joint déformable fixé à elle , sur au moins l'un de ses côtés à l'écart des moyens d'interverrouillage qui y sont prévus et en regard de l'autre élément, le joint étant adapté pour assurer, dans une position en saillie sur la tranche, une étanchéité aux liquides lorsqu'il est écrasé contre ledit côté en regard de l'autre élément par rapprochement des premier et deuxième éléments et verrouillage mutuel entre eux.

- le joint est une colle polyoléfine malléable, ayant un pouvoir collant supérieur à une température proche de sa température de ramollissement qu'à température ambiante,

- le joint est collé plus solidement au premier élément qu'au second élément, et est collable et décollable de façon répétitive à ce second élément, à température ambiante,

- le joint est un cordon malléable collant thermoplastique, en particulier en polypropylène, pouvant coller de façon répétitive à température ambiante.

- l'un au moins des éléments présente sur au moins un de ses côtés, une forme en creux où est disposé le joint,

- et l'autre élément présente en regard de la forme en creux une excroissance adaptée pour qu'une partie au moins du joint soit déformée par cette excroissance lors de l'interverrouillage des éléments.

- le joint soit disposé, sur l'un desdits éléments, exclusivement au-dessus des moyens d'interverrouillage, au niveau de la deuxième couche,

- et que les moyens d'interverrouillage de ces éléments, eux-mêmes situés au niveau de cette deuxième couche, se verrouillent mutuellement par emboítement, dans une première position de blocage relatif des éléments suivant une direction parallèle ou sensiblement parallèle au plan général alors commun desdits éléments, lesquels sont déverrouillables à partir de leur dite première position de blocage, par décalage en hauteur d'un élément par rapport à l'autre, tel par exemple qu'une inclinaison d'un élément par rapport à l'autre,

- et le joint, lié fixement au premier élément, adhère à l'autre élément sous une pression créée par l'interverrouillage des deux éléments comprise entre 1,5 kg/cm et 7 kg/cm, environ (à 10 % près).

- que l'excroissance présente une face supérieure globalement oblique par rapport au plan général de l'(des) élément(s) considéré(s), cette face se terminant par un apex libre situé en regard d'une partie de la cavité qui lui fait face, en position de blocage, pour solliciter le joint à se déformer au moins partiellement vers le haut,

- et, dans ce cas, que l'excroissance, à l'endroit de son apex, puisse présenter une saillie qui définisse un obstacle interdisant une sortie du joint vers le bas.

- la figure 1 montre, en coupe, deux éléments adjacents de revêtement de sol, dans un état non verrouillé, en regard l'un de l'autre,

- la figure 2 montre une variante de réalisation de la figure 1,

- la figure 3 montre les éléments de la figure 2 dans leur état verrouillé,

- la figure 4 montre le détail IV de la figure 2, en vue agrandie,

- la figure 5 montre le joint de la figure 2 seul, en vue agrandie,

- la figure 6 montre une autre alternative de réalisation, toujours dans l'état face à face, non verrouillé des deux éléments de revêtement,

- la figure 7 montre, en vue agrandie, une perspective locale d'un élément de revêtement pourvu d'un joint d'étanchéité allongé, en forme de ruban discontinu,

- et la figure 8 montre schématiquement, en coupe, un "faux-parquet" ou "laminé".

- une couche supérieure (ou couche d'usure) rigide, dure et pleine 5, contenant du bois (typiquement constituée de bois), présentant une face supérieure d'aspect visible et continu 5a, cette couche supérieure (typiquement d'une épaisseur comprise entre 1,5 mm et 10 mm) pouvant être recouverte d'une couche protectrice, telle que du vernis, de l'huile ou une cire, 7,

- une deuxième couche sous-jacente, 9, de support de la couche supérieure, située immédiatement sous elle, cette deuxième couche qui est en un matériau rigide contenant du bois (y compris les particules agglomérées) pouvant être continue ou discontinue (en présentant alors une série de fentes susceptibles d'être formées par des tasseaux espacés les uns des autres), cette deuxième couche ayant typiquement une épaisseur comprise entre 0,3 mm et 8 mm,

- avantageusement, une couche pleine de contrebalancement 11, dure, contenant du bois (y compris les particules agglomérées) et s'étendant alors (lorsqu'elle existe) immédiatement sous la seconde couche 9, pour la tenue mécanique du parquet dans son ensemble, et tout particulièrement de la couche supérieure 5 (épaisseur comprise entre 0,1 mm et 5 mm),

- et/ou une couche d'insonorisation 13 (voir figure 2), en un matériau acoustiquement absorbant (mousse, masse lourde, ...) située soit directement sous la couche de contrebalancement 11, soit directement sous la seconde couche 9 (étant précisé que, hormis cette couche d'insonorisation 13, qui peut être rapportée après fabrication, les autres sont liées ensemble au moment de la fabrication du parquet, typiquement par collage sous pression).

- une couche supérieure rigide, dure et pleine, en résine, 210, présentant une face supérieure d'aspect, visible, continue, 210a, ainsi qu'une face inférieure 210b, également continue ;

- une feuille intermédiaire décorative 230 (papier, bois, ...) donnant au produit son aspect visible à travers la couche supérieure transparente 210,

- une seconde couche sous-jacente 250, rigide, de support de la couche supérieure 210 et située immédiatement sous la couche 230, cette deuxième couche en matériau rigide contenant du bois (particules ou fibres ; HDF) lié par une résine synthétique et présentant une épaisseur comprise entre 0,1 mm et 3 mm,

- et éventuellement, une couche supplémentaire d'insonorisation 290 qui peut être identique à la couche 13 présentée pour le "vrai parquet", c'est-à-dire contenant une matière expansée et/ou un matériau viscoélastique (élastomère), étant toutefois précisé que ladite couche d'insonorisation 290 est alors située immédiatement sous la couche de soutien et de structuration 250.

Claims (10)

- Eléments de revêtement de sol comprenant un premier élément (3) de revêtement de sol, multicouche, à poser flottant, présentant plusieurs côtés, une tranche, ce premier élément comprenant :caractérisés en ce que le joint (21') présente une face frontale (37) adhésive pour coller contre le côté en regard (19'a) de l'autre élément, en position de verrouillage mutuel des premier et deuxième éléments (1, 3).une première couche rigide dure (5, 5', 50, 21), présentant une face supérieure visible,et au moins une deuxième couche sous-jacente (9, 9', 90, 250) mécaniquement résistante, rigide, de support de la première couche, cette deuxième couche sous-jacente comprenant des moyens d'interverrouillage (15, 115) adaptés pour coopérer mécaniquement avec des moyens complémentaires (17) d'interverrouillage dont est pourvu un deuxième élément (1) adapté pour coopérer avec le premier et qui comprend les mêmes dites première et seconde couches, la deuxième couche du premier ou du deuxième élément (1, 3) comprenant en outre un joint déformable (21 ; 21'; 45, 45', 51, 51', 125) fixé à elle (19a), sur au moins l'un de ses côtés à l'écart des moyens d'interverrouillage qui y sont prévus et en regard de l'autre élément, le joint étant adapté pour assurer, dans une position en saillie sur la tranche, une étanchéité aux liquides lorsqu'il est écrasé contre ledit côté (19'a) en regard de l'autre élément par rapprochement des premier et deuxième éléments et verrouillage mutuel entre eux,

- Éléments selon la revendication 1, caractérisés en ce que le joint (21) est une colle polyoléfine malléable, ayant un pouvoir collant supérieur à une température proche de sa température de ramollissement qu'à température ambiante.

- Éléments selon la revendication 1 ou la revendication 2, caractérisés en ce que le joint (21) est collé plus solidement au premier élément qu'au second élément, et est collable et décollable de façon répétitive à ce second élément, à température ambiante.

- Éléments selon l'une des revendications précédentes, caractérisés en ce que le joint (21) est un cordon malléable collant thermoplastique, en particulier en polypropylène, pouvant coller de façon répétitive à température ambiante.

- Éléments selon l'une des revendications précédentes, dans lesquels :l'un au moins des éléments présente sur au moins un de ses côtés, une forme en creux (55', 27) où est disposé le joint (51, 21'),et l'autre élément présente en regard de la forme en creux une excroissance (25, 53') adaptée pour qu'une partie au moins du joint soit déformée par cette excroissance lors de l'interverrouillage des éléments.

- Éléments selon l'une quelconque des revendications précédentes, dans lesquels :le joint (21; 21' ; 47, 47' ; 53, 53' ; 125) est disposé sur l'un desdits éléments, exclusivement au-dessus des moyens d'interverrouillage, au niveau de la deuxième couche (9, 9', 9", 90),les moyens d'interverrouillage (15, 17; 115) de ces éléments, situés également au niveau de cette deuxième couche, se verrouillent mutuellement par emboítement, dans une première position de blocage relatif des éléments, suivant une direction parallèle ou sensiblement parallèle au plan général alors commun desdits éléments, lesquels sont déverrouillables à partir de leur dite première position de blocage, par décalage en hauteur d'un élément par rapport à l'autre, tel par exemple qu'une inclinaison d'un élément par rapport à l'autre,et le joint (21), lié fixement au premier élément, adhère à l'autre élément sous une pression créée par l'interverrouillage des deux éléments comprise entre 1,5 kg/cm et 7 kg/cm.

- Éléments de revêtement de sol selon la revendication 5, caractérisés en ce que l'excroissance (25) présente une face supérieure (25a) globalement oblique par rapport au plan général de l'(des) élément(s) considéré(s), cette face se terminant par un apex libre (25b) situé en regard d'une partie de la forme en creux qui lui fait face, en position de blocage, pour solliciter le joint à se déformer, au moins partiellement vers le haut.

- Éléments selon la revendication 7, caractérisés en ce que l'excroissance (25) à l'endroit de son apex (25b) présente une saillie qui définit un obstacle interdisant une sortie du joint vers le bas.

- Éléments selon l'une quelconque des revendications précédentes, caractérisés en ce que, suivant son plan général (100), l'élément pourvu du joint présente une longueur (L) et, suivant cette longueur, ledit joint consiste en une succession de tronçons de joint (125a, 125b) avec une interruption (150a, 150b) entre deux tronçons successifs.

- Éléments selon l'une quelconque des revendications précédentes, caractérisés en ce que le joint (21') se présente comme un boudin (33) présentant une aile (35) naturellement dressée le long de la tranche de l'élément auquel il est fixé.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0107251 | 2001-06-01 | ||

| FR0107251A FR2825397B1 (fr) | 2001-06-01 | 2001-06-01 | Element(s) de revetement de sol a joint d'etancheite |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1262609A1 true EP1262609A1 (fr) | 2002-12-04 |

| EP1262609B1 EP1262609B1 (fr) | 2006-07-19 |

Family

ID=8863903

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02291309A Expired - Lifetime EP1262609B1 (fr) | 2001-06-01 | 2002-05-29 | Eléments de revêtement de sol à joint d'étanchéité |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP1262609B1 (fr) |

| AT (1) | ATE333545T1 (fr) |

| DE (1) | DE60213161T2 (fr) |

| ES (1) | ES2266423T3 (fr) |

| FR (1) | FR2825397B1 (fr) |

Cited By (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2004016422A1 (fr) | 2002-08-14 | 2004-02-26 | Shaw Industries Group, Inc. | Revetement de sol a rainure et languette resistant a l'eau |

| EP1412596A1 (fr) * | 2001-07-27 | 2004-04-28 | Välinge Innovation AB | Panneaux de plancher dotes de moyens d'etancheite |

| US6766622B1 (en) * | 1998-07-24 | 2004-07-27 | Unilin Beheer B.V. | Floor panel for floor covering and method for making the floor panel |

| EP1549486A1 (fr) * | 2002-08-14 | 2005-07-06 | Shaw Industries Group, Inc. | Revetement de sol a rainure et languette resistant a l'eau |

| EP1593796A1 (fr) * | 2004-05-07 | 2005-11-09 | Nordson Corporation | Elément plan et procédé pour former les moyens de liaison latéraux d'éléments plans |

| FR2910034A1 (fr) * | 2006-12-13 | 2008-06-20 | Pierre Geraud | Procede de realisation d'un parquet a lames adjacentes, et parquet ainsi constitue |

| US7757452B2 (en) | 2002-04-03 | 2010-07-20 | Valinge Innovation Ab | Mechanical locking system for floorboards |

| US7802415B2 (en) | 2001-07-27 | 2010-09-28 | Valinge Innovation Ab | Floor panel with sealing means |

| US7823359B2 (en) | 1993-05-10 | 2010-11-02 | Valinge Innovation Ab | Floor panel with a tongue, groove and a strip |

| EP1497511B1 (fr) * | 2002-04-08 | 2010-12-15 | Välinge Innovation AB | Panneau de revêtement de sol stratifié |

| US7930862B2 (en) | 2006-01-12 | 2011-04-26 | Valinge Innovation Ab | Floorboards having a resilent surface layer with a decorative groove |

| US8011155B2 (en) | 2000-01-24 | 2011-09-06 | Valinge Innovation Ab | Locking system for mechanical joining of floorboards and method for production thereof |

| US8033075B2 (en) | 1998-06-03 | 2011-10-11 | Välinge Innovation AB | Locking system and flooring board |

| WO2012004700A2 (fr) | 2010-07-09 | 2012-01-12 | Flooring Industries Limited, Sarl | Panneau pour former un revêtement de sol |

| US8112891B2 (en) | 2003-02-24 | 2012-02-14 | Valinge Innovation Ab | Method for manufacturing floorboard having surface layer of flexible and resilient fibers |

| US8250825B2 (en) | 2001-09-20 | 2012-08-28 | Välinge Innovation AB | Flooring and method for laying and manufacturing the same |

| BE1019654A3 (nl) * | 2010-07-09 | 2012-09-04 | Flooring Ind Ltd S A R L | Paneel voor het vormen van een vloerbekleding. |

| US8365499B2 (en) | 2009-09-04 | 2013-02-05 | Valinge Innovation Ab | Resilient floor |

| US8875464B2 (en) | 2012-04-26 | 2014-11-04 | Valinge Innovation Ab | Building panels of solid wood |

| US8925275B2 (en) | 2010-05-10 | 2015-01-06 | Flooring Industries Limited, Sarl | Floor panel |

| US8935899B2 (en) | 2012-02-02 | 2015-01-20 | Valinge Innovation Ab | Lamella core and a method for producing it |

| US9140010B2 (en) | 2012-07-02 | 2015-09-22 | Valinge Flooring Technology Ab | Panel forming |

| US9163414B2 (en) | 2010-05-10 | 2015-10-20 | Flooring Industries Limited, Sarl | Floor panel |

| US9200460B2 (en) | 2006-06-02 | 2015-12-01 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US9314936B2 (en) | 2011-08-29 | 2016-04-19 | Valinge Flooring Technology Ab | Mechanical locking system for floor panels |

| EP3091140A1 (fr) * | 2015-05-05 | 2016-11-09 | Admiral Composite Technologies, Inc. | Systeme et elements de pont |

| US9528278B2 (en) | 2009-12-22 | 2016-12-27 | Flooring Industries Limited, Sarl | Panel, covering and method for installing such panels |

| US9605436B2 (en) | 2003-12-02 | 2017-03-28 | Valinge Innovation Ab | Floorboard, system and method for forming a flooring, and a flooring formed thereof |

| US9623433B2 (en) | 2004-10-05 | 2017-04-18 | Valinge Innovation Ab | Appliance and method for surface treatment of a board shaped material and floorboard |

| CN107938990A (zh) * | 2017-12-27 | 2018-04-20 | 肇庆乐华陶瓷洁具有限公司 | 一种防滑地砖 |

| US9975267B2 (en) | 2013-08-27 | 2018-05-22 | Valinge Innovation Ab | Method for producing a lamella core |

| US10059084B2 (en) | 2014-07-16 | 2018-08-28 | Valinge Innovation Ab | Method to produce a thermoplastic wear resistant foil |

| US10190323B2 (en) | 2010-05-10 | 2019-01-29 | Flooring Industries Limited, Sarl | Floor panel |

| US10301830B2 (en) | 2013-03-25 | 2019-05-28 | Valinge Innovation Ab | Floorboards provided with a mechanical locking system |

| US10760283B2 (en) | 2012-02-23 | 2020-09-01 | Admiral Composite Technologies, Inc. | Deck system and components |

| US11725395B2 (en) | 2009-09-04 | 2023-08-15 | Välinge Innovation AB | Resilient floor |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE525661C2 (sv) | 2002-03-20 | 2005-03-29 | Vaelinge Innovation Ab | System för bildande av dekorativa fogpartier och golvskivor därför |

| US8850769B2 (en) | 2002-04-15 | 2014-10-07 | Valinge Innovation Ab | Floorboards for floating floors |

| US7677001B2 (en) | 2003-03-06 | 2010-03-16 | Valinge Innovation Ab | Flooring systems and methods for installation |

| US7845140B2 (en) | 2003-03-06 | 2010-12-07 | Valinge Innovation Ab | Flooring and method for installation and manufacturing thereof |

| SE0300642D0 (sv) * | 2003-03-11 | 2003-03-11 | Pergo Europ Ab | Process for sealing a joint |

| US20050166516A1 (en) | 2004-01-13 | 2005-08-04 | Valinge Aluminium Ab | Floor covering and locking systems |

| US7841144B2 (en) | 2005-03-30 | 2010-11-30 | Valinge Innovation Ab | Mechanical locking system for panels and method of installing same |

| US8215078B2 (en) | 2005-02-15 | 2012-07-10 | Välinge Innovation Belgium BVBA | Building panel with compressed edges and method of making same |

| US8061104B2 (en) | 2005-05-20 | 2011-11-22 | Valinge Innovation Ab | Mechanical locking system for floor panels |

| WO2008088239A1 (fr) * | 2007-01-18 | 2008-07-24 | Yury Andreevich Kutsenko | Unité de raccordement de panneaux de construction |

| DE102007062106B4 (de) * | 2007-10-05 | 2013-04-04 | Hamberger Industriewerke Gmbh | Verbindung für Fußbodenpaneele |

| DE102017105153A1 (de) | 2017-03-10 | 2018-09-13 | GKT Gummi- und Kunststofftechnik Fürstenwalde GmbH | Bodendielensystem |

| DE102017105146A1 (de) | 2017-03-10 | 2018-09-13 | GKT Gummi- und Kunststofftechnik Fürstenwalde GmbH | Bodendielensystem |

| EP4119741A1 (fr) * | 2021-07-16 | 2023-01-18 | Flooring Industries Limited, SARL | Panneau décoratif |

| WO2023285954A1 (fr) * | 2021-07-16 | 2023-01-19 | Flooring Industries Limited, Sarl | Panneau décoratif |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29703962U1 (de) * | 1997-03-05 | 1997-04-24 | Witex AG, 32832 Augustdorf | Element zur Erzeugung eines Fußboden- oder Wandflächenbelages, insbesondere Laminatpaneel |

| DE20001225U1 (de) * | 2000-01-14 | 2000-07-27 | Hornitex Werke Gebr. Künnemeyer GmbH & Co. KG, 32805 Horn-Bad Meinberg | Profil zum formschlüssigen, leimfreien und wieder lösbaren Verbinden von Fußbodendielen, Paneel oder ähnlichen Bauteilen |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4123885A (en) * | 1976-04-30 | 1978-11-07 | Cyclops Corporation | Building panel joint |

| DE19946755A1 (de) * | 1999-09-29 | 2001-05-03 | Weiss Ausbausysteme Gmbh | Platte zur Bodenverlegung, sowie Bodenbelag hieraus |

-

2001

- 2001-06-01 FR FR0107251A patent/FR2825397B1/fr not_active Expired - Fee Related

-

2002

- 2002-05-29 EP EP02291309A patent/EP1262609B1/fr not_active Expired - Lifetime

- 2002-05-29 AT AT02291309T patent/ATE333545T1/de not_active IP Right Cessation

- 2002-05-29 ES ES02291309T patent/ES2266423T3/es not_active Expired - Lifetime

- 2002-05-29 DE DE60213161T patent/DE60213161T2/de not_active Expired - Lifetime

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29703962U1 (de) * | 1997-03-05 | 1997-04-24 | Witex AG, 32832 Augustdorf | Element zur Erzeugung eines Fußboden- oder Wandflächenbelages, insbesondere Laminatpaneel |

| DE20001225U1 (de) * | 2000-01-14 | 2000-07-27 | Hornitex Werke Gebr. Künnemeyer GmbH & Co. KG, 32805 Horn-Bad Meinberg | Profil zum formschlüssigen, leimfreien und wieder lösbaren Verbinden von Fußbodendielen, Paneel oder ähnlichen Bauteilen |

Cited By (115)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7823359B2 (en) | 1993-05-10 | 2010-11-02 | Valinge Innovation Ab | Floor panel with a tongue, groove and a strip |

| US8033075B2 (en) | 1998-06-03 | 2011-10-11 | Välinge Innovation AB | Locking system and flooring board |

| US6766622B1 (en) * | 1998-07-24 | 2004-07-27 | Unilin Beheer B.V. | Floor panel for floor covering and method for making the floor panel |

| US8011155B2 (en) | 2000-01-24 | 2011-09-06 | Valinge Innovation Ab | Locking system for mechanical joining of floorboards and method for production thereof |

| EP2146024A3 (fr) * | 2001-07-27 | 2011-05-25 | Välinge Innovation AB | Panneaux de plancher dotés de moyens d'étanchéité |

| US8028486B2 (en) | 2001-07-27 | 2011-10-04 | Valinge Innovation Ab | Floor panel with sealing means |

| US8584423B2 (en) | 2001-07-27 | 2013-11-19 | Valinge Innovation Ab | Floor panel with sealing means |

| EP1412596B1 (fr) * | 2001-07-27 | 2009-08-26 | Välinge Innovation AB | Panneau de plancher avec des moyens d'assemblage pour liaison mécanique et des moyens élastiques de compensation |

| EP2146024A2 (fr) * | 2001-07-27 | 2010-01-20 | Välinge Innovation AB | Panneaux de plancher dotés de moyens d'étanchéité |

| EP1412596A1 (fr) * | 2001-07-27 | 2004-04-28 | Välinge Innovation AB | Panneaux de plancher dotes de moyens d'etancheite |

| US7802415B2 (en) | 2001-07-27 | 2010-09-28 | Valinge Innovation Ab | Floor panel with sealing means |

| US8250825B2 (en) | 2001-09-20 | 2012-08-28 | Välinge Innovation AB | Flooring and method for laying and manufacturing the same |

| US7757452B2 (en) | 2002-04-03 | 2010-07-20 | Valinge Innovation Ab | Mechanical locking system for floorboards |

| US9194135B2 (en) | 2002-04-08 | 2015-11-24 | Valinge Innovation Ab | Floorboards for floorings |

| US8720151B2 (en) | 2002-04-08 | 2014-05-13 | Valinge Innovation Ab | Floorboards for flooring |

| US8381488B2 (en) | 2002-04-08 | 2013-02-26 | Valinge Innovation Ab | Floorboards for floorings |

| EP2281973A3 (fr) * | 2002-04-08 | 2015-03-18 | Välinge Innovation AB | Panneau de plancher |

| EP1497511B1 (fr) * | 2002-04-08 | 2010-12-15 | Välinge Innovation AB | Panneau de revêtement de sol stratifié |

| US8245477B2 (en) | 2002-04-08 | 2012-08-21 | Välinge Innovation AB | Floorboards for floorings |

| WO2004016422A1 (fr) | 2002-08-14 | 2004-02-26 | Shaw Industries Group, Inc. | Revetement de sol a rainure et languette resistant a l'eau |

| EP1549486A1 (fr) * | 2002-08-14 | 2005-07-06 | Shaw Industries Group, Inc. | Revetement de sol a rainure et languette resistant a l'eau |

| EP1549486A4 (fr) * | 2002-08-14 | 2006-12-13 | Shaw Ind Group Inc | Revetement de sol a rainure et languette resistant a l'eau |

| US9410328B2 (en) | 2003-02-24 | 2016-08-09 | Valinge Innovation Ab | Floorboard and method for manufacturing thereof |

| US8112891B2 (en) | 2003-02-24 | 2012-02-14 | Valinge Innovation Ab | Method for manufacturing floorboard having surface layer of flexible and resilient fibers |

| US10137659B2 (en) | 2003-02-24 | 2018-11-27 | Valinge Innovation Ab | Floorboard and method for manufacturing thereof |

| US8800150B2 (en) | 2003-02-24 | 2014-08-12 | Valinge Innovation Ab | Floorboard and method for manufacturing thereof |

| US9605436B2 (en) | 2003-12-02 | 2017-03-28 | Valinge Innovation Ab | Floorboard, system and method for forming a flooring, and a flooring formed thereof |

| EP1593796A1 (fr) * | 2004-05-07 | 2005-11-09 | Nordson Corporation | Elément plan et procédé pour former les moyens de liaison latéraux d'éléments plans |

| US9623433B2 (en) | 2004-10-05 | 2017-04-18 | Valinge Innovation Ab | Appliance and method for surface treatment of a board shaped material and floorboard |

| US8511031B2 (en) | 2006-01-12 | 2013-08-20 | Valinge Innovation Ab | Set F floorboards with overlapping edges |

| US8245478B2 (en) | 2006-01-12 | 2012-08-21 | Välinge Innovation AB | Set of floorboards with sealing arrangement |

| US7930862B2 (en) | 2006-01-12 | 2011-04-26 | Valinge Innovation Ab | Floorboards having a resilent surface layer with a decorative groove |

| US9765530B2 (en) | 2006-01-12 | 2017-09-19 | Valinge Innovation Ab | Floorboards comprising a decorative edge part in a resilient surface layer |

| US11066836B2 (en) | 2006-01-12 | 2021-07-20 | Valinge Innovation Ab | Floorboards comprising a decorative edge part in a resilient surface layer |

| US10450760B2 (en) | 2006-01-12 | 2019-10-22 | Valinge Innovation Ab | Floorboards comprising a decorative edge part in a resilient surface layer |

| US11702847B2 (en) | 2006-01-12 | 2023-07-18 | Valinge Innovation Ab | Floorboards comprising a decorative edge part in a resilient surface layer |

| US9222267B2 (en) | 2006-01-12 | 2015-12-29 | Valinge Innovation Ab | Set of floorboards having a resilient groove |

| US10125499B2 (en) | 2006-06-02 | 2018-11-13 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US9366037B2 (en) | 2006-06-02 | 2016-06-14 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US10745921B2 (en) | 2006-06-02 | 2020-08-18 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US9200460B2 (en) | 2006-06-02 | 2015-12-01 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US10975579B2 (en) | 2006-06-02 | 2021-04-13 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US10519674B2 (en) | 2006-06-02 | 2019-12-31 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US10975578B2 (en) | 2006-06-02 | 2021-04-13 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US11680414B2 (en) | 2006-06-02 | 2023-06-20 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US10358831B2 (en) | 2006-06-02 | 2019-07-23 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US9890542B2 (en) | 2006-06-02 | 2018-02-13 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US11933055B2 (en) | 2006-06-02 | 2024-03-19 | Unilin, Bv | Floor covering, floor element and method for manufacturing floor elements |

| US9695599B2 (en) | 2006-06-02 | 2017-07-04 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| US9487957B2 (en) | 2006-06-02 | 2016-11-08 | Flooring Industries Limited, Sarl | Floor covering, floor element and method for manufacturing floor elements |

| FR2910034A1 (fr) * | 2006-12-13 | 2008-06-20 | Pierre Geraud | Procede de realisation d'un parquet a lames adjacentes, et parquet ainsi constitue |

| US9249581B2 (en) | 2009-09-04 | 2016-02-02 | Valinge Innovation Ab | Resilient floor |

| US8756899B2 (en) | 2009-09-04 | 2014-06-24 | Valinge Innovation Ab | Resilient floor |

| US8365499B2 (en) | 2009-09-04 | 2013-02-05 | Valinge Innovation Ab | Resilient floor |

| US11725395B2 (en) | 2009-09-04 | 2023-08-15 | Välinge Innovation AB | Resilient floor |

| US9670682B2 (en) | 2009-12-22 | 2017-06-06 | Flooring Industries Limited, Sarl | Panel, covering and method for installing such panels |

| US10428534B2 (en) | 2009-12-22 | 2019-10-01 | Flooring Industries Limited, Sarl | Panel, covering and method for installing such panels |

| US11668099B2 (en) | 2009-12-22 | 2023-06-06 | Flooring Industries Limited, Sarl | Panel, covering and method for installing such panels |

| US10550582B2 (en) | 2009-12-22 | 2020-02-04 | Flooring Industries Limited, Sarl | Panel, covering and method for installing such panels |

| US9670683B2 (en) | 2009-12-22 | 2017-06-06 | Flooring Industries Limited,Sarl | Panel, covering and method for installing such panels |

| US9528278B2 (en) | 2009-12-22 | 2016-12-27 | Flooring Industries Limited, Sarl | Panel, covering and method for installing such panels |

| US9163414B2 (en) | 2010-05-10 | 2015-10-20 | Flooring Industries Limited, Sarl | Floor panel |

| US11566432B2 (en) | 2010-05-10 | 2023-01-31 | Flooring Industries Limited, Sarl | Floor panel |

| US12123201B2 (en) | 2010-05-10 | 2024-10-22 | Unilin, Bv | Floor panel |

| US12031337B2 (en) | 2010-05-10 | 2024-07-09 | Unilin, Bv | Floor panel |

| US12012764B2 (en) | 2010-05-10 | 2024-06-18 | Unilin Bv | Floor panel |

| US10041259B2 (en) | 2010-05-10 | 2018-08-07 | Flooring Industries Limited, Sarl | Floor panel |

| US11976471B2 (en) | 2010-05-10 | 2024-05-07 | Unilin Bv | Floor panel |

| US10094123B2 (en) | 2010-05-10 | 2018-10-09 | Flooring Industries Limited, Sarl | Floor panel |

| US10100533B2 (en) | 2010-05-10 | 2018-10-16 | Flooring Industries Limited, Sarl | Floor panel |

| US10815676B2 (en) | 2010-05-10 | 2020-10-27 | Flooring Industries Limited, Sarl | Floor panel |

| US9453348B1 (en) | 2010-05-10 | 2016-09-27 | Flooring Industries Limited, Sarl | Floor panel |

| US10190323B2 (en) | 2010-05-10 | 2019-01-29 | Flooring Industries Limited, Sarl | Floor panel |

| US10208490B2 (en) | 2010-05-10 | 2019-02-19 | Flooring Industries Limited, Sarl | Floor panel |

| US10214921B2 (en) | 2010-05-10 | 2019-02-26 | Flooring Industries Limited, Sarl | Floor panel |

| US10233655B2 (en) | 2010-05-10 | 2019-03-19 | Flooring Industries Limited, Sarl | Floor panel |

| US10267048B2 (en) | 2010-05-10 | 2019-04-23 | Flooring Industries Limited, Sarl | Floor panel |

| US10301831B2 (en) | 2010-05-10 | 2019-05-28 | Flooring Industries Limited, Sarl | Floor panel |

| US11795702B2 (en) | 2010-05-10 | 2023-10-24 | Flooring Industries Limited Sarl | Floor panel |

| US9366035B2 (en) | 2010-05-10 | 2016-06-14 | Flooring Industries Limited, Sarl | Floor panel |

| US9783995B2 (en) | 2010-05-10 | 2017-10-10 | Flooring Industries Limited, Sarl | Floor panel |

| US10870994B2 (en) | 2010-05-10 | 2020-12-22 | Flooring Industries Limited Sarl | Floor panel |

| US11634913B2 (en) | 2010-05-10 | 2023-04-25 | Flooring Industries Limited, Sarl | Floor panel |

| US11634914B2 (en) | 2010-05-10 | 2023-04-25 | Flooring Industries Limited, Sarl | Floor panel |

| US9809984B2 (en) | 2010-05-10 | 2017-11-07 | Flooring Industries Limited, Sarl | Floor panel |

| US10597876B2 (en) | 2010-05-10 | 2020-03-24 | Flooring Industries Limited, Sarl | Floor panel |

| US11505949B2 (en) | 2010-05-10 | 2022-11-22 | Flooring Industries Limited, Sarl | Floor panel |

| US11377857B2 (en) | 2010-05-10 | 2022-07-05 | Flooring Industries Limited, Sarl | Floor panel |

| US11371249B2 (en) | 2010-05-10 | 2022-06-28 | Flooring Industries Limited, Sarl | Floor panel |

| US11236514B2 (en) | 2010-05-10 | 2022-02-01 | Flooring Industries Limited, Sarl | Floor panel |

| US10876303B2 (en) | 2010-05-10 | 2020-12-29 | Flooring Industries Limited, Sarl | Floor panel |

| US10889998B2 (en) | 2010-05-10 | 2021-01-12 | Flooring Industries Limited, Sarl | Floor panel |

| US10927553B2 (en) | 2010-05-10 | 2021-02-23 | Flooring Industries Limited, Sarl | Floor panel |

| US9080330B2 (en) | 2010-05-10 | 2015-07-14 | Flooring Industries Limited, Sarl | Floor panel |

| US11193282B2 (en) | 2010-05-10 | 2021-12-07 | Flooring Industries Limited, Sarl | Floor panel |

| US8925275B2 (en) | 2010-05-10 | 2015-01-06 | Flooring Industries Limited, Sarl | Floor panel |

| WO2012004700A2 (fr) | 2010-07-09 | 2012-01-12 | Flooring Industries Limited, Sarl | Panneau pour former un revêtement de sol |

| BE1019654A3 (nl) * | 2010-07-09 | 2012-09-04 | Flooring Ind Ltd S A R L | Paneel voor het vormen van een vloerbekleding. |

| WO2012004700A3 (fr) * | 2010-07-09 | 2012-08-02 | Flooring Industries Limited, Sarl | Panneau pour former un revêtement de sol |

| US9314936B2 (en) | 2011-08-29 | 2016-04-19 | Valinge Flooring Technology Ab | Mechanical locking system for floor panels |

| US8935899B2 (en) | 2012-02-02 | 2015-01-20 | Valinge Innovation Ab | Lamella core and a method for producing it |

| US9758966B2 (en) | 2012-02-02 | 2017-09-12 | Valinge Innovation Ab | Lamella core and a method for producing it |

| US10760283B2 (en) | 2012-02-23 | 2020-09-01 | Admiral Composite Technologies, Inc. | Deck system and components |

| US8875464B2 (en) | 2012-04-26 | 2014-11-04 | Valinge Innovation Ab | Building panels of solid wood |

| US9663956B2 (en) | 2012-07-02 | 2017-05-30 | Ceraloc Innovation Ab | Panel forming |

| US9140010B2 (en) | 2012-07-02 | 2015-09-22 | Valinge Flooring Technology Ab | Panel forming |

| US9556623B2 (en) | 2012-07-02 | 2017-01-31 | Ceraloc Innovation Ab | Panel forming |

| US9482015B2 (en) | 2012-07-02 | 2016-11-01 | Ceraloc Innovation Ab | Panel forming |

| US10301830B2 (en) | 2013-03-25 | 2019-05-28 | Valinge Innovation Ab | Floorboards provided with a mechanical locking system |

| US11898356B2 (en) | 2013-03-25 | 2024-02-13 | Välinge Innovation AB | Floorboards provided with a mechanical locking system |

| US9975267B2 (en) | 2013-08-27 | 2018-05-22 | Valinge Innovation Ab | Method for producing a lamella core |

| US10059084B2 (en) | 2014-07-16 | 2018-08-28 | Valinge Innovation Ab | Method to produce a thermoplastic wear resistant foil |

| US10493731B2 (en) | 2014-07-16 | 2019-12-03 | Valinge Innovation Ab | Method to produce a thermoplastic wear resistant foil |

| EP3091140A1 (fr) * | 2015-05-05 | 2016-11-09 | Admiral Composite Technologies, Inc. | Systeme et elements de pont |

| CN107938990A (zh) * | 2017-12-27 | 2018-04-20 | 肇庆乐华陶瓷洁具有限公司 | 一种防滑地砖 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE60213161D1 (de) | 2006-08-31 |

| ATE333545T1 (de) | 2006-08-15 |

| FR2825397A1 (fr) | 2002-12-06 |

| DE60213161T2 (de) | 2007-06-14 |

| EP1262609B1 (fr) | 2006-07-19 |

| ES2266423T3 (es) | 2007-03-01 |

| FR2825397B1 (fr) | 2004-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1262609B1 (fr) | Eléments de revêtement de sol à joint d'étanchéité | |

| CA2612000C (fr) | Panneau, en particulier pour le revetement de sols | |

| EP0690185A1 (fr) | Latte de parquet | |

| WO2001088307A1 (fr) | Dispositif d'assemblage des bords longitudinaux de panneaux, lattes ou lambris, a repartition de forces | |

| EP0354149A1 (fr) | Procédé et dispositif de jonction étanche de panneaux exposés au ruissellement | |

| WO2004035960A1 (fr) | Module d'assemblage pour revetements de sols ou murs | |

| WO2006077297A1 (fr) | Dalle autobloquante pour revetements de sols | |

| EP2369092B1 (fr) | Élément de bordure monobloc à coller | |

| FR2981103A3 (fr) | Bande de desolidarisation | |

| FR2899257A1 (fr) | Cloison pour la realisation de cloisonnages | |

| WO2018007731A1 (fr) | Dalle composite et systeme de revetement comprenant de telles dalles | |

| EP0313485B1 (fr) | Dalle plancher surélevé | |

| EP3006646A1 (fr) | Système de revêtement du type dalles sur plots comprenant au moins un contenant | |

| EP2369095B1 (fr) | Système d'élément de bordure | |

| WO2003016656A1 (fr) | Procede d'assemblage des bords a repartition de forces | |

| FR3017400B1 (fr) | Ensemble d'elements de construction et materiau de remplissage pour le joint entre des elements de construction | |

| FR2889219A1 (fr) | Panneaux a assembler par rotation et profils correspondants | |

| EP1231337A1 (fr) | Structures appropriées à l'aménagement de locaux humides et procédé de montage relatif | |

| LU83563A1 (fr) | Tpanneaux isolants rigides non porteures supports d'etancheite de toitures utilisables pour la pose de l'etancheite de toitures en semi-independance | |

| WO2000061872A1 (fr) | Procede de realisation d'un joint de chaussee souple, et joint obtenu par un tel procede | |

| FR2471464A1 (fr) | Dispositif de revetement mural et son procede de pose | |

| WO2018046817A1 (fr) | Element de construction | |

| EP2055861B1 (fr) | Procédé de pose d'un matériau isolant et ensemble d'accessoires de pose correspondant | |

| WO2001034921A1 (fr) | Panneau de recouvrement pour construction comprenant des elements male et femelle pour former un joint et son procede de fabrication | |

| FR2808825A1 (fr) | Dispositif d'assemblage des bords longitudinaux de panneaux, lattes ou lambris, a repartition de forces |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| AKX | Designation fees paid | ||

| 17P | Request for examination filed |

Effective date: 20030607 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: TARKETT SAS |

|

| 17Q | First examination report despatched |

Effective date: 20050408 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060719 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060802 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REF | Corresponds to: |

Ref document number: 60213161 Country of ref document: DE Date of ref document: 20060831 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061019 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061219 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2266423 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070420 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061020 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060719 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20180601 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BG Payment date: 20180221 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20180529 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20190526 Year of fee payment: 18 Ref country code: LU Payment date: 20190527 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20190530 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190527 Year of fee payment: 18 Ref country code: BE Payment date: 20190527 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20190528 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190529 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190530 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 60213161 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20200601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200601 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20200531 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20200529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200531 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201201 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200531 |