EP1236552B1 - Method and plant for the production of fiberboards - Google Patents

Method and plant for the production of fiberboards Download PDFInfo

- Publication number

- EP1236552B1 EP1236552B1 EP02003478A EP02003478A EP1236552B1 EP 1236552 B1 EP1236552 B1 EP 1236552B1 EP 02003478 A EP02003478 A EP 02003478A EP 02003478 A EP02003478 A EP 02003478A EP 1236552 B1 EP1236552 B1 EP 1236552B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- press

- fiber mat

- humidity

- water

- several

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B5/00—Presses characterised by the use of pressing means other than those mentioned in the preceding groups

- B30B5/04—Presses characterised by the use of pressing means other than those mentioned in the preceding groups wherein the pressing means is in the form of an endless band

- B30B5/06—Presses characterised by the use of pressing means other than those mentioned in the preceding groups wherein the pressing means is in the form of an endless band co-operating with another endless band

- B30B5/065—Presses characterised by the use of pressing means other than those mentioned in the preceding groups wherein the pressing means is in the form of an endless band co-operating with another endless band using anti-friction means for the pressing band

- B30B5/067—Presses characterised by the use of pressing means other than those mentioned in the preceding groups wherein the pressing means is in the form of an endless band co-operating with another endless band using anti-friction means for the pressing band using anti-friction roller means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/08—Moulding or pressing

- B27N3/24—Moulding or pressing characterised by using continuously acting presses having endless belts or chains moved within the compression zone

Definitions

- the invention relates to a process for the production of wood-based panels, in particular of fibreboards in semi-dry process according to the preamble of claim 1 and a system for carrying out the method of claim 28.

- a method or such a system is known from WO 98/41372 known.

- Fibrous boards which are produced in the semi-dry or wet process, have a very low adhesive content of about 0.5 - 1%, or some fiberboard are produced entirely without adhesive.

- an adhesive content of, for example, 12% causes up to 30% of the cost of producing an MDF board, and as the cost of petroleum increases, the cost of the adhesive continues to rise, making the fiberboard very expensive.

- Fibrous plates from the semi-dry and wet process are so far pressed only on discontinuous multi-floor systems.

- a large amount of polluted sewage is produced, on the one hand during the formation of nonwoven fabric via a wire and, on the other hand, during the hot pressing.

- This process was further developed in the 40 and 50 years to the semi-dry process to reduce wastewater pollution.

- There are a number of protective rights U.S. Patent 2,757,115 ; U.S. Patent 2,757,148 ; U.S. Patent 2,757,149 and U.S. Patent 2,757,150 ).

- a small amount of water is also squeezed out of the mat during the semi-dry process at the beginning of the hot pressing.

- the pressing time for a 3 mm fibreboard is about 4 minutes, which in the dry process is just under 1 minute.

- the multi-floor press must have a large number of floors (up to 35 units) to ensure that the capacity of the system is sufficient for operation. Due to the high number of floors, the presses are expensive. The operating costs of such a system are due to the multi-day press also very high.

- the fibers In the semi-dry process, the fibers must be dried to a moisture content of less than 35% so that they can be formed into a fiber mat without the use of a wire. At higher humidities, the fibers are matted, so that a pneumatic or mechanical scattering is not possible is. After scattering the fiber mat is pre-pressed continuously and divided into individual fiber mat sections according to the floor size by means of a saw. These mat sections are transported on screens or metal wire mesh, which are often still mounted on sheets, in the loading basket, where they vary in length depending on the floor.

- the fiber mat sections are dried to a moisture content of about 18% and, after the pre-press, water is sprayed onto the top of the fiber mat. Due to the water, the fiber mat moisture in front of the press rises to about 32%. Since at the beginning of the pressing the water is only on the upper side and therefore heats up the top faster than the bottom, the fiber mat top is plasticized at the beginning of the pressing more than the bottom.

- the sieves and sheets are transported back to the form strand after pressing around the press or under the press, which takes a few minutes.

- the screens must be cleaned in some plants with water. During transport and cleaning, the screens and sheets cool. They must then be heated to the heating plate temperature of 190 ° C at the beginning of the pressing, which takes 20 - 60 seconds.

- the specific pressure is reduced and the fiber mat is dried in 2 - 4 minutes to about 8% moisture, with the water vapor is discharged through the sieve.

- the specific pressure is usually adjusted so that it is slightly larger than the vapor pressure in the fiber mat. This prevents the fiber mat from bursting in the press.

- the fiber mat is compacted at a specific pressure of about 3 N / mm 2 to the final thickness and dried to about 2% moisture. A path control of the individual floors can not be performed, the fiberboard therefore have high thickness tolerances.

- the invention is based on the object to provide a method and to provide a system with which a fiberboard with little or no adhesive can be produced and with which the pressing time can be drastically shortened, and the properties of the plate and the thickness tolerances of the plate can be improved ,

- the system for carrying out the method according to claim 28 is that there is a continuously operating press with the pressing pressure transmitting and the fiber mat passing through the press nip endless steel belts as press, the steel belts are guided circumferentially about drive frame and idler pulleys around the frame top and the frame base , Which are supported with adjustable press nip on revolving, guided with their axes transverse to the strip running direction rolling bars relative to the compassionober- and frame base, wherein the rolling rods are guided at both ends in guide chains, that before and between the scattering station and the continuously operating press several on the Hot water spraying devices and devices for applying release agents are arranged on the conveyor belt and directed towards the surfaces of the fiber mat, from the continuously operating press a pre-press with steam preheating device and upper and lower wire belt v is seen, the continuously operating press as a storage for the fiber mat and water and steam removal from the fiber mat an existing stainless material, with the lower steel belt circumferentially guided, endless metal fabric belt, which led before entering the press ni

- the pressing time can be significantly reduced compared to the known cyclic half-drying processes.

- the pressing time for a 4 mm thick fiberboard is reduced from 4 minutes to about 1 minute (see Table 1).

- a significant advantage is that the heating of the fiber mat is drastically reduced by the steam preheating of the fiber mat to at least 100 ° C. At this temperature, the viscosity of the water decreases, whereby the flow resistance is reduced and the water can be squeezed faster from the mat.

- the steam preheating of the fiber mat to 100 ° C is particularly advantageous in the production of fibreboard with a thickness greater than 4 mm, as this, the press time reduction is particularly high.

- the table shows selected process parameters during hot pressing in a continuous press according to the method of the invention for a 4 mm thick fiberboard.

- phase Time [seconds] Sp. Pressure [N / mm 2 ]

- Start - End Damp DS [%]

- Start - End Humidity MS [%]

- Start - End Temperature MS [° C]

- Start - End 1. compaction DS 5 - 15 0 - 5 35 - 2 35 - 6 100-105 2.

- Curing (and compacting MS) 25 - 50 4 - 2.5 0.5-0.2 6 - 2 110 - 135

- the fiber mat in the continuous press can also be pressed with a hotplate temperature higher than 190 ° C, because the pressing time is shorter and at the end of the pressing the fiberboard can be cooled. As a result, the pressing time is significantly reduced.

- increasing the pressure plate temperature is not possible due to the risk of steam bursting, especially the upper surface layer.

- the risk of topcoat bursting is significantly reduced.

- a predetermined path-pressure program can be regulated very accurately in the continuous press, wherein the continuous press is preferably designed so that very large deformations per meter of press length are possible in the transport direction.

- the press nip can be optimally adapted to the individual phases.

- the press nip can be enlarged so far that just surface blemishes are avoided. This reduces the flow resistance perpendicular to the surface in the fiber mat and the fiberboard can be dried faster.

- the fiber board can be relieved after an optimized program at the end of the pressing. In connection with the cooling of the fiber mat surface, the moisture content of the fiberboard must not be below 2%. be reduced, which on the one hand shortens the curing phase and in the subsequent air conditioning of the plate is beneficial.

- the fiberboard has a more even distribution of moisture over the slab cross-section.

- the continuous compression according to the invention also leads to significantly reduced electrical and thermal energy costs.

- the loading and unloading about 70% more electrical energy per m 3 of produced fiberboard is required compared to the continuous process according to the invention, since a much higher connected load must be installed.

- the multi-day press including the required sieves has higher radiation losses, more thermal energy is required to operate the press.

- a multi-day press on average with higher press plate temperatures pressed. Since the temperature in the continuous press is lowered significantly towards the end of the pressing, less water is needed and evaporated from the fiber mat and thus less energy is brought into the fiber board.

- the steam preheating steam with a low vapor pressure below 3 bar can be used, which is available as a very favorable steam from the fiber processing available. This also reduces the cost of the heating energy at the beginning of the pressing.

- fiber-fiber bonding is achieved in two ways: on the one hand via a so-called hydrogen bond, especially of the wood constituents cellulose and hemicellulose, and on the other hand through the softened lignin.

- hydrogen bond especially of the wood constituents cellulose and hemicellulose

- softened lignin it is important that the individual fibers have very close contact with each other over a longer distance.

- the wood chips are prebaked in the preheating at a temperature higher than 180 ° C, preferably 190 to 220 ° C, in the preheating in order to achieve that substances are formed in the wood by conversion processes, which lead to a better bonding during the hot pressing.

- the formation of furfural is promoted by the formation of acids in the preheater.

- the formation of acids is supported by the high temperature in the preheating.

- Furfural promotes condensation reactions between the wood components.

- acid - such as sulfuric acid - may be added, which also promotes the formation of furfural.

- Hardwoods usually produce more sticky substances than softwoods. Therefore, deciduous trees are particularly suitable for this process.

- the fiber mat can be scattered by means of a single scattering machine or the fibers are divided after production in the refiner into coarse and fine fibers or already prepared separately by means of two refiners.

- the coarse fibers are then preferably scattered into the center of the fiber mat as the middle layer and the fine fibers as the cover layer.

- the fibers must not be dried below a moisture content of 16% or the fibers must not a humidity of 16% fall below, otherwise they verborn. Horny fibers only form an insufficient hydrogen bond. This means that care must also be taken during the transport of the fibers that the moisture content is not undershot. Since during transport of the fiber in the air stream with air of a relative humidity lower than the equilibrium moisture content of the fiber, the fibers quickly release moisture, either the transport air must be air-conditioned by, for example, steam injection or the fibers should have a slightly higher humidity after the dryer as having on the forming belt.

- the moisture of the fiber mat is increased by the steam preheating depending on the preheating by the condensation of water vapor. If the entire fiber mat is warmed through, the mat moisture increases by about 7%. When about 50% of the mat is heated, the humidity increase is about 4%.

- the method must be controlled in any case so that the fiber mat moisture at the beginning of the hot pressing is not less than 25% and not more than 35%, because if the humidity is below 25%, only insufficient wood-specific adhesive joints can be formed. Then the consumption of glue increases very strongly. If the humidity is over 35%, on the other hand, the pressing time is greatly increased due to the longer drying period.

- the fiber mat surface In order to obtain a closed fibreboard surface with a high density and to protect the steel strips from soiling, it is favorable to spray water onto the fiber mat surface in a total amount of 20-700 g / m 2 , depending on the consistency of the fibers and the fiberboard thickness.

- the water can also be sprayed onto the conveyor belt or onto the sieve belt during steam preheating. It is also favorable to spray release agent onto the fiber mat surface and / or the conveyor belt so that the fibers do not stick to the metal fabric belt during the preheating, the conveyor belt, the steel belts and the metal belt in the continuously operating press.

- the amount of water that is sprayed on before the steaming should not be so large that there is free water on the fiber mat surface, as it then comes to problems in the vaporization by an uneven condensation of steam and uncontrollable conditions.

- a larger amount of water than 60 g / m 2 can be sprayed onto the fiber mat only after the steaming in the pre-press with steam preheating.

- the water should preferably be heated to temperatures of 60-95 ° C before spraying. Since the residence time of the water from the spraying to the fiber mat contact with the steel strip in the continuous press is very short, this water is almost not absorbed by the fibers and thus affects the density profile only insignificantly. From Another advantage is that the water is only sprayed from above onto the fiber mat. The water is then evaporated immediately on contact with the steel strip and can only flow vertically into the fiber mat.

- the vapor formed does not penetrate into the fiber mat.

- the steam flows over the metal fabric belt from the press against the transport direction towards the inlet and transverse to the transport direction to the edge of the press.

- the moisture of the fiber mat is then not increased and the pressing time is not shortened.

- a larger amount of water must not be sprayed on the fiber mat side, which faces the metal fabric tape, since the moisture of the fiber mat would then not increased and the pressing time would not be shortened.

- the fibers must be dried to a moisture content which, in addition to the moisture due to the vapor deposition, the water spraying and the water from the release agent application, is within the abovementioned range.

- the amount of sprayed-on water and the added amount of steam must be measured separately for the upper and lower fiber mat sides.

- the amount of steam required to heat the water sprayed on and taken up by the wood can be calculated from the water temperature and the sprayed water Calculate amount of water.

- the amount of steam needed to heat the fibers can be calculated from the initial temperature and humidity of the fibers.

- the penetration depth of the steam is determined separately for the upper and lower bobbins due to the measured and controlled amount of steam.

- the moisture distribution over the fiber mat cross section is directly determinable.

- appropriate measuring devices - such as microwave measuring devices - the moisture distribution over the fiber mat cross section can also be measured.

- the knowledge of the moisture and the moisture distribution over the fiber mat cross-section immediately before the continuously operating press is important both for the formation of a sufficient bond and a minimum pressing time as well as for the formation of the density profile of importance. For a low pressing time is favorable to steam the fiber mat over the entire cross-section and spray as much hot water on the fiber mat.

- the density profile of the finished fiberboard should be measured immediately after the continuous press. Fibrous plates from the semi-dry process often have no significant density reduction in the Fiberboard center on. Fiberboards produced in the dry process show a density minimum in the middle of the fibreboard, which leads to higher bending strengths with the same material input. It has now been found that fibreboards with similar density profiles as are produced by the dry process can be produced by the process according to the invention. For this purpose, not the entire fiber mat cross section should be preheated and softened with steam, but only the outer layers.

- the evaporation depth must be reduced by reducing the amount of steam introduced and possibly the amount of water sprayed on be increased. Also important is an increased heating of the metal fabric strip temperature in the inlet to the continuously operating press, which should be at least 40 ° C higher than the temperature of the steel strips in the inlet to the continuously operating press. A separate control of the top and bottom heating circuit of the press plates has proved to be advantageous.

- the temperature of the fiber mat in the outer layers is also slightly higher than in the cycle. It has been found that this higher temperature promotes the formation of condensation reactions - especially of lignin - so that In the method according to the invention a firmer fiber to fiber bond can be achieved. Slightly better bending properties can therefore be achieved with the same adhesive content.

- the transverse tensile strength of the fiber boards produced in the laboratory process according to the invention are slightly lower at the edge of the fiber board than in the center of the fiber board. This is caused by the fact that the curing temperature at the edge is slightly lower.

- the curing temperature is lower in the fiber mat because the steel belts, the press plates and the rolling bars are cooler at the edge than in the center of the press. They cool by the escaping water and the circulating air.

- the press plates are 50 mm wider on each press side than the fiber mat. It has now been found that by increasing the distance from the edge of the press plate to the fiber mat to ⁇ 100 mm, the curing temperature at the edge is higher and the transverse tensile strength of the fiberboard at the edge is significantly improved.

- the fiber mat can be scattered at the edge even with a higher basis weight, which can also achieve an increase in the transverse tensile strength.

- the continuous fiberboard strand produced in accordance with the invention is subjected to after-treatment after a size-spreading, as in the conventional semi-dry process, to improve the properties.

- the fiberboard are passed through a heat channel or stacked warm in a heated hall.

- the heat treatment of the fiber boards at temperatures between 110 ° and 200 ° C after the continuous press increases the bonding of the individual fibers, which improves the bending properties and the swelling values.

- the fiberboard can be warmly stacked or pulled as a package through a heat channel.

- the metal fabric belt in the continuous press has the function to allow drainage and Entdampfung the fiber mat.

- the metal fabric belt must therefore have a structure which allows a removal of the water and the water vapor within the structure perpendicular to the transport direction without large flow resistance. This means that a larger free cross-section is present within the metal fabric belt transversely to the transport direction.

- the continuous press can be performed in a width of more than 4 m, since the fiber plate is drained and evaporated only on the metal fabric belt.

- the metal fabric tape to the fiber mat side may have a smooth or coarse structure. Usually a smooth structure is desired if the fiberboard is to be coated later. For individual applications, a coarse structure with a screen print on the plate surface is favorable.

- the plant is designed so that the lower steel strip is wider than the upper steel strip and covers the guide chain for guiding the rolling bars.

- the lower steel band can then be pressed down with hold-down rollers. At these points, the water is collected and removed.

- hold-down rollers are provided from the beginning of the press to about 20% of the press length.

- the specific pressure is important because of the avoidance of relative movements between metal fabric belt and steel strip due to thermal expansion and thus avoidance of scratches on the steel strip. Since this process mainly produces thin fiberboard, the metal fabric tape must not have any thickness tolerances greater than ⁇ 0.075 mm. The thickness tolerance would also show up in the product and lead to a larger cut.

- the drawing shows the system as the fiber mat 10 made according to the pressing program from left to right, treated and how it is pressed in the continuous press 5 to the fiber board 30 and cured.

- the fiber mat 10 is compressed in the continuous press 5 at high pressure, pressed out some water and then relieved and dried.

- the fiber mat 10 is compacted to the final thickness and cured, the curing phase is started when the moisture content of the fiber mat 10 is 5% - 8%.

- FIG. 1 From the FIG. 1 is the system shown in a schematic representation, with which the fiber mat 10 is sprinkled from fibers on a conveyor belt 20 from the scattering station 1.

- the conveyor belt 20 serves to further guide the fiber mat 10 if necessary by a pre-press 2, hot water spraying and / or Trennstoffsprühvortechniken 21 to the pre-press with Dampfvor Creekinraum 4.

- the endless conveyor belt 20 is guided over pulleys 24.

- the fiber mat 10 is continued with the conveyor belt 20 down to the lower endless belt 23 of the pre-press with Dampfvortage 4, wherein at the reversal, the guide roller 24 is arranged recoverable to guide the fiber mat 10 in a discharge chute 22 in case of disturbances.

- a mat moisture sensor 3 is arranged. From scattering station 1, a single or multi-layer fiber mat 10 can be scattered as needed. For this purpose, five or more different scattering bins are provided, for example, with superfine fibers 32 and 36 (or also wood dust) for the cover layers, with fibers 33 and 35 for the intermediate layers and with coarse fibers 34 for the middle layer.

- the pre-press with Dampfvor Anlageninutter 4 consists of two endless, around the steam feed 29 and pulleys 27 rotating sieve belts 23, wherein the lower wire 23 leads the possibly preheated fiber mat 10 close to the inlet region of the continuously operating press 5 or to the Metal fabric tape 25 hands.

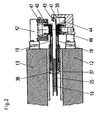

- a so-called double belt press which consists in its main parts of a movable frame upper part 9 and a stationary frame lower part 8, which form the adjustable press nip 11.

- Frame upper part 9 and frame lower part 8 are circulated via drive drums 16 and deflection drums 17 of steel belts 18 and 19.

- At the press nip 11 facing sides of the frame top 9 and frame lower part 8 are heated and coolable press plates 12 and 13 are mounted, which support the steel belts 18/19 by means of likewise circulating guided with guide chains 39 and 40 rolling rods 37 and 38.

- the finished wood-based material or fiber board extending from the continuously operating press 5 is designated 30.

- the lower steel belt 18, a guided over pulleys 27 associated with circulating metal mesh belt 25, which consists of a stainless material of high thermal conductivity such as stainless steel or phosphor bronze, the upper and lower steel belt 18 and 19 and the metal belt fabric 25 in the return common are passed through an insulated tunnel 26 to prevent heat dissipation and to save energy, and the metal fabric belt 25 is heated by a hot plate 28 to a much higher temperature before entering the press nip 11, as the associated steel strip 18 in the inlet to the press nip 11 owns.

- the press length is expediently divided into a heating zone 6 and a cooling zone 7. For a separate control of these zones, both the heating zone 6 and the cooling zone 7 with the cooling plates 14 and 15 via a separate Rollteppichabstützung equipped with guide chains circulating guided rolling rods.

- the density profile of the finished fiberboard 30 is checked by means of a raw density sensor 31 and regulated with the determined value, the temperature and humidity of the fiber mat prior to entry into the continuously operating press 5.

- a section AA off FIG. 1 is in FIG. 2

- the guide chains 39/40 are guided with the rolling rods 37 and 38 on guide rails 47 and 50.

- a plurality of hold-down rollers 43 are mounted on the lower side rail 41.

- a trained on the lower side rail 41 channel 44 serves to derive the emerging from the fiber mat 10 via transverse grooves 45 of the metal fabric belt 25 water and condensing vapor.

- a purpose designed metal fabric tape 25 is in FIG. 3 in side view according to the FIG. 1 shown.

- the longitudinal wires shown as a chain 46 thereby form a sufficiently flat support surface for the fiber mat 10 and are held together by the transverse wires designated as shot 48.

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Wood Science & Technology (AREA)

- Forests & Forestry (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

- Chemical And Physical Treatments For Wood And The Like (AREA)

Abstract

Description

Die Erfindung betrifft ein Verfahren zur Herstellung von Holzwerkstoffplatten, insbesondere von Faserplatten im Halbtrockenverfahren nach dem Oberbegriff des Anspruches 1 sowie einer Anlage zur Durchführung des Verfahrens nach Anspruch 28. Ein solches Verfahren bzw. eine solche Anlage ist aus der

Faserplatten, welche im Halbtrocken- oder Nassverfahren produziert werden, weisen einen sehr niedrigen Klebstoffgehalt von etwa 0,5 - 1 % auf, bzw. einige Faserplatten sind vollkommen ohne Klebstoff produziert. Dagegen beträgt der Klebstoffgehalt bei Faserplatten nach dem Trockenverfahren - zum Beispiel von MDF-Platten - über 10 % bezogen auf die Holzsubstanz (Hamstofformaldehyharz). Ein Klebstoffanteil von zum Beispiel 12 % verursacht jedoch bis zu 30 % der Herstellkosten einer MDF-Platte, wobei bei steigenden Kosten für Erdöl die Kosten für den Klebstoff weiter steigen und die Faserplatte damit sehr teuer wird.Fibrous boards, which are produced in the semi-dry or wet process, have a very low adhesive content of about 0.5 - 1%, or some fiberboard are produced entirely without adhesive. In contrast, the adhesive content of fiberboards by the dry process - for example of MDF boards - over 10% based on the wood substance (urea formaldehyde resin). However, an adhesive content of, for example, 12% causes up to 30% of the cost of producing an MDF board, and as the cost of petroleum increases, the cost of the adhesive continues to rise, making the fiberboard very expensive.

Faserplatten aus dem Halbtrocken- und Nassverfahren werden bisher ausschließlich auf diskontinuierlich arbeitenden Mehretagenanlagen verpresst. Während der Produktion von Faserplatten im Nassverfahren fällt eine große Menge an verschmutzen Abwässer an, zum einen bei der Vliesbildung über ein Langsieb und zum anderen während der Heißpressung. Dieses Verfahren wurde in den 40 und 50 Jahren zu dem Halbtrockenverfahren weiter entwickelt, um die Abwasserverschmutzung zu vermindern. Dazu gibt es eine Reihe von Schutzrechten (

Beim Halbtrockenverfahren müssen die Fasern auf Feuchten unter 35 % getrocknet werden, damit sie ohne die Verwendung eines Langsiebes zu einer Fasermatte geformt werden können. Bei höheren Feuchten sind die Fasern verfilzt, sodass eine pneumatische oder mechanische Streuung nicht möglich ist. Nach der Streuung wird die Fasermatte kontinuierlich vorgepresst und in einzelne Fasermattenabschnitte entsprechend der Etagengröße mittels einer Säge aufgeteilt. Diese Mattenanschnitte werden auf Siebe oder Metalldrahtgewebe, die häufig noch auf Blechen montiert sind, in den Beschickkorb befördert, wo sie je nach Etage unterschiedlich lange liegen.In the semi-dry process, the fibers must be dried to a moisture content of less than 35% so that they can be formed into a fiber mat without the use of a wire. At higher humidities, the fibers are matted, so that a pneumatic or mechanical scattering is not possible is. After scattering the fiber mat is pre-pressed continuously and divided into individual fiber mat sections according to the floor size by means of a saw. These mat sections are transported on screens or metal wire mesh, which are often still mounted on sheets, in the loading basket, where they vary in length depending on the floor.

Häufig werden die Fasermattenabschnitte auf eine Feuchte um die 18 % getrocknet und nach der Vorpresse wird auf die Fasermattenoberseite Wasser gesprüht. Durch das Wasser steigt die Fasermattenfeuchte vor der Presse auf etwa 32 % an. Da sich zu Beginn der Pressung das Wasser nur auf der Oberseite befindet und sich deshalb die Oberseite schneller erwärmt als die Unterseite, wird die Fasermattenoberseite zu Beginn der Pressung stärker plastifiziert als die Unterseite. Die Siebe und Bleche werden nach der Pressung um die Presse oder unter der Presse zum Formstrang zurück transportiert, welches einige Minuten dauert. Außerdem müssen die Siebe in einigen Werken mit Wasser gereinigt werden. Während des Transportes und der Reinigung kühlen die Siebe und Bleche ab. Sie müssen dann zu Beginn der Pressung auf die Heizplattentemperatur von 190 °C erwärmt werden, wozu 20 - 60 Sekunden benötigt werden.Frequently, the fiber mat sections are dried to a moisture content of about 18% and, after the pre-press, water is sprayed onto the top of the fiber mat. Due to the water, the fiber mat moisture in front of the press rises to about 32%. Since at the beginning of the pressing the water is only on the upper side and therefore heats up the top faster than the bottom, the fiber mat top is plasticized at the beginning of the pressing more than the bottom. The sieves and sheets are transported back to the form strand after pressing around the press or under the press, which takes a few minutes. In addition, the screens must be cleaned in some plants with water. During transport and cleaning, the screens and sheets cool. They must then be heated to the heating plate temperature of 190 ° C at the beginning of the pressing, which takes 20 - 60 seconds.

Um ein Teil des Wassers aus der Fasermatte zu entfernen, ohne es verdampfen zu müssen, wird zu Beginn der Pressung ein hoher spezifischer Druck von 5,5 bis 6 N/mm2 auf die Fasermatte aufgebracht. In dieser Phase wird ein geringer Teil des Wassers aus der Fasermatte gequetscht. Das Wasser wird durch das Sieb zu den Fasermattenschmalflächen transportiert und läuft dann von den Pressplatten herunter. In dieser Phase wird auch die Dichte der äußeren Faserplattenschichten definiert. Die Dichte ist auf Grund der ungleichmäßigen Plastifizierung auf der siebabgewandten Plattenaußenseite höher als auf der siebzugewandten Plattenaußenseite. Das Dichteprofil der so hergestellten Faserplatte ist somit meist asymmetrisch, welches bei einigen Anwendungen zu Nachteilen durch einen Plattenverzug führt. Wenn die Faserplatte Feuchte aufnimmt oder abgibt, quillt oder schwindet sie auf Grund des asymmetrischen Dichteprofils einseitig stärker und verzieht sich dadurch.In order to remove some of the water from the fiber mat, without having to evaporate it, is at the beginning of the pressing a high specific Pressure of 5.5 to 6 N / mm 2 applied to the fiber mat. At this stage, a small portion of the water is squeezed out of the fiber mat. The water is transported through the sieve to the fiber mat narrow surfaces and then runs down from the press plates. In this phase, the density of the outer fibreboard layers is also defined. Due to the uneven plasticization, the density is higher on the outside of the panel facing away from the panel than on the panel side facing the panel. The density profile of the fiber board thus produced is thus usually asymmetric, which leads to disadvantages in some applications by a plate distortion. When the fiberboard picks up or releases moisture, it swells or shrinks more due to its asymmetric density profile and therefore warps.

Nach der Hochdruckphase wird der spezifische Druck reduziert und die Fasermatte in 2 - 4 Minuten auf etwa 8 % Feuchte getrocknet, wobei über das Sieb der Wasserdampf abgeführt wird. Der spezifische Druck wird meist so eingestellt, dass er etwas größer ist als der Dampfdruck in der Fasermatte. Damit wird verhindert, dass die Fasermatte in der Presse aufplatzt.

Anschließend wird in einer dritten Phase die Fasermatte mit einem spezifischen Druck von ca. 3 N/mm2 auf die Enddicke verdichtet und auf ca. 2 % Feuchte getrocknet. Eine Wegregelung der einzelnen Etagen kann nicht durchgeführt werden, die Faserplatten weisen daher hohe Dickentoleranzen auf.After the high pressure phase, the specific pressure is reduced and the fiber mat is dried in 2 - 4 minutes to about 8% moisture, with the water vapor is discharged through the sieve. The specific pressure is usually adjusted so that it is slightly larger than the vapor pressure in the fiber mat. This prevents the fiber mat from bursting in the press.

Subsequently, in a third phase, the fiber mat is compacted at a specific pressure of about 3 N / mm 2 to the final thickness and dried to about 2% moisture. A path control of the individual floors can not be performed, the fiberboard therefore have high thickness tolerances.

Der Erfindung liegt die Aufgabe zu Grunde, ein Verfahren anzugeben und eine Anlage zu schaffen, mit dem eine Faserplatte mit wenig oder ohne Klebstoff herstellbar ist und mit dem die Presszeit drastisch verkürzt werden kann, sowie die Eigenschaften der Platte und die Dickentoleranzen der Platte verbessert werden.The invention is based on the object to provide a method and to provide a system with which a fiberboard with little or no adhesive can be produced and with which the pressing time can be drastically shortened, and the properties of the plate and the thickness tolerances of the plate can be improved ,

Die Lösung dieser Aufgabe besteht nach Anspruch 1 in der Verwirklichung folgender Verfahrensschritte:

- a) die ohne Klebstoff aufbereiteten oder nur mit niedrigem Klebstoffgehalt beleimten Fasern werden auf eine Feuchte von 16% - 25% getrocknet und aus einer Streustation auf ein Transportband zur Fasermatte gestreut,

- b) die Feuchte der Fasermatte wird in einer kontinuierlich arbeitende Vorpresse durch Einleiten von Sattdampf oder überhitztem Wasserdampf oder Dampf-/Luftgemischen so erhöht, dass eine Feuchte von minimal 25% bis maximal 35% unmittelbar vor dem Eintritt in die Presse erreicht wird, womit gleichzeitig eine wesentliche Erwärmung der Fasermatte erfolgt,

- c) unmittelbar daran wird die Fasermatte auf ein endloses mit dem unteren Stahlband umlaufendes nicht rostendes Metallgewebeband einer kontinuierlich arbeitenden Presse übergeben und in den Pressspalt einer kontinuierlich arbeitenden Presse eingeführt,

- d) innerhalb von etwa 20% der Pressenlänge der kontinuierlich arbeitenden Presse wird die Fasermatte in einer Verdichtungsphase mit hohem spezifischen Druck von maximal 5,5 N/mm2 komprimiert und dabei Wasser ausgepresst,

- e) in einer sich anschließenden Trocknungsphase innerhalb der kontinuierlich arbeitenden Presse erfolgt die Verdampfung und Abführung des Dampfes sowie des Wassers insbesondere aus der Mittelschicht mit reduziertem spezifischem Druck von maximal 1 N/mm2 und wird solange aufrecht erhalten, bis eine Feuchte in der Fasermatte von 5 bis 8% erreicht ist und

- f) in einer abschließendem Aushärtephase in der kontinuierlich arbeitenden Presse wird die Fasermatte unter einem maximalen Druck von 3,5 N/mm2 auf das Endmaß verdichtet und getrocknet bis in der Mittelschicht eine ungefähre Feuchte von 2% erreicht ist.

- a) the fibers prepared without adhesive or glued only with low adhesive content are dried to a moisture content of 16% -25% and scattered from a scattering station onto a conveyor belt to the fiber mat,

- b) the moisture of the fiber mat is increased in a continuous pre-press by introducing saturated steam or superheated steam or steam / air mixtures so that a humidity of at least 25% to a maximum of 35% is reached immediately before entering the press, which at the same time there is a substantial heating of the fiber mat,

- c) immediately thereafter, the fiber mat is placed on an endless stainless steel belt surrounding the lower steel belt handed over to press working continuously and inserted into the press gap of a continuously working press,

- d) within about 20% of the press length of the continuously operating press, the fiber mat is compressed in a compression phase with a high specific pressure of maximum 5.5 N / mm 2 while water is pressed out,

- e) in a subsequent drying phase within the continuously operating press, the evaporation and removal of the vapor and the water in particular from the middle layer with reduced specific pressure of 1 N / mm 2 and is maintained until a moisture in the fiber mat of 5 to 8% is reached and

- f) in a final curing phase in the continuous press the fiber mat is compacted under a maximum pressure of 3.5 N / mm 2 to final gauge and dried until an approximate humidity of 2% is reached in the middle layer.

Mit diesen Verfahrensschritten sind erstmals sogar Faserplatten bis zu einer Dicke von 50 mm herzustellen, weil mit der vorgeschlagenen Vorwärmung der Fasermatte kürzere Presszeiten möglich sind.For the first time, even fibreboards up to a thickness of 50 mm can be produced with these process steps, since shorter pressing times are possible with the proposed preheating of the fiber mat.

Auch mit den nachfolgenden angepassten Verfahrensschritten des Anspruches 1 nach Anspruch sind Faserplatten zu fertigen:

- Dabei wird die Feuchte der Fasermatte in einer kontinuierlich arbeitende Vorpresse durch Einleiten von Sattdampf oder überhitztem Wasserdampf oder Dampf-/Luftgemischen um eine Feuchte von 2% bis 7% und mittels Warmwassersprühung vor und nach der Vorpresse um eine Feuchte von 2% bis 8% so erhöht, dass eine Feuchte von minimal 25% bis maximal 35% unmittelbar vor dem Eintritt in die Presse erreicht wird, womit gleichzeitig eine wesentliche Erwärmung der Fasermatte erfolgt.

- The moisture of the fiber mat in a continuously operating pre-press by introducing saturated steam or superheated steam or air / air mixtures by a humidity of 2% to 7% and by hot water spray before and after the pre-press by a humidity of 2% to 8% so increases that a humidity of at least 25% to a maximum of 35% is reached immediately before entering the press, whereby at the same time there is a significant heating of the fiber mat.

Und nach einem weiteren Ausführungsbeispiel nach Anspruch 3, ist die bevorzugte Herstellung für eine Faserplatte ≤ 4 mm durch folgende Anpassung der Verfahrensschritte gekennzeichnet:

- im Verfahrensschritt d) wird innerhalb von etwa 20% der Pressenlänge der kontinuierlich arbeitenden Presse die Fasermatte in einer Verdichtungsphase mit hohem spezifischen Druck von maximal 5,0 N/mm2 komprimiert und dabei Wasser ausgepresst, und

- im Verfahrensschritt f) wird in einer abschließenden Aushärtephase in der kontinuierlich arbeitenden Presse die Fasermatte unter einem maximalen Druck von 4 N/mm2 auf das Endmaß verdichtet und getrocknet bis in der Mittelschicht eine ungefähre Feuchte von 2% erreicht ist.

- in process step d) is compressed within about 20% of the press length of the continuously operating press the fiber mat in a compression phase with a high specific pressure of not more than 5.0 N / mm 2 and thereby squeezed out water, and

- In process step f), the fiber mat is compacted to the final dimension under a maximum pressure of 4 N / mm 2 in a final curing phase in the continuously operating press and dried until an approximate moisture content of 2% is reached in the middle layer.

Die Anlage zur Durchführung des Verfahrens nach Anspruch 28 besteht darin, dass als Presse eine kontinuierlich arbeitenden Presse mit den Pressdruck übertragenden und die Fasermatte durch den Pressspalt ziehenden endlosen Stahlbändern besteht, die Stahlbänder über Antriebs- und Umlenktrommeln um das Rahmenoberteil und das Rahmenunterteil umlaufend geführt sind, die sich mit einstellbarem Pressspalt über mitlaufende, mit ihren Achsen quer zur Bandlaufrichtung geführten Rollstangen gegenüber den Rahmenober- und Rahmenunterteil abstützen, wobei die Rollstangen an beiden Enden in Führungsketten geführt sind, dass vor und zwischen der Streustation und der kontinuierlich arbeitenden Presse mehrere auf das Transportband und zu den Oberflächen der Fasermatte gerichtete Warmwassersprüheinrichtungen und Einrichtungen zum Auftragen von Trennmitteln angeordnet sind, von der kontinuierlich arbeitenden Presse eine Vorpresse mit Dampfvorwärmeinrichtung und oberem und unterem Siebband vorgesehen ist, die kontinuierlich arbeitenden Presse als Ablage für die Fasermatte und zur Wasser- und Dampfabführung aus der Fasermatte eine aus nicht rostendem Material bestehendes, mit dem unteren Stahlband umlaufend geführtes, endloses Metallgewebeband aufweist, das vor dem Einlauf in den Pressspalt über eine Heizplatte geführt ist und das untere Stahlband zum Ableiten des ausgepressten Wassers mit einer größeren Breite ausgeführt ist als das obere Stahlband.The system for carrying out the method according to claim 28 is that there is a continuously operating press with the pressing pressure transmitting and the fiber mat passing through the press nip endless steel belts as press, the steel belts are guided circumferentially about drive frame and idler pulleys around the frame top and the frame base , Which are supported with adjustable press nip on revolving, guided with their axes transverse to the strip running direction rolling bars relative to the Rahmenober- and frame base, wherein the rolling rods are guided at both ends in guide chains, that before and between the scattering station and the continuously operating press several on the Hot water spraying devices and devices for applying release agents are arranged on the conveyor belt and directed towards the surfaces of the fiber mat, from the continuously operating press a pre-press with steam preheating device and upper and lower wire belt v is seen, the continuously operating press as a storage for the fiber mat and water and steam removal from the fiber mat an existing stainless material, with the lower steel belt circumferentially guided, endless metal fabric belt, which led before entering the press nip on a hot plate and the lower steel strip for discharging the squeezed out water is made larger in width than the upper steel strip.

Durch das erfindungsgemäße Verfahren und die Anlage gemäß der Erfindung, kann die Presszeit gegenüber den bekannten taktweise arbeitenden Halbtrockenverfahren deutlich reduziert werden. Beispielsweise wird die Presszeit für eine 4 mm dicke Faserplatte von 4 Minuten auf ca. 1 Minute reduziert (siehe Tabelle 1). Ein wesentlicher Vorteil ist, dass durch die Dampfvorwärmung der Fasermatte auf mindestens 100 °C die Aufheizzeit der Fasermatte drastisch vermindert wird. Bei dieser Temperatur sinkt die Viskosität des Wassers, wodurch der Strömungswiderstand sich vermindert und das Wasser schneller aus der Matte gequetscht werden kann. Die Dampfvorwärmung der Fasermatte auf 100° Celsius ist besonders bei der Herstellung von Faserplatten mit einer Dicke größer 4 mm von Vorteil, da hierfür die Presszeitverkürzung besonders hoch ausfällt.

In der Tabelle sind ausgewählte Prozessparameter während des Heißpressens in einer kontinuierlichen Presse gemäß dem erfindungsgemäßen Verfahrens für eine 4 mm dicke Faserplatte dargestellt.

The table shows selected process parameters during hot pressing in a continuous press according to the method of the invention for a 4 mm thick fiberboard.

Im Gegensatz zur Herstellung in Mehretagenpressen kann in der kontinuierlichen Presse die Fasermatte auch mit einer höheren Heizplattentemperatur als 190 °C verpresst werden, da die Presszeit kürzer ist und am Ende der Pressung die Faserplatte gekühlt werden kann. Dadurch wird die Presszeit erheblich vermindert. - In der Mehretagenpresse ist auf Grund der Dampfplatzergefahr, vor allem der oberen Deckschicht, die Anhebung der Pressplattentemperatur nicht möglich. - Wenn die Faserplatte am Ende der kontinuierlichen Pressung auf um die 110 °C gekühlt wird, wird die Gefahr der Deckschichtplatzer erheblich vermindert.In contrast to the production in multi-daylight presses, in the continuous press the fiber mat can also be pressed with a hotplate temperature higher than 190 ° C, because the pressing time is shorter and at the end of the pressing the fiberboard can be cooled. As a result, the pressing time is significantly reduced. - In the multi-daylight press, increasing the pressure plate temperature is not possible due to the risk of steam bursting, especially the upper surface layer. - If the fiberboard is cooled to around 110 ° C at the end of the continuous pressing process, the risk of topcoat bursting is significantly reduced.

Mit dem erfindungsgemäßen kontinuierlichen Verfahren kann in der kontinuierlichen Presse ein vorgegebenes Weg-Druck-Programm sehr genau ausgeregelt werden, wobei die kontinuierliche Presse bevorzugt so ausgeführt wird, dass in Transportrichtung sehr große Verformungen pro Meter Presslänge möglich sind. Dadurch kann der Pressspalt optimal auf die einzelnen Phasen angepasst werden. So kann während der Trocknung der Pressspalt so weit vergrößert werden, dass gerade eben Oberflächenplatzer vermieden werden. Dadurch vermindert sich der Strömungswiderstand senkrecht zur Oberfläche in der Fasermatte und die Faserplatte kann schneller getrocknet werden. Ebenso kann die Faserplatte am Ende der Pressung nach einem optimierten Programm entlastet werden. In Zusammenhang mit der Abkühlung der Fasermattenoberfläche darf die Feuchte der Faserplatte nicht auf unter 2 % vermindert werden, welches zum einen die Aushärtephase verkürzt und bei der späteren Klimatisierung der Platte von Vorteil ist. Die Faserplatte weist unmittelbar nach der kontinuierlichen Presse eine gleichmäßigere Feuchteverteilung über den Plattenquerschnitt auf.With the continuous process according to the invention, a predetermined path-pressure program can be regulated very accurately in the continuous press, wherein the continuous press is preferably designed so that very large deformations per meter of press length are possible in the transport direction. As a result, the press nip can be optimally adapted to the individual phases. Thus, during drying, the press nip can be enlarged so far that just surface blemishes are avoided. This reduces the flow resistance perpendicular to the surface in the fiber mat and the fiberboard can be dried faster. Likewise, the fiber board can be relieved after an optimized program at the end of the pressing. In connection with the cooling of the fiber mat surface, the moisture content of the fiberboard must not be below 2%. be reduced, which on the one hand shortens the curing phase and in the subsequent air conditioning of the plate is beneficial. Immediately after the continuous press, the fiberboard has a more even distribution of moisture over the slab cross-section.

Durch die genaue Einstellung des Pressspaltes über die gesamte Pressenbreite in der kontinuierlich arbeitenden Presse ist es möglich, Faserplatten mit sehr geringen Dickentoleranzen zu produzieren. Dadurch kann die Rohplattendicke und damit die Schleifzugabe reduziert werden. Dies trägt wiederum zu einer Presszeitverminderung bei, da für die gleiche Fertigplattendicke eine geringere Plattendicke in der Heißpresse gefahren werden kann.Due to the precise adjustment of the press nip over the entire press width in the continuous press, it is possible to produce fiberboard with very small thickness tolerances. As a result, the raw plate thickness and thus the grinding allowance can be reduced. This in turn contributes to a press time reduction, since for the same finished plate thickness, a smaller plate thickness can be driven in the hot press.

Die kontinuierliche Verpressung gemäß der Erfindung führt auch zu deutlich verminderten elektrischen und thermischen Energiekosten. Für die diskontinuierliche Pressung, das Beschicken und Entleeren wird etwa 70 % mehr Elektroenergie pro m3 hergestellter Faserplatte im Vergleich zum erfindungsgemäßen kontinuierlichen Verfahren benötigt, da eine wesentlich höhere Anschlussleistung installiert werden muss. Da die Mehretagen Presse einschließlich der benötigten Siebe höhere Abstrahlverluste hat, wird auch mehr thermische Energie zum Betreiben der Presse benötigt. Zusätzlich wird bei einer Mehretagen-Presse im Mittel mit höheren Pressplattentemperaturen gepresst. Da bei der kontinuierlichen Presse die Temperatur gegen Ende der Pressung deutlich gesenkt wird, wird weniger Wasser benötigt und aus der Fasermatte verdampft und damit weniger Energie in die Faserplatte gebracht. Weiterhin kann bei der Dampfvorwärmung Dampf mit niedrigem Dampfdruck unter 3 bar verwendet werden, welcher als sehr günstiger Abdampf aus der Faseraufbereitung zur Verfügung steht. Auch dadurch werden die Kosten für die Aufheizenergie zu Beginn der Pressung vermindert.The continuous compression according to the invention also leads to significantly reduced electrical and thermal energy costs. For the discontinuous pressing, the loading and unloading about 70% more electrical energy per m 3 of produced fiberboard is required compared to the continuous process according to the invention, since a much higher connected load must be installed. Since the multi-day press including the required sieves has higher radiation losses, more thermal energy is required to operate the press. In addition, in a multi-day press on average with higher press plate temperatures pressed. Since the temperature in the continuous press is lowered significantly towards the end of the pressing, less water is needed and evaporated from the fiber mat and thus less energy is brought into the fiber board. Furthermore, in the steam preheating steam with a low vapor pressure below 3 bar can be used, which is available as a very favorable steam from the fiber processing available. This also reduces the cost of the heating energy at the beginning of the pressing.

Beim Halbtrockenverfahren wird eine Faser-Faser-Bindung auf 2 Arten erreicht: zum einen über eine so genannte Wasserstoffbrückenbindungen vor allem der Holzbestandteile Cellulose und Hemicellulose und zum anderen über das erweichte Lignin. Für beide Bindungstypen ist es wichtig, dass die einzelnen Fasern über eine längere Strecke einen sehr engen Kontakt zueinander aufweisen. Durch die Dampfvorwärmung wird nun folgender Vorteil erreicht werden: die Faser sind schon zu Beginn der Pressung plastifiziert und damit sehr flexibel, wodurch sich mehr Kontaktflächen zwischen den Fasern während der ersten Verdichtung ausbilden können. Sie werden beim Verdichten weniger zerquetscht. Sie schmiegen sich eng aneinander und lassen sich leichter in Hohlräume drücken. Die Querzugfestigkeit der Faserplatten ist dadurch bei gleichem Klebstoffgehalt etwas besser als ohne Dampfvorwärmung und auch die irreversible Rückfederung bei der Dickenquellung ist vermindert.In the semi-dry process, fiber-fiber bonding is achieved in two ways: on the one hand via a so-called hydrogen bond, especially of the wood constituents cellulose and hemicellulose, and on the other hand through the softened lignin. For both bond types, it is important that the individual fibers have very close contact with each other over a longer distance. The following advantage can now be achieved by steam preheating: the fibers are already plasticized at the beginning of the pressing and are therefore very flexible, as a result of which more contact surfaces between the fibers can form during the first compression. They are crushed less during compaction. They nestle close together and are easier to press into cavities. The transverse tensile strength of the fiberboard is thereby slightly better with the same adhesive content than without steam preheating and the irreversible springback in the thickness swelling is reduced.

Die Hackschnitzel werden im Vorwärmverfahren bei einer höheren Temperatur als 180 °C, bevorzugt 190 bis 220 °C, im Vorwärmen vorgedämpft, um zu erreichen, dass im Holz durch Umwandlungsprozesse Substanzen gebildet werden, die während der Heißpressung zu einer besseren Verklebung führen. Insbesondere wird die Bildung von Furfural durch die Bildung von Säuren im Vorwärmer gefördert. Die Bildung von Säuren wird durch die hohe Temperatur im Vorwärmen unterstützt. Furfural fördert Kondensationsreaktionen zwischen den Holzbestandteilen. Eventuell kann bei der Vorwärmung oder dem Refiner Säure - wie zum Beispiel Schwefelsäure - zugegeben werden, die ebenfalls die Bildung von Furfural fördert. Bei Laubhölzern werden in der Regel mehr klebrige Substanzen als bei Nadelhölzern gebildet. Daher eignen sich für dieses Verfahren Laubhölzer besonders gut. Weiterhin ist es günstig Aluminiumsulfat etwa 0,5 % atro Stoff zur Fällung von den künstlichen Kondensationsklebstoffen und den natürlichen Harzsäuren während der Vorwärmung oder in den Refiner oder in der Blow-Line zuzugeben. Auch zur Fällung der Harze ist es vorteilhaft, dass der pH-Wert der Fasern auf kleiner 4,5 durch die Zugabe von Säure abgesenkt wird.The wood chips are prebaked in the preheating at a temperature higher than 180 ° C, preferably 190 to 220 ° C, in the preheating in order to achieve that substances are formed in the wood by conversion processes, which lead to a better bonding during the hot pressing. In particular, the formation of furfural is promoted by the formation of acids in the preheater. The formation of acids is supported by the high temperature in the preheating. Furfural promotes condensation reactions between the wood components. Eventually, during preheating or refining, acid - such as sulfuric acid - may be added, which also promotes the formation of furfural. Hardwoods usually produce more sticky substances than softwoods. Therefore, deciduous trees are particularly suitable for this process. Furthermore, it is advantageous to add aluminum sulfate about 0.5% of free substance for precipitation of the artificial condensation adhesives and the natural resin acids during preheating or in the refiner or in the blow-line. It is also advantageous for the precipitation of the resins that the pH of the fibers is lowered to less than 4.5 by the addition of acid.

Zu Beginn der Heißpressung bis etwa 20 % der Presslänge wird etwas Wasser aus der Fasermatte gequetscht, welches durch das Metallgewebeband als Wasser bzw. als Dampf auf den Rand des unteren Stahlbandes transportiert wird. Dort wird das Wasser aufgefangen und der Dampf abgesaugt. Der abgesaugte Dampf wird kondensiert und mit dem aufgefangenen Wasser vermischt. Dieses Wasser muss über einen Filter geführt werden, um es von groben unlösbaren Teilen zu reinigen. Das aufbereitete Wasser enthält gelöste bzw. suspendierte Holzsubstanzen, die sich besonders für die Verklebung eignen. Daher wird es wieder als Sprühwasser verwendet. Zusätzlich wird durch die Wiederverwendung des Wassers der Wasserkreislauf geschlossen, sodass im Vergleich zum Trockenverfahren keine größere Verschmutzung von Trinkwasser auftritt.At the beginning of the hot pressing to about 20% of the pressing length, some water is squeezed out of the fiber mat, which is transported through the metal fabric belt as water or as steam to the edge of the lower steel belt. There the water is collected and the steam is sucked off. Of the extracted steam is condensed and mixed with the collected water. This water must be passed through a filter to clean it from coarse insoluble parts. The treated water contains dissolved or suspended wood substances, which are particularly suitable for bonding. Therefore, it is used again as a spray water. In addition, the water cycle is closed by the reuse of the water, so that compared to the dry process no major pollution of drinking water occurs.

Die Fasermatte kann mittels einer einzigen Streumaschine gestreut werden oder die Fasern werden nach der Herstellung im Refiner in grobe und feine Fasern aufgeteilt oder schon getrennt mittels zweier Refiner hergestellt. Die groben Fasern werden dann bevorzugt in die Fasermattenmitte als Mittelschicht und die feinen Fasern als Deckschicht gestreut. Für Faserplatten, die direkt lackiert werden sollen, ist es günstig sehr feine Fasern (Feinstfasern) oder Staub auf die Oberfläche in einer Menge von 20 - 50 g/m2 zu streuen. Durch die sehr feinen Fasern kann eine sehr geschlossene Oberfläche an der Faserplatte erzielt werden, wodurch zum Beispiel der Lackverbrauch gesenkt werden kann.The fiber mat can be scattered by means of a single scattering machine or the fibers are divided after production in the refiner into coarse and fine fibers or already prepared separately by means of two refiners. The coarse fibers are then preferably scattered into the center of the fiber mat as the middle layer and the fine fibers as the cover layer. For fiberboards which are to be directly painted, it is favorable to scatter very fine fibers (fine fibers) or dust on the surface in an amount of 20-50 g / m 2 . Due to the very fine fibers, a very closed surface can be achieved on the fiberboard, whereby, for example, the paint consumption can be reduced.

Zur Durchführung des erfindungsgemäßen Verfahrens dürfen die Fasern nicht unter eine Feuchte von 16 % getrocknet werden bzw. die Fasern dürfen nicht eine Feuchte von 16% unterschreiten, da sie sonst verhornen. Verhornte Fasern bilden nur eine unzureichende Wasserstoffbrückenbindung aus. Das heißt, dass auch während des Transportes der Fasern darauf geachtet werden muss, dass die Feuchte nicht unterschritten wird. Da während des Transportes der Faser im Luftstrom mit Luft einer relativen Luftfeuchte, die niedriger ist als die Ausgleichsfeuchte der Faser, die Fasern schnell Feuchte abgeben, muss entweder die Transportluft durch zum Beispiel Dampfeindüsung klimatisiert werden oder die Fasern sollten nach dem Trockner eine etwas größere Feuchte als auf dem Formband aufweisen.To carry out the process according to the invention, the fibers must not be dried below a moisture content of 16% or the fibers must not a humidity of 16% fall below, otherwise they verborn. Horny fibers only form an insufficient hydrogen bond. This means that care must also be taken during the transport of the fibers that the moisture content is not undershot. Since during transport of the fiber in the air stream with air of a relative humidity lower than the equilibrium moisture content of the fiber, the fibers quickly release moisture, either the transport air must be air-conditioned by, for example, steam injection or the fibers should have a slightly higher humidity after the dryer as having on the forming belt.

Die Feuchte der Fasermatte wird durch die Dampfvorwärmung in Abhängigkeit der Vorwärmtiefe durch die Kondensation des Wasserdampfes erhöht. Wenn die gesamte Fasermatte durchwärmt wird, erhöht sich die Mattenfeuchte um ca. 7 %. Wenn etwa 50 % der Matte erwärmt werden, beträgt die Feuchteerhöhung etwa 4 %. Das Verfahren muss auf jeden Fall so gesteuert werden, dass die Fasermattenfeuchte zu Beginn der Heißpressung nicht unter 25 % und nicht über 35 % beträgt, denn falls die Feuchte unter 25 % beträgt, können nur unzureichende holzeigene Klebeverbindungen ausgebildet werden. Dann steigt der Klebstoffverbrauch sehr stark an. Falls die Feuchte über 35 % beträgt, verlängert sich andererseits die Presszeit auf Grund der längeren Trocknungsphase sehr stark.The moisture of the fiber mat is increased by the steam preheating depending on the preheating by the condensation of water vapor. If the entire fiber mat is warmed through, the mat moisture increases by about 7%. When about 50% of the mat is heated, the humidity increase is about 4%. The method must be controlled in any case so that the fiber mat moisture at the beginning of the hot pressing is not less than 25% and not more than 35%, because if the humidity is below 25%, only insufficient wood-specific adhesive joints can be formed. Then the consumption of glue increases very strongly. If the humidity is over 35%, on the other hand, the pressing time is greatly increased due to the longer drying period.

Um eine geschlossene Faserplattenoberfläche mit einer hohen Dichte zu erzielen und um die Stahlbänder vor Verschmutzungen zu schützen, ist es günstig auf die Fasermattenoberfläche Wasser in einer Menge von insgesamt 20 - 700 g/m2, je nach Konsistenz der Fasern und der Faserplattedicke zu sprühen. Das Wasser kann auch auf das Transportband oder auf das Siebband bei der Dampfvorwärmung gesprüht werden. Günstig ist es auch Trennmittel auf die Fasermattenoberfläche und/oder das Transportband zu sprühen, damit die Fasern nicht mit dem Metallgewebeband bei der Vorwärmung, dem Transportband, den Stahlbändern und dem Metallgewebeband in der kontinuierlich arbeitenden Presse verkleben. Die Wassermenge, die vor der Bedampfung aufgesprüht wird, darf aber nicht so groß sein, dass sich freies Wasser auf der Fasermattenoberfläche befindet, da es dann zu Problemen in der Bedampfung durch eine ungleichmäßige Kondensation von Dampf und zu unkontrollierbaren Verhältnissen kommt.In order to obtain a closed fibreboard surface with a high density and to protect the steel strips from soiling, it is favorable to spray water onto the fiber mat surface in a total amount of 20-700 g / m 2 , depending on the consistency of the fibers and the fiberboard thickness. The water can also be sprayed onto the conveyor belt or onto the sieve belt during steam preheating. It is also favorable to spray release agent onto the fiber mat surface and / or the conveyor belt so that the fibers do not stick to the metal fabric belt during the preheating, the conveyor belt, the steel belts and the metal belt in the continuously operating press. The amount of water that is sprayed on before the steaming, however, should not be so large that there is free water on the fiber mat surface, as it then comes to problems in the vaporization by an uneven condensation of steam and uncontrollable conditions.

Daher kann eine größere Wassermenge als 60 g/m2 nur nach der Bedampfung in der Vorpresse mit Dampfvorwärmung auf die Fasermatte gesprüht werden. Das Wasser sollte bevorzugt vor dem Aufsprühen auf Temperaturen von 60 - 95 °C erwärmt werden. Da die Verweilzeit des Wassers vom Aufsprühen bis zum Fasermattenkontakt mit dem Stahlband in der kontinuierlich arbeitenden Presse sehr kurz ist, wird dieses Wasser fast nicht von den Fasern aufgenommen und beeinflusst damit das Dichteprofil nur unwesentlich. Von Vorteil ist auch, wenn das Wasser nur von oben auf die Fasermatte gesprüht wird. Das Wasser wird dann bei Kontakt mit dem Stahlband sofort verdampft und kann nur senkrecht in die Fasermatte strömen. Falls das Wasser auf die untere Fasermattenhälfte, also der siebzugewandten Fasermatteseite aufgetragen wird, dringt der gebildete Dampf nicht in die Fasermatte ein. Nach der Verdampfung strömt der Dampf über das Metallgewebeband aus der Presse entgegen der Transportrichtung in Richtung Einlauf und quer zur Transportrichtung zum Pressenrand. Die Feuchte der Fasermatte wird dann nicht erhöht und die Presszeit nicht verkürzt. Eine größere Wassermenge darf nicht auf die Fasermattenseite gesprüht werden, die dem Metallgewebeband zugewandt ist, da die Feuchte der Fasermatte dann nicht erhöht und die Presszeit nicht verkürzt werden würde.Therefore, a larger amount of water than 60 g / m 2 can be sprayed onto the fiber mat only after the steaming in the pre-press with steam preheating. The water should preferably be heated to temperatures of 60-95 ° C before spraying. Since the residence time of the water from the spraying to the fiber mat contact with the steel strip in the continuous press is very short, this water is almost not absorbed by the fibers and thus affects the density profile only insignificantly. From Another advantage is that the water is only sprayed from above onto the fiber mat. The water is then evaporated immediately on contact with the steel strip and can only flow vertically into the fiber mat. If the water is applied to the lower fiber mat half, so the sieve-facing Fasermatteseite, the vapor formed does not penetrate into the fiber mat. After evaporation, the steam flows over the metal fabric belt from the press against the transport direction towards the inlet and transverse to the transport direction to the edge of the press. The moisture of the fiber mat is then not increased and the pressing time is not shortened. A larger amount of water must not be sprayed on the fiber mat side, which faces the metal fabric tape, since the moisture of the fiber mat would then not increased and the pressing time would not be shortened.

Die Fasern müssen für das erfindungsgemäße Verfahren auf eine Feuchte getrocknet werden, die zuzüglich der Feuchte durch die Bedampfung, der Wasserbesprühung und des Wassers aus dem Trennmittelauftrag innerhalb des oben genannten Bereiches liegt. Um den Feuchteeintrag in die einzelnen Fasermattenschichten genau zu steuern, muss die Menge an aufgesprühten Wasser und die zugegebene Dampfmenge jeweils für die obere und untere Fasermattenseite getrennt gemessen werden. Die Dampfmenge, die zur Erwärmung des aufgesprühten und vom Holz aufgenommenen Wassers benötigt wird, lässt sich aus der Wassertemperatur und der aufgesprühten Wassermenge berechnen. Ebenso kann die Dampfmenge, die zur Erwärmung der Fasern benötigt wird, aus der Anfangstemperatur und der Feuchte der Fasern berechnet werden. Das heißt, dass die Eindringtiefe des Dampfes auf Grund der gemessenen und geregelten Dampfmenge für die obere und untere Fasermattenhälfte getrennt bestimmt wird. Damit ist auch die Feuchteverteilung über den Fasermattenquerschnitt unmittelbar bestimmbar. Durch entsprechende Messgeräte - wie Mikrowellenmessgeräte - kann die Feuchteverteilung über den Fasermattenquerschnitt auch gemessen werden. Die Kenntnis der Feuchte und der Feuchteverteilung über den Fasermattenquerschnitt unmittelbar vor der kontinuierlich arbeitenden Presse ist sowohl für die Ausbildung einer ausreichenden Verklebung und einer minimalen Presszeit wichtig als auch für die Ausbildung des Rohdichteprofils von Bedeutung. Für eine geringe Presszeit ist günstig, die Fasermatte über den gesamten Querschnitt zu bedampfen und möglichst viel Warmwasser auf die Fasermatte zu sprühen.For the process according to the invention, the fibers must be dried to a moisture content which, in addition to the moisture due to the vapor deposition, the water spraying and the water from the release agent application, is within the abovementioned range. In order to precisely control the moisture input into the individual fiber mat layers, the amount of sprayed-on water and the added amount of steam must be measured separately for the upper and lower fiber mat sides. The amount of steam required to heat the water sprayed on and taken up by the wood can be calculated from the water temperature and the sprayed water Calculate amount of water. Similarly, the amount of steam needed to heat the fibers can be calculated from the initial temperature and humidity of the fibers. That is, the penetration depth of the steam is determined separately for the upper and lower bobbins due to the measured and controlled amount of steam. Thus, the moisture distribution over the fiber mat cross section is directly determinable. By appropriate measuring devices - such as microwave measuring devices - the moisture distribution over the fiber mat cross section can also be measured. The knowledge of the moisture and the moisture distribution over the fiber mat cross-section immediately before the continuously operating press is important both for the formation of a sufficient bond and a minimum pressing time as well as for the formation of the density profile of importance. For a low pressing time is favorable to steam the fiber mat over the entire cross-section and spray as much hot water on the fiber mat.

Zur Regelung der Bedampfungstiefe, der aufgesprühten Wassermenge und zur Einsteuerung der Metallgewebebandtemperatur bzw. der oberen und unteren Heizplattentemperatur in der kontinuierlich arbeitenden Presse sollte das Rohdichteprofil der fertigen Faserplatte unmittelbar nach der kontinuierlich arbeitenden Presse gemessen werden. Faserplatten aus dem Halbtrockenverfahren weisen häufig keine deutliche Dichteabsenkung in der Faserplattenmitte auf. Im Trockenverfahren produzierte Faserplatten zeigen ein Dichteminimum in der Faserplattenmitte, welches zu höheren Biegefestigkeiten bei gleichem Materialeinsatz führt. Es hat sich nun herausgestellt, dass nach dem erfindungsgemäßen Verfahren Faserplatten mit ähnlichen Dichteprofilen, wie sie im Trockenverfahren produziert werden, hergestellt werden können. Dazu sollte nicht der gesamte Fasermattenquerschnitt mit Dampf vorgewärmt und erweicht werden, sondern nur die Deckschichten. Neben der Änderung des Pressspaltes zu Beginn der Heißpressung und während der Trocknungsphase muss die Bedampfungstiefe durch Verminderung der eingebrachten Dampfmenge reduziert und eventuell die aufgesprühte Wassermenge erhöht werden. Wichtig ist auch eine erhöhte Erwärmung der Metallgewebebandtemperatur im Einlauf zur kontinuierlich arbeitenden Presse, die mindestens 40° Celsius höher als die Temperatur der Stahlbänder im Einlauf zur kontinuierlich arbeitenden Presse sein sollte. Von Vorteil hat sich auch eine separate Regelung des oben und unteren Heizkreises der Pressplatten erwiesen.To control the depth of vapor deposition, the amount of water sprayed on and to control the metal belt temperature and the top and bottom heating plate temperature in the continuous press, the density profile of the finished fiberboard should be measured immediately after the continuous press. Fibrous plates from the semi-dry process often have no significant density reduction in the Fiberboard center on. Fiberboards produced in the dry process show a density minimum in the middle of the fibreboard, which leads to higher bending strengths with the same material input. It has now been found that fibreboards with similar density profiles as are produced by the dry process can be produced by the process according to the invention. For this purpose, not the entire fiber mat cross section should be preheated and softened with steam, but only the outer layers. In addition to the change in the press nip at the beginning of the hot pressing and during the drying phase, the evaporation depth must be reduced by reducing the amount of steam introduced and possibly the amount of water sprayed on be increased. Also important is an increased heating of the metal fabric strip temperature in the inlet to the continuously operating press, which should be at least 40 ° C higher than the temperature of the steel strips in the inlet to the continuously operating press. A separate control of the top and bottom heating circuit of the press plates has proved to be advantageous.

Da im kontinuierlichen Verfahren gemäß der Erfindung zu Beginn der Pressung eine höhere Pressplattentemperatur gefahren werden kann, ist die Temperatur der Fasermatte in den äußeren Schichten auch etwas höher als im Taktverfahren. Es hat sich herausgestellt, dass diese höhere Temperatur die Bildung von Kondensationsreaktionen - vor allem des Lignins - fördert, sodass im erfindungsgemäßen Verfahren eine festere Faser zu Faser Bindung erzielt werden kann. Etwas bessere Biegeeigenschaften sind daher bei gleichem Klebstoffgehalt erzielbar.Since in the continuous process according to the invention at the beginning of the pressing a higher platen temperature can be driven, the temperature of the fiber mat in the outer layers is also slightly higher than in the cycle. It has been found that this higher temperature promotes the formation of condensation reactions - especially of lignin - so that In the method according to the invention a firmer fiber to fiber bond can be achieved. Slightly better bending properties can therefore be achieved with the same adhesive content.

Die Querzugfestigkeit der im Labor erfindungsgemäßen Verfahren hergestellten Faserplatten sind am Faserplattenrand etwas niedriger als in der Faserplattenmitte. Dies wird dadurch verursacht, dass die Aushärtetemperatur am Rand etwas niedriger ist. Die Aushärtetemperatur ist in der Fasermatte niedriger, da die Stahlbänder, die Pressplatten und die Rollstangen am Rand kühler sind als in der Pressenmitte. Sie kühlen durch das austretende Wasser und die zirkulierende Luft ab. Im Allgemeinen sind die Pressplatten 50 mm je Pressenseite breiter als die Fasermatte. Es hat sich nun herausgestellt, dass durch Vergrößerung des Abstandes von Pressplattenrand zur Fasermatte auf ≥ 100 mm die Aushärtetemperatur am Rand höher ist und die Querzugfestigkeit der Faserplatte am Rand deutlich zu verbessern ist. Zusätzlich kann die Fasermatte am Rand noch mit einem höheren Flächengewicht gestreut werden, wodurch sich ebenfalls eine Erhöhung der Querzugfestigkeit erzielen lässt.The transverse tensile strength of the fiber boards produced in the laboratory process according to the invention are slightly lower at the edge of the fiber board than in the center of the fiber board. This is caused by the fact that the curing temperature at the edge is slightly lower. The curing temperature is lower in the fiber mat because the steel belts, the press plates and the rolling bars are cooler at the edge than in the center of the press. They cool by the escaping water and the circulating air. In general, the press plates are 50 mm wider on each press side than the fiber mat. It has now been found that by increasing the distance from the edge of the press plate to the fiber mat to ≥ 100 mm, the curing temperature at the edge is higher and the transverse tensile strength of the fiberboard at the edge is significantly improved. In addition, the fiber mat can be scattered at the edge even with a higher basis weight, which can also achieve an increase in the transverse tensile strength.

Der gemäß der Erfindung hergestellte endlose Faserplattenstrang wird nach einer Formataufieilung - wie bei dem herkömmlichen Halbtrockenverfahren - zur Verbesserung der Eigenschaften einer Nachbehandlung zugeführt.The continuous fiberboard strand produced in accordance with the invention is subjected to after-treatment after a size-spreading, as in the conventional semi-dry process, to improve the properties.

Insbesondere werden die Faserplatten durch einen Wärmekanal geführt oder in einer beheizten Halle warm eingestapelt. Durch die Wärmebehandlung der Faserplatten bei Temperaturen zwischen 110° und 200 °C nach der kontinuierlich arbeitenden Presse wird die Verklebung der einzelnen Fasern erhöht, wodurch die Biegeeigenschaften und die Quellwerte verbessert werden. Zur Durchführung der Wärmebehandlung können die Faserplatten warm eingestapelt werden oder als Paket durch einen Wärmekanal gezogen werden.In particular, the fiberboard are passed through a heat channel or stacked warm in a heated hall. The heat treatment of the fiber boards at temperatures between 110 ° and 200 ° C after the continuous press increases the bonding of the individual fibers, which improves the bending properties and the swelling values. To carry out the heat treatment, the fiberboard can be warmly stacked or pulled as a package through a heat channel.