EP1220249A2 - Commutateur pour le montage dans des boítiers en matière plastique pour composants électriques ou tableaux de commande - Google Patents

Commutateur pour le montage dans des boítiers en matière plastique pour composants électriques ou tableaux de commande Download PDFInfo

- Publication number

- EP1220249A2 EP1220249A2 EP01250440A EP01250440A EP1220249A2 EP 1220249 A2 EP1220249 A2 EP 1220249A2 EP 01250440 A EP01250440 A EP 01250440A EP 01250440 A EP01250440 A EP 01250440A EP 1220249 A2 EP1220249 A2 EP 1220249A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- control panel

- panel according

- switching element

- plastic

- switch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/70—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a plurality of operating members associated with different sets of contacts, e.g. keyboard

- H01H13/78—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a plurality of operating members associated with different sets of contacts, e.g. keyboard characterised by the contacts or the contact sites

- H01H13/785—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a plurality of operating members associated with different sets of contacts, e.g. keyboard characterised by the contacts or the contact sites characterised by the material of the contacts, e.g. conductive polymers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/02—Contacts characterised by the material thereof

- H01H1/021—Composite material

- H01H1/029—Composite material comprising conducting material dispersed in an elastic support or binding material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2201/00—Contacts

- H01H2201/022—Material

- H01H2201/032—Conductive polymer; Rubber

- H01H2201/036—Variable resistance

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2203/00—Form of contacts

- H01H2203/03—Form of contacts printed on casing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2223/00—Casings

- H01H2223/002—Casings sealed

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2229/00—Manufacturing

- H01H2229/044—Injection moulding

- H01H2229/046—Multi-colour or double shot injection moulding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2300/00—Orthogonal indexing scheme relating to electric switches, relays, selectors or emergency protective devices covered by H01H

- H01H2300/01—Application power window

Definitions

- the invention relates to an operating panel, comprising one Switches with fixed contacts and a switching element from one Plastic with pressure-dependent electrical conductivity.

- Such a switch is in the German patent DE 31 15 271 C2 described.

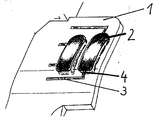

- This switch can according to figure 2 for example in an operating panel below the display device of a watch case can be used.

- Figure 4 has the switch used a rubber part from a electrically conductive elastomer depending on pressure. With this Rubber part is connected to a so-called switch body, which fixed contacts for electrical contacting the Has switch. On the side facing away from the switch body A push button is provided on the side of the rubber part A manual shift force is exerted on the rubber part can be to make this electrically conductive and such an electrically conductive connection between the fixed contacts manufacture.

- the object of the invention is to have an operating panel specify a switch, which is comparatively easy can be made.

- the task is solved in that the fixed contacts in the control panel made of plastic are integrated and the switching element with this in a multi-component injection molding process is made. This advantageously results an easy to manufacture component, with the Final assembly using the multi-component injection molding process is saved. It is particularly advantageous if also the conductor track forming conductive contacts made of conductive Plastic together with the control panel and the switching element manufactured in a multi-component injection molding process are. As a result, the fixed contacts and to these connecting conductor tracks inexpensively in Injection molding process along with the other injection molded ones Components are manufactured. This results in a special one cost-effective control panel.

- control panel has a Conversion part of a housing for electronic components forms.

- the switch on the control panel can be advantageous be electrically connected to the electronic components.

- the housing can be particularly advantageously used as a circuit carrier can be used for the electronic components. It can be used for the electronic components as well as the switch there is no need for a separate carrier plate, which on the one hand reduces the manufacturing costs and on the other hand, a particularly compact design of the housing is realized becomes.

- the control panel can, for example, by means of a plug connection be connected to the housing, for example at the same time the function of a lid for one Take over the housing opening, which is used to install the electronic Components are provided in the housing.

- a plug connection be connected to the housing, for example at the same time the function of a lid for one Take over the housing opening, which is used to install the electronic Components are provided in the housing.

- Particularly advantageous is, however, the one-piece manufacture of the housing and the control panel by injection molding.

- a compound is expediently used as the electrically conductive plastic made of metal powder and a thermoplastic elastomer used.

- Crucial for the function of filled conductive Compounds is that a continuous network is formed in which the filler particles touch or on approximate approx. 10 nm. With a continuous increase the proportion of filler initially only increases slightly up to a certain concentration a. In one narrow concentration range above a certain Filler concentration, the so-called percolation concentration, The conductivity then increases many times over on. With a further increase in the filler concentration a plateau value is reached, above which the conductivity no longer changed significantly. This plateau value is essentially on the shape of the filler particles and their inclination depending on the agglomeration of networks, but also e.g. B. of disturbances in the statistical filler distribution.

- the switch is extremely robust as it is made from a single unit Material exists and mechanical parts are omitted. Moreover no openings for the switch are necessary, so that housings are now produced in a simple manner that are dense to aggressive Media or against dust.

- buttons 2 consist of one electrical conductive plastic. You will be using the multi-component injection molding process together with the control panel 1 and the others Housing parts made, including electrical traces 3 can also be injected, if also for this conductive plastic is used. Alternatively, the Conductor tracks 3 but also by coating the control panel and the button 2 are produced (not shown). The Conductors 3 shown form fixed contacts 4 between the control panel 1 and the buttons 2, one of which is in the Drawing is indicated.

- the electrically conductive plastic for the button 2 is made from a compound of metal powder, e.g. B. aluminum powder, and a thermoplastic elastomer, the filler concentration just reached the area where the plastic begins to become conductive. now becomes a pressure effect exerted on a button 2, the filler particles approach and the electrical conductivity increases leaps and bounds.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Composite Materials (AREA)

- Materials Engineering (AREA)

- Push-Button Switches (AREA)

- Switch Cases, Indication, And Locking (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2000165853 DE10065853C1 (de) | 2000-12-22 | 2000-12-22 | Schalter mit Festkontakten und Schatelement aus einem Kunststoff |

| DE10065853 | 2000-12-22 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1220249A2 true EP1220249A2 (fr) | 2002-07-03 |

| EP1220249A3 EP1220249A3 (fr) | 2004-04-14 |

Family

ID=7669510

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01250440A Withdrawn EP1220249A3 (fr) | 2000-12-22 | 2001-12-13 | Commutateur pour le montage dans des boítiers en matière plastique pour composants électriques ou tableaux de commande |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1220249A3 (fr) |

| DE (1) | DE10065853C1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100808745B1 (ko) | 2003-06-12 | 2008-03-03 | 바이에리셰 모토렌 베르케 악티엔게젤샤프트 | 작동요소 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT412176B (de) * | 2001-06-26 | 2004-10-25 | Keba Ag | Tragbare vorrichtung zumindest zur visualisierung von prozessdaten einer maschine, eines roboters oder eines technischen prozesses |

| FR2879803B1 (fr) * | 2004-12-20 | 2007-01-19 | Dav Sa | Dispositif d'activation par surface tactile, notamment pour les commandes d'un vehicule |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6035937Y2 (ja) * | 1980-04-15 | 1985-10-25 | シチズン時計株式会社 | 時計ケ−スの外部操作スイツチ |

| US6135886A (en) * | 1997-10-01 | 2000-10-24 | Armstrong; Brad A. | Variable-conductance sensor with elastomeric dome-cap |

| JPH11512564A (ja) * | 1995-09-12 | 1999-10-26 | テクストロン オートモーティブ カンパニー インコーポレイテッド | アームレスト電気スイッチアレー |

| DE19542533C2 (de) * | 1995-11-15 | 2002-11-07 | Thueringisches Inst Textil | Verfahren zur Herstellung von Sensormaterial und seine Verwendung |

| DE19835613C2 (de) * | 1997-01-13 | 2002-12-12 | Aisin Seiki | Elektrisch leitfähige Harzzusammensetzung und deren Verwendung zur Herstellung von Harzformteilen |

| US6093353A (en) * | 1998-08-03 | 2000-07-25 | Lear Automotive Dearborn, Inc. | Method of forming electrical components |

| DE19836805A1 (de) * | 1998-08-14 | 2000-02-17 | Daum Gmbh | Datenhandschuh |

-

2000

- 2000-12-22 DE DE2000165853 patent/DE10065853C1/de not_active Expired - Fee Related

-

2001

- 2001-12-13 EP EP01250440A patent/EP1220249A3/fr not_active Withdrawn

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100808745B1 (ko) | 2003-06-12 | 2008-03-03 | 바이에리셰 모토렌 베르케 악티엔게젤샤프트 | 작동요소 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1220249A3 (fr) | 2004-04-14 |

| DE10065853C1 (de) | 2002-06-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1197402A2 (fr) | Volant de véhicule | |

| EP0278018B1 (fr) | Boîtier ou partie de boîtier possédant au moins une touche d'un interrupteur électrique | |

| EP2057653B1 (fr) | Commutateur electrique | |

| EP1220249A2 (fr) | Commutateur pour le montage dans des boítiers en matière plastique pour composants électriques ou tableaux de commande | |

| EP1049605A1 (fr) | Interrupteur a baton, notamment interrupteur sur colonne de direction destine a des vehicules | |

| DE19943490C2 (de) | Lenkstockschalter | |

| DE102014102709A1 (de) | Mehrfachschalter für ein Elektrogerät | |

| DE4221625C1 (en) | Electrical switch suitable for motor vehicle e.g. throttle flap or steering column - has Hall component and ferromagnetic shield assigned to housing base and cover | |

| DE9213143U1 (de) | Vakuumschütz mit einer Anschlußvorrichtung | |

| DE10248830C1 (de) | Elektrische Einrichtung | |

| DE2618572C3 (de) | Schiebetastenschalter | |

| DE102013102865A1 (de) | Mehrpolige Steckvorrichtung mit einem Schalter | |

| DE202007016121U1 (de) | Griff für eine Kraftfahrzeugtür mit Zierleiste | |

| DE10037142B4 (de) | Elektrisches Schaltelement | |

| DE3613291C1 (en) | Electrical switch | |

| EP3180796B1 (fr) | Interrupteur électrique | |

| DE9210551U1 (de) | Steckverbinder mit einer Druckkontaktleiste und einer Stirnkontaktleiste | |

| DE3531796A1 (de) | Elektromotorisches stellglied | |

| DE4126345C1 (en) | Electric switch suitable for motor vehicle e.g. throttle flap, steering column or drive - assigns permanent magnets of same polarity to both ends of Hall element, one magnet being connected to adjustable actuator and other adjustable for balancing control | |

| DE102018113100A1 (de) | Schalter für ein Elektrogerät | |

| EP2099266B1 (fr) | Transducteur ultrasonore doté d'une plaquette flexible | |

| DE19750307A1 (de) | Elektronischer Apparat, insbesondere Telefonapparat und Verfahren zu seiner Herstellung | |

| DE102008046767A1 (de) | Kontaktiereinrichtung | |

| DE19511989C2 (de) | Elektrische Schaltvorrichtung | |

| DE102005005252B4 (de) | Kontakteinrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20041015 |