EP1220249A2 - Switch adapted to be mounted in plastic housings for electrical components or control panels - Google Patents

Switch adapted to be mounted in plastic housings for electrical components or control panels Download PDFInfo

- Publication number

- EP1220249A2 EP1220249A2 EP01250440A EP01250440A EP1220249A2 EP 1220249 A2 EP1220249 A2 EP 1220249A2 EP 01250440 A EP01250440 A EP 01250440A EP 01250440 A EP01250440 A EP 01250440A EP 1220249 A2 EP1220249 A2 EP 1220249A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- control panel

- panel according

- switching element

- plastic

- switch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H13/00—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch

- H01H13/70—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a plurality of operating members associated with different sets of contacts, e.g. keyboard

- H01H13/78—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a plurality of operating members associated with different sets of contacts, e.g. keyboard characterised by the contacts or the contact sites

- H01H13/785—Switches having rectilinearly-movable operating part or parts adapted for pushing or pulling in one direction only, e.g. push-button switch having a plurality of operating members associated with different sets of contacts, e.g. keyboard characterised by the contacts or the contact sites characterised by the material of the contacts, e.g. conductive polymers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/02—Contacts characterised by the material thereof

- H01H1/021—Composite material

- H01H1/029—Composite material comprising conducting material dispersed in an elastic support or binding material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2201/00—Contacts

- H01H2201/022—Material

- H01H2201/032—Conductive polymer; Rubber

- H01H2201/036—Variable resistance

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2203/00—Form of contacts

- H01H2203/03—Form of contacts printed on casing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2223/00—Casings

- H01H2223/002—Casings sealed

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2229/00—Manufacturing

- H01H2229/044—Injection moulding

- H01H2229/046—Multi-colour or double shot injection moulding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H2300/00—Orthogonal indexing scheme relating to electric switches, relays, selectors or emergency protective devices covered by H01H

- H01H2300/01—Application power window

Definitions

- the invention relates to an operating panel, comprising one Switches with fixed contacts and a switching element from one Plastic with pressure-dependent electrical conductivity.

- Such a switch is in the German patent DE 31 15 271 C2 described.

- This switch can according to figure 2 for example in an operating panel below the display device of a watch case can be used.

- Figure 4 has the switch used a rubber part from a electrically conductive elastomer depending on pressure. With this Rubber part is connected to a so-called switch body, which fixed contacts for electrical contacting the Has switch. On the side facing away from the switch body A push button is provided on the side of the rubber part A manual shift force is exerted on the rubber part can be to make this electrically conductive and such an electrically conductive connection between the fixed contacts manufacture.

- the object of the invention is to have an operating panel specify a switch, which is comparatively easy can be made.

- the task is solved in that the fixed contacts in the control panel made of plastic are integrated and the switching element with this in a multi-component injection molding process is made. This advantageously results an easy to manufacture component, with the Final assembly using the multi-component injection molding process is saved. It is particularly advantageous if also the conductor track forming conductive contacts made of conductive Plastic together with the control panel and the switching element manufactured in a multi-component injection molding process are. As a result, the fixed contacts and to these connecting conductor tracks inexpensively in Injection molding process along with the other injection molded ones Components are manufactured. This results in a special one cost-effective control panel.

- control panel has a Conversion part of a housing for electronic components forms.

- the switch on the control panel can be advantageous be electrically connected to the electronic components.

- the housing can be particularly advantageously used as a circuit carrier can be used for the electronic components. It can be used for the electronic components as well as the switch there is no need for a separate carrier plate, which on the one hand reduces the manufacturing costs and on the other hand, a particularly compact design of the housing is realized becomes.

- the control panel can, for example, by means of a plug connection be connected to the housing, for example at the same time the function of a lid for one Take over the housing opening, which is used to install the electronic Components are provided in the housing.

- a plug connection be connected to the housing, for example at the same time the function of a lid for one Take over the housing opening, which is used to install the electronic Components are provided in the housing.

- Particularly advantageous is, however, the one-piece manufacture of the housing and the control panel by injection molding.

- a compound is expediently used as the electrically conductive plastic made of metal powder and a thermoplastic elastomer used.

- Crucial for the function of filled conductive Compounds is that a continuous network is formed in which the filler particles touch or on approximate approx. 10 nm. With a continuous increase the proportion of filler initially only increases slightly up to a certain concentration a. In one narrow concentration range above a certain Filler concentration, the so-called percolation concentration, The conductivity then increases many times over on. With a further increase in the filler concentration a plateau value is reached, above which the conductivity no longer changed significantly. This plateau value is essentially on the shape of the filler particles and their inclination depending on the agglomeration of networks, but also e.g. B. of disturbances in the statistical filler distribution.

- the switch is extremely robust as it is made from a single unit Material exists and mechanical parts are omitted. Moreover no openings for the switch are necessary, so that housings are now produced in a simple manner that are dense to aggressive Media or against dust.

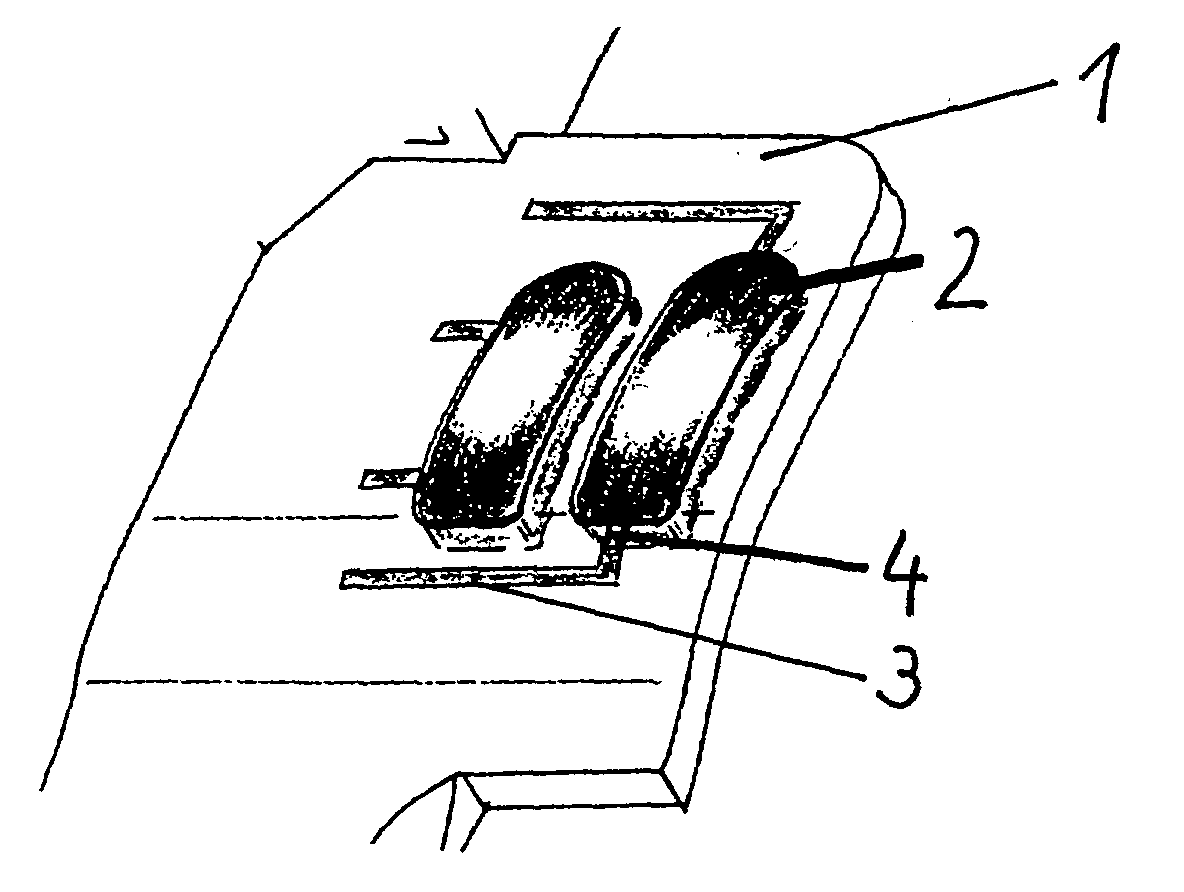

- buttons 2 consist of one electrical conductive plastic. You will be using the multi-component injection molding process together with the control panel 1 and the others Housing parts made, including electrical traces 3 can also be injected, if also for this conductive plastic is used. Alternatively, the Conductor tracks 3 but also by coating the control panel and the button 2 are produced (not shown). The Conductors 3 shown form fixed contacts 4 between the control panel 1 and the buttons 2, one of which is in the Drawing is indicated.

- the electrically conductive plastic for the button 2 is made from a compound of metal powder, e.g. B. aluminum powder, and a thermoplastic elastomer, the filler concentration just reached the area where the plastic begins to become conductive. now becomes a pressure effect exerted on a button 2, the filler particles approach and the electrical conductivity increases leaps and bounds.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Composite Materials (AREA)

- Materials Engineering (AREA)

- Push-Button Switches (AREA)

- Switch Cases, Indication, And Locking (AREA)

Abstract

Das Einbringen von Schaltern in ein Gehäuse bzw. auf eine Leiterplatte und deren Zusammenbau mit einem entsprechenden Gehäuse von Elektronik-Bauteilen erfordert Montage- und Justagearbeiten mit erheblichem technologischen Aufwand.The insertion of switches in a housing or on a PCB and its assembly with a corresponding Housing of electronic components requires assembly and Adjustment work with considerable technological effort.

Der Aufwand lässt sich verringern, indem der Schalter unter Verwendung eines Kunststoffes mit druckabhängiger elektrischer Leitfähigkeit zusammen mit dem Gehäuse (1) oder Bedien-Tableau im Mehrkomponentenspritzgießverfahren hergestellt wird. The effort can be reduced by producing the switch using a plastic with pressure-dependent electrical conductivity together with the housing (1) or control panel in a multi-component injection molding process.

Description

Die Erfindung betrifft ein Bedien-Tableau, aufweisend einen Schalter mit Festkontakten und einem Schaltelement aus einem Kunststoff mit druckabhängiger elektrischer Leitfähigkeit.The invention relates to an operating panel, comprising one Switches with fixed contacts and a switching element from one Plastic with pressure-dependent electrical conductivity.

Ein derartiger Schalter ist in dem deutschen Patent DE 31 15 271 C2 beschrieben. Dieser Schalter kann gemäß Figur 2 beispielsweise in einem Bedien-Tableau unterhalb der Anzeigeeinrichtung eines Uhrgehäuses verwendet werden. Gemäß Figur 4 weist der verwendete Schalter ein Gummiteil aus einem druckabhängig elektrisch leitfähigen Elastomer auf. Mit diesem Gummiteil ist ein sogenannter Schalterkörper verbunden, welcher Festkontakte zur elektrischen Kontaktierung des Schalters aufweist. Auf der dem Schalterkörper abgewandten Seite des Gummiteils ist ein Druckknopf vorgesehen, mit dessen Hilfe eine manuelle Schaltkraft auf das Gummiteil ausgeübt werden kann, um dieses elektrisch leitfähig zu machen und so eine elektrisch leitfähige Verbindung zwischen den Festkontakten herzustellen.Such a switch is in the German patent DE 31 15 271 C2 described. This switch can according to figure 2 for example in an operating panel below the display device of a watch case can be used. According to Figure 4 has the switch used a rubber part from a electrically conductive elastomer depending on pressure. With this Rubber part is connected to a so-called switch body, which fixed contacts for electrical contacting the Has switch. On the side facing away from the switch body A push button is provided on the side of the rubber part A manual shift force is exerted on the rubber part can be to make this electrically conductive and such an electrically conductive connection between the fixed contacts manufacture.

Die Aufgabe der Erfindung liegt darin, ein Bedien-Tableau mit einem Schalter anzugeben, welches sich vergleichsweise einfach herstellen lässt.The object of the invention is to have an operating panel specify a switch, which is comparatively easy can be made.

Die Aufgabe wird dadurch gelöst, dass die Festkontakte in das aus Kunststoff gefertigte Bedien-Tableau integriert sind und das Schaltelement mit diesem im Mehrkomponenten-Spritzgießverfahren hergestellt ist. Hierdurch entsteht vorteilhafterweise ein einfach herzustellendes Bauteil, wobei durch die Anwendung des Mehrkomponenten-Spritzgießverfahrens eine Endmontage eingespart wird. Besonders vorteilthaft ist es, wenn auch die Festkontakte bildende Leiterbahn aus leitfähigem Kunststoff zusammen mit dem Bedien-Tableau und dem Schaltelement im Mehrkomponenten-Spritzgießverfahren hergestellt sind. Hierdurch können zusätzlich die Festkontakte und die sich an diese anschließenden Leiterbahnen kostengünstig im Spritzgießverfahren zusammen mit den anderen spritzgegossenen Komponenten hergestellt werden. Hierdurch ergibt sich ein besonders kostengünstiges Bedien-Tableau.The task is solved in that the fixed contacts in the control panel made of plastic are integrated and the switching element with this in a multi-component injection molding process is made. This advantageously results an easy to manufacture component, with the Final assembly using the multi-component injection molding process is saved. It is particularly advantageous if also the conductor track forming conductive contacts made of conductive Plastic together with the control panel and the switching element manufactured in a multi-component injection molding process are. As a result, the fixed contacts and to these connecting conductor tracks inexpensively in Injection molding process along with the other injection molded ones Components are manufactured. This results in a special one cost-effective control panel.

Weiterhin ist es vorteilhaft, wenn dass Bedien-Tableau einen Wandlungsteil eines Gehäuses für elektronische Bauteile bildet. Dabei kann vorteilhaft der Schalter des Bedien-Tableaus elektrisch mit den elektronischen Bauteilen verbunden werden. Außerdem kann besonders vorteilhaft das Gehäuse als Schaltungsträger für die elektronischen Bauteile verwendet werden. Dabei kann für die elektronischen Bauteile sowie den Schalter auf eine gesonderte Trägerplatte komplett verzichtet werden, wodurch zum einen die Fertigungskosten reduziert werden und zum anderen eine besonders kompakte Bauweise des Gehäuses realisiert wird.It is also advantageous if the control panel has a Conversion part of a housing for electronic components forms. The switch on the control panel can be advantageous be electrically connected to the electronic components. In addition, the housing can be particularly advantageously used as a circuit carrier can be used for the electronic components. It can be used for the electronic components as well as the switch there is no need for a separate carrier plate, which on the one hand reduces the manufacturing costs and on the other hand, a particularly compact design of the housing is realized becomes.

Das Bedien-Tableau kann beispielsweise mittels einer Steckverbindung mit dem Gehäuse verbunden werden und dabei beispielsweise gleichzeitig die Funktion eines Deckels für eine Gehäuseöffnung übernehmen, welche zum Einbau der elektronischen Bauteile in das Gehäuse vorgesehen ist. Besonders vorteilhaft ist jedoch die einteilige Herstellung des Gehäuses und des Bedien-Tableaus durch Spritzgießen.The control panel can, for example, by means of a plug connection be connected to the housing, for example at the same time the function of a lid for one Take over the housing opening, which is used to install the electronic Components are provided in the housing. Particularly advantageous is, however, the one-piece manufacture of the housing and the control panel by injection molding.

Als elektrisch leitender Kunststoff wird zweckmäßig ein Compound aus Metallpulver und einem thermoplastischen Elastomer eingesetzt. Entscheidend für die Funktion gefüllter leitfähiger Compounds ist, daß sich ein durchgehendes Netzwerk ausbildet, in dem sich die Füllstoffpartikel berühren bzw. auf ca. 10 nm annähnern. Bei einer kontinuierlichen Steigerung des Füllstoffanteils steigt die Leitfähigkeit zunächst nur geringfügig bis zu einer bestimmten Konzentration a. In einem schmalen Konzentrationsbereich oberhalb einer bestimmten Füllstoffkonzentration, der sogenannten Perkolationskonzentration, steigt die Leitfähigkeit dann um ein Vielfaches an. Bei einer weiteren Steigerung der Füllstoffkonzentration wird ein Plateauwert erreicht, ab dem sich die Leitfähigkeit nicht mehr deutlich verändert. Dieser Plateauwert ist im wesentlichen von der Form der Füllstoffpartikel und deren Neigung zur Agglomeration von Netzwerken abhängig, aber auch z. B. von Störungen der statistischen Füllstoffverteilung.A compound is expediently used as the electrically conductive plastic made of metal powder and a thermoplastic elastomer used. Crucial for the function of filled conductive Compounds is that a continuous network is formed in which the filler particles touch or on approximate approx. 10 nm. With a continuous increase the proportion of filler initially only increases slightly up to a certain concentration a. In one narrow concentration range above a certain Filler concentration, the so-called percolation concentration, The conductivity then increases many times over on. With a further increase in the filler concentration a plateau value is reached, above which the conductivity no longer changed significantly. This plateau value is essentially on the shape of the filler particles and their inclination depending on the agglomeration of networks, but also e.g. B. of disturbances in the statistical filler distribution.

Liegt die Füllstoffkonzentration im Anfang des Perkolationsbereiches, so kommt es bei Druckeinwirkung auf den Kunststoff zu einem sprunghaften Ansteigen der elektrischen Leitfähigkeit. Diese Eigenschaft lässt sich zur Realisierung einer Tasterfunktion nutzen. Werden am Gehäuse mechanische Mittel zum Einrasten in der betätigten Stellung vorgesehen, so kann auch eine Schalterfunktion wie bei einem Kippschalter realisiert werden.If the filler concentration is in the beginning of the percolation range, so it comes under pressure on the plastic to a sudden increase in electrical conductivity. This property can be used to implement a Use button function. Are mechanical means on the housing provided to snap in the actuated position, so can also a switch function like a toggle switch become.

Sämtliche Montagearbeiten für den Schaltereinbau entfallen mit der erfindungsgemäßen Lösung. Werden auch die Leitungsverbindungen im Mehrkomponentenspritzgießverfahren mit hergestellt, so entfallen sogar die Arbeiten zur Herstellung der nötigen Leitungsverbindungen.All installation work for the switch installation is omitted with the solution according to the invention. Will also be the line connections manufactured in a multi-component injection molding process, this even eliminates the work required to manufacture the necessary line connections.

Der Schalter ist äußerst robust, da er aus einem einheitlichen Werkstoff besteht und mechanische Teile entfallen. Außerdem sind keine Gehäusedurchbrüche für den Schalter nötig, so dass nunmehr auf einfache Art und Weise Gehäuse hergestellt werden können, die dicht sind gegenüber aggressiven Medien oder gegenüber Staub.The switch is extremely robust as it is made from a single unit Material exists and mechanical parts are omitted. Moreover no openings for the switch are necessary, so that housings are now produced in a simple manner that are dense to aggressive Media or against dust.

Die Vorteile der Erfindung sind auch aus dem nachfolgend beschriebenen Ausführungsbeispiel ersichtlich. Die zugehörige Zeichnung zeigt ein Spritzgussgehäuseteil mit einem eingespritzten Schalter.The advantages of the invention are also apparent from that described below Embodiment can be seen. The associated Drawing shows an injection molded housing part with an injected Switch.

Eine Bedienplatte 1 eines Elektronik-Bauteils, z. B. dem Bedienteil

eines elektrischen Fensterhebers für ein Auto, trägt

zwei Taster 2. Die Taster 2 bestehen aus einem elektrisch

leitfähigen Kunststoff. Sie werden im Mehrkomponentenspritzgießverfahren

zusammen mit der Bedienplatte 1 und den weiteren

Gehäuseteilen hergestellt, wobei auch elektrische Leiterbahnen

3 mit eingespritzt werden können, wenn dafür ebenfalls

leitfähiger Kunststoff verwendet wird. Alternativ können die

Leiterbahnen 3 aber auch durch Beschichtung der Bedienplatte

und der Taster 2 hergestellt werden (nicht dargestellt). Die

dargestellten Leiterbahnen 3 bilden Festkontakte 4 zwischen

der Bedienplatte 1 und den Tastern 2, von denen einer in der

Zeichnung angedeutet ist.A

Der elektrisch leitfähige Kunststoff für die Taster 2 besteht

aus einem Compound aus Metallpulver, z. B. Aluminiumpulver,

und einem thermoplastischen Elastomer, wobei die Füllstoffkonzentration

gerade den Bereich erreicht, in dem der Kunststoff

beginnt, leitfähig zu werden. wird nun eine Druckwirkung

auf einen Taster 2 ausgeübt, so nähern sich die Füllstoffpartikel

und die elektrische Leitfähigkeit steigt

sprunghaft an.The electrically conductive plastic for the

Claims (8)

dadurch gekennzeichnet, dass

die Festkontakte in das aus Kunststoff gefertigte Bedien-Tableau integriert sind und das Schaltelement mit diesem im Mehrkomponenten-Spritzgießverfahren hergestellt ist.Control panel, comprising a switch with fixed contacts and a switching element made of plastic with pressure-dependent electrical conductivity,

characterized in that

the fixed contacts are integrated in the plastic control panel and the switching element is manufactured with it in a multi-component injection molding process.

dadurch gekennzeichnet, dass

dieses unmittelbar als Schaltungsträger fungiert.Control panel according to claim 1,

characterized in that

this acts directly as a circuit carrier.

dadurch gekennzeichnet, dass

dieses einen Wandungsteil eines Gehäuses für elektronische Bauteile bildet.Control panel according to one of the preceding claims,

characterized in that

this forms a wall part of a housing for electronic components.

dadurch gekennzeichnet, dass

das Schaltelement aus einem mit Metallpulver compoundierten thermoplastischen Elastomer besteht.Control panel according to one of the preceding claims,

characterized in that

the switching element consists of a thermoplastic elastomer compounded with metal powder.

dadurch gekennzeichnet, dass

die Konzentration des Metallpulvers im Perkolationsbereich liegt.Control panel according to claim 4,

characterized in that

the concentration of the metal powder is in the percolation range.

dadurch gekennzeichnet, dass

das Schaltelement ein Taster (2) ist. Control panel according to one of the preceding claims,

characterized in that

the switching element is a button (2).

dadurch gekennzeichnet, dass

am Bedien-Tableau Mittel zur mechanischen Arretierung in der betätigten Schalterstellung vorgesehen sind.Control panel according to one of claims 1 to 6,

characterized in that

Means for mechanical locking in the actuated switch position are provided on the control panel.

dadurch gekennzeichnet, dass

die Festkontakte bildende Leiterbahnen aus leitfähigem Kunststoff zusammen mit dem Bedien-Tableau und dem Schaltelement im Mehrkomponenten-Spritzgießverfahren hergestellt sind.Control panel according to one of claims 1 to 7,

characterized in that

the conductor tracks forming the fixed contacts are made of conductive plastic together with the control panel and the switching element in a multi-component injection molding process.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2000165853 DE10065853C1 (en) | 2000-12-22 | 2000-12-22 | Switch with fixed contacts and a switching element of plastic material with pressure dependent conductivity is produced in its entirety by a multicomponent injection molding process |

| DE10065853 | 2000-12-22 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1220249A2 true EP1220249A2 (en) | 2002-07-03 |

| EP1220249A3 EP1220249A3 (en) | 2004-04-14 |

Family

ID=7669510

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01250440A Withdrawn EP1220249A3 (en) | 2000-12-22 | 2001-12-13 | Switch adapted to be mounted in plastic housings for electrical components or control panels |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1220249A3 (en) |

| DE (1) | DE10065853C1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100808745B1 (en) | 2003-06-12 | 2008-03-03 | 바이에리셰 모토렌 베르케 악티엔게젤샤프트 | Operating element |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT412176B (en) * | 2001-06-26 | 2004-10-25 | Keba Ag | PORTABLE DEVICE AT LEAST FOR VISUALIZING PROCESS DATA FROM A MACHINE, A ROBOT OR A TECHNICAL PROCESS |

| FR2879803B1 (en) * | 2004-12-20 | 2007-01-19 | Dav Sa | TOUCH SURFACE ACTIVATION DEVICE, IN PARTICULAR FOR CONTROLS OF A VEHICLE |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6035937Y2 (en) * | 1980-04-15 | 1985-10-25 | シチズン時計株式会社 | External operation switch for watch case |

| US6135886A (en) * | 1997-10-01 | 2000-10-24 | Armstrong; Brad A. | Variable-conductance sensor with elastomeric dome-cap |

| EP0870312A4 (en) * | 1995-09-12 | 1999-08-25 | Textron Automotive Co Inc | Armrest electrical switch array |

| DE19542533C2 (en) * | 1995-11-15 | 2002-11-07 | Thueringisches Inst Textil | Process for the production of sensor material and its use |

| DE19835613C2 (en) * | 1997-01-13 | 2002-12-12 | Aisin Seiki | Electrically conductive resin composition and its use for the production of molded resin parts |

| US6093353A (en) * | 1998-08-03 | 2000-07-25 | Lear Automotive Dearborn, Inc. | Method of forming electrical components |

| DE19836805A1 (en) * | 1998-08-14 | 2000-02-17 | Daum Gmbh | System in form of data glove for scanning human hand movement and entering this in computer and glove is made of stitched flexible material so that it matches human hand back |

-

2000

- 2000-12-22 DE DE2000165853 patent/DE10065853C1/en not_active Expired - Fee Related

-

2001

- 2001-12-13 EP EP01250440A patent/EP1220249A3/en not_active Withdrawn

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100808745B1 (en) | 2003-06-12 | 2008-03-03 | 바이에리셰 모토렌 베르케 악티엔게젤샤프트 | Operating element |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1220249A3 (en) | 2004-04-14 |

| DE10065853C1 (en) | 2002-06-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1197402A2 (en) | Vehicle steering wheel | |

| EP0278018B1 (en) | Casing or part of casing with at least one key of an electrical switch | |

| EP2057653B1 (en) | Electrical switch | |

| EP1220249A2 (en) | Switch adapted to be mounted in plastic housings for electrical components or control panels | |

| EP1049605A1 (en) | Stick shift, especially a steering column switch for motor vehicles | |

| DE19943490C2 (en) | Steering column switch | |

| DE102014102709A1 (en) | Multiple switch for an electrical appliance | |

| DE102017006466A1 (en) | Switching control element | |

| DE9213143U1 (en) | Vacuum contactor with a connection device | |

| DE10248830C1 (en) | Electrical device used in vehicles comprises a circuit board and a dome switching mat made from a permanent elastic material arranged between a housing lower part and a housing upper part of an insulating housing | |

| DE2618572C3 (en) | Slide switch | |

| DE102013102865A1 (en) | Multipole plug-in device with a switch | |

| DE202007016121U1 (en) | Handle for a motor vehicle door with trim strip | |

| DE10037142B4 (en) | Electrical switching element | |

| DE3613291C1 (en) | Electrical switch | |

| EP3180796B1 (en) | Electric switch | |

| DE9210551U1 (en) | Connector with a pressure contact strip and a front contact strip | |

| DE3531796A1 (en) | ELECTRIC MOTOR ACTUATOR | |

| DE4126345C1 (en) | Electric switch suitable for motor vehicle e.g. throttle flap, steering column or drive - assigns permanent magnets of same polarity to both ends of Hall element, one magnet being connected to adjustable actuator and other adjustable for balancing control | |

| DE102018113100A1 (en) | Switch for an electrical appliance | |

| EP2099266B1 (en) | Ultrasonic transducer with a flexible circuit board | |

| DE19750307A1 (en) | Electronic apparatus, in particular telephone apparatus and process for its manufacture | |

| DE102008046767A1 (en) | Contacting device, has contact elements arranged in section of contour in assembly end position, where distance of contour to printed circuit board is larger than in areas of contour in which contact elements are in mounting end position | |

| DE19511989C2 (en) | Electrical switching device | |

| DE102005005252B4 (en) | contactor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20041015 |