EP1201931A2 - Gleitlager für eine Kreiselpumpe - Google Patents

Gleitlager für eine Kreiselpumpe Download PDFInfo

- Publication number

- EP1201931A2 EP1201931A2 EP01204014A EP01204014A EP1201931A2 EP 1201931 A2 EP1201931 A2 EP 1201931A2 EP 01204014 A EP01204014 A EP 01204014A EP 01204014 A EP01204014 A EP 01204014A EP 1201931 A2 EP1201931 A2 EP 1201931A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- aforementioned

- ring

- impeller

- pump

- case

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/04—Shafts or bearings, or assemblies thereof

- F04D29/041—Axial thrust balancing

- F04D29/0413—Axial thrust balancing hydrostatic; hydrodynamic thrust bearings

Definitions

- the object of the present invention is a protection device for centrifugal pumps with a vertical axis.

- the purpose of the present invention is, therefore, to provide a device which eliminates this drawback, foreseeing, indeed, a device which allows said pump to start up, run and stop in dry conditions without being damaged.

- a protection device for centrifugal pumps with a vertical axis where the aforementioned pump comprises a case which contains a shaft, with the pump also comprising an impeller connected to said shaft and free to rotate inside said case, characterised in that the aforementioned device comprises a first ring, which is mobile in rotation with the aforementioned impeller and a second ring, in a fixed position with respect to the case, so that the sliding contact between the aforementioned first and second ring allows the dry operation of the centrifugal pump.

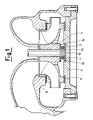

- the protection device for centrifugal pumps is applied to a pump which comprises a case or pump body 5 containing a shaft 21.

- the pump also comprises an impeller 3, connected to the shaft 21 and free to rotate inside the case 5.

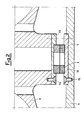

- the device 20 comprises a first ring 1, fixed upon the hub of the impeller 3 and a second ring 2, in a fixed position on the case 5.

- the second ring 2 is fixed to the closing lid 4 of the case 5, while the impeller 3 is provided with a wear ring 6.

- a first holding member 13 is associated with the impeller 3, and a first ring 1 is integral with said member 13.

- a second holding member 12 is associated with the lower lid 4 of the pump, and the second ring 2 is integral with said member 12.

- the first and the second ring are of the removable type.

- a plurality of screws 14, arranged on the hub of the impeller 3, allows a simple replacement of the first holding member 13 during the pump's maintenance operations; in the same way a plurality of screws 15, arranged on the closing lid 4 allows a simple replacement of the second holding member 12.

- At least one of the two rings is made of self-lubricating material with a very low friction coefficient.

- At least one of the two rings is made of a very hard material with a mirror-shine finish of the sliding face.

- the ring 1 made of very hard material, with a mirror-shine finish and an excellent resistance to wear, guarantees an excellent duration and operation.

- the ring 2 made of self-lubricating material with an extremely low friction coefficient, or alternatively made of very hard material with a mirror-shine finish guarantees favourable conditions for dry operation.

- Such a device substantially takes on the characteristics of an axial sliding bearing.

- the device of the invention can, for example, be installed in centrifugal pumps with a vertical axis, provided with wear rings with radial surfaces and a simple inlet.

- It can also be installed in centrifugal pumps with a vertical axis, provided with wear rings with a radial surface and a double inlet.

- the device of the invention allows the pump to start up, run and stop in dry working conditions without incurring damage of any sort.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI20002290 IT1319022B1 (it) | 2000-10-23 | 2000-10-23 | Dispositivo di protezione per pompe centrifughe ad asse verticale |

| ITMI002290 | 2000-10-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1201931A2 true EP1201931A2 (de) | 2002-05-02 |

| EP1201931A3 EP1201931A3 (de) | 2005-06-08 |

Family

ID=11446018

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01204014A Withdrawn EP1201931A3 (de) | 2000-10-23 | 2001-10-22 | Gleitlager für eine Kreiselpumpe |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1201931A3 (de) |

| IT (1) | IT1319022B1 (de) |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29503755U1 (de) * | 1995-03-08 | 1995-04-20 | Grundfos As | Flüssigkeitsgeschmiertes Axialgleitlager |

| DE19618767A1 (de) * | 1996-05-10 | 1997-11-13 | Wilo Gmbh | Selbsteinstellendes Axiallager für Hochdruckkreiselpumpen |

| US5765950A (en) * | 1996-11-29 | 1998-06-16 | Goulds Pumps, Incorporated | Thrust bearing assembly |

| US6106224A (en) * | 1998-04-02 | 2000-08-22 | Camco International Inc. | Downthrust pads for submersible centrifugal pumps |

-

2000

- 2000-10-23 IT ITMI20002290 patent/IT1319022B1/it active

-

2001

- 2001-10-22 EP EP01204014A patent/EP1201931A3/de not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| EP1201931A3 (de) | 2005-06-08 |

| ITMI20002290A1 (it) | 2002-04-23 |

| IT1319022B1 (it) | 2003-09-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101372981B (zh) | 散热风扇 | |

| US7847452B2 (en) | Motor with raised rotor | |

| CN100443732C (zh) | 电动泵 | |

| EP1298366A3 (de) | Wellendichtung und Turbine | |

| KR950005839B1 (ko) | 수중트러스트베어링장치 | |

| RU2668382C2 (ru) | Магнитный подшипниковый узел для ротационной машины и турбомашина, содержащая такой узел | |

| CA2150293A1 (en) | Centrifugal pump | |

| JP2017133654A (ja) | 軸封装置および回転機械 | |

| EP1201931A2 (de) | Gleitlager für eine Kreiselpumpe | |

| JP5512168B2 (ja) | ターボチャージャのためのスラスト軸受シール | |

| CN111720355B (zh) | 电动流体泵的轴承结构 | |

| CN100400892C (zh) | 电驱动的泵 | |

| JPS6388318A (ja) | 排気タ−ビン過給機 | |

| JP3912926B2 (ja) | 回転機械のフローティングシール | |

| CN110873060A (zh) | 一种泵体 | |

| JPS6327110Y2 (de) | ||

| EP1092877B1 (de) | Ausgeglichene Pumpe mit auf derselben Achse liegenden Ein- und Auslasskanälen | |

| JPH06129366A (ja) | ベーンポンプ | |

| CN101052783B (zh) | 具有可磨损末端的叶轮 | |

| JPH0735784U (ja) | ベーンポンプ | |

| CN205248955U (zh) | 一种滚动轴承润滑用挡油盘 | |

| KR200461409Y1 (ko) | 차량용 유체 팬 클러치 | |

| CN223104832U (zh) | 转轴组件及使用其的风机 | |

| SU1044834A1 (ru) | Рабочее колесо центробежного насоса | |

| SU1733704A1 (ru) | Гидравлическое уравновешивающее устройство |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20051209 |