EP1162003A2 - Device for applying substances to a web of material - Google Patents

Device for applying substances to a web of material Download PDFInfo

- Publication number

- EP1162003A2 EP1162003A2 EP01107006A EP01107006A EP1162003A2 EP 1162003 A2 EP1162003 A2 EP 1162003A2 EP 01107006 A EP01107006 A EP 01107006A EP 01107006 A EP01107006 A EP 01107006A EP 1162003 A2 EP1162003 A2 EP 1162003A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- application

- main roller

- main

- web

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0847—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the circumferential speed of the coating roller and the work speed having same direction but different value

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0826—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being a web or sheets

- B05C1/0834—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being a web or sheets the coating roller co-operating with other rollers, e.g. dosing, transfer rollers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/12—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being fed round the roller

Definitions

- the invention relates to a device for applying substances to web-like material.

- Such application and coating machines are known and comprise an application roller which extends over the width of the web-shaped material and which applies the substance contained in an application trough to the web-shaped material, the material being passed between the application roller and a counter-abutment roller. It is also known that the application roller is pressed magnetically against the counter-abutment roller by means of an elongated magnetic bar.

- a device is e.g. B. disclosed in EP 0 901 839 A1.

- the object of the invention is to provide a device for applying Develop substances on web-shaped material in such a way that, independently of the processed web width of the material web, no change of the Order role must be made. Another job is that with little effort and without removing the web of material Change of the order substance or an exchange and a cleaning of the Order tub is possible.

- the device comprises a machine frame, a elongated, tubular, rotatingly rubbed main roller, at least one application roll, one extending within the main roll, magnetic pressing device for pressing the application roll against the Main roller, a feed device for wetting the application roll with the substance to be applied and at least one further roller / roller in one Distance to the application roll is arranged on the circumference of the main roller, the web-shaped material between the roller / roller and the main roller passed through and brought into contact with the main roller by the roller / roller is.

- the invention therefore advantageously sees an indirect coating of the roll goods, ie. H. of the sheet material.

- the main advantage over that In addition to the indirect type of coating and the state of the art inexpensive design, in particular the achievable independence from the Web width of the material web to be coated. Since the main roller through the Job roll cannot be coated with the job substance permanently Drying or drying of the order substance take place on the main role. There is also no need to change the material to be coated on the fly different widths the usually necessary rapid change of the Magnetic pressure system or the adjustment of the width of the application roll to the Width of the material web.

- Another advantage of indirect coating is the higher possible Throughput speed of the material web.

- the surface speed of the main roller with the application substance thereon be selected differently from the surface speed of the web-like material, in particular to keep the surface speed of the main roller up to 40% lower compared to the surface speed of the web-like material.

- the adjustability of this speed difference should be possible from zero to 100% before and after. Typical values that can be mentioned are, for example, 100 m / min surface speed of the main roller and 150 to 200 m / min speed of the web-shaped material, the speeds from standstill to the desired speed being able to be regulated as desired. This measure leads to a correspondingly smaller and / or more uniform layer thickness of the application substance on the material web.

- the application roller can be driven be equipped so that the relative speed of the Application roll surface to the main roller surface is adjustable and thus the The thickness of the application layer influences or on the consistency (dynamic Viscosity and tixotropy).

- the job roll can also be done by two or more one above the other or side-by-side application rolls are replaced, thereby creating a indirect application of the main substance to the main roller and thus the Gush (wedge) of the order substance in the area of the narrowing Inlet gusset can be reduced or avoided entirely.

- Both will order rolls arranged one above the other or next to one another by the Magnet system pressed against the main roller.

- the preferably two job roles can essentially in the radial direction to the main roller be arranged one behind the other or side by side.

- the application rollers can be spaced apart, whereas the Spacer rollers have no mutual distance if they are radial to Main roller are arranged one behind the other.

- the roller / roller as a contact roller is formed, the web-shaped together with a further contact roller Brings material into contact with the main roller.

- the order medium is therefore from transfer the magnetically pressed application roller to the main roller and thence by the relative speed of the main roller to the web-shaped Material over a contact distance, which depends on the position of the Contact rollers, transferred to the material.

- the advantage is the inexpensive Production of the order roll. The transfer of the substance to be applied by the magnet system in connection with the Application roll on the main roller very evenly.

- the roller / roller as Pressure roller is formed by means of a magnetic pressure device can be pressed against the main roller.

- the advantage here is that the application of the Substance on the web-like material here is quasi forced, whereby an adjustment of the contact pressure of the contact roller by the magnet system is very well definable and the contact pressure, in particular not from the Tension of the sheet-like material across the width is generally dependent.

- the feed device for the substance to be applied is preferably designed as an application trough which, together with the application roller, can be displaced in the longitudinal direction relative to the main roller and can be pulled out of the device in the manner of a drawer.

- This lateral pulling out of the application tub as compared to the known removal from the front of the device, has the advantage that the web-like material no longer has to be removed for changing the application substance or in the case of cleaning work on the application tub.

- the laterally open and accessible construction means that the trays can also be emptied when installed.

- the application pan is advantageously designed to be tiltable, so that the substance to be applied can be emptied quickly and easily. According to the state of the art, full or filled with tubs had to be laboriously and carefully transported for emptying.

- the device according to the invention is open at the side Access to the front of the rollers / rollers or the application tray possible.

- the main roller is advantageously open on the machine frame by means of outer ring bearings stored.

- This external storage offers the compared to the prior art Advantage of better cooling of the inside of the main roller Magnet system, as a free air circulation within the main roller is possible. Excessive heating of the magnet system reduces its performance, what can now be reduced or avoided due to the open design of the main roller can.

- the preferred diameter of the main roller is 400 mm.

- edge wipers are used provided, which are arranged laterally on the application roll and in defined areas of the job role. Using the two on the side arranged scraper blades is the substance to be applied to the side Edges stripped from the application roll in such a way that the main roller only in one desired and easily adjustable area with the order substance is coated and consequently the material web only on the desired area is provided with the order substance. So there are adjustable, not coated edge areas on the material web.

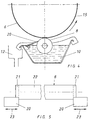

- FIG 1 shows a first embodiment of the invention Application machine.

- the centerpiece is the main roller 6, which is open on the machine frame 16 (Fig. 3) is mounted. This allows access to the internally hollow one Main roller 6.

- a Magnet system 7 arranged, which consists of a variety of solenoids consists.

- the magnet system 7 acts on a, below the main roller 6 arranged, application roller 8 and pushes or pulls it into contact with the Main roller 6.

- a Feeder 9 for the order substance can the order pan accordingly be filled.

- a surplus of the order substance is indicated by a Overflow pan or return pan 12 collected and back into the circuit returned.

- the order tray 10 can in the vertical direction by a Adjustment device 11 can be adjusted, whereby the immersion depth of the application roll 8 can be set in the order substance.

- Two contact rollers 1, 3 are preferably arranged above the main roller, over which the material web 4 to be coated is guided.

- the contact roller 3 is linearly adjustable up to a maximum stop 13, whereby the material web 4 can be brought into contact with the main roller 6.

- the main roller 6 is driven to rotate in the direction indicated by the arrow, the material web 4 with the corresponding speed of the Main roller 6 is guided past the surface.

- the order substance located in the order tub 10 is from the Order roll 8 added, the magnet system 7 to the main roller 6th is pressed. As a result, the application substance 15 is applied to the surface of the Main roller 6 transferred.

- the application roller 8 runs passively with the main roller 6 with, but can also have its own drive, so that this with a defined relative speed to the main roller 6 runs.

- the order substance 15 is carried along by the main roller 6 and onto the material web 4 transferred, which also at a relative speed to the main roller this runs along.

- the material web is coated within one Contact section 14, the length of which depends essentially on the position of the Feed roller 4 depends.

- FIG. 2 A second embodiment of the invention is shown in FIG. 2.

- the same components are provided with the same reference numbers.

- the Operation of the main roller 6, the application roller 8 and the application tray 10 and its associated parts correspond to those in connection with FIG. 1 described mode of operation.

- the way is different Transfer of the order substance 15 from the main roller 6 to the material web 4.

- the contact rollers 1 and 3 are provided, but here mainly work as deflection rollers.

- a pressure roller 2 is provided, which via a second Magnet system 5 can be pressed against the main roller 6 with a definable force.

- the Magnet system 5 is also arranged within the main roller 6 and can form a unit with the magnet system 7.

- the pressure roller 2 is now the web of material 4 pressed with a defined force on the main roller 6, whereby the Transfer of the order substance 15 located on the main roller 6 to the Material web 4 can be controlled in a defined manner. Depending on the contact pressure The pressure roller 2 can control the coating thickness on the material web 4 become.

- the transfer of the order substance from the main roller 6 to the Paper is therefore compulsory and in particular is not dependent on the Tension of the material web seen across its width. This one too Embodiment can the relative speed between the main roller 6 and Material web 4 can be regulated by different drive speeds the main role 6 and the material web 4.

- Both embodiments shown in Figures 1 and 2 stand out through an indirect transfer of the order substance to the material web, since the order substance first of all from the application roll 8 to the main roller 6 is transferred and in a second step from the main roller 6 to the Material web.

- the basic structure of the application machine can be seen in FIG. 3 where it can be seen that the application machine is a space-saving Arrangement.

- the main roller 6 is open on a machine frame 16 stored.

- the contact rollers 1, 3 and Pressure roller 2 not shown. Depending on the embodiment, these are above the Main roller 6 arranged.

- the magnet systems 7, 5 are within the main roller arranged.

- the order tray 10 below the main roller 6 is the order tray 10, in which the Application roll 8 (not shown) is arranged.

- the order tray 10 can be adjusted in the vertical direction 18.

- the Tray adjustment 17 can the order tray 10 together with the Application roller 8 laterally in the direction of arrow 19 from the machine frame 16 pulled out and inserted.

- This side pulling out of the Order tray 10 or order roll 8 also has the advantage that a Step arrangement of several machines is possible. Due to the possibility of lateral tub manipulation can be a staircase design of several Contract machines are done.

- FIGS. 4 and 5 show the possibility of arranging an edge wiping knife 20 on both sides of the application roller 8, which edge abut against the application roller 8 and wipes off the substance 15 to be applied to the main roller laterally at the edges of the application roller 8.

- the areas 21 on the edges of the application roll 8 therefore remain free of the order substance 16, so that no order substance 15 is applied to the main roller 6 there either.

- the scraper blades 20 can be moved parallel to the longitudinal extent of the application roller 8, as indicated by the double arrows 23 in FIG. 5. As a result, the width of the effective region 21 of the edge wipers 20 on the application roller 8 can be adjusted.

- the main roller 6 is wetted with the application substance 15 only in the desired and easily adjustable region 22, so that the material web 4 is also coated with the application substance only in the desired, set region 22.

- the edge wipers 20 thus determine the width of the Order substance 15 coated area 22 of the material web, the Edges of the material web 4 e.g. in a range of 50 mm from the Order substance 15 can be kept free.

- Figure 6 shows that the main roller 6 by means of outer ring bearings 24 on Machine frame 16 is mounted.

- This external storage offers compared to State of the art has the advantage of better cooling of the inside of the Main roller 6 arranged magnet system 7, because of the open storage free air circulation within the main roller 6 is possible.

- the main roller 6 will driven in the example shown by a drive 25 via a toothed belt.

Landscapes

- Coating Apparatus (AREA)

- Treatment Of Fiber Materials (AREA)

- Heating, Cooling, Or Curing Plastics Or The Like In General (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zum Auftragen von Substanzen auf

bahnförmiges Material.

Derartige Auftrags- und Beschichtungsmaschinen sind bekannt und umfassen

eine über die Breite des bahnförmigen Materials sich erstreckende Auftragswalze,

welche die in einer Auftragswanne enthaltene Substanz auf dem bahnförmigen

Material aufträgt, wobei das Material zwischen der Auftragswalze und einer

Gegenanlagewalze hindurchgeführt wird. Dabei ist es ferner bekannt, dass die

Auftragswalze mittels eines langgestreckten Magnetbalkens magnetisch gegen

die Gegenanlagewalze gepresst wird. Eine derartige Vorrichtung ist z. B. in der EP

0 901 839 A1 offenbart.The invention relates to a device for applying substances to web-like material.

Such application and coating machines are known and comprise an application roller which extends over the width of the web-shaped material and which applies the substance contained in an application trough to the web-shaped material, the material being passed between the application roller and a counter-abutment roller. It is also known that the application roller is pressed magnetically against the counter-abutment roller by means of an elongated magnetic bar. Such a device is e.g. B. disclosed in EP 0 901 839 A1.

Als Nachteil dieses direkten Auftragsverfahrens wird gesehen, dass die Auftragswalze einer Änderung der zu verarbeitenden Bahnbreite des Materials angepasst werden muss. Dazu muss die Maschine stillgesetzt und die Auftragswalze ausgetauscht werden.A disadvantage of this direct order process is seen that the Application roller of a change in the web width of the material to be processed needs to be adjusted. To do this, the machine must be stopped and the Application roller can be replaced.

Bei einem Wechsel der Auftragssubstanz oder einer Reinigung der Auftragswanne muss die Maschine ebenfalls stillgesetzt und die Auftragswanne ausgebaut werden. Zuvor muss jedoch die Materialbahn entfernt werden. Dies ist ein erheblicher Nachteil.When changing the order substance or cleaning the Order tray, the machine must also be stopped and the order tray get extended. However, the material web must first be removed. This is a significant disadvantage.

Die Aufgabe der Erfindung besteht darin, eine Vorrichtung zum Auftragen von Substanzen auf bahnförmiges Material derart weiterzubilden, dass, unabhängig von der verarbeiteten Bahnbreite der Materialbahn, kein Wechsel der Auftragsrolle vorgenommen werden muss. Eine weitere Aufgabe besteht darin, dass mit nur geringem Aufwand und ohne entfernen der Materialbahn ein Wechsel der Auftragssubstanz bzw. ein Austausch und eine Reinigung der Auftragswanne möglich ist. The object of the invention is to provide a device for applying Develop substances on web-shaped material in such a way that, independently of the processed web width of the material web, no change of the Order role must be made. Another job is that with little effort and without removing the web of material Change of the order substance or an exchange and a cleaning of the Order tub is possible.

Diese Aufgaben werden durch die Merkmale des unabhängigen Patentanspruchs gelöst.These tasks are characterized by the features of the independent claim solved.

Erfindungsgemäß umfasst die Vorrichtung ein Maschinengerüst, eine langgestreckte, rohrförmig ausgebildete, rotierend angeriebene Hauptwalze, mindestens eine Auftragsrolle, eine innerhalb der Hauptwalze sich erstreckende, magnetische Anpresseinrichtung zum Anpressen der Auftragsrolle an die Hauptwalze, eine Zuführeinrichtung zum Benetzen der Auftragsrolle mit der aufzutragenden Substanz und mindestens eine weitere Rolle/ Walze, die in einem Abstand zur Auftragsrolle am Umfang der Hauptwalze angeordnet ist, wobei das bahnförmige Material zwischen der Rolle/Walze und der Hauptwalze hindurchgeführt und durch die Rolle/Walze in Kontakt mit der Hauptwalze bringbar ist.According to the invention, the device comprises a machine frame, a elongated, tubular, rotatingly rubbed main roller, at least one application roll, one extending within the main roll, magnetic pressing device for pressing the application roll against the Main roller, a feed device for wetting the application roll with the substance to be applied and at least one further roller / roller in one Distance to the application roll is arranged on the circumference of the main roller, the web-shaped material between the roller / roller and the main roller passed through and brought into contact with the main roller by the roller / roller is.

Die Erfindung sieht also vorteilhaft eine indirekte Beschichtung der Rollenware, d. h. des bahnförmigen Materials, vor. Den wesentlichen Vorteil gegenüber dem Stand der Technik stellt dabei neben der indirekten Art der Beschichtung und der kostengünstigen Bauart insbesondere die erreichbare Unabhängigkeit von der Bahnbreite der zu beschichtenden Materialbahn dar. Da die Hauptwalze durch die Auftragsrolle permanent neu mit der Auftragssubstanz beschichtet wird, kann kein Eintrocken bzw. Antrocknen der Auftragssubstanz an der Hauptrolle stattfinden. Es entfallen auch bei fliegendem Wechsel des zu beschichtenden Materials mit unterschiedlichen Breiten das üblicherweise notwendige rasche Umstellen des Magnetanpresssystems bzw. die Anpassung der Breite der Auftragsrolle an die Breite der Materialbahn.The invention therefore advantageously sees an indirect coating of the roll goods, ie. H. of the sheet material. The main advantage over that In addition to the indirect type of coating and the state of the art inexpensive design, in particular the achievable independence from the Web width of the material web to be coated. Since the main roller through the Job roll cannot be coated with the job substance permanently Drying or drying of the order substance take place on the main role. There is also no need to change the material to be coated on the fly different widths the usually necessary rapid change of the Magnetic pressure system or the adjustment of the width of the application roll to the Width of the material web.

Ein weiterer Vorteil der indirekten Beschichtung ist die dadurch mögliche höhere Durchlaufgeschwindigkeit der Materialbahn.Another advantage of indirect coating is the higher possible Throughput speed of the material web.

Gemäß einer ersten Ausgestaltung der Erfindung ist vorgesehen, die

Oberflächengeschwindigkeit der Hauptwalze mit der darauf befindlichen

Auftragssubstanz unterschiedlich zur Oberflächengeschwindigkeit des

bahnförmigen Materials zu wählen, insbesondere die Oberflächengeschwindigkeit

der Hauptwalze um bis zu 40% geringer zu halten verglichen mit der

Oberflächengeschwindigkeit des bahnförmigen Materials. Die Einstellbarkeit

dieses Geschwindigkeitsunterschiedes soll von Null bis zu 100% im Vor- als auch

Nachlauf möglich sein.

Als typische Werte können beispielsweise 100 m/min Oberflächengeschwindigkeit

der Hauptwalze und 150 bis 200 m/min Geschwindigkeit des bahnförmigen

Materials genannt, wobei die Geschwindigkeiten von Stillstand bis

Sollgeschwindigkeit beliebig regelbar sein müssen.

Diese Maßnahme führt zu einer entsprechend geringeren und/oder

gleichmäßigeren Schichtdicke der Auftragssubstanz auf der Materialbahn.According to a first embodiment of the invention, it is provided that the surface speed of the main roller with the application substance thereon be selected differently from the surface speed of the web-like material, in particular to keep the surface speed of the main roller up to 40% lower compared to the surface speed of the web-like material. The adjustability of this speed difference should be possible from zero to 100% before and after.

Typical values that can be mentioned are, for example, 100 m / min surface speed of the main roller and 150 to 200 m / min speed of the web-shaped material, the speeds from standstill to the desired speed being able to be regulated as desired.

This measure leads to a correspondingly smaller and / or more uniform layer thickness of the application substance on the material web.

In einer bevorzugten Ausbildung der Erfindung kann die Auftragsrolle antreibbar ausgerüstet werden, so dass die Relativgeschwindigkeit der Auftragsrollenoberfläche zur Hauptwalzenoberfläche regelbar ist und dadurch die Dicke der Auftragsschicht beeinflusst bzw. auf die Konsistenz (dynamische Viskosität und Tixotropie) eingegangen werden kann.In a preferred embodiment of the invention, the application roller can be driven be equipped so that the relative speed of the Application roll surface to the main roller surface is adjustable and thus the The thickness of the application layer influences or on the consistency (dynamic Viscosity and tixotropy).

Dabei kann die Auftragsrolle auch durch zwei oder mehrere übereinander oder nebeneinander angeordneten Auftragsrollen ersetzt werden, wodurch eine indirekte Beaufschlagung der Hauptwalze mit der Auftragssubstanz und damit der Schwall (Keil) der Auftragssubstanz im Bereich des sich verengenden Einlaufzwickels reduziert bzw. ganz vermieden werden kann. Dabei werden beide übereinander oder nebeneinander angeordneten Auftragsrollen durch das Magnetsystem an die Hauptwalze gepresst. Die vorzugsweise zwei Auftragsrollen können hierbei in radialer Richtung zur Hauptwalze im wesentlichen hintereinander- oder nebeneinanderliegend angeordnet sein. Für den Fall, daß die beiden Auftragsrollen radial zur Hauptwalze nebeneinander auf einem Umkreis liegen, können die Auftragsrollen voneinander beabstandet sein, wohingegen die Abstandsrollen keinen gegenseitigen Abstand aufweisen, wenn sie radial zur Hauptwalze hintereinander angeordnet sind.The job roll can also be done by two or more one above the other or side-by-side application rolls are replaced, thereby creating a indirect application of the main substance to the main roller and thus the Gush (wedge) of the order substance in the area of the narrowing Inlet gusset can be reduced or avoided entirely. Both will order rolls arranged one above the other or next to one another by the Magnet system pressed against the main roller. The preferably two job roles can essentially in the radial direction to the main roller be arranged one behind the other or side by side. In the event that two application rollers radially to the main roller side by side on a circumference lie, the application rollers can be spaced apart, whereas the Spacer rollers have no mutual distance if they are radial to Main roller are arranged one behind the other.

In einer ersten Variante ist vorgesehen, dass die Rolle/Walze als Anlegewalze ausgebildet ist, die zusammen mit einer weiteren Anlegewalze das bahnförmige Material in Kontakt mit der Hauptwalze bringt. Das Auftragsmedium wird also von der magnetisch angepressten Auftragsrolle auf die Hauptwalze übertragen und von dort durch die Relativgeschwindigkeit von Hauptwalze zum bahnförmigen Material über eine Kontaktstrecke, die abhängig ist von der Position der Anlegewalzen, auf das Material übertragen. Der Vorteil ist die kostengünstige Herstellung der Auftragsrolle. Weiterhin erfolgt die Übertragung der aufzutragenden Substanz durch das Magnetsystem in Verbindung mit der Auftragsrolle auf die Hauptwalze sehr gleichmäßig.In a first variant it is provided that the roller / roller as a contact roller is formed, the web-shaped together with a further contact roller Brings material into contact with the main roller. The order medium is therefore from transfer the magnetically pressed application roller to the main roller and thence by the relative speed of the main roller to the web-shaped Material over a contact distance, which depends on the position of the Contact rollers, transferred to the material. The advantage is the inexpensive Production of the order roll. The transfer of the substance to be applied by the magnet system in connection with the Application roll on the main roller very evenly.

In einer anderen Ausführungsform ist vorgesehen, daß die Rolle/Walze als Anpressrolle ausgebildet ist, die mittels einer magnetischen Anpresseinrichtung gegen die Hauptwalze pressbar ist. Vorteil hierbei ist, dass die Aufbringung der Substanz auf das bahnförmige Material hier quasi zwangsweise erfolgt, wobei durch das Magnetsystem eine Einstellung des Anpressdruckes der Anpressrolle sehr gut definierbar ist und der Anpressdruck insbesondere nicht von der Spannung des bahnförmigen Materials über die Breite generell abhängig ist.In another embodiment it is provided that the roller / roller as Pressure roller is formed by means of a magnetic pressure device can be pressed against the main roller. The advantage here is that the application of the Substance on the web-like material here is quasi forced, whereby an adjustment of the contact pressure of the contact roller by the magnet system is very well definable and the contact pressure, in particular not from the Tension of the sheet-like material across the width is generally dependent.

Vorzugsweise ist die Zuführeinrichtung für die aufzutragende Substanz als

Auftragswanne ausgebildet, die zusammen mit der Auftragsrolle in Längsrichtung

gegenüber der Hauptwalze verschiebbar und schubladenartig aus der Vorrichtung

ausziehbar ist. Dieses seitliche Ausziehen der Auftragswanne, gegenüber dem

bekannten Ausbau nach vorne aus der Vorrichtung, hat den Vorteil, dass für einen

Wechsel der Auftragssubstanz bzw. im Falle von Reinigungsarbeiten an der

Auftragswanne das bahnförmige Material nicht mehr entfernt werden muss. Durch

die seitlich offene und zugängliche Konstruktion kann deshalb auch eine

Entleerung der Wannen in eingebautem Zustand erfolgen. Vorteilhaft ist die

Auftragswanne im eingefahrenen Zustand kippbar ausgeführt, so daß eine

einfache und rasche Entleerung der aufzutragenden Substanz möglich ist.

Gemäss dem Stand der Technik mussten volle bzw. mit Auftragssubstanzen

gefüllte Wannen mühsam und sorgfältig zum Entleeren transportiert werden.The feed device for the substance to be applied is preferably designed as an application trough which, together with the application roller, can be displaced in the longitudinal direction relative to the main roller and can be pulled out of the device in the manner of a drawer. This lateral pulling out of the application tub, as compared to the known removal from the front of the device, has the advantage that the web-like material no longer has to be removed for changing the application substance or in the case of cleaning work on the application tub. The laterally open and accessible construction means that the trays can also be emptied when installed. In the retracted state, the application pan is advantageously designed to be tiltable, so that the substance to be applied can be emptied quickly and easily.

According to the state of the art, full or filled with tubs had to be laboriously and carefully transported for emptying.

Generell gesagt ist bei der erfindungsgemäßen Vorrichtung ein seitlich offener Zugriff auf die Stirnseite der Rollen/Walzen bzw. der Auftragswanne möglich. Generally speaking, the device according to the invention is open at the side Access to the front of the rollers / rollers or the application tray possible.

Vorteilhaft ist die Hauptwalze mittels Außenringlagern offen am Maschinengerüst gelagert. Diese Außenlagerung bietet gegenüber dem Stand der Technik den Vorteil der besseren Kühlung des im Inneren der Hauptwalze angeordneten Magnetsystems, da eine freie Luftzirkulation innerhalb der Hauptwalze möglich ist. Eine übermäßige Erwärmung des Magnetsystems reduziert dessen Leistung, was durch die offene Bauweise der Hauptwalze nun verringert oder vermieden werden kann. Der bevorzugte Durchmesser der Hauptwalze beträgt 400 mm.The main roller is advantageously open on the machine frame by means of outer ring bearings stored. This external storage offers the compared to the prior art Advantage of better cooling of the inside of the main roller Magnet system, as a free air circulation within the main roller is possible. Excessive heating of the magnet system reduces its performance, what can now be reduced or avoided due to the open design of the main roller can. The preferred diameter of the main roller is 400 mm.

In einer bevorzugten Ausbildung der Erfindung sind Randabstreifrakeln vorgesehen, die seitlich an der Auftragsrolle verschiebbar angeordnet sind und in definierten Bereichen an der Auftragsrolle anliegen. Mittels der beiden seitlich angeordneten Randabstreifrakeln wird die aufzutragende Substanz seitlich an den Rändern von der Auftragsrolle abgestreift derart, daß die Hauptwalze nur in einem gewünschten und einfach einstellbaren Bereich mit der Auftragssubstanz beschichtet wird und folglich die Materialbahn nur auf dem gewünschten Bereich mit der Auftragssubstanz versehen wird. Es ergeben sich so einstellbare, nicht beschichtete Randbereiche auf der Materialbahn.In a preferred embodiment of the invention, edge wipers are used provided, which are arranged laterally on the application roll and in defined areas of the job role. Using the two on the side arranged scraper blades is the substance to be applied to the side Edges stripped from the application roll in such a way that the main roller only in one desired and easily adjustable area with the order substance is coated and consequently the material web only on the desired area is provided with the order substance. So there are adjustable, not coated edge areas on the material web.

Nachfolgend wird die Erfindung anhand von Ausführungsbeispielen mit Bezugnahme auf mehrere Zeichnungsfiguren näher beschrieben. Dabei ergeben sich weitere Merkmale, Vorteile und Anwendungsgebiete der Erfindung.The invention is described below with the aid of exemplary embodiments Described in more detail with reference to several drawing figures. Surrender other features, advantages and areas of application of the invention.

Es zeigen:

- Fig. 1:

- schematisch einen Schnitt durch die Vorrichtung in einer ersten Ausführungsform;

- Fig. 2:

- schematisch einen Schnitt durch die Vorrichtung in einer zweiten Ausführungsform;

- Fig. 3:

- eine vereinfachte Vorderansicht der Vorrichtung;

- Fig. 4:

- schematisch einen Schnitt durch die Vorrichtung im Bereich der Auftragsrolle mit zusätzlicher Randabstreifrakel;

- Fig. 5:

- schematisch eine Draufsicht auf die Auftragsrolle mit Radabstreifrakeln;

- Fig. 6:

- eine perspektivische Ansicht des Maschinengestells mit darin gelagerter Hauptwalze.

- Fig. 1:

- schematically shows a section through the device in a first embodiment;

- Fig. 2:

- schematically shows a section through the device in a second embodiment;

- Fig. 3:

- a simplified front view of the device;

- Fig. 4:

- schematically shows a section through the device in the area of the application roll with an additional edge doctor blade;

- Fig. 5:

- schematically a top view of the application roll with doctor blades;

- Fig. 6:

- a perspective view of the machine frame with the main roller stored therein.

Figur 1 zeigt eine erste Ausführungsform der erfindungsgemäßen

Auftragsmaschine. Kernstück ist die Hauptwalze 6, die offen am Maschinengerüst

16 (Fig. 3) gelagert ist. Dies gestattet den Zugriff auf die innen hohl ausgebildete

Hauptwalze 6. In der Hauptwalze 6 ist, in Längsrichtung gesehen, ein

Magnetsystem 7 angeordnet, welches aus einer Vielzahl von Magnetspulen

besteht. Das Magnetsystem 7 wirkt auf eine, unterhalb der Hauptwalze 6

angeordnete, Auftragsrolle 8 und drückt bzw. zieht diese in Kontakt mit der

Hauptwalze 6. Unterhalb der Auftragsrolle 8 befindet sich eine Auftragswanne 10,

die mit einer Beschichtungssubstanz, z. B. Klebstoff, gefüllt ist, wobei die

Auftragsrolle 8 teilweise in die Beschichtungssubstanz eintaucht. Mittels einer

Zuführung 9 für die Auftragssubstanz kann die Auftragswanne entsprechend

befüllt werden. Ein Überschuss von Auftragssubstanz wird durch eine

Überlaufwanne bzw. Rücklaufwanne 12 aufgefangen und wieder in den Kreislauf

zurückgeführt. Die Auftragswanne 10 kann in vertikaler Richtung durch eine

Verstelleinrichtung 11 verstellt werden, wodurch die Eintauchtiefe der Auftragsrolle

8 in die Auftragssubstanz eingestellt werden kann.Figure 1 shows a first embodiment of the invention

Application machine. The centerpiece is the

Oberhalb der Hauptwalze sind vorzugsweise zwei Anlegewalzen 1, 3 angeordnet,

über welche die zu beschichtende Materialbahn 4 geführt ist. Die Anlagewalze 3

ist linear bis zu einem Maximalanschlag 13 verstellbar, wodurch die Materialbahn

4 in Kontakt mit der Hauptwalze 6 bringbar ist.Two

Die Hauptwalze 6 ist in der angegebenen Pfeilrichtung rotierend angetrieben,

wobei die Materialbahn 4 mit der entsprechenden Geschwindigkeit der

Hauptwalze 6 an deren Oberfläche vorbeigeführt wird. The

Die in der Auftragswanne 10 befindliche Auftragssubstanz wird von der

Auftragsrolle 8 aufgenommen, die vom Magnetsystem 7 an die Hauptwalze 6

gedrückt wird. Dadurch wird die Auftragssubstanz 15 auf die Oberfläche der

Hauptwalze 6 übertragen. Die Auftragswalze 8 läuft passiv mit der Hauptwalze 6

mit, kann aber auch einen eigenen Antrieb aufweisen, so daß diese mit einer

definierten Relativgeschwindigkeit zur Hauptwalze 6 läuft. Die Auftragssubstanz

15 wird von der Hauptwalze 6 mitgenommen und auf die Materialbahn 4

übertragen, die ebenfalls mit einer Relativgeschwindigkeit zur Hauptwalze an

dieser entlang läuft. Das Beschichten der Materialbahn geschieht innerhalb einer

Kontaktstrecke 14, deren Länge im wesentlichen von der Position der

Anlegewalze 4 abhängt.The order substance located in the

Eine zweite Ausführungsform der Erfindung ist in Figur 2 gezeigt. Im Vergleich mit

Figur 1 sind hierbei gleiche Bauteile mit gleichen Bezugsziffern versehen. Die

Funktionsweise der Hauptwalze 6, der Auftragsrolle 8 und der Auftragswanne 10

und deren zugehörigen Teile entspricht der in Zusammenhang mit Figur 1

beschriebenen Funktionsweise. Unterschiedlich ist die Art und Weise der

Übertragung der Auftragssubstanz 15 von der Hauptwalze 6 auf die Materialbahn

4. Es sind wiederum die Anlegewalzen 1 und 3 vorgesehen, die hier jedoch

hauptsächlich als Umlenkwalzen arbeiten. Zusätzlich ist zwischen den

Anlagewalzen 1, 3 eine Anpressrolle 2 vorgesehen, welche über ein zweites

Magnetsystem 5 mit definierbarer Kraft an die Hauptwalze 6 anpressbar ist. Das

Magnetsystem 5 ist ebenfalls innerhalb der Hauptwalze 6 angeordnet und kann

mit dem Magnetsystem 7 eine Einheit bilden. Durch die Anpressrolle 2 wird nun

die Materialbahn 4 mit definierter Kraft an die Hauptwalze 6 gepresst, wodurch die

Übertragung der auf der Hauptwalze 6 befindlichen Auftragssubstanz 15 auf die

Materialbahn 4 definiert gesteuert werden kann. Je nach Anpressdruck der

Anpresswalze 2 kann die Beschichtungsstärke auf der Materialbahn 4 gesteuert

werden. Die Übertragung der Auftragssubstanz von der Hauptwalze 6 auf das

Papier erfolgt also zwangsweise und ist insbesondere nicht abhängig von der

Spannung der Materialbahn über deren Breite gesehen. Auch bei dieser

Ausführungsform kann die Relativgeschwindigkeit zwischen Hauptwalze 6 und

Materialbahn 4 regelbar sein, durch unterschiedliche Antriebsgeschwindigkeiten

der Hauptrolle 6 und der Materialbahn 4.A second embodiment of the invention is shown in FIG. 2. In comparison with

1, the same components are provided with the same reference numbers. The

Operation of the

Beide in den Figuren 1 und 2 dargestellten Ausführungsformen zeichnen sich

durch eine indirekte Übertragung der Auftragssubstanz auf die Materialbahn aus,

da die Auftragssubstanz zunächst von der Auftragsrolle 8 auf die Hauptwalze 6

übertragen wird und in einem zweiten Schritt von der Hauptwalze 6 auf die

Materialbahn.Both embodiments shown in Figures 1 and 2 stand out

through an indirect transfer of the order substance to the material web,

since the order substance first of all from the

Der grundsätzliche Aufbau der Auftragsmaschine kann Figur 3 entnommen

werden, wo ersichtlich ist, daß die Auftragsmaschine eine platzsparende

Anordnung besitzt. Die Hauptwalze 6 ist an einem Maschinengerüst 16 offen

gelagert. Aus Gründen der Übersichtlichkeit sind die Anlegewalzen 1, 3 sowie die

Anpressrolle 2 nicht gezeigt. Diese werden je nach Ausführungsform oberhalb der

Hauptwalze 6 angeordnet. Innerhalb der Hauptwalze sind die Magnetsysteme 7, 5

angeordnet.The basic structure of the application machine can be seen in FIG. 3

where it can be seen that the application machine is a space-saving

Arrangement. The

Unterhalb der Hauptwalze 6 befindet sich die Auftragswanne 10, in welcher die

Auftragsrolle 8 (nicht gezeigt) angeordnet ist. Mittels der Verstelleinrichtung 11

kann die Auftragswanne 10 in vertikaler Richtung 18 verstellt werden. Mittels der

Wannenverstellung 17 kann die Auftragswanne 10 zusammen mit der

Auftragsrolle 8 seitlich in Pfeilrichtung 19 aus dem Maschinengestell 16

herausgezogen und eingeführt werden. Dieses seitliche Herausziehen der

Auftragswanne 10 bzw. Auftragsrolle 8 hat ferner noch den Vorteil, daß eine

Stufenanordnung von mehreren Maschinen möglich ist. Durch die Möglichkeit der

seitlichen Wannenmanipulation kann eine treppenförmige Bauweise mehrerer

Auftragsmaschinen erfolgen.Below the

Durch die Verstellmöglichkeiten von Auftragswanne 10 und Auftragsrolle 8 in

vertikaler Richtung 18 und horizontaler Richtung 19 ergibt sich trotz kompakter

Bauweise der Auftragsmaschine eine gute Zugänglichkeit für Wartungs- und

Reparaturarbeiten. Due to the adjustment options of

In den Figuren 4 und 5 ist die Möglichkeit dargestellt, an beiden Seiten der

Auftragsrolle 8 eine Randabstreifrakel 20 anzuordnen, welche an der Auftragsrolle

8 anliegt und die auf die Hauptwalze aufzutragenden Substanz 15 seitlich an den

Rändern der Auftragsrolle 8 abstreift. Die Bereiche 21 an den Rändern der

Auftragsrolle 8 bleiben demnach frei von Auftragssubstanz 16, so daß dort auch

keine Auftragssubstanz 15 auf die Hauptwalze 6 aufgebracht wird.

Die Randabstreifrakeln 20 sind parallel zur Längserstreckung der Auftragsrolle 8

verschiebbar, wie es mit den Doppelpfeilen 23 in Figur 5 angedeutet ist. Dadurch

ist die Breite des wirksamen Bereichs 21 der Randabstreifrakeln 20 auf der

Auftragsrolle 8 einstellbar. Die Hauptwalze 6 wird nur in dem gewünschten und

einfach einstellbaren Bereich 22 mit der Auftragssubstanz 15 benetzt, so daß die

Materialbahn 4 ebenfalls nur im gewünschten, eingestellten Bereich 22 mit der

Auftragssubstanz beschichtet wird.FIGS. 4 and 5 show the possibility of arranging an

The

Die Randabstreifrakeln 20 bestimmen also die Breite des mit der

Auftragssubstanz 15 beschichteten Bereiches 22 der Materialbahn, wobei die

Ränder der Materialbahn 4 z.B. in einem Bereich von 50 mm von der

Auftragssubstanz 15 freigehalten werden können.The edge wipers 20 thus determine the width of the

Figur 6 zeigt, daß die Hauptwalze 6 mittels Außenringlagern 24 offen am

Maschinengerüst 16 gelagert ist. Diese Außenlagerung bietet gegenüber dem

Stand der Technik den Vorteil der besseren Kühlung des im Inneren der

Hauptwalze 6 angeordneten Magnetsystems 7, da durch die offene Lagerung eine

freie Luftzirkulation innerhalb der Hauptwalze 6 möglich ist. Die Hauptwalze 6 wird

im gezeigten Beispiel von einem Antrieb 25 über einen Zahnriemen angetrieben. Figure 6 shows that the

- 11

- AnlegewalzeContact roller

- 22nd

- AnpressrollePressure roller

- 33rd

- AnlegewalzeContact roller

- 44th

- MaterialbahnMaterial web

- 55

-

Magnetsystem 2

Magnet system 2 - 66

- HauptwalzeMain roller

- 77

-

Magnetsystem 1

Magnet system 1 - 88th

- AuftragsrolleJob role

- 99

- ZuführungFeed

- 1010th

- AuftragswanneOrder tray

- 1111

- Verstelleinrichtung (Wanne)Adjustment device (tub)

- 1212th

- Überlauf/RücklaufOverflow / return

- 1313

- Anschlagattack

- 1414

- KontaktstreckeContact distance

- 1515

- AuftragssubstanzOrder substance

- 1616

- MaschinengerüstMachine frame

- 1717th

- WannenverstellungTub adjustment

- 1818th

- PfeilrichtungArrow direction

- 1919th

- PfeilrichtungArrow direction

- 2020th

- RandabstreifrakelEdge scraper

- 2121

- BereichArea

- 2222

- BereichArea

- 2323

- PfeilrichtungArrow direction

- 2424th

- AußenringlagerOuter ring bearing

- 2525th

- Antriebdrive

Claims (14)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20010388U | 2000-06-09 | ||

| DE20010388U DE20010388U1 (en) | 2000-06-09 | 2000-06-09 | Device for applying substances to sheet material |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP1162003A2 true EP1162003A2 (en) | 2001-12-12 |

| EP1162003A3 EP1162003A3 (en) | 2003-01-02 |

| EP1162003B1 EP1162003B1 (en) | 2004-04-28 |

| EP1162003B2 EP1162003B2 (en) | 2009-08-26 |

Family

ID=7942707

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01107006A Expired - Lifetime EP1162003B2 (en) | 2000-06-09 | 2001-03-21 | Device for applying substances to a web of material |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1162003B2 (en) |

| AT (1) | ATE265276T1 (en) |

| DE (2) | DE20010388U1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005105900A1 (en) * | 2004-04-28 | 2005-11-10 | Se Tylose Gmbh & Co. Kg | Method and device for grinding cellulose |

| EP1614483A2 (en) * | 2004-07-05 | 2006-01-11 | Jakob Weiss & Sohne Maschinenfabrik Gmbh | Doctoring means and method |

| WO2010009778A1 (en) * | 2008-07-24 | 2010-01-28 | Khs Ag | Applicator device |

| ITFI20120137A1 (en) * | 2012-06-29 | 2013-12-30 | Perini Fabio Spa | "DEVICE FOR THE APPLICATION OF A LIQUID SUBSTANCE ON A MATTRESS AND RELATED MATERIAL" |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004032568B4 (en) * | 2004-07-05 | 2007-09-20 | Jakob Weiß & Söhne Maschinenfabrik GmbH | Doctor blade and doctor blade method |

| DE102004039732A1 (en) * | 2004-08-17 | 2006-02-23 | Man Roland Druckmaschinen Ag | Color film coating device for use in printing unit of rotary printing press, has roll coater whose supply and differential speed between backing roller and coater are controlled based on magnetic field strength of magnet within roller |

| DE102005062528A1 (en) * | 2005-12-16 | 2007-06-21 | Gebr. Schmid Gmbh & Co. | Substrate e.g. silicon wafer, surface treatment e.g. layer removal, device, has conveyor arranged beneath transport level so that substrate contacts level to moisten surface with process medium in direct contact between conveyor and surface |

| DE102005062527A1 (en) | 2005-12-16 | 2007-06-21 | Gebr. Schmid Gmbh & Co. | Substrate surface treatment device for production of solar cell, has suction unit provided for suction of fluid process medium from environment of conveying unit and arranged under transport plane in vertical direction |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0901839A2 (en) | 1997-09-11 | 1999-03-17 | Johannes Zimmer | Device for applying fluids onto a substrate |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1472709A (en) * | 1975-03-10 | 1977-05-04 | Wiggins Teape Ltd | Coating apparatus |

| DE2554318C3 (en) * | 1975-12-03 | 1981-11-26 | Agfa-Gevaert Ag, 5090 Leverkusen | Method and device for coating magnetic tapes with the aid of the halftone printing process |

| AT374379B (en) † | 1982-03-29 | 1984-04-10 | Zimmer Johannes | DEVICE FOR THE EVEN APPLICATION OF DETERMINABLE LIQUID AMOUNTS |

| AT378151B (en) * | 1983-10-07 | 1985-06-25 | Johannes Zimmer | PRINTING AND APPLICATION MACHINE FOR FLOWABLE MEDIA ON RAILWAYS |

| AT386761B (en) † | 1986-04-30 | 1988-10-10 | Zimmer Johannes | DEVICE FOR APPLYING LOW OR LOWEST AMOUNTS OF FLOWABLE SUBSTANCES |

| AT386968B (en) * | 1986-12-05 | 1988-11-10 | Zimmer Johannes | DEVICE FOR APPLYING DETERMINABLE QUANTITIES OF FLOWABLE MEDIA |

| JP2614119B2 (en) * | 1989-10-16 | 1997-05-28 | 富士写真フイルム株式会社 | Coating device and method |

| DE4013464C2 (en) * | 1990-04-27 | 1995-01-05 | Heidelberger Druckmasch Ag | Rubberizing the printing form of a printing press |

| DE4014463A1 (en) * | 1990-05-07 | 1991-11-14 | Jagenberg Ag | DEVICE FOR COATING A MATERIAL SHEET, IN PARTICULAR A PAPER OR CARDBOARD SHEET |

| DE19549254A1 (en) * | 1994-12-27 | 1996-07-04 | Johannes Zimmer | Fluid application system for moving webs |

| ATE210223T1 (en) * | 1995-07-29 | 2001-12-15 | Jagenberg Papiertech Gmbh | APPLICATION SYSTEM FOR A DEVICE FOR COATING A PAPER OR CARDBOARD WEB |

-

2000

- 2000-06-09 DE DE20010388U patent/DE20010388U1/en not_active Expired - Lifetime

-

2001

- 2001-03-21 EP EP01107006A patent/EP1162003B2/en not_active Expired - Lifetime

- 2001-03-21 AT AT01107006T patent/ATE265276T1/en not_active IP Right Cessation

- 2001-03-21 DE DE50102100T patent/DE50102100D1/en not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0901839A2 (en) | 1997-09-11 | 1999-03-17 | Johannes Zimmer | Device for applying fluids onto a substrate |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005105900A1 (en) * | 2004-04-28 | 2005-11-10 | Se Tylose Gmbh & Co. Kg | Method and device for grinding cellulose |

| US7578458B2 (en) | 2004-04-28 | 2009-08-25 | Se Tylose Gmbh & Co., Kg | Method and device for grinding cellulose |

| EP1614483A2 (en) * | 2004-07-05 | 2006-01-11 | Jakob Weiss & Sohne Maschinenfabrik Gmbh | Doctoring means and method |

| EP1614483A3 (en) * | 2004-07-05 | 2006-11-15 | Jakob Weiss & Sohne Maschinenfabrik Gmbh | Doctoring means and method |

| WO2010009778A1 (en) * | 2008-07-24 | 2010-01-28 | Khs Ag | Applicator device |

| ITFI20120137A1 (en) * | 2012-06-29 | 2013-12-30 | Perini Fabio Spa | "DEVICE FOR THE APPLICATION OF A LIQUID SUBSTANCE ON A MATTRESS AND RELATED MATERIAL" |

Also Published As

| Publication number | Publication date |

|---|---|

| DE50102100D1 (en) | 2004-06-03 |

| ATE265276T1 (en) | 2004-05-15 |

| EP1162003B1 (en) | 2004-04-28 |

| DE20010388U1 (en) | 2001-10-11 |

| EP1162003B2 (en) | 2009-08-26 |

| EP1162003A3 (en) | 2003-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2935413C2 (en) | Device for the continuous treatment of a textile or similar material web with a treatment medium in foam form | |

| DE69114042T2 (en) | Process for limiting the width of the coating when coating paper or cardboard and device for carrying out this process. | |

| CH626000A5 (en) | ||

| DE69401751T2 (en) | DEVICE AND METHOD FOR APPLYING ADHESIVE ON A WINDING CORE FOR RAILWAY MATERIAL | |

| DE4446308C2 (en) | Device for applying a liquid or pasty medium to a running web of material | |

| DE102006012972B4 (en) | Device for controlling the lateral offset of webs of material | |

| EP0408704B2 (en) | Arrangement for applying substances to a web of material | |

| EP1162003B1 (en) | Device for applying substances to a web of material | |

| DE3010038A1 (en) | DEVICE FOR CONTINUOUSLY TREATING TEXTILES AND THE LIKE RAILWAYS WITH FOAM | |

| DD149167A5 (en) | DEVICE FOR APPLYING FOAM TO A RUNNING TRACK | |

| EP0108887B1 (en) | Coating apparatus | |

| DE3928439C2 (en) | Deflection adjustment roller | |

| EP1043119A2 (en) | Method and apparatus for external grinding of thin-walled tube | |

| DE3419590C2 (en) | ||

| DE19827712B4 (en) | Device for direct or indirect application of a liquid or pasty application medium to a moving material web | |

| AT394665B (en) | MULTIPURPOSE MACHINING DEVICE | |

| EP0047484B1 (en) | Padder | |

| DE29716541U1 (en) | Device for applying liquids to a substrate | |

| DE3618935C2 (en) | ||

| DE4440948A1 (en) | Wet paper web feed into paper-making drying section | |

| EP0757129A1 (en) | Application system for a device for coating a paper or paperboard sheet | |

| DE69018135T2 (en) | Moistening device for tape-like material, in particular paper. | |

| DE19604934A1 (en) | Application system for a device for coating a paper or cardboard web | |

| DE69101808T2 (en) | Adhesive application device for continuous webs of goods in an apparatus for producing paper products. | |

| DE19960772A1 (en) | Indirect application method for liquid/paste material to paper/cardboard has application edge defined by application of water to roller edge sections |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7B 05C 1/08 A, 7B 05C 1/12 B |

|

| 17P | Request for examination filed |

Effective date: 20030328 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040428 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040428 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040428 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50102100 Country of ref document: DE Date of ref document: 20040603 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040728 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040808 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: LUCHS & PARTNER PATENTANWAELTE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040811 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLAR | Examination of admissibility of opposition: information related to receipt of reply deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE4 |

|

| PLAZ | Examination of admissibility of opposition: despatch of communication + time limit |

Free format text: ORIGINAL CODE: EPIDOSNOPE2 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20050302 Year of fee payment: 5 |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLAR | Examination of admissibility of opposition: information related to receipt of reply deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE4 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050321 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050321 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050321 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050324 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20050330 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLAR | Examination of admissibility of opposition: information related to receipt of reply deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE4 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| 26 | Opposition filed |

Opponent name: J. ZIMMER MASCHINENBAU GES. M.B.H. Effective date: 20050128 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| R26 | Opposition filed (corrected) |

Opponent name: J. ZIMMER MASCHINENBAU GES. M.B.H. Effective date: 20050128 |

|

| R26 | Opposition filed (corrected) |

Opponent name: J. ZIMMER MASCHINENBAU GES. M.B.H. Effective date: 20050128 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: J. ZIMMER MASCHINENBAU GES. M.B.H. |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20050610 Year of fee payment: 5 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: J. ZIMMER MASCHINENBAU GES. M.B.H. |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: J. ZIMMER MASCHINENBAU GES. M.B.H. |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060322 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20060328 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20061130 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20070321 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20071001 |

|

| BERE | Be: lapsed |

Owner name: *TIMATEC MASCHINEN UND ANLAGENBAU G.M.B.H. Effective date: 20060331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071001 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070321 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20080303 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080214 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20060220 Year of fee payment: 6 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20090826 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20050322 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090321 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091001 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080326 Year of fee payment: 8 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20091201 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20091201 |