EP1155643A2 - Supporting device - Google Patents

Supporting device Download PDFInfo

- Publication number

- EP1155643A2 EP1155643A2 EP01111560A EP01111560A EP1155643A2 EP 1155643 A2 EP1155643 A2 EP 1155643A2 EP 01111560 A EP01111560 A EP 01111560A EP 01111560 A EP01111560 A EP 01111560A EP 1155643 A2 EP1155643 A2 EP 1155643A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- elements

- spring

- adjustment

- adjusting

- support device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C23/00—Spring mattresses with rigid frame or forming part of the bedstead, e.g. box springs; Divan bases; Slatted bed bases

- A47C23/002—Spring mattresses with rigid frame or forming part of the bedstead, e.g. box springs; Divan bases; Slatted bed bases with separate resilient support elements, e.g. elastomeric springs arranged in a two-dimensional matrix pattern

Definitions

- the present invention relates to a support device, in particular Mattress, cushion element or spring base therefor, with several at least provided in a region of the support device Single support elements that have an almost punctual resolution of the Cause support surface in terms of their spring property, and several, at least part of the individual support elements, optionally activatable adjustment elements for adjusting the spring properties, in particular the spring hardness and / or the spring travel of the individual support elements.

- Such individual support elements are used for spring mattresses and upholstered furniture known for a long time. But also with spring frames for mattresses have been such individual support elements instead of the conventional for some time Slats used. Especially in the shoulder and pelvic area can be immersed deeper through the selective support and so that an improvement in lying comfort can be achieved.

- spring frames also have individual support elements an adjustment option for individual adjustment the spring properties desirable.

- the individual support elements Interchangeable design, so that for example a softer single support element can be exchanged for a harder one can and vice versa.

- individual support elements to provide elements with an open form that are inserted into this form can and thus the spring travel or the spring hardness of the individual support element change.

- clip-in clamping devices there are also individual support elements known with clip-in clamping devices.

- the invention has for its object the adjustment of To improve support devices of the type mentioned. In particular, should individual adaptation can be facilitated.

- the Handling simplified. Two or more adjustment elements can be used be activated together, for example by the individual support elements in a certain area of the support surface, the uniform requirements subject to be adjusted together. This eliminates one Individual setting to the same values among each other and it is guaranteed that in such an area they are actually always the same Values can be set.

- the adjustment elements can be used in support devices Single support elements, which are arranged in columns and rows, or columns can be activated together line by line. This will be an adjustment option created that like conventional slatted frames on one Line acts across the entire width of the support surface.

- the adjustment function is not only easier for the user to carry out, but also from the effect also easier to grasp, since it is based on previous experience matches with slatted frames.

- Activation device can be activated together. This allows advantageously entire areas of the support surface individually at the same time be adjusted. For example, the shoulder and / or the Pelvic area with two or more rows of individual support elements be individually adjustable together.

- the adjustment elements can be permanently installed in the support device and can be activated quickly and easily. But you can too be designed to be activated for activation only in the support device. This makes it possible, for example, to create the adjustment elements can be used at various locations on the support surface bring to.

- the spring travel and / or spring hardness can be configured be gradually adjustable according to the invention. With just two steps created an effective and easy-to-use adjustment option become.

- the spring travel and / or spring hardness continuously adjustable over at least one area. This creates a particularly high variability in spring properties created. Nevertheless, the adjustment device remains due to the common adjustability of the individual support elements easy to handle.

- One way to change the spring properties is the adjusting elements for adjusting the spring hardness and / or the spring travel as an adjustment body that can be attached to the individual support elements from the outside to train.

- These adjustment bodies are both for individual support elements with open form as well as with single support elements with closed Form can be used.

- the adjustment body can be elastic or rigid be trained. With elastic training change the created Adjustment body the spring hardness and thus the spring characteristic. With rigid Training can additionally or alternatively the spring travel of the individual support elements to be changed.

- the adjustment elements can also be used as open Form of the individual support elements insertable adjustment body.

- the adjustment bodies can be elastic or rigid his. With an elastic configuration, the spring hardness changes again and thus the spring characteristic of the individual support elements. With rigid Training changes the travel, the individual support elements can also be blocked completely or partially.

- the adjusting elements can each be designed to be displaceable his.

- the adjustment elements in line or Column direction or perpendicular to that spanned by these two directions Level, so perpendicular to the support surface, adjustable his.

- Another possibility is to twist the adjustment elements, in particular about an axis perpendicular to the supporting surface, or by Pivoting, in particular about an axis lying in the support surface, to activate.

- Another possibility is to adjust the adjustment elements by increasing the volume to activate.

- the adjustment elements are activated in particular mechanically. she can also be done electrically, hydraulically or pneumatically. At The adjustment elements that can be activated together become mechanical adjustment connected by rods, shafts or similar means. With hydraulically or pneumatically activated adjustment elements the jointly activatable adjusting elements are preferably hydraulic or connected pneumatically.

- the adjustment elements can in particular be reinforced by material act at least a part of the individual support elements. For example elastic elements are placed on the spring legs of the individual support elements, which are then deformed together with the respective spring leg.

- the adjustment elements can also be blocked by blocking at least one Part of the individual support elements act. In particular, with multi-stage Spring elements are blocked individual stages. So one can three-stage spring characteristic in a two-stage or a two-stage in one single-stage spring characteristic can be adjusted.

- a single-stage spring characteristic can also be activated the adjustment elements changed into a two-stage or multi-stage spring characteristic become.

- an annular spring element second annular spring element of lower height are used and thereby forming a second stage.

- the activated adjustment elements can also only start from a certain one Spring travel come into effect. So with single support elements with several annular spring elements arranged side by side individual annular spring elements depending on the Activation of the adjustment elements after a longer or shorter first Actuate travel.

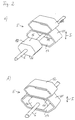

- Fig. 1 shows an embodiment of the invention designed as a spring base for a mattress Support device with a frame 1, the leg 2 comprise a lying surface 3, over which a plurality of elastic Individual support elements 4 is arranged distributed.

- a point-elastic support is realized, especially in a lateral position a particularly deep immersion of the shoulder and pelvis enables, while a normal immersion is given in reserve.

- the individual support elements 4 are arranged in rows and columns the rows parallel to the short legs 2 of the frame 1 and the Columns run perpendicular to this.

- the individual support elements 4 include an annular spring body which, for example, on a base a cross bar, which is supported and carries a flat support plate which the mattress rests on.

- the ring planes of the spring bodies 5 of the individual support elements 4 each extend perpendicular to the alignment of the rows. That way you can the spring body penetrated by a common adjusting rod 6 be in the transverse direction, i.e. parallel to the short sides 2 of the Frame 1 is stored. In fact, however, are only in the shoulder area here 7 and in the pool area 8 such adjustment rods 6 are arranged, while the remaining areas 9 have no such adjustment rods. In principle, however, they can also be provided there.

- the adjustment rods 6 carry adjustment elements 10 and are in their longitudinal direction between a first position and a second position slidably guided.

- the adjustment elements 10 In the first position of the adjusting rods 6 shown in FIG. 1 the adjustment elements 10, each of which is a single support element 4 is assigned, laterally next to the associated annular Spring body 5 and have no influence on this.

- the adjustment elements 10 In the second Position which is achieved by longitudinally displacing the adjusting rod 6, are the adjustment elements 10 within the annular spring body 5 and thereby influence its spring properties.

- the adjustment elements 10 can be designed as an elastic ring be, which rests on the inside of the annular spring body 5 and its This increases spring hardness.

- the displacement mechanism for the adjusting rods 6 can basically can be realized arbitrarily.

- the adjustment rods 6 of an area, for example the shoulder area 7 and / or the pelvic area 8 be coupled so that they are automatically adjustable together.

- a whole area 7, 8 can thus be individually customized in a simple manner Spring properties can be adapted to the needs.

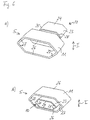

- Fig. 2 shows an embodiment of a solid adjustment body Adjustment element 10 in a single support element 4 with a Spring body 5, each of the two arranged one above the other the shape of an elongated hexagon rings 11, 12.

- the Adjustment element 10 also has the shape of an elongated hexagon on and is arranged on an adjusting rod 6, which is perpendicular extends to the ring plane of the lower ring 11 therethrough.

- the adjusting rod 6 carries further adjusting elements, not shown here 10, the number of which in particular the number of individual support elements 4 one Row of individual support elements arranged next to one another in a frame 1 4 corresponds.

- the adjustment rod 6 is in the first position shown in FIG. 2a the adjusting element 10 outside the lower ring 11. The same applies to the other adjusting elements of the adjusting rod, not shown here 6 in relation to the individual support elements 4 assigned to them.

- 2b shows the second position of the adjusting rod 6, in which the adjusting element is 10 is located within the lower ring 11. As you can see, is the adjusting element 10 on the lower longitudinal side 13 and the upper Long side 14 of the lower ring 11.

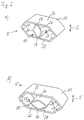

- Fig. 3 shows a variant of the adjusting elements 10, which also with individual support elements 4 can be used with a spring body, which two superimposed, the shape of an elongated hexagon having rings 11, 12 comprises.

- the adjusting element 10 is also here massive adjustment body designed and with a corresponding number further adjustment elements, not shown here, on an adjustment rod 6 arranged.

- the adjustment rod 6 is not in its longitudinal direction displaceable, but rotatably mounted about its longitudinal axis, and the adjusting elements 10 are always within the lower ring 11.

- the adjusting element In the first rotational position of the adjusting rod 6 shown in FIG. 3a is the adjusting element, which is designed as a flat, approximately cuboid body 10 with its two narrow sides 17 on the lower long side 13 and the upper longitudinal side 14 of the lower ring 11 from the inside on. With a rigid design of the adjusting element 10, the lower ring 11 blocked, so that the spring properties of the spring body 5 can only be determined by the upper ring 12. In addition, the travel is shortened accordingly. With an elastic configuration of the adjusting element 10, the adjusting element 10 determines the spring properties of the Spring body 5 in addition to the rings 11 and 12 with. The maximum Travel is only slightly shortened.

- the adjusting element 10 In the second rotational position of the adjusting rod 6 shown in FIG. 3b the adjusting element 10 is not on the lower ring 11, but the Broad sides 18 of the adjusting element 10 now lie on the long sides 13 and 14 of the ring 11 at a distance from each other.

- the lower ring 11 is therefore not blocked or the adjusting element 10 has no influence on the Spring hardness. This is therefore only determined by the two rings 11 and 12.

- the maximum travel is essentially determined by the adjustment rod 6 determines which the compression of the lower ring 11 at Applying a force in the direction of arrow I limited. Via the adjustment rod 6 can also the spring body 5 of the individual support elements 4th a whole series can be adjusted together.

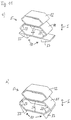

- Fig. 4 shows a spring body 5 of a single support element 4 with three side by side arranged, the shape of an elongated hexagon having rings 19, the ring planes of which run parallel to one another and which are integrally connected to one another with their upper longitudinal sides 20 are.

- the two outer rings 19 are each on a support surface 21 supported, while the middle ring 19 shown in Fig. 4a Situation is unsupported.

- the middle ring 19 is also assigned a support surface 22 which is spaced from the central ring 19 and therefore only after a first spring travel to effect is coming.

- the support surface assigned to the middle ring 19 is now 22 between the first position shown in Fig. 4a and in Fig. 4b shown second position adjustable, the adjustment at least together with at least one further support surface of this type another spring body of an individual support element 4, however, this is not shown in FIG. 4.

- the support surface 22 is spaced as described to the middle ring 19.

- the support surface 22 is already without a first spring travel on the middle ring 19 so that the spring hardness of the spring body 5 determined in this position from the start by all three rings 19 becomes.

- the support surface 22 can between one single-stage and a two-stage spring characteristic of the spring body selected become.

- the ratio of the first spring travel can be varied for the second travel.

- the common adjustment of the spring body 5 of several individual support elements 4 can basically be done in any way.

- the support surfaces 22 connected to each other via an adjusting rod be between a first position in which the support surfaces 22 are spaced from the associated middle rings 19, and one second position, in which they rest against it, guided is.

- the support surfaces 22 can also simply be in one piece with one another be formed when the spring body 5 is arranged in a row accordingly are.

- FIG. 5 Another variant of an adjusting element 10 for use with a Spring body 5, which has the shape of an elongated, hexagonal Has ring 11 is shown in Fig. 5.

- the adjusting element 10 has here also the shape of an elongated, hexagonal ring 23 and is designed so that the adjusting element 10 is inserted into the ring 11 and the long sides 24 and the narrow sides 25 of the hexagonal ring 23 from the inside on the corresponding sides 26, 27 of the ring 11 abut.

- Fig. 5b This inserted position of the adjusting element 10 is shown in Fig. 5b, 5a shows the extended position of the adjusting element 10 shows.

- the spring hardness of the Spring body 5 together through the ring 11 and the adjusting element 10 determined, while in the extended position of Fig. 5a alone Ring 11 sets the spring hardness.

- the travel is practical in both cases equal.

- the common adjustment of the rings 23 of several spring bodies 5 can again be done in any way, for example via an adjusting rod connecting the adjusting elements 10.

- the variant of an adjusting element 10 shown in FIG. 6 is similar the variant shown in Fig. 5.

- the ring 23 of the adjusting element 10 is smaller than the free opening cross section of the ring 11 of the spring body 5, that is in the retracted position does not abut on all sides of the ring 11 from the inside. Rather lies only the lower long side 24 of the ring 23 on the lower long side 26 of the ring 11.

- the adjusting element is in the retracted position 10 created a two-stage spring characteristic.

- the adjusting element 10 only takes effect after a first spring travel and determines the spring hardness of the Spring body 5 with.

- In the extended position of the adjustment element 10, on the other hand is a single-stage spring characteristic.

- the adjustment of the Adjustment element 10 also takes place here in principle in any way Way together with further adjusting elements 10.

- the variant of the adjusting element 10 shown in FIG. 7 can also between a single-stage and a two-stage spring characteristic to get voted.

- the adjusting element 10 is here as a diamond-shaped ring 28 formed within the ring 11 forming the spring body 5 about an axis perpendicular to its ring surface rotatably arranged in the ring 11 is.

- the ring 28 In the first position of the adjusting element shown in FIG. 7a 10 is the ring 28 with the lying on its major axis flattened tips 29 from the inside on the two long sides 26 of the ring 11 on and therefore determines the spring hardness during the entire spring travel of the spring body 4a.

- FIG. 8 shows an adjusting element 10 in the form of an octagonal disk 31, which is centered on a ring 11, which is also hexagonal here, of a spring body 5 through adjusting rod 6 is arranged.

- adjusting rod 6 By twisting the adjusting rod 6 changes the distance between the peripheral surface 32 of the disk 31 and the two long sides 26 of the ring 11.

- the travel of the ring 11 With a rigid disk 31, the travel of the ring 11 can be in three Levels can be adjusted.

- elastic disc 31 in which case the Washer 31, the spring hardness of the spring body 5 after covering a first Co-travel determines the length of the first travel can be adjusted in three stages.

- the adjustment rod 6 carries here again several washers 31 around at least two spring bodies 5 to adjust together.

- Fig. 9 shows an adjusting element 10, which from the outside to a spring body 5 can be created.

- the spring body again in the form of an elongated, hexagonal ring 11.

- the adjusting element 10 is modeled on the lower half of the ring 11 and arranged approximately at their height.

- By moving perpendicular to The plane of the ring 11 can be the adjusting element 10 from the in Fig. 9a shown first position in the second position shown in Fig. 9b to be brought.

- the adjusting element 10 could also be directly below of the ring 11 arranged and by moving in the ring plane perpendicular to the longitudinal sides 26 of the ring 11 in the engaged position are brought from Fig. 9b.

- the adjustment element is in the first position 10 out of engagement with the ring 11 so that the spring hardness of Spring body 5 is determined solely by the ring 11.

- In the second Position of the adjusting element 10 lies on the ring 11 from below and therefore determines the spring hardness of the spring body 5. The travel is not influenced by the adjusting element 10.

- the adjusting element 10 is common here with at least one additional adjusting element in principle operated in any way.

- FIG. 10 shows an adjusting element 10, which is connected to the adjusting element 10 9 corresponds.

- the adjustment between that shown in Fig. 10a Engagement position with the spring body 5 and that shown in Fig. 10b Disengaged position takes place here by turning the Adjusting element 10 about an axis extending in spring direction I.

- the adjustment is again carried out together in a fundamentally arbitrary manner with at least one additional adjustment element.

- Adjustment element 10 formed in two parts. And that exists Adjustment element 10 from two wedges 33, which between the one shown in Fig. 11a Disengaged position and the engagement position shown in Fig. 11b are pivotable. The wedges 33 are in the engaged position on the two lower narrow sides 27 of the ring 11 and determine thereby the spring properties of the spring body 5 with.

- Fig. 12 finally shows a variant in which an elastic on the Spring body 5 biased adjustment element 10 is provided.

- the spring body 5 has the shape of a elongated hexagonal ring 11, against its lower narrow sides 27 the adjusting element 10 is biased with two corresponding sides 34 is.

- these sides 34 of the adjusting element 10 against the biasing force of the narrow sides 27 of the ring 11 are moved away and kept away.

- the spring hardness of the spring body 5 determined solely by the ring 11.

- engagement position of the adjusting element 10 is the spring hardness on the other hand additionally determined by the prestressed adjusting element 10. The adjustment is again made in any way Way together with at least one other adjusting element.

- the jointly adjustable adjusting elements 10 can easily adjust the spring hardness of Single support elements 4 are made.

- the formation of the adjustment elements 10 is basically arbitrary.

- the variants shown and embodiments can also fundamentally with one another can be combined as desired.

- the adjustment elements 10 are adjusted mechanically in particular. But it can also be electro-motorized, hydraulic or pneumatic respectively. The adjustment can in all cases depend on the spring hardness and / or get the travel. In addition, the level of the spring characteristic to be changed.

- the adjustment elements 10 are either for this rigid or elastic. You can, as can the spring body 5 consist in particular of metal or plastic, or also Wood. Basically, a height adjustment of the spring body 4a possible via the adjusting elements 10 according to the invention.

- the invention can be applied in particular, as shown in FIG. 1, for slat bases for mattresses, but also in mattresses themselves or in upholstery elements as well as in the seat or the back of seating furniture.

- the jointly adjustable individual support elements 4 is only provided in certain areas of the support surface. It can provide only a part of the support surface with individual support elements 4 be, in particular the shoulder and / or pelvic area of a lying surface, while other support means such as slats are arranged are.

Landscapes

- Springs (AREA)

- Mattresses And Other Support Structures For Chairs And Beds (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

- Physical Deposition Of Substances That Are Components Of Semiconductor Devices (AREA)

- Seal Device For Vehicle (AREA)

- Diaphragms For Electromechanical Transducers (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft eine Stützvorrichtung, insbesondere Matratze, Polsterelement oder Unterfederung hierfür, mit mehreren mindestens in einem Bereich der Stützvorrichtung vorgesehenen elastischen Einzelstützelementen, die eine annähernd punktuelle Auflösung der Stützfläche hinsichtlich ihrer Federeigenschaft bewirken, und mehreren, mindestens einem Teil der Einzelstützelemente zugeordneten, wahlweise aktivierbaren Verstellelementen zur Verstellung der Federeigenschaften, insbesondere der Federhärte und/oder des Federweges der Einzelstützelemente.The present invention relates to a support device, in particular Mattress, cushion element or spring base therefor, with several at least provided in a region of the support device Single support elements that have an almost punctual resolution of the Cause support surface in terms of their spring property, and several, at least part of the individual support elements, optionally activatable adjustment elements for adjusting the spring properties, in particular the spring hardness and / or the spring travel of the individual support elements.

Bei Federkernmatratzen und Polstermöbeln sind solche Einzelstützelemente seit langem bekannt. Aber auch bei Federrahmen für Matratzen werden seit einiger Zeit derartige Einzelstützelemente anstelle der herkömmlichen Latten eingesetzt. Insbesondere im Schulter- und Beckenbereich kann durch die punktuelle Abstützung ein tieferes Eintauchen und damit eine Verbesserung des Liegekomforts erreicht werden.Such individual support elements are used for spring mattresses and upholstered furniture known for a long time. But also with spring frames for mattresses have been such individual support elements instead of the conventional for some time Slats used. Especially in the shoulder and pelvic area can be immersed deeper through the selective support and so that an improvement in lying comfort can be achieved.

Wie bei herkömmlichen Lattenrosten ist auch bei Federrahmen mit Einzelstützelementen eine Einstellmöglichkeit zur individuellen Anpassung der Federeigenschaften wünschenswert. Hierfür ist es bekannt, die Einzelstützelemente austauschbar auszugestalten, so daß beispielsweise ein weicheres Einzelstützelement gegen ein härteres ausgetauscht werden kann und umgekehrt. Außerdem ist es bekannt, bei Einzelstützelementen mit offener Form Elemente vorzusehen, die in diese Form eingefügt werden können und die dadurch den Federweg oder die Federhärte des Einzelstützelementes verändern. Schließlich sind auch Einzelstützelemente mit einklipsbaren Spannvorrichtungen bekannt.As with conventional slatted frames, spring frames also have individual support elements an adjustment option for individual adjustment the spring properties desirable. For this, it is known the individual support elements Interchangeable design, so that for example a softer single support element can be exchanged for a harder one can and vice versa. It is also known for individual support elements to provide elements with an open form that are inserted into this form can and thus the spring travel or the spring hardness of the individual support element change. Finally, there are also individual support elements known with clip-in clamping devices.

Der Erfindung liegt die Aufgabe zugrunde, die Einstellmöglichkeit von Stützvorrichtungen der genannten Art zu verbessern. Insbesondere soll die individuelle Anpassung erleichtert werden.The invention has for its object the adjustment of To improve support devices of the type mentioned. In particular, should individual adaptation can be facilitated.

Diese Aufgabe wird dadurch gelöst, daß die Verstellelemente zumindest teilweise gemeinsam aktivierbar sind.This object is achieved in that the adjusting elements at least partially activated together.

Durch die gemeinsame Aktivierbarkeit der Einzelstützelemente wird die Handhabung vereinfacht. Dabei können zwei oder mehr Verstellelemente gemeinsam aktivierbar sein, beispielsweise indem die Einzelstützelemente in einem bestimmten Bereich der Stützfläche, die einheitlichen Anforderungen unterliegen, gemeinsam verstellt werden. Dadurch entfällt eine Einzeleinstellung auf untereinander gleiche Werte und es wird gewährleistet, daß in solchen Bereich tatsächlich auch stets untereinander gleiche Werte eingestellt werden.Due to the fact that the individual support elements can be activated together, the Handling simplified. Two or more adjustment elements can be used be activated together, for example by the individual support elements in a certain area of the support surface, the uniform requirements subject to be adjusted together. This eliminates one Individual setting to the same values among each other and it is guaranteed that in such an area they are actually always the same Values can be set.

Beispielsweise können die Verstellelemente bei Stützvorrichtungen mit Einzelstützelementen, die in Spalten und Zeilen angeordnet sind, spalten-oder zeilenweise gemeinsam aktivierbar sein. Damit wird eine Verstellmöglichkeit geschaffen, die wie bei herkömmlichen Lattenrosten auf einer Linie über die gesamte Breite der Stützfläche wirkt. Die Verstellfunktion ist dadurch für den Nutzer nicht nur leichter durchführbar, sondern von der Wirkung her auch leichter erfaßbar, da sie mit der bisherigen Erfahrung bei Lattenrosten übereinstimmt.For example, the adjustment elements can be used in support devices Single support elements, which are arranged in columns and rows, or columns can be activated together line by line. This will be an adjustment option created that like conventional slatted frames on one Line acts across the entire width of the support surface. The adjustment function is not only easier for the user to carry out, but also from the effect also easier to grasp, since it is based on previous experience matches with slatted frames.

Es können jeweils auch mehrere Zeilen oder Spalten durch eine kombinierte Aktivierungsvorrichtung gemeinsam aktivierbar sein. Dadurch können vorteilhafterweise ganze Bereiche der Stützfläche gleichzeitig individuell angepaßt werden. Beispielsweise können der Schulter- und/oder der Beckenbereich mit jeweils zwei oder mehr Zeilen aus Einzelstützelementen gemeinsam individuell verstellbar sein.It is also possible to combine several rows or columns Activation device can be activated together. This allows advantageously entire areas of the support surface individually at the same time be adjusted. For example, the shoulder and / or the Pelvic area with two or more rows of individual support elements be individually adjustable together.

Die Verstellelemente können in der Stützvorrichtung fest installiert und dadurch schnell und problemlos aktivierbar sein. Sie können aber auch zur Aktivierung erst in die Stützvorrichtung einsetzbar ausgebildet sein. Damit kann beispielsweise die Möglichkeit geschaffen werden, die Verstellelemente wahlweise an verschiedenen Orten der Stützfläche zum Einsatz zu bringen.The adjustment elements can be permanently installed in the support device and can be activated quickly and easily. But you can too be designed to be activated for activation only in the support device. This makes it possible, for example, to create the adjustment elements can be used at various locations on the support surface bring to.

Die Federwege und/oder Federhärten können nach einer Ausgestaltung der Erfindung stufenweise einstellbar sein. Bereits mit zwei Stufen kann eine wirksame und einfach handhabbare Verstellmöglichkeit geschaffen werden.The spring travel and / or spring hardness can be configured be gradually adjustable according to the invention. With just two steps created an effective and easy-to-use adjustment option become.

Nach einer weiteren Ausgestaltung der Erfindung sind die Federwege und/oder Federhärten über mindestens einen Bereich kontinuierlich einstellbar. Dadurch wird eine besonders hohe Variabilität der Federeigenschaften geschaffen. Dennoch bleibt die Einstellvorrichtung aufgrund der gemeinsamen Verstellbarkeit der Einzelstützelemente gut handhabbar.According to a further embodiment of the invention, the spring travel and / or spring hardness continuously adjustable over at least one area. This creates a particularly high variability in spring properties created. Nevertheless, the adjustment device remains due to the common adjustability of the individual support elements easy to handle.

Eine Möglichkeit der Veränderung der Federeigenschaften besteht darin, die Verstellelemente zur Verstellung der Federhärte und/oder des Federweges als von außen an die Einzelstützelemente anlegbare Verstellkörper auszubilden. Diese Verstellkörper sind sowohl bei Einzelstützelementen mit offener Form als auch bei Einzelstützelementen mit geschlossener Form einsetzbar. Die Verstellkörper können dabei elastisch oder starr ausgebildet sein. Bei elastischer Ausbildung verändern die angelegten Verstellkörper die Federhärte und damit die Federkennlinie. Bei starrer Ausbildung kann zusätzlich oder alternativ der Federweg der Einzelstützelemente verändert werden.One way to change the spring properties is the adjusting elements for adjusting the spring hardness and / or the spring travel as an adjustment body that can be attached to the individual support elements from the outside to train. These adjustment bodies are both for individual support elements with open form as well as with single support elements with closed Form can be used. The adjustment body can be elastic or rigid be trained. With elastic training change the created Adjustment body the spring hardness and thus the spring characteristic. With rigid Training can additionally or alternatively the spring travel of the individual support elements to be changed.

Bei Einzelstützelementen mit mindestens abschnittsweise offener Form, insbesondere Ringform, können die Verstellelemente auch als in die offene Form der Einzelstützelemente einfügbare Verstellkörper ausgebildet sein. Auch in diesem Fall können die Verstellkörper elastisch oder starr ausgebildet sein. Bei elastischer Ausgestaltung verändert sich wieder die Federhärte und damit die Federkennlinie der Einzelstützelemente. Bei starrer Ausbildung verändert sich der Federweg, wobei die Einzelstützelemente auch vollständig oder teilweise blockiert werden können.In the case of individual support elements with an open shape at least in sections, especially ring shape, the adjustment elements can also be used as open Form of the individual support elements insertable adjustment body. In this case too, the adjustment bodies can be elastic or rigid his. With an elastic configuration, the spring hardness changes again and thus the spring characteristic of the individual support elements. With rigid Training changes the travel, the individual support elements can also be blocked completely or partially.

Zur Aktivierung können die Verstellelemente jeweils verschiebbar ausgebildet sein. Beispielsweise können die Verstellelemente in Zeilen- oder Spaltenrichtung oder senkrecht zu der von diesen beiden Richtungen aufgespannten Ebene, also senkrecht zur Stützfläche, verstellbar ausgebildet sein.For activation, the adjusting elements can each be designed to be displaceable his. For example, the adjustment elements in line or Column direction or perpendicular to that spanned by these two directions Level, so perpendicular to the support surface, adjustable his.

Eine andere Möglichkeit besteht darin, die Verstellelemente durch Verdrehen, insbesondere um eine zur Stützfläche senkrechte Achse, oder durch Verschwenken, insbesondere um eine in der Stützfläche liegende Achse, zu aktivieren.Another possibility is to twist the adjustment elements, in particular about an axis perpendicular to the supporting surface, or by Pivoting, in particular about an axis lying in the support surface, to activate.

Weitere Möglichkeiten bestehen darin, die Verstellelemente in Richtung auf ihre Aktivierungsstellung vorzuspannen und Mittel zur Beaufschlagung der Verstellelemente entgegen der Vorspannkraft vorzusehen. Die Aktivierung erfolgt dann dadurch, daß die entgegen der Vorspannkraft wirkenden Mittel außer Eingriff gebracht werden. Other options are to move the adjustment elements in the direction to pretension for their activation position and means for loading to provide the adjusting elements against the biasing force. The Activation then takes place in that the counter-biasing force effective agents are disengaged.

Noch eine Möglichkeit besteht darin, die Verstellelemente durch Volumenvergrößerung zu aktivieren.Another possibility is to adjust the adjustment elements by increasing the volume to activate.

Die Aktivierung der Verstellelemente erfolgt insbesondere mechanisch. Sie kann aber auch elektrisch, hydraulisch oder pneumatisch erfolgen. Bei mechanischer Verstellung werden die gemeinsam aktivierbaren Verstellelemente durch Stangen, Wellen oder ähnliche Mittel miteinander verbunden. Bei hydraulisch oder pneumatisch aktivierbaren Verstellelementen sind die gemeinsam aktivierbaren Verstellelemente bevorzugt hydraulisch oder pneumatisch miteinander verbunden.The adjustment elements are activated in particular mechanically. she can also be done electrically, hydraulically or pneumatically. At The adjustment elements that can be activated together become mechanical adjustment connected by rods, shafts or similar means. With hydraulically or pneumatically activated adjustment elements the jointly activatable adjusting elements are preferably hydraulic or connected pneumatically.

Die Verstellelemente können insbesondere durch Materialverstärkung mindestens eines Teils der Einzelstützelemente wirken. Beispielsweise werden an Federschenkel der Einzelstützelemente elastische Elemente angelegt, die dann zusammen mit dem jeweilige Federschenkel verformt werden. Die Verstellelemente können auch durch Blockieren mindestens eines Teils der Einzelstützelemente wirken. Insbesondere können bei mehrstufigen Federelementen einzelne Stufen blockiert werden. So kann eine dreistufige Federkennlinie in eine zweistufige oder eine zweistufige in eine einstufige Federkennlinie verstellt werden.The adjustment elements can in particular be reinforced by material act at least a part of the individual support elements. For example elastic elements are placed on the spring legs of the individual support elements, which are then deformed together with the respective spring leg. The adjustment elements can also be blocked by blocking at least one Part of the individual support elements act. In particular, with multi-stage Spring elements are blocked individual stages. So one can three-stage spring characteristic in a two-stage or a two-stage in one single-stage spring characteristic can be adjusted.

Andererseits kann auch eine einstufige Federkennlinie durch Aktivieren der Verstellelemente in eine zwei- oder mehrstufige Federkennlinie verändert werden. Beispielsweise kann in ein ringförmiges Federelement ein zweites ringförmiges Federelement geringerer Höhe eingesetzt werden und dadurch eine zweite Stufe bilden.On the other hand, a single-stage spring characteristic can also be activated the adjustment elements changed into a two-stage or multi-stage spring characteristic become. For example, an annular spring element second annular spring element of lower height are used and thereby forming a second stage.

Die aktivierten Verstellelemente können außerdem auch erst ab einem bestimmten Federweg zur Wirkung kommen. So können bei Einzelstützelementen mit mehreren nebeneinander angeordneten ringförmigen Federelementen einzelne ringförmige Federelemente in Abhängigkeit von der Aktivierung der Verstellelemente nach einem längeren oder kürzeren ersten Federweg in Funktion treten.The activated adjustment elements can also only start from a certain one Spring travel come into effect. So with single support elements with several annular spring elements arranged side by side individual annular spring elements depending on the Activation of the adjustment elements after a longer or shorter first Actuate travel.

Grundsätzlich können alle dargestellten und beschriebenen Verstellelemente auch zur unabhängigen Aktivierung von Einzelstützelementen verwendet werden. Erfindungsgemäß ist jedoch die gemeinsame Verstellung bevorzugt.Basically all adjustment elements shown and described can also used for independent activation of individual support elements become. However, the common adjustment is according to the invention prefers.

Ausführungsbeispiele der Erfindung sind in den Zeichnungen dargestellt und werden nachfolgend beschrieben. Es zeigen, jeweils in schematischer Darstellung,

- Fig. 1

- eine erfindungsgemäße Stützvorrichtung,

- Fig. 2

- eine erste Variante eines Verstellelementes für eine erfindungsgemäße Stützvorrichtung,

- Fig. 3 - 12

- weitere Varianten hierzu.

- Fig. 1

- a support device according to the invention,

- Fig. 2

- a first variant of an adjusting element for a support device according to the invention,

- 3 - 12

- further variants of this.

Fig. 1 zeigt eine als Unterfederung für eine Matratze ausgebildete erfindungsgemäße

Stützvorrichtung mit einem Rahmen 1, dessen Schenkel 2

eine Liegefläche 3 umfassen, über welche eine Vielzahl von elastischen

Einzelstützelementen 4 verteilt angeordnet ist. Durch diese Ausgestaltung

wird eine punktelastische Abstützung realisiert, die insbesondere in Seitenlage

ein besonders tiefes Eintauchen der Schulter und des Beckens

ermöglicht, während in Rücklage ein normales Eintauchen gegeben ist.Fig. 1 shows an embodiment of the invention designed as a spring base for a mattress

Support device with a frame 1, the

Die Einzelstützelemente 4 sind in Reihen und Spalten angeordnet, wobei

die Reihen parallel zu den kurzen Schenkeln 2 des Rahmens 1 und die

Spalten senkrecht hierzu verlaufen. Die Einzelstützelemente 4 umfassen

einen ringförmigen Federkörper, welcher auf einer Unterlage, beispielsweise

eine Querleiste, abgestützt ist und eine flache Stützplatte trägt, auf

welcher die Matratze aufliegt.The

Die Ringebenen der Federkörper 5 der Einzelstützelemente 4 verlaufen jeweils

senkrecht zu der Ausrichtung der Reihen. Auf diese Weise können

die Federkörper von einer gemeinsamen Verstellstange 6 durchgriffen

werden, die in Querrichtung, also parallel zu den kurzen Seiten 2 des

Rahmens 1 gelagert ist. Tatsächlich sind hier jedoch nur im Schulterbereich

7 und im Beckenbereich 8 derartige Verstellstangen 6 angeordnet,

während die übrigen Bereiche 9 keine solchen Verstellstangen aufweisen.

Grundsätzlich können sie aber auch dort vorgesehen werden. Die Verstellstangen

6 tragen Verstellelemente 10 und sind in ihrer Längsrichtung zwischen

einer ersten Stellung und einer zweiten Stellung verschiebbar geführt.The ring planes of the

In der in Fig. 1 dargestellten ersten Stellung der Verstellstangen 6 befinden

sich die Verstellelemente 10, von denen jedes jeweils einem Einzelstützelemente

4 zugeordnet ist, seitlich neben dem zugehörigen ringförmigen

Federkörper 5 und haben auf diesen keinen Einfluß. In der zweiten

Stellung, die durch Längsverschieben der Verstellstange 6 erreicht wird,

befinden sich die Verstellelemente 10 innerhalb des ringförmigen Federkörpers

5 und beeinflussen dadurch dessen Federeigenschaften. Beispielsweise

können die Verstellelemente 10 als elastischer Ring ausgebildet

sein, der innen an dem ringförmigen Federkörper 5 anliegt und dessen

Federhärte dadurch erhöht.In the first position of the adjusting

Der Verschiebemechanismus für die Verstellstangen 6 kann grundsätzlich

beliebig realisiert werden. Dabei können die Verstellstangen 6 eines Bereiches,

beispielsweise des Schulterbereiches 7 und/oder des Beckenbereiches

8 gekoppelt sein, so daß sie automatisch gemeinsam verstellbar sind.

Damit kann in einfacher Weise ein ganzer Bereich 7, 8 individuell in seinen

Federeigenschaften an die Bedürfnisse angepaßt werden.The displacement mechanism for the adjusting

Fig. 2 zeigt ein Ausführungsbeispiel eines als massiver Verstellkörper ausgebildeten

Verstellelementes 10 bei einem Einzelstützelement 4 mit einem

Federkörper 5, der aus zwei übereinander angeordneten jeweils die Form

eines langgestrecken Hexagons aufweisenden Ringen 11, 12 besteht. Das

Verstellelement 10 weist ebenfalls die Form eines langgestreckten Hexagons

auf und ist auf einer Verstellstange 6 angeordnet, die sich senkrecht

zu der Ringebene des unteren Ringes 11 durch diesen hindurch erstreckt.

Die Verstellstange 6 trägt hier nicht dargestellte weitere Verstellelemente

10, deren Anzahl insbesondere der Anzahl von Einzelstützelementen 4 einer

Reihe in einem Rahmen 1 nebeneinander angeordneter Einzelstützelemente

4 entspricht.Fig. 2 shows an embodiment of a solid adjustment

In der in Fig. 2a dargestellten ersten Stellung der Verstellstange 6 befindet

sich das Verstellelement 10 außerhalb des unteren Ringes 11. Dasselbe

gilt für die hier nicht dargestellten übrigen Verstellelemente der Verstellstange

6 in bezug auf die ihnen zugeordneten Einzelstützelemente 4. Fig.

2b zeigt die zweite Stellung der Verstellstange 6, in welcher sich das Verstellelement

10 innerhalb des unteren Ringes 11 befindet. Wie man sieht,

liegt das Verstellelement 10 an der unteren Längsseite 13 und der oberen

Längsseite 14 des unteren Ringes 11 an.The

Bei starrer Ausbildung des Verstellelementes 10 ist der untere Ring 11 des

Federkörpers 5 somit blockiert. Dasselbe gilt für die übrigen auf der selben

Verstellstange 6 angeordneten Verstellelemente 10 und die diesen zugeordneten

Federkörper. Das bedeutet, daß durch Verstellen der Verstellstange

6 von der ersten Stellung in die zweite Stellung der untere Ring 11

der Federkörper 5 dieser Reihe blockiert wird. Die Federkennlinie der Federkörper

ist daher jeweils nur durch den oberen Ring 12 der Federkörper

5 bestimmt. In der in Fig. 2a dargestellten ersten Stellung der Verstellstange

6 bestimmen dagegen beide Ringe 11 und 12 die Federeigenschaften

des Federkörpers 5, so daß durch Verstellen der Verstellstange 6 die

Einzelstützelemente 4 einer Reihe auf zwei verschiedene Härten eingestellt

werden können.With a rigid design of the adjusting

Bei Verwendung von starren Verstellelementen 10 ändert sich zugleich der

maximale Federweg der Einzelstützelemente 4, da bei in den unteren Ring

11 eingefahrenem Verstellelement 10 nur noch der Federweg des oberen

Ringes 12 zur Verfügung steht, während bei ausgefahrenem Verstellelement

10 der Federweg des unteren Ringes 11 hinzukommt. Wird anstelle

eines starren Verstellelementes 10 ein elastisches Verstellelement verwendet,

so ändert sich der maximale Federweg praktisch nicht, sondern lediglich

die Federhärte, die nun zusätzlich zu den Federeigenschaften des oberen

Ringes 12 und des unteren Ringes 11 auch durch die Federeigenschaften

des Verstellelementes 10 bestimmt wird, bei eingefahrenem Verstellelement

10 also zunimmt.When using

Fig. 3 zeigt eine Variante der Verstellelemente 10, die ebenfalls bei Einzelstützelementen

4 mit einem Federkörper eingesetzt werden kann, welcher

zwei übereinander angeordnete, die Form eines langgestreckten Hexagons

aufweisende Ringe 11, 12 umfaßt. Das Verstellelement 10 ist auch hier als

massiver Verstellkörper ausgebildet und mit einer entsprechenden Anzahl

weiterer, hier nicht dargestellter Verstellelemente auf einer Verstellstange

6 angeordnet. Die Verstellstange 6 ist aber nun nicht in ihrer Längsrichtung

verschiebbar, sondern um ihre Längsachse verdrehbar gelagert, und

die Verstellelemente 10 befinden sich stets innerhalb des unteren Ringes

11.Fig. 3 shows a variant of the adjusting

In der in Fig. 3a dargestellten ersten Drehstellung der Verstellstange 6

liegt das als flacher, annähernd quaderförmiger Körper ausgebildete Verstellelement

10 mit seinen beiden Schmalseiten 17 an der unteren Längsseite

13 und der oberen Längsseite 14 des unteren Ringes 11 von innen

an. Bei starrer Ausbildung des Verstellelementes 10 wird dadurch der

untere Ring 11 blockiert, so daß die Federeigenschaften des Federkörpers

5 nur durch den oberen Ring 12 bestimmt werden. Außerdem ist der Federweg

entsprechend verkürzt. Bei elastischer Ausgestaltung des Verstellelementes

10 bestimmt das Verstellelement 10 die Federeigenschaften des

Federkörpers 5 zusätzlich zu den Ringen 11 und 12 mit. Der maximale

Federweg ist nur unwesentlich verkürzt.In the first rotational position of the adjusting

Bei der in Fig. 3b dargestellten zweiten Drehstellung der Verstellstange 6

liegt das Verstellelement 10 nicht am unteren Ring 11 an, sondern die

Breitseiten 18 des Verstellelementes 10 liegen nun den Längsseiten 13

und 14 des Ringes 11 mit Abstand gegenüber. Der untere Ring 11 ist daher

nicht blockiert bzw. das Verstellelement 10 hat keinen Einfluß auf die

Federhärte. Diese wird daher nur durch die beiden Ringe 11 und 12 bestimmt.

Der maximale Federweg wird im wesentlichen durch die Verstellstange

6 bestimmt, welche die Kompression des unteren Ringes 11 bei

Einbringen einer Kraft in Richtung des Pfeils I begrenzt. Über die Verstellstange

6 können auch hier die Federkörper 5 der Einzelstützelemente 4

einer ganzen Reihe gemeinsam verstellt werden. In the second rotational position of the adjusting

Fig. 4 zeigt einen Federkörper 5 eines Einzelstützelementes 4 mit drei nebeneinander

angeordneten, die Form eines langgestreckten Hexagons

aufweisenden Ringen 19, deren Ringebenen parallel zueinander verlaufen

und die mit ihren oberen Längsseiten 20 einstückig miteinander verbunden

sind. Die beiden äußeren Ringe 19 sind jeweils auf einer Stützfläche

21 abgestützt, während der mittlere Ring 19 in der in Fig. 4a dargestellten

Situation nicht abgestützt ist. Dem mittleren Ring 19 ist aber ebenfalls

eine Stützfläche 22 zugeordnet, die vom mittleren Ring 19 beabstandet ist

und daher erst nach Zurücklegen eines ersten Federweges zur Wirkung

kommt.Fig. 4 shows a

Das heißt, bei Belastung des Federkörpers 5 in Richtung des Pfeils I wird

der Federkörper 5 komprimiert, wobei die Federhärte zunächst nur durch

die beiden äußeren Ringe 19 bestimmt ist. Nach Zurücklegen eines ersten

Federweges schlägt der mittlere Ring 19 an der ihm zugeordneten Stützfläche

22 an, so daß während eines zweiten Federweges die Federhärte

nun durch alle drei Ringe 19 bestimmt sind. Auf diese Weise wird eine

zweistufige Federkennlinie realisiert.That is, when the

Erfindungsgemäß ist nun die dem mittleren Ring 19 zugeordnete Stützfläche

22 zwischen der in Fig. 4a dargestellten ersten Stellung und der in

Fig. 4b dargestellten zweiten Stellung verstellbar, wobei die Verstellung

gemeinsam mit mindestens einer weiteren eben solchen Stützfläche mindestens

eines weiteren Federkörpers eines Einzelstützelementes 4 erfolgt,

was in Fig. 4 jedoch nicht dargestellt ist. In der in Fig. 4a dargestellten ersten

Stellung weist die Stützfläche 22, wie beschrieben, einen Abstand

zum mittleren Ring 19 auf. In der in Fig. 4b dargestellten zweiten Stellung

liegt die Stützfläche 22 dagegen bereits ohne Zurücklegen eines ersten Federweges

an dem mittleren Ring 19 an, so daß die Federhärte des Federkörpers

5 in dieser Stellung von Anfang an durch alle drei Ringe 19 bestimmt

wird. Durch Verstellung der Stützfläche 22 kann so zwischen einer

einstufigen und einer zweistufigen Federkennlinie des Federkörpers gewählt

werden. In entsprechender Weise könnte statt dessen auch durch

eine Verstellung der Stützfläche 22 das Verhältnis des ersten Federweges

zum zweiten Federweg variiert werden.According to the invention, the support surface assigned to the

Die gemeinsame Verstellung der Federkörper 5 mehrerer Einzelstützelemente

4 kann grundsätzlich in beliebiger Weise erfolgen. Beispielsweise

können die Stützflächen 22 über eine Verstellstange miteinander verbunden

sein, die zwischen einer ersten Stellung, in welcher die Stützflächen

22 von den zugeordneten mittleren Ringen 19 beabstandet sind, und einer

zweiten Stellung, in welcher sie an diesen anliegen, verschiebbar geführt

ist. Die Stützflächen 22 können aber auch einfach einstückig miteinander

ausgebildet sein, wenn die Federkörper 5 entsprechend in einer Reihe angeordnet

sind.The common adjustment of the

Eine weitere Variante eines Verstellelementes 10 zur Verwendung mit einem

Federkörper 5, welcher die Form eines langgestreckten, hexagonalen

Ringes 11 aufweist, ist in Fig. 5 dargestellt. Das Verstellelement 10 weist

hier ebenfalls die Form eines langgestreckten, hexagonalen Ringes 23 auf

und ist so ausgestaltet, daß das Verstellelement 10 in den Ring 11 eingesetzt

werden kann und dabei die Längsseiten 24 und die Schmalseiten 25

des hexagonalen Ringes 23 von innen an den entsprechenden Seiten 26,

27 des Ringes 11 anliegen.Another variant of an adjusting

Diese eingesetzte Stellung des Verstellelementes 10 ist in Fig. 5b dargestellt,

während Fig. 5a die ausgefahrene Stellung des Verstellelementes 10

zeigt. In der eingefahrenen Stellung der Fig. 5b wird die Federhärte des

Federkörpers 5 gemeinsam durch den Ring 11 und das Verstellelement 10

bestimmt, während in der ausgefahrenen Stellung der Fig. 5a allein der

Ring 11 die Federhärte festlegt. Der Federweg ist in beiden Fällen praktisch

gleich. Die gemeinsame Verstellung der Ringe 23 mehrerer Federkörper

5 kann wieder grundsätzlich in beliebiger Weise erfolgen, beispielsweise

über eine die Verstellelemente 10 verbindende Verstellstange.This inserted position of the adjusting

Die in Fig. 6 dargestellte Variante eines Verstellelementes 10 ist ähnlich

der in Fig. 5 dargestellten Variante. Der Unterschied besteht darin, daß

der Ring 23 des Verstellelementes 10 kleiner ist als der freie Öffnungquerschnitt

des Ringes 11 des Federkörpers 5, also in der eingefahrenen Stellung

nicht von innen an allen Seiten des Ringes 11 anliegt. Vielmehr liegt

nur die untere Längsseite 24 des Ringes 23 an der unteren Längsseite 26

des Ringes 11 an. Dadurch wird in der eingefahrenen Stellung des Verstellelementes

10 eine zweistufige Federkennlinie geschaffen. Das heißt,

das Verstellelement 10 kommt erst nach einem ersten Federweg zur Wirkung

und bestimmt während eines zweiten Federweges die Federhärte des

Federkörpers 5 mit. In der ausgefahrenen Stellung des Verstellelementes

10 liegt dagegen eine einstufige Federkennlinie vor. Die Verstellung des

Verstellelementes 10 erfolgt auch hier wieder grundsätzlich in beliebiger

Weise gemeinsam mit weiteren Verstellelementen 10.The variant of an adjusting

Durch die in Fig. 7 dargestellte Variante des Verstellelementes 10 kann

ebenfalls zwischen einer einstufigen und einer zweistufigen Federkennlinie

gewählt werden. Das Verstellelement 10 ist hier als rautenförmiger Ring

28 ausgebildet, der innerhalb des den Federkörper 5 bildenden Ringes 11

um eine zu seiner Ringfläche senkrechte Achse drehbar im Ring 11 angeordnet

ist. In der in Fig. 7a dargestellten ersten Stellung des Verstellelementes

10 liegt der Ring 28 mit den auf seiner großen Achse liegenden

abgeflachten Spitzen 29 von innen an den beiden Längsseiten 26 des Ringes

11 an und bestimmt daher während des gesamten Federweges die Federhärte

des Federkörpers 4a mit.The variant of the adjusting

In der in Fig. 7b dargestellten um 90° verdrehten Drehstellung des Verstellelementes

10 liegen die auf der kurzen Achse des Ringes 28 liegenden

abgeflachten Spitzen 30 den beiden Längsseiten 26 des Ringes 11 gegenüber.

Durch gleichzeitiges Absenken des Verstellelementes 10 liegt eine

abgeflachte Spitze 30 von innen an der unteren Längsseite 26 des Ringes

11 an, während die andere abgeflachte Spitze 30 aufgrund der geringeren

Erstreckung der kurzen Achse des Ringes 28 einen Abstand zu der oberen

Längsseite 26 des Ringes 11 aufweist. Daher kommen die Federeigenschaften

des Verstellelementes 10 in dieser Drehstellung erst nach Zurücklegen

eines ersten Federweges des Federkörpers 5 zur Wirkung und

bestimmen die Federhärte des Federkörpers 5 nur während des zweiten

Federweges mit.In the rotational position of the adjusting element rotated by 90 ° shown in FIG.

Fig. 8 zeigt ein Verstellelement 10 in Form einer achteckigen Scheibe 31,

die zentrisch auf einer den auch hier hexagonalen Ring 11 eines Federkörpers

5 durchgreifenden Verstellstange 6 angeordnet ist. Durch Verdrehen

der Verstellstange 6 ändert sich der Abstand zwischen der Umfangsfläche

32 der Scheibe 31 und den beiden Längsseiten 26 des Ringes 11.

Bei starrer Scheibe 31 kann dadurch der Federweg des Ringes 11 in drei

Stufen verstellt werden. Bei elastischer Scheibe 31, in welchem Fall die

Scheibe 31 die Federhärte des Federkörpers 5 nach Zurücklegen eines ersten

Federweges mitbestimmt, kann dadurch die Länge des ersten Federweges

in drei Stufen verstellt werden. 8 shows an adjusting

Neben einer Verdrehung der Verstellstange 6 kann diese auch in ihrer

Längsachse verschiebbar ausgebildet sein, so daß die Scheibe 31 auch

aus dem Ring 11 ausfahrbar ist. Dadurch kann neben einer stufenweisen

Verstellung die Wirkung der Scheibe 31 auch ganz ausgeschaltet werden.

Durch entsprechende Ausbildung der Scheibe 31 kann außerdem eine

kontinuierliche Verstellung verwirklicht werden. Die Verstellstange 6 trägt

auch hier wieder mehrere Scheiben 31, um mindestens zwei Federkörper

5 gemeinsam zu verstellen.In addition to a rotation of the adjusting

Fig. 9 zeigt ein Verstellelement 10, welches von außen an einen Federkörper

5 anlegbar ist. Im dargestellten Ausführungsbeispiel weist der Federkörper

wieder die Form eines langgestreckten, hexagonalen Ringes 11 auf.

Das Verstellelement 10 ist der unteren Hälfte des Ringes 11 nachgebildet

und etwa auf deren Höhe angeordnet. Durch Verschieben senkrecht zur

Ringebene des Ringes 11 kann das Verstellelement 10 aus der in Fig. 9a

dargestellten ersten Stellung in die in Fig. 9b dargestellte zweite Stellung

gebracht werden. Das Verstellelement 10 könnte aber auch direkt unterhalb

des Ringes 11 angeordnet und durch Verschieben in Ringebene

senkrecht zu den Längsseiten 26 des Ringes 11 in die Eingriffsstellung

von Fig. 9b gebracht werden. In der ersten Stellung befindet sich das Verstellelement

10 außer Eingriff mit dem Ring 11, so daß die Federhärte des

Federkörpers 5 allein durch den Ring 11 bestimmt wird. In der zweiten

Stellung des Verstellelementes 10 liegt dieses von unten an dem Ring 11

an und bestimmt daher die Federhärte des Federkörpers 5 mit. Der Federweg

wird durch das Verstellelement 10 nicht beeinflußt. Wie bei den

zuvor beschriebenen Varianten wird auch hier das Verstellelement 10 gemeinsam

mit mindestens einem weiteren Verstellelement in grundsätzlich

beliebiger Weise betätigt. Fig. 9 shows an adjusting

Fig. 10 zeigt ein Verstellelement 10, welches mit dem Verstellelement 10

der Fig. 9 übereinstimmt. Die Verstellung zwischen der in Fig. 10a dargestellten

Eingriffsstellung mit dem Federkörper 5 und der in Fig. 10b dargestellten

Außereingriffstellung erfolgt hier jedoch durch Verdrehen des

Vertellelementes 10 um eine sich in Federrichtung I erstreckende Achse.

Die Verstellung erfolgt wiederum in grundsätzlicher beliebiger Weise gemeinsam

mit mindestens einem weiteren Verstellelement.10 shows an adjusting

Bei der in Fig. 11 dargestellten Variante ist das jedem Federkörper 5 zugeordnete

Verstellelement 10 zweiteilig ausgebildet. Und zwar besteht das

Verstellelement 10 aus zwei Keilen 33, die zwischen der in Fig. 11a dargestellten

Außereingriffstellung und der in Fig. 11b dargestellten Eingriffsstellung

verschwenkbar sind. In der Eingriffsstellung liegen die Keile 33

an den beiden unteren Schmalseiten 27 des Ringes 11 an und bestimmen

dadurch die Federeigenschaften des Federkörpers 5 mit.In the variant shown in FIG. 11, that is assigned to each

Fig. 12 zeigt schließlich eine Variante, bei welcher ein elastisch auf den

Federkörper 5 vorgespanntes Verstellelement 10 vorgesehen ist. In dem

dargestellten Ausführungsbeispiel weist der Federkörper 5 die Form eines

langgestreckten hexagonalen Ringes 11 auf, gegen dessen untere Schmalseiten

27 das Verstellelement 10 mit zwei entsprechenden Seiten 34 vorgespannt

ist. Durch einen hier nicht dargestellten Mechanismus können

diese Seiten 34 des Verstellelementes 10 entgegen der Vorspannkraft von

den Schmalseiten 27 des Ringes 11 wegbewegt und ferngehalten werden.

In dieser in Fig. 12b dargestellten Freigabestellung wird die Federhärte

des Federkörpers 5 allein durch den Ring 11 bestimmt. In der in Fig. 12a

dargestellten Eingriffsstellung des Verstellelementes 10 wird die Federhärte

dagegen zusätzlich durch das vorgespannte Verstellelement 10 bestimmt.

Die Verstellung erfolgt auch hier wieder in grundsätzlich beliebiger

Weise gemeinsam mit mindestens einem weiteren Verstellelement.Fig. 12 finally shows a variant in which an elastic on the

Mit den erfindungsgemäß gemeinsam verstellbaren Verstellelementen 10

kann in einfacher Weise eine individuelle Anpassung der Federhärte von

Einzelstützelementen 4 vorgenommen werden. Die Ausbildung der Verstellelemente

10 ist dabei grundsätzlich beliebig. Die dargestellten Varianten

und Ausführungsformen können untereinander auch grundsätzlich

beliebig kombiniert werden.With the jointly

Die Verstellung der Verstellelemente 10 erfolgt insbesondere mechanisch.

Sie kann aber auch elektro-motorisch oder hydraulisch bzw. pneumatisch

erfolgen. Die Verstellung kann sich in allen Fällen auf die Federhärte

und/oder den Federweg beziehen. Außerdem kann die Stufigkeit der Federkennlinie

verändert werden. Die Verstellelemente 10 sind hierfür entweder

starr oder elastisch ausgebildet. Sie können, ebenso wie die Federkörper

5 insbesondere aus Metall oder Kunststoff bestehen, oder auch aus

Holz. Grundsätzlich ist auch eine Höhenverstellung der Federkörper 4a

über die erfindungsgemäßen Verstellelemente 10 möglich.The

Angewendet werden kann die Erfindung insbesondere, wie in Fig. 1 gezeigt,

bei Unterfederungen für Matratzen, aber auch in Matratzen selbst

oder in Polsterelementen sowie im Sitz oder der Lehne von Sitzmöbeln. In

allen Fällen können die gemeinsam verstellbaren Einzelstützelemente 4

nur in bestimmten Bereichen der Stützfläche vorgesehen sei. Es kann

auch nur ein Teil der Stützfläche mit Einzelstützelementen 4 versehen

sein, insbesondere der Schulter- und/oder Beckenbereich einer Liegefläche,

während im übrigen andere Stützmittel wie beispielsweise Latten angeordnet

sind. The invention can be applied in particular, as shown in FIG. 1,

for slat bases for mattresses, but also in mattresses themselves

or in upholstery elements as well as in the seat or the back of seating furniture. In

In all cases, the jointly adjustable

- 11

- Rahmenframe

- 22nd

- Schenkelleg

- 33rd

- LiegeflächeLying surface

- 44th

- EinzelstützelementSingle support element

- 55

- FederkörperSpring body

- 66

- VerstellstangeAdjustment rod

- 77

- SchulterbereichShoulder area

- 88th

- BeckenbereichPelvic area

- 99

- BereichArea

- 1010th

- VerstellelementAdjustment element

- 1111

- Ringring

- 1212th

- Ringring

- 1313

- untere Längsseite von 11lower long side of 11

- 1414

- obere Längsseite von 11upper long side of 11

- 1515

- untere Längsseite von 10lower long side of 10

- 1616

- obere Längsseite von 10upper long side of 10

- 1717th

- Schmalseite von 10Narrow side of 10

- 1818th

- Breitseite von 10Broadside of 10

- 1919th

- Ringring

- 2020th

- obere Längsseite von 19upper long side of 19

- 2121

- StützflächeSupport surface

- 2222

- StützflächeSupport surface

- 2323

- Ringring

- 2424th

- Längsseite von 23Long side of 23

- 2525th

- Schmalseite von 23Narrow side of 23

- 2626

- Längsseite von 11 Long side of 11

- 2727

- Schmalseite von 11Narrow side of 11

- 2828

- Ringring

- 2929

- Spitze von 28Top of 28

- 3030th

- Spitze von 28Top of 28

- 3131

- Scheibedisc

- 3232

- Umfangsfläche von 31Circumferential area of 31

- 3333

- Keilwedge

- 3434

- Seite von 10Page of 10

- II.

- FederrichtungSpring direction

Claims (10)

dadurch gekennzeichnet, daß die Verstellelemente (10) zumindest teilweise gemeinsam aktivierbar sind.Support device, in particular mattress, cushion element or spring base therefor, with a plurality of elastic individual support elements (4) provided at least in one area of the support device, which bring about an almost selective dissolution of the support surface with regard to its spring properties, and a plurality of at least some of the individual support elements (4) associated with optionally activatable adjustment elements (10) for adjusting the spring properties, in particular the spring hardness and / or the spring travel of the individual support elements (4),

characterized in that the adjusting elements (10) can be activated at least partially together.

dadurch gekennzeichnet, daß die Einzelstützelemente (4) in Spalten und Zeilen angeordnet sind und daß in zumindest einem Bereich (2, 3) der Stützvorrichtung die Einzelstützelemente (4) einer Spalte oder einer Zeile jeweils gemeinsam aktivierbar sind, wobei bevorzugt die Verstellelemente (10) mehrerer Zeilen oder Spalten gemeinsam aktivierbar sind.Support device according to claim 1,

characterized in that the individual support elements (4) are arranged in columns and rows and that in at least one area (2, 3) of the support device the individual support elements (4) of a column or row can be activated together, preferably the adjustment elements (10) several rows or columns can be activated together.

dadurch gekennzeichnet, daß die Verstellelemente (10) in der Stützvorrichtung fest installiert sind oder zur Aktivierung in die Stützvorrichtung einsetzbar sind. Support device according to one of the preceding claims,

characterized in that the adjusting elements (10) are permanently installed in the support device or can be used for activation in the support device.

dadurch gekennzeichnet, daß die Federwege und/oder Federhärten der Einzelstützelemente (4) stufenweise einstellbar sind und/oder daß die Federwege und/oder Federhärten der Einzelstützelemente (4) über mindestens einen Bereich kontinuierlich einstellbar sind.Support device according to one of the preceding claims,

characterized in that the spring travel and / or spring hardness of the individual support elements (4) can be adjusted in stages and / or in that the spring travel and / or spring hardness of the individual support elements (4) can be continuously adjusted over at least one range.

dadurch gekennzeichnet, daß die Verstellelemente (10) zur Verstellung der Federhärte und/oder des Federweges als von außen an die Einzelstützelemente (4) anlegbare Verstellkörper ausgebildet sind oder daß die Einzelstützelemente (4) mindestens abschnittsweise eine offene Form, insbesondere Ringform, aufweisen und daß die Verstellelemente (10) als in die offene Form der Einzelstützelemente (4) einfügbare Verstellkörper ausgebildet sind, wobei bevorzugt die Einzelstützelemente (4) in Federrichtung (I) mehrere Öffnungen übereinander aufweisen und Verstellelemente (4) wahlweise auf verschiedener Höhe in die Öffnungen der Einzelstützelemente (4) einfügbar sind.Support device according to one of the preceding claims,

characterized in that the adjusting elements (10) for adjusting the spring hardness and / or the spring travel are designed as adjusting bodies which can be placed on the individual supporting elements (4) from the outside, or in that the individual supporting elements (4) have an open shape, in particular a ring shape, at least in sections, and in that the adjustment elements (10) are designed as adjustment bodies which can be inserted into the open shape of the individual support elements (4), the individual support elements (4) preferably having a plurality of openings one above the other in the spring direction (I) and adjustment elements (4) optionally at different heights in the openings of the individual support elements (4) can be inserted.

dadurch gekennzeichnet, daß die Verstellelemente (10) elastisch oder starr ausgebildet sind.Support device according to one of the preceding claims,

characterized in that the adjusting elements (10) are elastic or rigid.

dadurch gekennzeichnet, daß die Verstelleelemente (10) durch Verschieben, Verdrehen, Verschwenken, Vorspannen oder durch Volumenvergrößerung aktivierbar sind. Support device according to one of the preceding claims,

characterized in that the adjusting elements (10) can be activated by shifting, twisting, pivoting, prestressing or by increasing the volume.

dadurch gekennzeichnet, daß die Verstellelemente (10) durch Materialverstärkung oder durch Blockieren mindestens eines Teils der Einzelstützelemente (4) wirken.Support device according to one of the preceding claims,

characterized in that the adjusting elements (10) act by reinforcing the material or by blocking at least some of the individual support elements (4).

dadurch gekennzeichnet, daß die aktivierten Verstellelemente (10) erst ab einem bestimmten Federweg zur Wirkung kommen.Support device according to one of the preceding claims,

characterized in that the activated adjusting elements (10) only come into effect after a certain spring travel.

dadurch gekennzeichnet, daß die Aktivierung der Verstellelemente (10) mechanisch, elektro-motorisch, hydraulisch oder pneumatisch erfolgt.Support device according to one of the preceding claims,

characterized in that the adjustment elements (10) are activated mechanically, electromotively, hydraulically or pneumatically.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10024530A DE10024530A1 (en) | 2000-05-18 | 2000-05-18 | Support device |

| DE10024530 | 2000-05-18 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1155643A2 true EP1155643A2 (en) | 2001-11-21 |

| EP1155643A3 EP1155643A3 (en) | 2002-09-11 |

| EP1155643B1 EP1155643B1 (en) | 2005-08-03 |

Family

ID=7642635

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01111560A Expired - Lifetime EP1155643B1 (en) | 2000-05-18 | 2001-05-11 | Supporting device |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1155643B1 (en) |

| AT (1) | ATE300900T1 (en) |

| DE (3) | DE10024530A1 (en) |

| ES (1) | ES2246958T3 (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1327404A1 (en) * | 2002-01-07 | 2003-07-16 | Lovato s.r.l. | An elastic element of support of a part of the body |

| EP1386564A1 (en) * | 2002-07-31 | 2004-02-04 | Froli Kunststoffwerk Heinrich Fromme OHG | Springelement for a sitting or lying furniture |

| EP1716790A1 (en) * | 2005-04-21 | 2006-11-02 | Diemer & Dr. Jaspert GbR | Spring system |

| DE202006012078U1 (en) * | 2006-08-04 | 2007-09-27 | Froli Kunststoffwerk Heinrich Fromme Ohg | Bearing element for a cushion support of sitting and lying surfaces |

| EP3400842A1 (en) * | 2017-05-12 | 2018-11-14 | Tournadre SA Standard Gum | Stiffness adjustment device |

| CN111202383A (en) * | 2020-01-10 | 2020-05-29 | 浙江宏都寝具有限公司 | Hardness-adjustable mattress |

| EP3669706A1 (en) | 2018-12-21 | 2020-06-24 | Tournadre SA Standard Gum | Flexible element with adjustable height |

| EP3669705A1 (en) | 2018-12-21 | 2020-06-24 | Tournadre SA Standard Gum | Flexible member with adjustable stiffness for bedding and/or seating furniture |

| FR3090307A1 (en) | 2018-12-21 | 2020-06-26 | Tournadre Sa Standard Gum | Flexible element with adjustable stiffness for sleeping and / or seating furniture |

| US10722042B2 (en) | 2017-05-12 | 2020-07-28 | Tournadre Sa Standard Gum | Element of adjustable stiffness for beds or seats |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20213821U1 (en) * | 2002-09-05 | 2003-10-16 | FROLI Kunststoffwerk Heinrich Fromme oHG, 33758 Schloß Holte-Stukenbrock | spring element |

| FR2884883B1 (en) * | 2005-04-22 | 2010-09-10 | Delahousse Et Fils Sa | NEW SPRING MEMBER FOR CARCASS SUSPENSION OF A SOMMIER SEAT, MATTRESS OR OTHER |

| DE202006012077U1 (en) * | 2006-08-04 | 2007-09-27 | Froli Kunststoffwerk Heinrich Fromme Ohg | Bearing element for a cushion support of sitting and lying surfaces |

| DE202007004007U1 (en) * | 2007-03-14 | 2007-06-21 | Hartmann, Siegbert | Adjustable single spring is used to provide support for a chair or platform has a leaf spring form |

| DE202007000005U1 (en) * | 2007-04-02 | 2008-05-08 | Froli Kunststoffwerk Heinrich Fromme Ohg | Bearing element for a cushion support of sitting and lying surfaces |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0223617A2 (en) * | 1985-06-18 | 1987-05-27 | National Aeronautics And Space Administration | Segmented tubular cushion springs and spring assembly |

| US4962916A (en) * | 1989-11-17 | 1990-10-16 | Uniroyal Chemical Company, Inc. | Compression spring |

| EP0543799A1 (en) * | 1989-06-08 | 1993-05-26 | Superba S.A. | Upper mattress for mattress-system |

-

2000

- 2000-05-18 DE DE10024530A patent/DE10024530A1/en not_active Withdrawn

-

2001

- 2001-05-11 EP EP01111560A patent/EP1155643B1/en not_active Expired - Lifetime

- 2001-05-11 AT AT01111560T patent/ATE300900T1/en not_active IP Right Cessation

- 2001-05-11 DE DE50106940T patent/DE50106940D1/en not_active Expired - Lifetime

- 2001-05-11 ES ES01111560T patent/ES2246958T3/en not_active Expired - Lifetime

- 2001-05-18 DE DE20108407U patent/DE20108407U1/en not_active Expired - Lifetime

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0223617A2 (en) * | 1985-06-18 | 1987-05-27 | National Aeronautics And Space Administration | Segmented tubular cushion springs and spring assembly |

| EP0543799A1 (en) * | 1989-06-08 | 1993-05-26 | Superba S.A. | Upper mattress for mattress-system |

| EP0401712B1 (en) * | 1989-06-08 | 1994-01-05 | Superba S.A. | Mattress-system |

| US4962916A (en) * | 1989-11-17 | 1990-10-16 | Uniroyal Chemical Company, Inc. | Compression spring |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1327404A1 (en) * | 2002-01-07 | 2003-07-16 | Lovato s.r.l. | An elastic element of support of a part of the body |

| EP1386564A1 (en) * | 2002-07-31 | 2004-02-04 | Froli Kunststoffwerk Heinrich Fromme OHG | Springelement for a sitting or lying furniture |

| JP2004065963A (en) * | 2002-07-31 | 2004-03-04 | Froli Kunststoffwerk Heinrich Fromme Ohg | Spring member for bed |

| EP1716790A1 (en) * | 2005-04-21 | 2006-11-02 | Diemer & Dr. Jaspert GbR | Spring system |

| DE202006012078U1 (en) * | 2006-08-04 | 2007-09-27 | Froli Kunststoffwerk Heinrich Fromme Ohg | Bearing element for a cushion support of sitting and lying surfaces |

| US10722042B2 (en) | 2017-05-12 | 2020-07-28 | Tournadre Sa Standard Gum | Element of adjustable stiffness for beds or seats |

| EP3400842A1 (en) * | 2017-05-12 | 2018-11-14 | Tournadre SA Standard Gum | Stiffness adjustment device |

| FR3066088A1 (en) * | 2017-05-12 | 2018-11-16 | Tournadre Sa Standard Gum | STIFF ADJUSTER DEVICE |

| US10932586B2 (en) | 2017-05-12 | 2021-03-02 | Tournadre Sa Standard Gum | Stiffness adjustment device |

| EP3669706A1 (en) | 2018-12-21 | 2020-06-24 | Tournadre SA Standard Gum | Flexible element with adjustable height |

| FR3090307A1 (en) | 2018-12-21 | 2020-06-26 | Tournadre Sa Standard Gum | Flexible element with adjustable stiffness for sleeping and / or seating furniture |

| FR3090305A1 (en) | 2018-12-21 | 2020-06-26 | Tournadre Sa Standard Gum | Flexible element with adjustable height |

| FR3090306A1 (en) | 2018-12-21 | 2020-06-26 | Tournadre Sa Standard Gum | Flexible element with adjustable stiffness for sleeping and / or seating furniture |

| EP3669705A1 (en) | 2018-12-21 | 2020-06-24 | Tournadre SA Standard Gum | Flexible member with adjustable stiffness for bedding and/or seating furniture |

| US11311112B2 (en) | 2018-12-21 | 2022-04-26 | Tournadre Sa Standard Gum | Supple member with adjustable stiffness for lying and/or sitting furniture |

| US11311113B2 (en) | 2018-12-21 | 2022-04-26 | Tournadre Sa Standard Gum | Height-adjustable supple member |