EP1050341A2 - Tubular electrofilter with movable electrodes - Google Patents

Tubular electrofilter with movable electrodes Download PDFInfo

- Publication number

- EP1050341A2 EP1050341A2 EP00109289A EP00109289A EP1050341A2 EP 1050341 A2 EP1050341 A2 EP 1050341A2 EP 00109289 A EP00109289 A EP 00109289A EP 00109289 A EP00109289 A EP 00109289A EP 1050341 A2 EP1050341 A2 EP 1050341A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- electrodes

- tubular

- precipitation

- electrode

- shaped

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/02—Plant or installations having external electricity supply

- B03C3/04—Plant or installations having external electricity supply dry type

- B03C3/06—Plant or installations having external electricity supply dry type characterised by presence of stationary tube electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/41—Ionising-electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/74—Cleaning the electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/86—Electrode-carrying means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/10—Ionising electrode has multiple serrated ends or parts

Definitions

- the invention relates to a tubular electrostatic precipitator with at least one tubular precipitation electrode and each a coaxially arranged wire or rod Outflow electrode.

- Electrostatic filters usually consist of a on 35 to 75 kV charged spray electrode, which is a grounded Precipitation electrode at an appropriate distance faces.

- the precipitation electrode must be sufficient large surface area for the precipitation of the filtered dust particles have and is mostly with a device for shaking of precipitation. Due to the high The gas flowing through is ionized, whereby in the electric force field between the two electrodes a directed Stream of negative gas ions towards the grounded Hiking tube. If by such an electrostatic precipitator Pumped gas with solid or liquid suspended particles is bombarded by the ions and charged also negative. As a result of the electric field the charged particles are driven towards the precipitation electrode.

- tubular electrostatic precipitators in which a wire-shaped Outflow electrode is surrounded by a grounded cylinder also other designs, such as plate electrostatic precipitators, known.

- the invention now aims to provide a tubular electrostatic precipitator to create of the type mentioned, which also for the use in bio-firing systems is suitable and in can be cleaned mechanically in a particularly simple manner.

- the tube electrostatic filter according to the invention solves this problem formed so that the discharge electrode on a pivotable or slidable holding part is fixed and from the position coaxial to the precipitation electrode into one of the Inner wall of the tubular precipitation electrode adjacent Position is displaceable or pivotable.

- the discharge electrode which are designed as wire or rope can be moved or pivoted in a suitable manner can and in one of the inner wall of the tubular precipitation electrode neighboring location can be spent in the now released clear cross section of the precipitation electrode a corresponding cleaning device, for example a pipe brush or the like, are introduced and efficient quick cleaning.

- a corresponding cleaning device for example a pipe brush or the like

- the design according to the invention is particularly advantageous made so that a plurality of cylindrical Precipitation electrodes in a common housing is arranged, at the lower end of which a dust hopper is connected is and that the discharge electrodes on a common Holding part fixed and slidable or pivotable with this are arranged.

- Such a design is particularly advantageous taken so that the axes of the cylindrical electrodes on the circumference of at least one circle in the same Pitch angles are arranged to each other and that the common holding part is star-shaped, the Length of the arms from the center of the star-shaped part to Clamping point of the outflow electrodes the radius of the circle corresponds and the star-shaped holding part around the axis of the Circle is pivotable, such training in constructively simple way of pivoting the joint Outflow electrodes to release the light to be cleaned Cross-section of the precipitation electrodes allows.

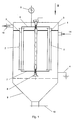

- FIG. 1 shows a schematic side view a device according to the invention

- Fig. 2 is a plan view 1 in the direction of arrow II of FIG modified training with the cover of the device removed according to Fig. 1.

- Fig. 1 is a plurality of tubular in a housing 1 or cylindrical precipitation electrodes 2 arranged. Each coaxial to the axis of the tubular precipitation electrodes wires 3 are tensioned, which are the outflow electrodes form.

- the tubular precipitation electrodes are grounded together with the housing 1 via a line 4, whereas the outflow electrodes 3 with a high voltage source 5 are connected.

- the outflow electrodes 3 are on one common carrier or holding part 6 set, the lower ends of these discharge electrodes to a corresponding one Brackets 7 are set.

- the counter holder 7 is relative to Housing 1 stored in a bearing 8.

- the lower end of the housing is funnel-shaped Mouth 9, which can be closed by a slide 10.

- the falling one collects in this funnel-shaped mouth 9 Dust, which is removed by opening the slide 10 can be.

- the tubular or cylindrical deposition or precipitation electrodes 2 corresponding amounts of solids, which are removed by mechanical cleaning have to.

- the upper holding part 6 is for the outflow electrodes 3 are star-shaped and around one Axis 11 pivotally mounted.

- the pivoting can be in the sense of the double arrow 12 such that the outflow electrodes 3 in the vicinity of the inner wall 13 of the precipitation electrodes 2 can be pivoted.

- the carrier or holding part 6 can hiebei all outflow electrodes at the same time 3 pivoted into such a non-operational position so that the complete clear cross-section of the separating electrodes 2 for mechanical cleaning, for example by means of brushes.

Abstract

Description

Die Erfindung bezieht sich auf einen Röhrenelektrofilter mit wenigstens einer rohrförmigen Niederschlagselektrode und jeweils einer koaxial angeordneten draht- oder stabförmigen Ausströmelektrode.The invention relates to a tubular electrostatic precipitator with at least one tubular precipitation electrode and each a coaxially arranged wire or rod Outflow electrode.

Als Elektrofilter werden Anlagen zur Entstaubung von zumeist industriellen Gasen, wie Gichtgasen, Rauchgasen oder dgl. benannt. Die Wirkungsweise beruht auf dem Korona-Effekt und bezeichnet eine elektrische Entladungsform, die an scharfen Kanten, an Spitzen oder an Drähten bei Atmosphärendruck und hohen Spannungen auftritt. Elektrofilter bestehen aus einer zumeist auf 35 bis 75 kV aufgeladenen Sprühelektrode, der eine geerdete Niederschlagselektrode in entsprechender Entfernung gegenübersteht. Die Niederschlagselektrode muß eine hinreichend große Oberfläche für den Niederschlag der ausgefilterten Staubteilchen aufweisen und ist zumeist mit einer Vorrichtung zum Abschütteln des Niederschlages verbunden. Durch die angelegte hohe Spannung wird das durchströmende Gas ionisiert, wobei in dem elektrischen Kraftfeld zwischen den beiden Elektroden ein gerichteter Strom von negativen Gasionen in Richtung zum geerdeten Rohr wandern. Wenn durch einen derartigen Elektrofilter nun ein Gas mit festen oder flüssigen Schwebestoffteilchen gefördert wird, so werden diese von den Ionen bombardiert und laden sich gleichfalls negativ auf. Infolge des elektrischen Feldes werden die geladenen Teilchen zur Niederschlagselektrode hingetrieben.Systems for dedusting are mostly used as electrostatic precipitators industrial gases, such as top gases, flue gases or the like. named. The mode of action is based on the corona effect and is called an electrical discharge form that is sharp Edges, on tips or on wires at atmospheric pressure and high voltages occur. Electrostatic filters usually consist of a on 35 to 75 kV charged spray electrode, which is a grounded Precipitation electrode at an appropriate distance faces. The precipitation electrode must be sufficient large surface area for the precipitation of the filtered dust particles have and is mostly with a device for shaking of precipitation. Due to the high The gas flowing through is ionized, whereby in the electric force field between the two electrodes a directed Stream of negative gas ions towards the grounded Hiking tube. If by such an electrostatic precipitator Pumped gas with solid or liquid suspended particles is bombarded by the ions and charged also negative. As a result of the electric field the charged particles are driven towards the precipitation electrode.

Neben Röhrenelektrofiltern, bei welchen eine drahtförmige Ausströmelektrode von einem geerdeten Zylinder umgeben ist, sind auch andere Bauformen, wie beispielsweise Plattenelektrofilter, bekannt.In addition to tubular electrostatic precipitators, in which a wire-shaped Outflow electrode is surrounded by a grounded cylinder also other designs, such as plate electrostatic precipitators, known.

Bei der Verwendung von derartigen Röhrenelektrofiltern für die Reinigung beispielsweise von Biofeuerungsabgasen stellen sich in der Folge eine Reihe von aufwendigen Reinigungsproblemen, da in derartigen Biofeuerungsabgasen auch teerartige, bituminöse Partikel enthalten sind, welche gemeinsam mit den Staubteilchen eine gut haftende Schicht an der Innenwand der Niederschlagselektrode ergeben. Derartige Filter bedürfen daher einer relativ häufigen Reinigung, wobei mit Rücksicht auf die Anwesenheit von klebrigen, bituminösen Teilchen ein einfaches Abschütteln in der Regel nicht ausreicht, um die Oberflächen der Abscheidungs- bzw. Niederschlagselektrode wieder von dem Niederschlag zu befreien. Derartige Filter müssen daher mechanisch gereinigt werden, wofür Bürsten eingesetzt werden können. Bei Röhrenfilter wird aber die Reinigung der Innenwand der zylinderförmigen Niederschlagelektrode durch die Ausströmelektrode behindert.When using such tube electrostatic filters for the cleaning of, for example, bio-combustion exhaust gases as a result, a number of complex cleaning problems since in such biofuel exhaust gases also tar-like, bituminous particles are contained, which together with the Dust particles have a well adhering layer on the inner wall of the Precipitation electrode result. Such filters therefore need a relatively frequent cleaning, taking into account the Presence of sticky, bituminous particles a simple Shaking off is usually not enough to cover the surfaces of the Deposition or precipitation electrode again from the precipitation to free. Such filters must therefore be cleaned mechanically what brushes can be used for. At Tube filter is cleaning the inner wall of the cylindrical Precipitation electrode hindered by the discharge electrode.

Die Erfindung zielt nun darauf ab, einen Röhrenelektrofilter der eingangs genannten Art zu schaffen, welcher auch für die Verwendung in Biofeuerungsanlagen geeignet ist und in besonders einfacher Weise mechanisch gereinigt werden kann. Zur Lösung dieser Aufgabe ist der erfindungsgemäße Röhrenelektrofilter so ausgebildet, daß die Ausströmelektrode an einem verschwenkbaren oder verschiebbaren Halteteil festgelegt ist und aus der zur Niederschlagselektrode koaxialen Lage in eine der Innenwand der rohrförmigen Niederschlagselektrode benachbarte Lage verschieb- oder verschwenkbar ist. Dadurch, daß die Ausströmelektrode, welche als Draht oder Seil ausgebildet sein kann, in geeigneter Weise verschoben oder verschwenkt werden kann und in eine der Innenwand der rohrförmigen Niederschlagselektrode benachbarte Lage verbracht werden kann, kann in den nunmehr freigegebenen lichten Querschnitt der Niederschlagselektrode ein entsprechendes Reinigungsgerät, beispielsweise eine Rohrbürste oder dgl., eingeführt werden und effiziente rasche Reinigung erfolgen. Vor der neuerlichen Inbetriebnahme ist es lediglich erforderlich die Ausströmelektrode wiederum in ihre im wesentlichen koaxiale Lage zum Mantel der zylinderförmigen bzw. rohrförmigen Niederschlagselektrode zurück zu verschieben und zu verschwenken, um auf die Art und Weise die geeignete Ausbildung des Korona-Effekts und die gewünschte gerichtete Strömung beim neuerlichen Reinigungsvorgang zu gewährleisten.The invention now aims to provide a tubular electrostatic precipitator to create of the type mentioned, which also for the use in bio-firing systems is suitable and in can be cleaned mechanically in a particularly simple manner. For The tube electrostatic filter according to the invention solves this problem formed so that the discharge electrode on a pivotable or slidable holding part is fixed and from the position coaxial to the precipitation electrode into one of the Inner wall of the tubular precipitation electrode adjacent Position is displaceable or pivotable. Because the discharge electrode, which are designed as wire or rope can be moved or pivoted in a suitable manner can and in one of the inner wall of the tubular precipitation electrode neighboring location can be spent in the now released clear cross section of the precipitation electrode a corresponding cleaning device, for example a pipe brush or the like, are introduced and efficient quick cleaning. Before starting up again it is only necessary to turn the discharge electrode in their essentially coaxial position to the jacket of the cylindrical or tubular precipitation electrode to move back and swivel to find the appropriate one Formation of the corona effect and the desired directed To ensure flow during the new cleaning process.

In besonders vorteilhafter Weise ist die Ausbildung erfindungsgemäß so getroffen, daß eine Mehrzahl von zylinderförmigen Niederschlagselektroden in einem gemeinsamen Gehäuse angeordnet ist, an dessen unterem Ende ein Staubtrichter angeschlossen ist und daß die Ausströmelektroden auf einem gemeinsamen Halteteil festgelegt und mit diesem verschieb- oder verschwenkbar angeordnet sind. Mit einer derartigen eine Mehrzahl von zylinderförmigen Niederschlagselektroden aufweisenden Filtereinrichtung lassen sich auch große Gasmengen mit kleinbauenden Filtern zuverlässig reinigen, wobei die erforderliche Reinigung der Elektroden selbst und insbesondere der Niederschlagselektroden durch die gemeinsame Verschwenkung bzw. Verschiebung der Ausströmelektroden mit geringsten Stillstandszeiten ermöglicht wird.The design according to the invention is particularly advantageous made so that a plurality of cylindrical Precipitation electrodes in a common housing is arranged, at the lower end of which a dust hopper is connected is and that the discharge electrodes on a common Holding part fixed and slidable or pivotable with this are arranged. With such a majority of cylindrical filter devices having precipitation electrodes large quantities of gas can also be Clean filters reliably, doing the necessary cleaning the electrodes themselves and in particular the precipitation electrodes through the joint pivoting or shifting the discharge electrodes with minimal downtimes becomes.

In besonders vorteilhafter Weise ist eine derartige Ausbildung so getroffen, daß die Achsen der zylinderförmigen Elektroden am Umfang wenigstens eines Kreises in gleichen Teilungswinkeln zueinander angeordnet sind und daß der gemeinsame Halteteil sternförmig ausgebildet ist, wobei die Länge der Arme vom Mittelpunkt des sternförmigen Teils bis zur Einspannstelle der Ausströmelektroden dem Radius des Kreises entspricht und der sternförmige Halteteil um die Achse des Kreises verschwenkbar ist, wobei eine derartige Ausbildung in konstruktiv einfacher Weise die gemeinsame Verschwenkung der Ausströmelektroden zur Freigabe des zu reinigenden lichten Querschnittes der Niederschlagselektroden ermöglicht.Such a design is particularly advantageous taken so that the axes of the cylindrical electrodes on the circumference of at least one circle in the same Pitch angles are arranged to each other and that the common holding part is star-shaped, the Length of the arms from the center of the star-shaped part to Clamping point of the outflow electrodes the radius of the circle corresponds and the star-shaped holding part around the axis of the Circle is pivotable, such training in constructively simple way of pivoting the joint Outflow electrodes to release the light to be cleaned Cross-section of the precipitation electrodes allows.

Die Erfindung wird nachfolgend anhand eines in der

Zeichnung schematisch dargestellten Ausführungsbeispieles näher

erläutert. In dieser zeigen Fig. 1 eine schematische Seitenansicht

einer erfindungsgemäßen Vorrichtung und Fig. 2 eine Draufsicht

in Richtung des Pfeiles II der Fig. 1 auf eine

abgewandelte Ausbildung bei abgenommenem Deckel der Vorrichtung

nach Fig. 1.The invention is based on one in the

Drawing schematically illustrated embodiment

explained. 1 shows a schematic side view

a device according to the invention and Fig. 2 is a

In Fig. 1 ist in einem Gehäuse 1 eine Mehrzahl von rohrförmigen

bzw. zylinderförmigen Niederschlagselektroden 2 angeordnet.

Jeweils koaxial zur Achse der rohrförmigen Niederschlagselektroden

sind Drähte 3 gespannt, welche die Ausströmelektroden

ausbilden. Die rohrförmigen Niederschlagselektroden

sind gemeinsam mit dem Gehäuse 1 über eine Leitung 4 geerdet,

wohingegen die Ausströmelektroden 3 mit einer Hochspannungsquelle

5 verbunden sind. Die Ausströmelektroden 3 sind an einem

gemeinsamen Träger oder Halteteil 6 festgelegt, wobei die

unteren Enden dieser Ausströmelektroden an einen entsprechenden

Gegenhalter 7 festgelegt sind. Der Gegenhalter 7 ist relativ zum

Gehäuse 1 in einem Lager 8 gelagert.In Fig. 1 is a plurality of tubular in a

Das untere Ende des Gehäuses weist eine trichterförmige

Mündung 9 auf, welche durch einen Schieber 10 verschließbar ist.

In dieser trichterförmigen Mündung 9 sammelt sich der herabfallende

Staub, welcher durch Öffnen des Schiebers 10 entfernt

werden kann. Im Zuge des Betriebes legen sich an der Innenwand

der rohrförmigen bzw. zylinderförmigen Abscheide- bzw. Niederschlagselektroden

2 entsprechende Mengen an Feststoffen fest,

welche durch mechanische Reinigung wieder entfernt werden

müssen.The lower end of the housing is funnel-

Wie in Fig. 2 dargestellt, ist der obere Halteteil 6 für

die Ausströmelektroden 3 sternförmig ausgebildet und um eine

Achse 11 verschwenkbar gelagert. Die Verschwenkung kann im Sinne

des Doppelpfeiles 12 derart erfolgen, daß die Ausströmelektroden

3 in die Nähe der Innenwand 13 der Niederschlagselektroden

2 verschwenkt werden. Durch Verschwenken des Trägers

bzw. Halteteiles 6 können hiebei gleichzeitig alle Ausströmelektroden

3 in eine derartige Außerbetriebstellung verschwenkt

werden, sodaß der vollständige lichte Querschnitt der Abscheideelektroden

2 für eine mechanische Reinigung, beispielsweise

mittels Bürsten, freigegeben wird.As shown in Fig. 2, the

Der Vollständigkeit halber ist in Fig. 1 mit 14 der Gaseinlass und mit 15 der Gasauslass für das zu reinigende Gas bezeichnet.For the sake of completeness, 14 in FIG Gas inlet and at 15 the gas outlet for the gas to be cleaned designated.

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT00109289T ATE316824T1 (en) | 1999-05-03 | 2000-04-29 | TUBULAR ELECTRICAL FILTER WITH MOVABLE ELECTRODES |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0078699A AT408846B (en) | 1999-05-03 | 1999-05-03 | TUBE POWER FILTER |

| AT78699 | 1999-05-03 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1050341A2 true EP1050341A2 (en) | 2000-11-08 |

| EP1050341A3 EP1050341A3 (en) | 2001-01-17 |

| EP1050341B1 EP1050341B1 (en) | 2006-02-01 |

Family

ID=3499723

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00109289A Expired - Lifetime EP1050341B1 (en) | 1999-05-03 | 2000-04-29 | Tubular electrofilter with movable electrodes |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1050341B1 (en) |

| AT (2) | AT408846B (en) |

| DE (1) | DE50012144D1 (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2065094A2 (en) | 2007-11-27 | 2009-06-03 | Jörg Meister | Electrostatic precipitator |

| EP2036615A3 (en) * | 2007-09-13 | 2010-02-17 | Peter Buchta | Electric filter for a firing device |

| US8257469B2 (en) * | 2009-03-18 | 2012-09-04 | Meister Environment Technology Ltd. | Electrostatic filter |

| EP1967273A3 (en) * | 2007-03-05 | 2013-10-16 | Schmatloch Nückel Technologietransfer | Electrofilter for a small firing device |

| CN107684977A (en) * | 2017-08-30 | 2018-02-13 | 珠海格力电器股份有限公司 | A kind of electrodecontamination structure and include its air cleaning unit |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202007004263U1 (en) | 2007-02-16 | 2007-07-05 | Otto Spanner Gmbh | Electric filter for cleaning flue gas, has electrode arrangement comprising spraying electrode and precipitation electrode, where one of electrodes is provided with electrically conducting coating on surface facing filter space |

| DE102007061199B4 (en) * | 2007-12-16 | 2010-02-11 | Elituus Ltd. & Co. Kg | Power plant and process for the treatment of process air from power plants |

| AU2020342698B2 (en) | 2019-09-03 | 2022-06-30 | Sl-Technik Gmbh | Biomass heating plant with optimised flue gas treatment |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2443662A (en) * | 1945-12-29 | 1948-06-22 | Westinghouse Electric Corp | Electrostatic dust precipitator |

| EP0397208A2 (en) * | 1989-05-12 | 1990-11-14 | FRITZ EGGER GESELLSCHAFT m.b.H. | Electrostatic precipitator for gas cleaning |

| AT394664B (en) * | 1989-05-02 | 1992-05-25 | Scheuch Alois Gmbh | Electrostatic granular-bed filter system |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE452956B (en) * | 1984-11-05 | 1988-01-04 | Flaekt Ab | FOR A MULTIPLE EMISSION ELECTRODES DETERMINED FAST HOLDING DEVICE |

| JPH10151363A (en) * | 1996-11-26 | 1998-06-09 | Shinwa Corp | Multicylinder electric precipitator |

-

1999

- 1999-05-03 AT AT0078699A patent/AT408846B/en not_active IP Right Cessation

-

2000

- 2000-04-29 DE DE50012144T patent/DE50012144D1/en not_active Expired - Lifetime

- 2000-04-29 AT AT00109289T patent/ATE316824T1/en not_active IP Right Cessation

- 2000-04-29 EP EP00109289A patent/EP1050341B1/en not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2443662A (en) * | 1945-12-29 | 1948-06-22 | Westinghouse Electric Corp | Electrostatic dust precipitator |

| AT394664B (en) * | 1989-05-02 | 1992-05-25 | Scheuch Alois Gmbh | Electrostatic granular-bed filter system |

| EP0397208A2 (en) * | 1989-05-12 | 1990-11-14 | FRITZ EGGER GESELLSCHAFT m.b.H. | Electrostatic precipitator for gas cleaning |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1967273A3 (en) * | 2007-03-05 | 2013-10-16 | Schmatloch Nückel Technologietransfer | Electrofilter for a small firing device |

| EP2036615A3 (en) * | 2007-09-13 | 2010-02-17 | Peter Buchta | Electric filter for a firing device |

| EP2065094A2 (en) | 2007-11-27 | 2009-06-03 | Jörg Meister | Electrostatic precipitator |

| US8257469B2 (en) * | 2009-03-18 | 2012-09-04 | Meister Environment Technology Ltd. | Electrostatic filter |

| CN107684977A (en) * | 2017-08-30 | 2018-02-13 | 珠海格力电器股份有限公司 | A kind of electrodecontamination structure and include its air cleaning unit |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1050341B1 (en) | 2006-02-01 |

| ATE316824T1 (en) | 2006-02-15 |

| DE50012144D1 (en) | 2006-04-13 |

| AT408846B (en) | 2002-03-25 |

| EP1050341A3 (en) | 2001-01-17 |

| ATA78699A (en) | 2001-08-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE202007004263U1 (en) | Electric filter for cleaning flue gas, has electrode arrangement comprising spraying electrode and precipitation electrode, where one of electrodes is provided with electrically conducting coating on surface facing filter space | |

| AT408843B (en) | DUST FILTER | |

| EP1050341A2 (en) | Tubular electrofilter with movable electrodes | |

| DE3626002C2 (en) | ||

| DE102011052946A1 (en) | Electrical separation device for filtering particles from gas flow by electrostatic separation, has inlet and suction openings that are arranged so that gas flows to collector through flow channel along wave crest extending direction | |

| EP2189223A1 (en) | Wet cleaning electric filter for cleaning exhaust gas and method suitable for this | |

| DE4326757A1 (en) | Electrostatic dust filter with rotating precipitator plates - has tangential dirty gas inlet channel for uniform dust pptn. on all precipitator plates | |

| EP2062649B1 (en) | Electrostatic separator with particulate rejection means, heating system and method for operation | |

| DE425039C (en) | Process for the electrical purification of gases | |

| DE102006009765B4 (en) | Tube electrostatic precipitator | |

| EP3025785B1 (en) | Device and method for purification of flue gas of a metallurgical plant | |

| AT393969B (en) | METHOD FOR CLEANING THE IONIZATION ELECTRODES AND THE RAW GAS SPACE IN AN ELECTRIC PROPELLER FILTER FILTER SYSTEM AND A SYSTEM WITH WHICH THE SAME METHOD IS APPLIED | |

| DE3230709A1 (en) | Dust cyclone and process for the operation of such a dust cyclone | |

| DE202019101213U1 (en) | Electrostatic particle separation device | |

| EP2108457A2 (en) | Chimney system with electrostatic precipitator | |

| LU84410A1 (en) | DEVICE FOR ELIMINATING OR AVOIDING WALL DEPOSITS IN SPRAY DRYERS FOR NEUTRALIZING ACID OR ACID-CONTAINING POLLUTANTS IN THE SMOKE GAS FROM COMBUSTION SYSTEMS | |

| DE588707C (en) | Device for the electrical separation and recovery of dust-like substances from gases | |

| DE19613720C2 (en) | Dust separator and method for dust separation for an electrostatic filter | |

| DE19823342C2 (en) | electrostatic precipitator | |

| DE939990C (en) | Frictional electrostatic precipitator | |

| DE347364C (en) | Device for blowing off the dust from the emission and collecting electrodes of electrical gas cleaning systems | |

| DE739257C (en) | Electric gas purifier | |

| EP0352451A2 (en) | Electrofilter | |

| DE2428046B2 (en) | GAS EXTRACTION DEVICE | |

| DE2134165A1 (en) | ELECTRIC FILTERS, IN PARTICULAR WET ELECTRIC FILTERS |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7B 03C 3/74 A, 7B 03C 3/86 B, 7B 03C 3/06 B, 7B 03C 3/41 B |

|

| 17P | Request for examination filed |

Effective date: 20010208 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20030521 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 20060201 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060201 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060201 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060201 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060201 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50012144 Country of ref document: DE Date of ref document: 20060413 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060501 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060512 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060703 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20060201 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20061103 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060502 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070323 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060201 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20081203 Year of fee payment: 9 |

|

| BERE | Be: lapsed |

Owner name: FORSTHUBER, PAUL Effective date: 20090430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090430 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: APF ADVANCED PARTICLE FILTERS GMBH Free format text: FORSTHUBER, PAUL#NIEDERALM 78#A-5081 ANIF (AT) -TRANSFER TO- APF ADVANCED PARTICLE FILTERS GMBH#HANNAKSTRASSE 3A#5023 SALZBURG-GNIGL (AT) Ref country code: CH Ref legal event code: NV Representative=s name: OK PAT AG PATENTE MARKEN LIZENZEN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 50012144 Country of ref document: DE Owner name: APF ADVANCED PARTICLE FILTERS GMBH, AT Free format text: FORMER OWNER: FORSTHUBER, PAUL, ANIF, AT Effective date: 20130107 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20160830 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50012144 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20171103 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AECN Free format text: DAS PATENT IST AUFGRUND DES WEITERBEHANDLUNGSANTRAGS VOM 23.01.2018 REAKTIVIERT WORDEN. |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170430 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: LI Effective date: 20180124 Ref country code: CH Effective date: 20180124 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R124 Ref document number: 50012144 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20190604 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |