EP1003003A3 - Grinding room arrangement to install in a building - Google Patents

Grinding room arrangement to install in a building Download PDFInfo

- Publication number

- EP1003003A3 EP1003003A3 EP99122605A EP99122605A EP1003003A3 EP 1003003 A3 EP1003003 A3 EP 1003003A3 EP 99122605 A EP99122605 A EP 99122605A EP 99122605 A EP99122605 A EP 99122605A EP 1003003 A3 EP1003003 A3 EP 1003003A3

- Authority

- EP

- European Patent Office

- Prior art keywords

- cabin

- grinding

- building

- install

- dust

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B55/00—Safety devices for grinding or polishing machines; Accessories fitted to grinding or polishing machines for keeping tools or parts of the machine in good working condition

- B24B55/06—Dust extraction equipment on grinding or polishing machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C9/00—Appurtenances of abrasive blasting machines or devices, e.g. working chambers, arrangements for handling used abrasive material

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Ventilation (AREA)

- Working Measures On Existing Buildindgs (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

- Prevention Of Fouling (AREA)

- Grinding-Machine Dressing And Accessory Apparatuses (AREA)

Abstract

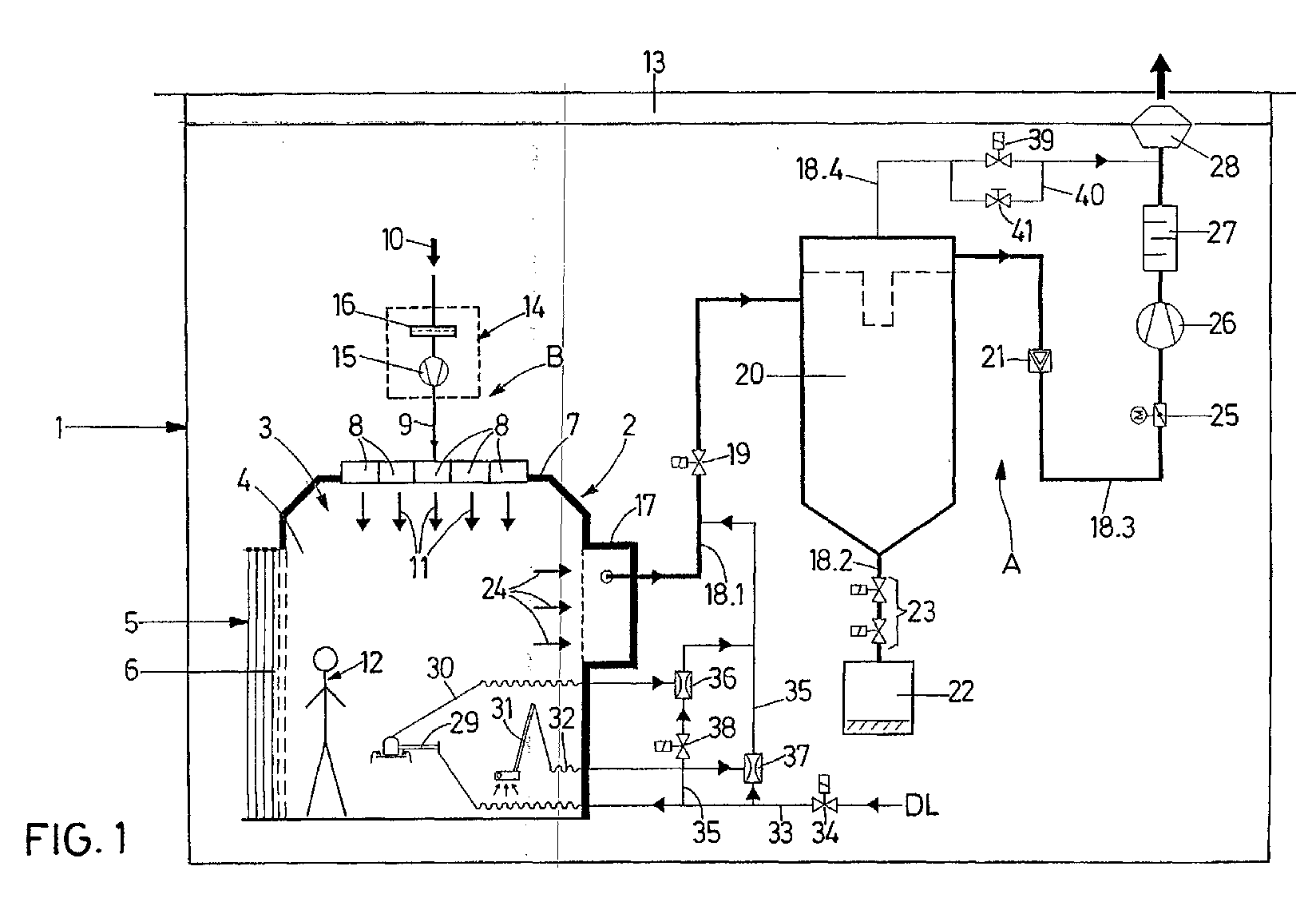

Eine Schleifkabinenanordnung zum Einbau in Gebäude ist versehen mit einer begehbaren Schleifkabine (3) mit Seitenwänden (4), einem abdeckbaren Eingang (5) und einer Decke (7), einer Schleifeinrichtung (29) in der Kabine (3) zur staubenden Bearbeitung von Werkstücken, einer Belüftungseinrichtung (B) zur Klimatisierung und Erzeugung einer gegen Staub schützenden Luftströmung (11) in der Kabine (3), und einer Staubabsaugeinrichtung (A) zur Wegführung der bei der Bearbeitung entstehenden Stäube, wobei die Belüftungseinrichtung (B) aus einzelnen, in die rasterartig aufgebaute Decke (7) eingesetzten Ventilationsmodulen (8) besteht, die jeweils ihre Zuluft (9) direkt aus dem Gebäude (1) beziehen. A grinding cabin arrangement for installation in buildings is provided with a walk-in grinding cabin (3) with side walls (4), a coverable entrance (5) and a ceiling (7), a grinding device (29) in the cabin (3) for the dusty machining of workpieces , a ventilation device (B) for air conditioning and generation of a dust-protecting air flow (11) in the cabin (3), and a dust extraction device (A) for guiding away the dust generated during processing, the ventilation device (B) consisting of individual, in the grid-like ceiling (7) used ventilation modules (8), each of which draw their supply air (9) directly from the building (1).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29820577U DE29820577U1 (en) | 1998-11-18 | 1998-11-18 | Grinding cabin arrangement for installation in buildings |

| DE29820577U | 1998-11-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1003003A2 EP1003003A2 (en) | 2000-05-24 |

| EP1003003A3 true EP1003003A3 (en) | 2003-05-21 |

Family

ID=8065471

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99122605A Withdrawn EP1003003A3 (en) | 1998-11-18 | 1999-11-13 | Grinding room arrangement to install in a building |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1003003A3 (en) |

| DE (1) | DE29820577U1 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10302594A1 (en) * | 2003-01-22 | 2004-07-29 | Oellerich, Jörn | Surface preparation of plastic, in particular carbon fiber reinforced plastic, surfaces, involves use of a gas jet containing abrasive |

| CN111113220B (en) * | 2019-11-14 | 2021-06-01 | 湖州双金机械配件有限公司 | Be used for high manganese cast steel production auxiliary device for pouring |

| CN112108999A (en) * | 2020-09-27 | 2020-12-22 | 宁波博尔钛新能源设备有限公司 | Polishing and dust removing device |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2696910A (en) * | 1948-06-09 | 1954-12-14 | Svenska Flaektfabriken Ab | Method and apparatus for separating waste particles from media used in sandblasting |

| US3407719A (en) * | 1967-04-28 | 1968-10-29 | Zero Mfg Company | Blast room with uniform down-draft ventilation |

| US5063834A (en) * | 1988-06-10 | 1991-11-12 | Halton Oy | Focussed ventilation procedure and focussed ventilation means |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29515615U1 (en) | 1995-10-02 | 1996-03-21 | GOSAG Stahl- und Anlagenbau GmbH, 06308 Klostermansfeld | Work cabin system for cleaning and surface treatment of objects |

-

1998

- 1998-11-18 DE DE29820577U patent/DE29820577U1/en not_active Expired - Lifetime

-

1999

- 1999-11-13 EP EP99122605A patent/EP1003003A3/en not_active Withdrawn

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2696910A (en) * | 1948-06-09 | 1954-12-14 | Svenska Flaektfabriken Ab | Method and apparatus for separating waste particles from media used in sandblasting |

| US3407719A (en) * | 1967-04-28 | 1968-10-29 | Zero Mfg Company | Blast room with uniform down-draft ventilation |

| US5063834A (en) * | 1988-06-10 | 1991-11-12 | Halton Oy | Focussed ventilation procedure and focussed ventilation means |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1003003A2 (en) | 2000-05-24 |

| DE29820577U1 (en) | 1999-01-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH708655A1 (en) | Air purifier with ozone and particulate matter cleaning. | |

| DE69915367D1 (en) | METHOD AND DEVICE FOR VENTILATING A CLEAN ROOM | |

| SE515895C2 (en) | Air filtration device, method and system | |

| EP1003003A3 (en) | Grinding room arrangement to install in a building | |

| EP3643975A1 (en) | Ventilation device for interior rooms of residential and business premises | |

| JPH064125B2 (en) | Clean bench | |

| KR20180044546A (en) | Air cleaning system using natural convection | |

| EP0962720A3 (en) | Ventilation structure of planarization chamber | |

| ATE138181T1 (en) | DISCUSSION AIR DUCT FOR INDOOR AIR CONDITIONING SYSTEMS | |

| KR20160087243A (en) | Sanding Booth for low dust type | |

| EP1096208A3 (en) | Room ventilation system for air collector units in a building using ducting arrangements and method for using the same | |

| JPS62268941A (en) | clean room | |

| JPH0424037Y2 (en) | ||

| JPS61168735A (en) | Clean room | |

| DE60113904T2 (en) | Work cabin for natural stone with controlled atmosphere | |

| EP0805313A3 (en) | Ventilation outlet | |

| CN211676750U (en) | Waste gas collecting system of gantry paint spraying shed | |

| JPS57207738A (en) | Ventilating device for whole facility of factory | |

| DE102010003100B4 (en) | Apparatus and method for heating church spaces and / or large rooms | |

| JP3502994B2 (en) | Oil mist transport method | |

| DE59803301D1 (en) | Measuring room with air conditioning | |

| JPH0467094B2 (en) | ||

| DE102007005870B4 (en) | wall element | |

| CN206867883U (en) | A kind of built-in experimental animal cage box return air filtering | |

| JPH02243882A (en) | Clean room |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7B 24C 9/00 B Ipc: 7B 24B 55/06 B Ipc: 7F 24F 3/16 A |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: LOY, JUERGEN |

|

| 17P | Request for examination filed |

Effective date: 20030617 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20050301 |