EP0931997A2 - Verschliessbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut - Google Patents

Verschliessbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut Download PDFInfo

- Publication number

- EP0931997A2 EP0931997A2 EP99100936A EP99100936A EP0931997A2 EP 0931997 A2 EP0931997 A2 EP 0931997A2 EP 99100936 A EP99100936 A EP 99100936A EP 99100936 A EP99100936 A EP 99100936A EP 0931997 A2 EP0931997 A2 EP 0931997A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- seal

- sealing gap

- container

- walls

- container according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000007789 sealing Methods 0.000 claims abstract description 89

- 239000004744 fabric Substances 0.000 claims description 6

- 230000015572 biosynthetic process Effects 0.000 claims description 4

- 238000009413 insulation Methods 0.000 claims description 4

- 238000007788 roughening Methods 0.000 claims description 3

- 238000009833 condensation Methods 0.000 description 9

- 230000005494 condensation Effects 0.000 description 9

- 239000000463 material Substances 0.000 description 5

- 230000000694 effects Effects 0.000 description 4

- 229920001821 foam rubber Polymers 0.000 description 4

- 230000014759 maintenance of location Effects 0.000 description 4

- 230000002829 reductive effect Effects 0.000 description 4

- 230000036961 partial effect Effects 0.000 description 3

- 238000001816 cooling Methods 0.000 description 2

- 239000013013 elastic material Substances 0.000 description 2

- 238000005057 refrigeration Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000001413 cellular effect Effects 0.000 description 1

- 210000003850 cellular structure Anatomy 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 230000005489 elastic deformation Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- PXHVJJICTQNCMI-UHFFFAOYSA-N nickel Substances [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 238000007665 sagging Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25D—REFRIGERATORS; COLD ROOMS; ICE-BOXES; COOLING OR FREEZING APPARATUS NOT OTHERWISE PROVIDED FOR

- F25D23/00—General constructional features

- F25D23/08—Parts formed wholly or mainly of plastics materials

- F25D23/082—Strips

- F25D23/087—Sealing strips

Definitions

- the invention relates to a lockable Container for holding before temperature changes goods to be protected, in particular refrigerated goods, with at least one closure element, the at least a seal that takes effect in the closed position is assigned for the respective sealing gap.

- Known closable containers of the The aforementioned genus are e.g. B. refrigeration cabinets whose Locking elements as doors or drawers are trained.

- the container is common equipped with a refrigerator so that the Temperature inside the container for Cooling of the refrigerated goods can be lowered accordingly can.

- the one Avoids heat conduction through the wall.

- Sealing gap assigned a seal, so that the Sealing gap in the closed position of the respective Closure element is sealed.

- the invention is based on the object Container of the aforementioned type to provide which regarding its Isolation, especially in terms of Condensation critical area of everyone Closure element associated sealing gap is improved.

- each seal is an extruded profile, which, following the course of the respective sealing gap, is attached such that the seal at least partially with predetermined ones Profile areas located in the sealing gap, and that at least the predetermined profile area of the Seal is elastically deformable, such that resulting from closing forces Contact pressure to fill in the form-fitting Sealing gap leading flattening of the seal causes, the attachment of the seal such is that formed by the flattening Sealing surfaces of the seal on one walls of the respective sealing gap Container or the closure element so concern that in the area of a Dew point sections of the walls, that limit a sealing gap are covered.

- the dimensioning and shaping of the profile of the Seal are essentially involved profile areas chosen that the seal, or its profile areas the predetermined width of the predetermined At least fill in the sealing gap.

- the closed position press the sealing gap bounding walls of the container or Closure element thus the seal, at least however, their elastically deformable profile area so together that the seal adheres to this Walls optimally created, the in the area of a Dew point lying sections of the walls bounding each sealing gap be completely covered.

- the covered Sections of the walls are therefore not in contact with Air, so that condensation in the air contained moisture in an advantageous manner in these critical areas is prevented.

- the with unwanted condensation There is therefore no danger of icing.

- This is especially for refrigerated cabinets with metallic Relevant surfaces that have a high Have thermal conductivity so that the dew point may lie outside the refrigerator.

- the predetermined profile areas each Seal from the inside of the container in extend the sealing gap.

- each Closure element may be arranged.

- the strand-shaped seal can for example be along the walls bounding the respective sealing gap of the closure element, which Locking element a door, a drawer or the like can be.

- the seal is with that Closure element for example glued or the like firmly connected.

- the seal releasably on the walls of the Closure element, for example by means of Screw connection, is attached.

- the walls of the closure element to the predetermined profile areas of the seal adapted Have shapes in which the extruded profile trained seal can be used form-fitting, z. B. can be inserted.

- any seal Sections of the respective sealing gap bounding walls of the container is held.

- the seal is thus arranged in a stationary manner.

- the seal can turn detachable or fixed with the sealing gap facing Sections of the inner walls of the container be connected.

- Sections of the walls of the container or Closure element are special after one advantageous training with breakthroughs provided that the cross-sectional area of each reduce openwork wall.

- the Breakthroughs in an advantageous manner for attachment of attachments and additional equipment.

- hinges, hinges or similar articulation elements for doors or Guides for drawers with corresponding, in engaging predetermined breakthroughs Fasteners are mounted.

- the Breakthroughs can also be used to attach Storage for the interior of the container dividing shelves can be used. Around to get a continuous surface that too the openings are easy to clean a poorly heat-conducting material, e.g. Silicone, be closed.

- Breakthroughs circular, but other z. B. oval, angular or the like forms of Breakthroughs are possible.

- the shape of the breakthroughs can the intended purpose, z. B. for attaching the closure elements or Fitted shelves.

- Multiple breakthroughs can e.g. B. be arranged in series, wherein preferably several rows of openings are arranged side by side.

- the breakthroughs adjacent rows are marked with particularly advantageous offset from each other, making one for heat conduction in the wall effective cross-section is further minimized.

- the thermal insulation property of a usually made of thermally insulating material existing gasket will advantageously improved in that as an extruded profile trained seal at least one cavity having.

- the cavity has a thermally insulating effect. Cavities can also be used to hold Braces are used.

- a preferred embodiment of the invention provides before that the seal is tubular is.

- a rubber-like plastic such as. B.

- Foam rubber used as a material for the Seal.

- Foam rubber has the advantage that because of its cellular structure, has low thermal conductivity and as an insulator works.

- Foam rubber is also beneficial forms pure so that an existing one Seal due to the special elastic Property of this material optimal to the walls or surfaces to be sealed.

- the tubular one Seal at least one form-keeping element.

- the form-keeping element can be one in the tubular seal received component in the design of a profile, the Profile shape depending on the design of the seal Sealing gap is arbitrarily selectable.

- Such Seal has the advantage that the shape specification by the profile designed as a form-keeping element by the contact pressure in the closed position of the Closure element caused elastic deformation the seal, especially its predetermined one Profile areas, so pretending that they adhere to the the respective sealing gap bounding walls of the Container or the closure element optimal hugs.

- the Shape retention elements can also be used to create a secure attachment of the seal to the Closure element or container, e.g. B. by Screw on as a form-keeping element trained profile on a sealing gap limiting wall, to ensure.

- the closure element in terms of size dimensioned to match the inside dimensions of the Container is adjusted and in the closed position an inside of the container is adjacent. If that Locking element is designed as a door, so So the door does not hit the wall of the Container, but is inserted inside.

- the seal is then conveniently on the end faces the closure element arranged so that the Seal between the inside of the container and the end faces of the closure element for Commitment comes.

- the seal is preferably designed so that the Seal on the surface a little Has coefficient of friction.

- elastic fabric layer can be achieved for example made of polyester and on the back with a soft elastic material is coated.

- rubber, Foam rubber or PVC are used.

- each predetermined Profile area of the seal made of thermal insulating and soft elastic material with a hardness ⁇ 70 Shore exists.

- Such one Material gives those who serve as contact surfaces Profile areas a high elastic Deformability, with which the profile areas optimal to any given shape of the can create walls that delimit a sealing gap.

- the entire seal can consist of such a material.

- the surface of the seal a fabric layer arranged on the seal.

- the predetermined profile areas the seal with a fabric layer Mistake.

- the whole Surface of the seal such a fabric layer have or can the entire seal from z. B. rubberized fabric.

- each one of the closure have the front panel serving the container, is next to that through the walls of the container and of the front panels of the drawers Sealing gap an additional, each between Walls of adjacent drawers To seal the sealing gap.

- This aspect of the invention can also be used as an independent inventive idea to be viewed as.

- the seal to seal the is thereby characterized that a front end of the seal a smaller width than the sealing gap between has the front panels of the drawers, and that a rear area of the seal behind the Front panels of the drawers of the drawers is arranged, the rear region of the Seal a larger width than the sealing gap between the front panels.

- the seal preferably runs between lateral inner walls of the container, the Seal with its free ends, e.g. B. means appropriately trained end brackets, each held stationary on the inner wall of the container is.

- the seal is arranged so that in the closed position of the drawers at least the predetermined profile areas of the seal from Inside of the container in the sealing gap extend into it.

- the seal preferably has a wedge-shaped cross-sectional shape in which the predetermined profile areas through the wedge flanks the wedge-shaped seal.

- the Wedge flanks of the elastically deformable seal nestle so close to the sealing gap bounding walls of the front panels of the drawers that in turn a large area of the Gasket is given to cover the im Range of a dew point temperature Sections of the walls of the front panels of the Drawers.

- the cross-sectional shape of the seal has the Advantage that the seal in the gap between the Front panels of the drawers even at very small gap widths is always securely threaded and thus an optimal sealing function inserted drawer or closed Container fulfilled.

- a development of the invention provides that Container as a refrigerator with at least two Drawers are formed, each one Closure of the refrigerator serving front panel have, and the front panels a front Form thermal insulation of the refrigerator, where in facing areas of the drawers at least one stationary seal is provided and the front panels of the Drawers through a sealing gap with a certain width spaced from each other are, each seal essentially in that Sealing gap is arranged between the front panels and at least a portion of each seal in the essentially the width of the sealing gap between the front panels.

- the seal can be between lateral Trending inside walls of the container Be hollow profile, the seal with their free ends, for example by means of trained end brackets, each on the Inner wall of the container is held stationary.

- the seal designed as a hollow profile can Example one designed as a shape-maintaining element Have profile, which for example an L or T-profile shape. With the shape retention element in addition to the shape specification, a stiffening of the Seal reached, so that a deflection or Sagging, especially with very long ones Sealing gaps that need to be sealed are avoided becomes.

- the Refrigerators With the provided seal, the Refrigerators the sealing gap between the front panels the drawers are securely sealed.

- the usable drawer height or the available cooling space of the refrigerator is larger than at hitherto known refrigeration units, because the width of the Seal only slightly larger than the width of the There is a sealing gap between the drawers and thus the available drawer height is not determined by the Seal is limited.

- the previously known Refrigerators will be the drawer height or the Cold room through one for attaching the seal required cross rail considerably limited because the width of the cross rail is much larger than is the width of the sealing gap.

- a front end of the Seal a smaller width than the sealing gap between the front panels of the drawers, and that a rear area of the seal is behind the front panels of the drawers are arranged, the rear area of the seal being a larger one Width than the sealing gap between the front panels having.

- the seal ensures that the sealing gap is completely sealed and the critical with regard to condensation Sections of the walls delimiting the sealing gap the front panels of the drawers are covered.

- the cross-sectional shape of the seal is preferred wedge-shaped, the predetermined Profile areas formed by the wedge flanks become.

- the one wedge-shaped cross-sectional shape having seal compared to others possible cross-sectional shapes the advantage that even with very small widths of the sealing gap the seal securely in the sealing gap between the inserted drawers can be threaded.

- the seal on the front panels of the Drawers can be arranged, the seal for Example is designed as a brush.

- the one Sealing gap delimiting walls of the front panels Drawers can each have a brush have trained seal, so that the Sealing gap when closed or inserted Drawers are sealed by the brushes.

- Fig. 1 is a closable container 1 for Recording of temperature changes before protective goods, especially refrigerated goods, with a Shutter element 2 shown.

- the box-shaped Container 1 has on its front 3 Opening 4 with a door 5 trained closure element 2 closed can be, the container 1 in Fig. 1 in partially opened position is shown.

- Of the Interior of the container 1 is parallel shelves 22 one above the other equipped on which the goods to be cooled is discardable.

- the locking element 2 designed as a door 5 is struck on an inner wall of the container 1, the door 5 is effective in the closed position expectant seal 6 is assigned.

- the seal 6 is as along the end walls 19 of the door 5th extending extruded profile 7 is formed.

- the seal 6 is one through walls of the Container 1 and the closure element 2 limited sealing gap 9 assigned.

- Walls the Limit sealing gap 9 include the walls in the Closure area of the container 1, e.g. B. the Walls 8, as well as the walls on the closure element 2, e.g. B. the end walls 19 which, in Closed position of the closure element 2, also are in the closure area of the container 1.

- the walls delimiting the sealing gap 9 have in Row arranged openings 21 on here are circular, with adjacent Breakthrough rows staggered are.

- FIG. 2 is a container 1 'with another Execution of closure elements shown.

- the Container 1 ' is also box-shaped, however, has two as the closure element 2 ' Drawers 11, 11 'arranged one above the other.

- the drawers 11, 11 'each have one Front plate 12, 12 ', which, when inserted Drawers, the front closure of the Serve container 1 '.

- On the front panels 12, 12 ' are attached in the middle to handle 13,13 ' each in a drawer of a container 1 'drawers held and pushed out 11,11 'to be able to operate.

- the drawers too 11, 11 ' have an effect in the closed position becoming seal 6 ', which one through walls of Container 1 'or the closure elements 2' limited sealing gap 9 'is assigned.

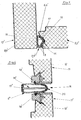

- the seal 6, 6 'shown in Fig. 3 can two versions of a container for Sealing of the walls of the container 1,1 ' and the closure elements 2,2 'limited Sealing gap 9.9 'can be used.

- the cut one Partial view of the container 1, 1 ' shows a Closure element 2,2 'in the closed position, the Locking element 2,2 'as door 5 or drawer 11, 11 'can be formed.

- the one in the sealing gap 9,9 'arranged seal 6,6' is as tubular extruded profile 7, has thus a cavity 15.

- the seal 6.6 ' has a shape retention element 16, which as in the cavity 15 insertable profile 17th is trained.

- the profile 17 has approximately the shape of a V profile.

- the contact forces acting in the closed position deform the seal 6,6 'such that the predetermined profile areas 18 to the Sealing gap 9,9 'delimiting walls of the container 1.1 'and the closure elements 2.2' nestle, wherein the seal 6,6 'the sealing gap 9,9' form-fitting fills in the area of a Dew point sections of the walls of the container 1,1 'or the closure elements 2.2 'completely covers and thus one prevents unwanted condensation.

- the sealing element 6 ′′ which is the between the front plates 12, 12 ' adjacent drawers 11,11 'formed Sealing gap 14 seals.

- the tubular one Seal 6 ′′ has an approximately wedge-shaped Cross-sectional shape, the hose being a Formholding element 16 'encloses.

- the Shape retention element 16 ' is a profile 17', which has a double T-shaped profile shape. That as Sheet metal formed profile 17 'is in the range of front end of the seal 6 '' on both sides angled, which rounds the profile 17 ' 20 has mechanical damage to the Prevent seal 6 ''. In the field of Rounding the profile 17 'can Cellular foam insert and the like upholstery be arranged in addition to the seal mechanical damage in this area Tips or edges of the profile 17 'advantageously protect.

- the seal 6 '' extends in the closed position of the drawers 11, 11 'from the inside of the Container 1 'into the sealing gap 14, the seal 6 '' through which Closing forces of the drawers 11, 11 'resulting Contact pressure, form-fitting the sealing gap 14 fills out.

- the seal 6 '' By flattening the predetermined Profile areas 18 'of the seal 6' 'nestles the seal 6, 6 'to the sealing gap 14 bounding walls of the front panels 12, 12 'of Drawers 11, 11 '.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Gasket Seals (AREA)

- Refrigerator Housings (AREA)

Abstract

Description

- Fig. 1

- eine schematische Ansicht eines Behältnisses mit einer Tür als Verschlußelement,

- Fig. 2

- eine schematische Ansicht eines Behältnisses mit Schubladen als Verschlußelement,

- Fig. 3

- eine Teilansicht eines Behältnisses im Schnitt mit in Schließstellung befindlichem Verschlußelement und

- Fig. 4

- zwei als Schubladen vorliegende Verschlußelemente in Schließstellung in einer geschnittenen Teilansicht.

Claims (14)

- Verschließbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut, mit mindestens einem Verschlußelement, dem wenigstens eine in Schließstellung wirksam werdende Dichtung für den jeweiligen Dichtspalt zugeordnet ist, dadurch gekennzeichnet,

daß jede Dichtung (6,6',6'') ein Strangprofil (7) ist, welches, dem Verlauf des jeweiligen Dichtspaltes (9,9',14) folgend, derart angebracht ist, daß sich die Dichtung (6,6' ,6'') wenigstens teilweise mit vorbestimmten Profilbereichen (18,18') in dem Dichtspalt (9,9',14) befindet, und daß wenigstens der vorbestimmte Profilbereich (18,18') der Dichtung (6,6',6'') elastisch verformbar ausgebildet ist, derart, daß aus Schließkräften resultierender Anpreßdruck ein zum formschlüssigen Ausfüllen des Dichtspaltes (9,9',14) führendes Abplatten der Dichtung (6,6',6'') bewirkt, wobei die Anbringung der Dichtung (6,6',6'') derart getroffen ist, daß durch die Abplattung gebildete Schmiegeflächen der Dichtung (6,6',6'') an den einen jeweiligen Dichtspalt (9,9',14) begrenzenden Wänden des Behältnisses (1,1') bzw. des Verschlußelementes (2,2') so anliegen, daß die im Bereich einer Taupunkttemperatur liegenden Abschnitte der Wände, die einen Dichtspalt (9,9',14) begrenzen, abgedeckt sind. - Behältnis nach Anspruch 1, dadurch gekennzeichnet, daß sich die vorbestimmten Profilbereiche (18,18') jeder Dichtung (6,6',6'') vom Innenbereich des Behältnisses (1,1') aus in den Dichtspalt (9,9',14) hinein erstrecken.

- Behältnis nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß jede Dichtung (6,6',6'') jeweils an den an der Bildung des Dichtspalts (9,9',14) beteiligten Abschnitten der Wände jedes Verschlußelements (2,2') angeordnet ist.

- Behältnis nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß jede Dichtung (6,6',6'') an Abschnitten der Wände des Behältnisses (1,1') gehalten ist.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die im Bereich der Taupunkttemperatur liegenden Abschnitte der Wände des Behältnisses (1,1') bzw. des Verschlußelementes (2,2') Durchbrüche (21) aufweisen, die die Querschnittsfläche der jeweils durchbrochenen Wand verringern.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß jede als Strangprofil (7) ausgebildete Dichtung (6,6',6'') wenigstens einen Hohlraum (15) aufweist.

- Behältnis nach Anspruch 6, dadurch gekennzeichnet, daß die Dichtung (6,6',6'') wenigstens ein Formhaltungselement (16,16') aufweist.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß das Verschlußelement (2,2') in Schließstellung an Innwände des Behältnisses angrenzt.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die Dichtung (6,6',6'') an der Stirnwand des Verschlußelements (2,2') angeordnet ist.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die Dichtung (6,6',6'') eine Oberfläche mit einem kleinen Reibungskoeffizienten aufweist.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß die vorbestimmten Profilbereiche (18,18') der Dichtung (6,6',6'') zumindest abschnittsweise eine aufrauhende Oberflächenstruktur besitzen.

- Behältnis nach Anspruch 11, dadurch gekennzeichnet, daß die aufrauhende Oberfächenstruktur der Dichtung (6,6',6'') durch ein Gewebe gebildet ist und daß das Gewebe eine an der Dichtung (6,6',6'') befindliche Gewebelage ist.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß insbesondere bei der Verwendung von Schubladen als Verschlußelemente ein vorderes Ende der Dichtung (6'') eine kleinere Breite als der Dichtspalt (14) zwischen den Frontplatten (12,12') der Schublade (11,11') aufweist, und daß ein hinterer Bereich der Dichtung (6'') hinter den Frontplatten (12,12') der Schubladen (11,11') angeordnet ist, wobei der hintere Bereich der Dichtung (6'') eine größere Breite als der Dichtspalt (14) zwischen den Frontplatten (12,12') aufweist.

- Behältnis nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, daß es als Kühlmöbel mit mindestens zwei Schubladen (11,11') ausgebildet ist, die jeweils eine dem Verschluß des Kühlmöbels dienende Frontplatte (12,12') aufweisen, und die Frontplatten (12,12') eine vorderseitige thermische Isolierung des Kühlmöbels bilden, wobei in einander zugekehrten Bereichen der Schubläden (11,11') wenigstens eine ortsfest angeordnete Dichtung (6'') vorgesehen ist und wobei die Frontplatten (12,12') der Schubläden (11,11') durch einen Dichtspalt (14) mit einer bestimmten Breite beabstandet zueinander angeordnet sind, jede Dichtung (6'') im wesentlichen in dem Dichtspalt (14) zwischen den Frontplatten (12,12') angeordnet ist und mindestens ein Teilbereich jeder Dichtung (6'') im wesentlichen die Breite des Dichtspaltes (14) zwischen den Frontplatten (12,12') aufweist.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19801965 | 1998-01-21 | ||

| DE1998101965 DE19801965A1 (de) | 1998-01-21 | 1998-01-21 | Kühlmöbel |

| DE1998110107 DE19810107A1 (de) | 1998-03-10 | 1998-03-10 | Verschließbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut |

| DE19810107 | 1998-03-10 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0931997A2 true EP0931997A2 (de) | 1999-07-28 |

| EP0931997A3 EP0931997A3 (de) | 1999-09-29 |

Family

ID=26043227

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99100936A Withdrawn EP0931997A3 (de) | 1998-01-21 | 1999-01-20 | Verschliessbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0931997A3 (de) |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1917353A1 (de) * | 1953-07-10 | 1970-11-05 | Canfield Co Gmbh H O | Befestigungsleiste am Dichtungsfuss von Hohlprofildichtungen |

| US3037251A (en) * | 1959-04-08 | 1962-06-05 | Robert L Landis | Sealing gaskets |

| US4173378A (en) * | 1978-07-31 | 1979-11-06 | White Consolidated Industries, Inc. | Refrigerator sealed food storage drawer |

| DE3329086C1 (de) * | 1983-08-11 | 1984-10-25 | Bosch-Siemens Hausgeräte GmbH, 7000 Stuttgart | Dichtungsprofil |

| US4538380A (en) * | 1983-11-16 | 1985-09-03 | Profile Extrusions Company | Low friction weather seal |

| GB8622822D0 (en) * | 1986-09-23 | 1986-10-29 | Commercial Vehicle Roofs Ltd | Sealing stripping for doors |

| US4860495A (en) * | 1987-12-23 | 1989-08-29 | Gerald Kessler | Low friction plastic weatherstrip |

| US5117587A (en) * | 1991-05-02 | 1992-06-02 | Rjf International Corporation | Sealing structure |

| DE19546984C2 (de) * | 1995-12-15 | 1999-07-22 | Hans Simon | Tiefkühl- und/oder Kühlschrank |

-

1999

- 1999-01-20 EP EP99100936A patent/EP0931997A3/de not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| EP0931997A3 (de) | 1999-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1937919B1 (de) | Möbelverschluss | |

| DE20321760U1 (de) | Tür mit Isolierverglasung und damit ausgestattetes Haushaltsgerät | |

| EP2059738B1 (de) | Kältegerät mit druckausgleichsventil | |

| DE112006000797B4 (de) | Dichtungskonstruktion für einen Kühlschrank | |

| DE202013012172U1 (de) | Kühlschrank | |

| EP3023035B1 (de) | Warenpräsentationsmöbel sowie details eines warenpräsentationsmöbels | |

| EP1957904B1 (de) | Kältegerät mit dekorrahmen | |

| EP1633224B1 (de) | Tür mit isolierverglasung und damit ausgestattetes haushaltsgerät | |

| DE102012010028A1 (de) | Rahmenanordnung für ein sektionaltorpaneel | |

| EP1651914B1 (de) | Dichtungsprofil für einen kühlgeräteschiebedeckel | |

| DE2521185A1 (de) | Verfahren und vorrichtung zur herstellung eines kuehlmoebels | |

| EP0931997A2 (de) | Verschliessbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut | |

| DE102009031278A1 (de) | Lebensmittel-Kühltruhe und Abdeckung hierfür | |

| DE102007008707A1 (de) | Kühlgerät | |

| DE102007062024A1 (de) | Kältegerät | |

| DE19810107A1 (de) | Verschließbares Behältnis zur Aufnahme von vor Temperaturänderungen zu schützendem Gut, insbesondere Kühlgut | |

| DE102006018424A1 (de) | Tür für ein Kältegerät | |

| EP1866585B1 (de) | Kühl- und/oder gefriergerät | |

| EP0213310B1 (de) | Aus Kunststoff extrudiertes Profil für Kühlschränke oder dergleichen | |

| DE102008021375A1 (de) | Kältegerät mit Druckausgleichsventil | |

| DE102011005892A1 (de) | Haushaltsgerät, insbesondere Kältegerät | |

| DE102012000342B4 (de) | Isolliertes Tor, insbesondere Kühlraumtor oder dergleichen | |

| DE102005043359A1 (de) | Modulares Kältegerät | |

| DE102021107667A1 (de) | Tür für einen Tiefkühlraum | |

| DE10154934A1 (de) | Kältegerät mit abgedichteter Tür |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 6F 25D 23/08 A, 6F 25D 25/02 B |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20000330 |