EP0908680A1 - Appareil de combustion pour combustible liquide et meche de combustion - Google Patents

Appareil de combustion pour combustible liquide et meche de combustion Download PDFInfo

- Publication number

- EP0908680A1 EP0908680A1 EP98902244A EP98902244A EP0908680A1 EP 0908680 A1 EP0908680 A1 EP 0908680A1 EP 98902244 A EP98902244 A EP 98902244A EP 98902244 A EP98902244 A EP 98902244A EP 0908680 A1 EP0908680 A1 EP 0908680A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wick

- flame

- liquid fuel

- producing section

- section

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23Q—IGNITION; EXTINGUISHING-DEVICES

- F23Q1/00—Mechanical igniters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23Q—IGNITION; EXTINGUISHING-DEVICES

- F23Q2/00—Lighters containing fuel, e.g. for cigarettes

- F23Q2/34—Component parts or accessories

- F23Q2/44—Wicks; Wick guides or fastenings

Definitions

- This invention relates to a wick that draws up to be burned a liquid fuel in a lighter or other liquid fuel burner using an alcohol fuel or the like and to a liquid fuel burner equipped with the wick.

- An alcohol fuel such as ethyl alcohol, a benzine fuel of the petroleum benzine type or a liquid gas fuel such as butane gas or propane gas is generally used as the fuel of a cigarette lighter, fire-lighting device, torch, lamp or other such burner.

- the performance, ease of use, and structural design of such burners differs depending on the kind of fuel used, and each has its own characteristics.

- the gas pressure is high in the use temperature range of the burner and the vessel storing the fuel has to have a pressure-resistant structure.

- the flame length changes with variation in the gas pressure and since it is a characteristic of the gas pressure to vary logarithmically and greatly with temperature, large change in flame length with temperature becomes a particular problem.

- the fuel supply mechanism of the burner requires a special design countermeasure for effecting temperature compensation, which complicates the structure and is disadvantageous from the aspect of cost.

- the means used to supply the liquid fuel from the fuel storage section to the flame-producing section is generally a wick that utilizes the surface tension of the liquid fuel to draw it up through continuous fine holes or fine voids among bundled fibers by capillarity and burns it at the tip portion thereof.

- the wick used for drawing up the fuel is a string-like one obtained by twisting fibers, one obtained by bundling fibers, one using both of these with the glass fibers enclosed in cotton yarn and the result interwoven with fine metal wires to prevent disintegration, or the like, whose the lower end portion functions to draw up fuel to be burned at the upper end tip portion.

- the flame-producing section of the wick has to be sealed by an openable/closable closure cap in order to prevent evaporation of the liquid fuel during nonuse.

- a striker wheel or other igniter must be installed near the wick for scattering sparks to light the wick.

- the closure cap Since the closure cap is ordinarily installed to open and close about a pivot at one end portion thereof, its cap portion for sealing the flame-producing section of the wick passes along an arcuate path and, therefore, when it is attempted to make such a lighter or other burner compact, the need to prevent interference of this path with the wick tip portion, the wick holder, the striker wheel etc. hinders the size reduction.

- the sealing end portion of the closure cap must interpose between the wick holder portion and the igniter, e.g., striker wheel, in order to enable covering of the peripheral portion of the wick holder portion, and if the igniter is spaced away from the wick in order to avoid interference of the sealing end portion with the igniter, a problem of igniting performance degradation may arise because of, for example, the elongated spark travel distance. Good igniting performance is therefore preferably secured by disposing the igniter near the wick.

- the igniter e.g., striker wheel

- the igniter when the igniter is installed closer to the wick, the flow of air around the flame changes to impede inflow of secondary air to the flame in proportion as the igniter is disposed nearer the flame and the flame tends to swell toward the igniter side so that its edge portion comes near or in contact therewith.

- the temperature of the igniter e.g., striker wheel

- striker wheel When the striker wheel is heated, the heat may, for example, be conducted to its plastic support portion to melt the support portion. The striker wheel may then be detached by the pressing force of the flint urged against the striker wheel, making it useless.

- this invention aims to provide a wick for a liquid fuel burner that by changing the shape of the flame-producing section enables the igniter to be located near the wick while avoiding interference with the closure cap.

- the invention further aims to provide a liquid fuel burner which by changing the shape of the wick holder enables the igniter to be disposed at a position near the wick to ensure good igniting performance, while avoiding interference with the closure cap, and also avoids elevated temperature states by preventing swelling of the flame toward the igniter side.

- the invention liquid fuel burner wick which overcomes the problems set out in the foregoing, is characterized in that, as regards drawing up by the capillarity of a draw-up section liquid fuel to be burned at a flame-producing section, the flame-producing section is constituted in a shape to have a tapered tip portion.

- the closure cap is constituted to open and close about a pivot at one end portion thereof, the tip portion of the flame-producing section on the side opposite from the pivot of the closure cap is removed to provide a tapered tip portion.

- the flame-producing section is composed of glass fibers

- its tip portion is preferably fusion-bonded into a pointed shape like the tip of a writing brush.

- This wick can be shaped by bundling glass fibers, heating and fusing a portion thereof with a high-temperature burner and drawing out and separating the fused portion.

- the wick can be one with a flame-producing section composed of a porous glass material having continuous bubbles or a sintered porous ceramic material and constituted in a tapered shape.

- the wick can be one whose flame-producing section and draw-up section are formed of different materials or otherwise be one whose flame-producing section and draw-up section are integrally formed of the same material.

- an alcohol fuel for example, one having a lower monovalent alcohol, namely, methyl alcohol, ethyl alcohol or propyl alcohol, as its main component and having mixed therewith a saturated hydrocarbon such as hexane or heptane for coloring the flame, or, otherwise, a benzine hydrocarbon or a petroleum hydrocarbon or the like.

- the spacing at which the closure cap and the wick are installed can be reduced, the spacing at which the wick and the igniter are installed can also be reduced and, moreover, the closure cap can be formed smaller, whereby design freedom increases and it becomes possible to realize a smaller burner, lower cost and other advantages.

- the tip portion of a flame-producing section made of glass fibers is fusion-bonded or where a flame-producing section composed of a porous glass material or porous ceramic material is given a tapered shape, the tip portion of the wick does not fray or experience other deformation even if a cap portion contacts the wick tip portion when the closure cap for preventing evaporation is placed over the wick or if a cigarette or other object to be lit contacts it.

- the shape of the wick therefore does not change even with repeated use over a long time period, a flame of stable shape can be maintained, temperature rise of components near the flame can be preclude since the flame does not approach or contact them, and a good sealed state of the closure cap can be secured with no wick portion being caught in the gap thereof during opening and closing.

- the flame-producing section of the wick is formed by heating and fusing bundled glass fibers and drawing out the fused portion, it can be easily fusion-bonded and provided in a good shape.

- the liquid fuel burner of the invention comprises a wick for drawing up by the capillarity of a draw-up section liquid fuel to be burned at a flame-producing section, an igniter for igniting the flame-producing section of the wick and a closure cap for preventing evaporation capable of sealing the flame-producing section of the wick openably and closably and is characterized in that a wick holder for holding the wick is provided around the flame-producing section at a tip of the wick and a tip portion of the wick holder is formed to differ in height in a circumferential direction, a tip portion of high height being disposed to be interposed between the flame-producing section of the wick and the igniter.

- the closure cap is constituted to open and close about a pivot at one end portion thereof and an edge portion of a sealing portion thereof for sealing the flame-producing section of the wick is formed to differ in height in a circumferential direction complementarily to the shape of the tip portion of the wick holder.

- wick held in the wick holder of the aforesaid type there can be used one whose flame-producing section and draw-up section are formed of different materials or, otherwise, one whose flame-producing section and draw-up section are integrally formed of the same material.

- the structure for forming the tip portion of the wick holder to differ in height in the circumferential direction can, as in embodiments explained later, be one where the tip of the wick holder is formed with an inclined surface or otherwise can be one where the tip portion of the wick holder is formed steplike.

- the tip portion of the wick holder for holding the wick is formed to differ in height in the circumferential direction and a portion of high height is disposed to be interposed between the wick and the igniter, the center position of the flame during burning by the wick held by this wick holder is displaced from the center of the wick in the direction of moving away to the opposite side from the igniter, thereby enabling the igniter (e.g., striker wheel) to be disposed near the wick.

- the igniter e.g., striker wheel

- the igniter can be installed nearer the wick to ensure good igniting performance while avoiding interference with the closure cap and preventing temperature increase, and, further enhancing design freedom and realizing size and cost reduction.

- the inner diameter, height and other dimensions of the tight sealing structure for preventing evaporation from the wick can be made smaller, which contributes to size reduction because the path of the opening/closing operation becomes short and the igniter can be closely disposed.

- the wick held by the wick holder of the foregoing type is of a shape removed of the tip portion of the flame-producing section on the side opposite the pivot in open/close operation of the closure cap, e.g, where the tip portion of a wick made of glass fibers is fusion-bonded into a pointed shape like the tip of a writing brush or where it is formed by sintering, interference with the opening/closing of the closure cap is further avoided and the closure cap can be made small.

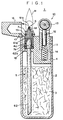

- Figure 1 shows the general sectional structure of a lighter as an example of a liquid fuel burner incorporating a wick according to this embodiment of the invention.

- a wick 6 is formed separately of different materials at an upper flame-producing section 61 and a lower draw-up section 62 and the two are joined by a wick holder 7 with the lower end portion of the flame-producing section 61 and the upper end portion of the draw-up section 62 in a contacted state.

- the flame-producing section 61 is made from glass fibers by, for example, bundling the glass fibers and fusion-bonding the tip portion 61a to form it into a pointed shape like the tip of a writing brush.

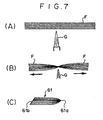

- glass fiber filaments F are cylindrically bundled to the required diameter like a string and the middle portion of the fiber bundle is heated with a high-temperature burner G, as shown in (A). Then, as shown in (B), the opposite ends of the glass fiber bundle are drawn outward as the heated portion of the glass fiber filaments F is melted. By this the molten portion of the glass fibers fuse and bind together and the tip portions are drawn to form a point like the tip of a writing brush. Further, as shown in (C), a base 61b is cut, obliquely for example, at a prescribed length, thereby fabricating the flame-producing section 61 of the wick 6 so as to have the bonded tip portion 61a.

- the base portion of this flame-producing section 61 is inserted and fixed in the cylindrical wick holder 7 made of metal.

- the draw-up section 62 formed as a rod having a large-diameter head portion 62a by molding and sintering polyethylene powder, is inserted leg portion first into a fuel tank 2 through a mounting hole in a top cover 4, the lower end of the head portion 62a of the draw-up section 62 is held by a retaining portion at the lower end of the hole of the top cover 4, and a fastening thread 7a on the outer periphery of the wick holder 7 is screwed into a threaded hole 4a from above to sandwich an O-ring 18, thereby attaching the flame-producing section 61 to the top cover 4 while joining it with the draw-up section 62.

- the amount of fuel consumed by the wick 6 when lit, the flame shape and the flame length are determined by the thickness, number and length of the glass fibers of the flame-producing section 61.

- the formation pattern of the gaps in the draw-up section 62 which determines the fuel draw-up and supply characteristics, differs with the thickness, the particle diameter of the sintered polyethylene, the sintered density and the like of the draw-up section 62.

- the head portion 62a of the draw-up section 62 being formed to a large diameter to have a large volume, constitutes a fuel reservoir for holding the liquid fuel. Burning stabilization is obtained by this fuel reservoir.

- a flame-producing section 61 having a glass fiber thickness of 6 ⁇ m, a fiber density (metsuke amount) of 150mg/cm 3 , an outer diameter of 3mm and a length of 10mm is inserted into the wick holder 7 to protrude to a length of 3mm from the tip portion of the wick holder 7.

- the draw-up section 62 is obtained by placing in a mold polyethylene powder that is a mixture of particles of 70-200 mesh with an average particle size of 140 mesh and sintering it for 10 minutes at 170°C.

- the head portion 62a is formed to an outer diameter of 4.2mm and a length of 3mm and the lower leg portion to an outer diameter of 4mm and a length of 37mm.

- This wick 6 is incorporated into the lighter 1, as the burner, with the draw-up section 62 inserted into a fuel reservoir section 5 to draw up and supply liquid fuel to the flame-producing section 61 and effects burning at the tip portion 61a of the flame-producing section 61 upon being lit by an igniter 10.

- the flame of the burning at the flame-producing section 61 is maintained without changing in shape or length by establishing a characteristic whereby the amount of fuel supplied by the draw-up section 62 is equal to or greater than the amount of fuel consumption of the flame-producing section 61.

- the lighter 1 has the tank 2 of cylindrical shape with closed bottom. Fiber material 3 (stuffing) is inserted into the interior of the fuel tank 2 and the top cover 4 is fixed to the upper portion of the tank 2 to constitute the fuel reservoir section 5 for storing liquid fuel.

- the tank 2 is, for example, provided as a shaped article made of polypropylene with an inner volume of 5cm 3 .

- the fiber material 3 is polypropylene fiber of a thickness of 1-2 denier compacted in the tank 2 to a density of 0.1g/cm 3 . 4g of liquid fuel, a mixture of 95wt% ethyl alcohol and 5wt% n-hexane, is poured and impregnated into this fiber material 3 for storage therein.

- the wick 6 is inserted to pass through the middle of the top cover 4 vertically into the tank 2 and the wick holder 7 portion is fixed to the top cover 4.

- the lower end portion of the draw-up section 62 of the wick 6 contacts the fiber material 3 in the tank 2 and draws up the liquid fuel impregnated in the fiber material 3 utilizing capillarity.

- the flame-producing section 61 of the wick 6 is lit to burn and generate a flame, and the amount of protrusion of the flame-producing section 61 from the wick holder 7 is adjusted to about 3mm, as mentioned earlier, to obtain a flame length of 30mm.

- the igniter 10 is installed on the top cover 4 to face the tip of the flame-producing section 61 of the wick 6.

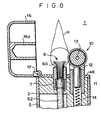

- a bracket 11 of the igniter 10 fixed to the top cover 4 has a flint 12 inserted therein to be vertically movable and a rotating striker wheel 13 is provided on the upper end of the bracket 11 as the proximate member nearest to the flame H.

- the tip of the flint 12 is pressed onto the peripheral surface of the rotating striker wheel 13 by the energizing force of a flint pusher spring 14 and rotation of the rotating striker wheel 13 causes sparks to fly toward the wick 6.

- a closure cap 16 for evaporation prevention is provided to openably/closably cover the flame-producing section 61 of the wick 6 together with the protruding portion of the wick holder 7.

- This closure cap 16 is rotatably pivoted by a pin 17 at one end portion of the upper surface of the top cover 4 of the tank 2.

- An O-ring 19 is attached to the outer peripheral root portion of the wick holder 7 and the inner peripheral surface of the sealing portion of the closure cap 16 presses thereon to enhance the sealing property.

- the upper end of the flame-producing section 61 of the wick 6 is 2.5mm higher than the height of the contact point of the rotating striker wheel 13 and the flint 12, and the positional relationship is set so that the distance between the center of the wick 6 and the center of the rotating striker wheel 13 is 10mm.

- the flame width is 9mm and the position of greatest flame width is 3mm from the lower end of the flame and this flame H burns without touching the rotating striker wheel 13 that is the igniter 10.

- the fact that the tip portion 61a of the flame-producing section 61 of the wick 6 is formed to be thin shortens the turning radius of the arc of the closure cap 16 relative the support point 17 (pin) that does not bring it into contact with the tip of the wick 6 or the wick holder 7. Accordingly, the distance between the pivot point of the closure cap 16 and the wick 6 can be reduced and, moreover, since the inner diameter of the sealing portion of the closure cap 16 need not be expanded greatly relative to the outer diameter of the wick holder 7, the closure cap 16 and the lighter 1 can be made small in size.

- the pivot position of the closure cap 16 has to be set so that during opening/closing operation thereof the inner surface of the closure cap 16 does not hit the tip of the wick 6 or the tip of the wick holder 7.

- the wick tip portion 61a is not made thin, e.g., in a lighter using a wick made of glass fibers in a unbonded state, the distance between the pivot of the closure cap 16 and the center of the wick 6 has to be set relatively long to establish a large turning radius, making the closure cap 16 and the overall structure of the lighter large (see Figure 8).

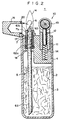

- the wick 6 of the lighter 1 of this embodiment is formed of a different material from that of the first embodiment.

- the flame-producing section 63 of the wick 6 of this embodiment is a porous ceramic sintered body formed in round rod-like shape, contains continuous bubbles (capillary passages) inside, and is formed thin at the tip portion.

- the upper portion of this flame-producing section 63 is mounted to protrude from the tip of the wick holder 7 by a prescribed amount (3mm).

- This protrusion amount, the diameter and the like determine the size of the flame H. For instance, it is constituted to have an outer diameter of 3.0mm and a length of 10mm.

- the draw-up section 62 whose tip portion abuts on the lower end portion of the flame-producing section 63 is again a porous material made of a sintered body of polyethylene powder and formed into round rod-like shape.

- An engagement groove 63c is provided in the upper outer periphery of the flame-producing section 63 and a projection 7b directed toward the center of the upper end portion of the wick holder 7 is engaged in and retained by the engagement groove 63c.

- the lower end portion of the flame-producing section 63 is unitarily joined with the upper end portion of the draw-up section 62 by screwing the flame-producing section 63 and the wick holder 7 into the top cover 4.

- the closure cap 16 for sealing the wick 6 and the protruding portion of the wick holder 7 has a seal member 20 attached to the tip portion of its sealing portion.

- This seal member 20 is constituted so as to press onto the top cover 4 around the wick holder 7 and establish sealing at the time of the closing operation of the closure cap 16.

- the other portions are formed like those of the first embodiment.

- the same constituent components are assigned the same references symbols and explanation thereof is omitted.

- the flame-producing section 63 of the wick 6 is formed in a rod-like shape of a porous ceramic sintered body and its tip portion is removed slantedly (a curved surface is also acceptable) at the side portion opposite from the support pin 17 of the closure cap 16.

- the wick 6 of the lighter 1 of this embodiment is integrally formed throughout of the same material.

- Other aspects are structured like those of the second embodiment ( Figure 2).

- the wick 6 has its flame-producing section 63 and draw-up section 64 formed integrally of a porous ceramic sintered body, is retained by the wick holder 7, and has the same shape as the one in Figure 2.

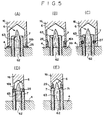

- Figures 5(A) to (E) show various examples of the seal structure of the flame-producing section of the wick 6 by the closure cap 16.

- Figures 6(A) to (F) show various examples of the structure for joining or fastening the flame-producing section and the draw-up section of the wick 6 and of the structure for attaching the wick 6 to the top cover 4 of the fuel tank together with the wick holder 7.

- the liquid fuel poured into the fuel reservoir section 5 of the lighter 1 or other burner is, in the case of an alcohol fuel, preferably one using an alcohol that is a lower monovalent alcohol, namely, methyl alcohol, ethyl alcohol or propyl alcohol, as its main component and having added thereto one or more kinds of hydrocarbon compound having nearly the same boiling point as the main component, namely, hexane, heptane, octane, nonane, cyclohexadiene, cycloheptene or other saturated hydrocarbon.

- a liquid fuel composed of at least one kind among heptane, octane and nonane can also be used.

- An liquid fuel of a benzine hydrocarbon is also acceptable.

- liquid fuel burners other than cigarette lighters include torches, lanterns and other such fire-lighting devices and lamps.

- the tip of the flame-producing portion 60 of the wick 6 frayed as shown in Figure 8, the diameter of the glass fibers of the flame-producing portion 60 tip spread to 6mm (initial diameter: 3mm), the flame width spread accordingly to 12mm (at a position 3mm from the lower end of the flame) against a flame H shape of a flame length of 30mm, a portion of the flame H touched the rotating striker wheel 13 and this portion of the rotating striker wheel 13 was heated and increased in temperature.

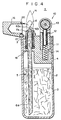

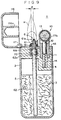

- Figure 9 shows the general sectional structure of a lighter as an example of a liquid fuel burner.

- the basic structure of the lighter 1 is as set out above, the wick 6 being installed as fixed by a wick holder 77 to pass vertically through the top cover 4 into the fuel tank 2.

- the wick 6 is formed separately of different materials at an upper flame-producing section 61 and a lower draw-up section 62 and the two are joined by the cylindrical wick holder 77, which is made of metal and formed to have an inclined tip portion, with the lower end portion of the flame-producing section 61 and the upper end portion of the draw-up section 62 in a contacted state.

- the lower end portion of the draw-up section 62 of the wick 6 contacts the fiber material 3 in the tank 2 and draws up the liquid fuel impregnated in the fiber material 3 utilizing capillarity.

- the flame-producing section 61 of the wick 6 is lit to burn and generate a flame H.

- the flame-producing section 61 is made from glass fibers by, as in Figure 1 for example, bundling glass fiber filaments and fusion-bonding the tip portion 61a to form it into a pointed shape like the tip of a writing brush.

- the draw-up section 62 formed as a rod having a large-diameter head portion 62a by molding and sintering polyethylene powder, has its head portion 62a inserted into the lower portion of the wick holder 77 and contacted with the base 61b of the flame-producing section 61 and the lower end portion of the wick holder 77 is caulked in this state, whereby the flame-producing section 61 and the draw-up section 62 are integrally joined to constitute the wick 6.

- a closure cap 116 for evaporation prevention is provided to openably/closably cover the flame-producing section 61 of the wick 6 together with projecting portion of the wick holder 77.

- This closure cap 116 is rotatably pivoted by a pin 17 at one end portion of the upper surface of the top cover 4 of the tank 2.

- an inner cover 116a for enclosing the outer periphery of the wick holder 77 of the wick 6 and covering/sealing the wick 6.

- An O-ring 19 is horizontally attached to the outer peripheral root portion of the wick holder 77 and the inner peripheral surface of the inner cover 116a of the closure cap 16 presses thereon to enhance the sealing property.

- a face plate 48 is provided on the upper surface of the top cover 4.

- the dimensions of the wick holder 77 are, for example, outer diameter of 4mm, inner diameter of 3mm and inclination angle of the tip portion 77a of 45°.

- the height of the wick 6 flame-producing section 61 projecting from this wick holder 77 is 3mm at the most exposed portion.

- the distance between the center of the wick 6 and the center of the rotating striker wheel 13 is set at 8mm.

- the flame H does not touch the rotating striker wheel 13 and good burning and use conditions can be obtained even if the distance between the center of the wick 6 and the center of the rotating striker wheel 13 is set to a narrow 8mm as stated above.

- the tip portion 61a of the glass fiber flame-producing section 61 of the wick 6 is fusion-bonded in this seventh embodiment, it can instead be left as an unbonded flame-producing portion 60 as shown in Figure 16.

- the tip end portion of the flame-producing portion 60 is preferably structured so as not to contact/interfere with the open/close path of the closure cap 116.

- the lighter 1 of this embodiment has the same type of wick holder 77 as in the preceding embodiment but the closure cap 120 is of a different type.

- one end portion of a main body formed in the shape of a flat plate is rotatably pivoted on the top cover 4 of the tank 2 by a pin 21, the tip portion on the opposite side from the pivot portion is provided to extend along and engage with the rotating striker wheel 13 of the igniter 10, and a projection 120b for opening operation is provided on the tip portion, the closure condition being in an inclined state.

- a cup-shaped closure portion 120a is fixed to the inner surface of the main body of the closure cap 120 to face the inclined shape of the inclined tip portion 77a of the wick holder 77.

- This closure portion 120a is constituted so that when closed its inclination angle is the same as the inclination angle of the wick holder 77.

- a seal member 22 is attached to the tip edge portion of the closure portion 120a and this seal member 22 is structured to press onto the inclined tip portion 77a of the wick holder 77.

- the flame-producing section 63 of the wick 6 in this embodiment is formed in round rod-like shape not of glass fibers but of a porous glass sintered body or porous ceramic sintered body, contains continuous bubbles (capillary passages) inside, and is formed thin at the tip portion. Its upper portion is mounted to protrude from the tip surface 77a of the wick holder 77 by a prescribed amount (3mm at the most exposed portion).

- the setting of this protrusion amount, the diameter and the like determine the size of the flame. For instance, it is constituted to have an outer diameter of 3.0mm and a length of 10mm.

- the draw-up section 62 whose tip portion abuts on the lower end of the flame-producing section 63 is again a porous material made of a sintered body of polyethylene powder and formed into round rod-like shape. Other aspects are formed like those of the seventh embodiment.

- the shape of the tip portion of the wick 6 of the lighter 1 of this embodiment is different.

- the flame-producing section 63 of the wick 6 is formed in a rod-like shape of a porous ceramic sintered body and its tip portion is removed slantedly at the side portion opposite from the support pin 17 of the closure cap 16, whereby it is structured to avoid interference with the opening/closing rotation of the closure cap 16.

- the closure cap 16 is structured to openably/closably cover the flame-producing section 63 of the wick 6 together with the projecting portion of the wick holder 77 but not to cover the top of the igniter 10.

- a seal member 22 is attached to the tip portion of the sealing portion of the closure cap 16 and this seal member 22 is constituted to achieve sealing by pressing onto the top cover 4 around the wick holder 77 at closing operation of the closure cap 16.

- the shapes of the tip portion of the wick 6 and the wick holder 77 of the lighter 1 of this embodiment are different.

- the flame-producing section 63 of the wick 6 is formed in a rod-like shape of a porous ceramic sintered body and the corner of its tip portion is removed slantedly at the side portion opposite from the support pin 17 of the closure cap 16 and, further, the tip portion 77a of the wick holder 77 is also removed of part of its highest portion, whereby they are structured to avoid interference with the opening/closing rotation of the closure cap 16.

- Other aspects are the same as in the ninth embodiment.

- the wick 6 of the lighter 1 of this embodiment is integrally formed throughout of the same material.

- Other aspects are structured like those of the tenth embodiment.

- the wick 6 has its flame-producing section 63 and draw-up section 64 formed integrally of a porous ceramic sintered body, is retained by the wick holder 77, and has the same shape as the one in Figure 12.

- Figures 14(A) to (F) show various examples of the seal structure of the flame-producing section of the wick 6 by the closure cap 16 in a lighters equipped with a wick holder 77 with an inclined tip.

- Figures 15(A) to (F) show various examples of the structure for joining or fastening the flame-producing section and the draw-up section of the wick and of the structure for attaching the wick to the fuel tank together with the wick holder.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Lighters Containing Fuel (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP36065/97 | 1997-02-20 | ||

| JP36064/97 | 1997-02-20 | ||

| JP03606597A JP3821528B2 (ja) | 1997-02-20 | 1997-02-20 | 液体燃料用燃焼器具 |

| JP3606497A JPH10232020A (ja) | 1997-02-20 | 1997-02-20 | 液体燃料用燃焼器具における燃焼芯 |

| PCT/JP1998/000632 WO1998037366A1 (fr) | 1997-02-20 | 1998-02-17 | Appareil de combustion pour combustible liquide et meche de combustion |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0908680A1 true EP0908680A1 (fr) | 1999-04-14 |

| EP0908680A4 EP0908680A4 (fr) | 2001-02-14 |

Family

ID=26375082

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98902244A Withdrawn EP0908680A4 (fr) | 1997-02-20 | 1998-02-17 | Appareil de combustion pour combustible liquide et meche de combustion |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6102688A (fr) |

| EP (1) | EP0908680A4 (fr) |

| KR (1) | KR20000064962A (fr) |

| CN (1) | CN1121577C (fr) |

| ID (1) | ID20260A (fr) |

| WO (1) | WO1998037366A1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2113178A1 (fr) * | 2008-04-30 | 2009-11-04 | Philip Morris Products S.A. | Système de fumée chauffé électriquement avec une portion de stockage liquide |

| US11344683B2 (en) | 2010-05-15 | 2022-05-31 | Rai Strategic Holdings, Inc. | Vaporizer related systems, methods, and apparatus |

| CN209495356U (zh) * | 2018-11-20 | 2019-10-15 | 之宝制造公司 | 用于模块化发火打火机的更新模块和燃料模块以及发火打火机 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR804310A (fr) * | 1935-05-16 | 1936-10-21 | Evans Case Co | Mèche incombustible pour briquets de fumeurs |

| FR939647A (fr) * | 1944-03-04 | 1948-11-19 | Cartouche rigide, constituée par une mèche combustible et utilisable dans les briquets de poche |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2539653A (en) * | 1945-07-17 | 1951-01-30 | Back Selig | Cigar and cigarette lighter |

| US2680962A (en) * | 1949-10-12 | 1954-06-15 | Ritepoint Inc | Cigarette lighter |

| JPS4315673Y1 (fr) * | 1967-07-06 | 1968-06-29 | ||

| US4035138A (en) * | 1976-08-25 | 1977-07-12 | Ben Walters | Apparatus for converting a beverage container into a lamp |

| US5211553A (en) * | 1992-02-25 | 1993-05-18 | Hollowick, Inc. | Burner for liquid fuel cell |

| US5425633A (en) * | 1994-09-29 | 1995-06-20 | Cole; Michael C. | Floating combustion apparatus |

-

1998

- 1998-02-17 CN CN98800506A patent/CN1121577C/zh not_active Expired - Fee Related

- 1998-02-17 WO PCT/JP1998/000632 patent/WO1998037366A1/fr not_active Application Discontinuation

- 1998-02-17 EP EP98902244A patent/EP0908680A4/fr not_active Withdrawn

- 1998-02-17 ID IDW980101D patent/ID20260A/id unknown

- 1998-02-17 KR KR1019980708411A patent/KR20000064962A/ko not_active Application Discontinuation

- 1998-02-17 US US09/171,470 patent/US6102688A/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR804310A (fr) * | 1935-05-16 | 1936-10-21 | Evans Case Co | Mèche incombustible pour briquets de fumeurs |

| FR939647A (fr) * | 1944-03-04 | 1948-11-19 | Cartouche rigide, constituée par une mèche combustible et utilisable dans les briquets de poche |

Non-Patent Citations (1)

| Title |

|---|

| See also references of WO9837366A1 * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0908680A4 (fr) | 2001-02-14 |

| KR20000064962A (ko) | 2000-11-06 |

| CN1224492A (zh) | 1999-07-28 |

| US6102688A (en) | 2000-08-15 |

| CN1121577C (zh) | 2003-09-17 |

| WO1998037366A1 (fr) | 1998-08-27 |

| ID20260A (id) | 1998-11-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0916896A1 (fr) | Dispositif pour bruler un combustible liquide | |

| EP0978686B1 (fr) | Meche de combustion d'une chambre de combustion de combustible liquide | |

| US6102688A (en) | Combustion apparatus for liquid fuel and combustion wick | |

| US6196832B1 (en) | combustion wick for liquid fuel combustion appliance | |

| JP3285502B2 (ja) | 液体燃料用燃焼器具 | |

| JP3821528B2 (ja) | 液体燃料用燃焼器具 | |

| EP0942233B1 (fr) | Structure de chambre de combustion pour allumeurs | |

| EP0869314B1 (fr) | Meche de combustion pour combustible | |

| MXPA98008702A (es) | Aparato de combustion para combustible liquido y mecha de combustion | |

| JPH10232020A (ja) | 液体燃料用燃焼器具における燃焼芯 | |

| JP3663274B2 (ja) | 液体燃料用燃焼器具 | |

| WO2007140053A2 (fr) | Appareil de combustion à combustible liquide | |

| JP2000009318A (ja) | 液体燃料燃焼器具 | |

| CA2263965A1 (fr) | Meche de combustion pour appareil brulant un combustible liquide | |

| MXPA98005378A (en) | Combustion appliance for liquid fuel | |

| MXPA98005117A (en) | Combustion wick for liquid fuel combustion appliance | |

| JPH11294765A (ja) | 液体燃料燃焼器具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19981022 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE DK ES FR GB IT NL SE |

|

| A4 | Supplementary search report drawn up and despatched |

Effective date: 20010103 |

|

| AK | Designated contracting states |

Kind code of ref document: A4 Designated state(s): DE DK ES FR GB IT NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20030902 |